EP1598447B1 - Procédé de décapage d'une pièce creuse de révolution et dispositif mettant en oeuvre un tel procédé - Google Patents

Procédé de décapage d'une pièce creuse de révolution et dispositif mettant en oeuvre un tel procédé Download PDFInfo

- Publication number

- EP1598447B1 EP1598447B1 EP05291048A EP05291048A EP1598447B1 EP 1598447 B1 EP1598447 B1 EP 1598447B1 EP 05291048 A EP05291048 A EP 05291048A EP 05291048 A EP05291048 A EP 05291048A EP 1598447 B1 EP1598447 B1 EP 1598447B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pickling

- composition

- vessel

- cavities

- axis

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005554 pickling Methods 0.000 title claims description 29

- 238000000034 method Methods 0.000 title claims description 15

- 239000000203 mixture Substances 0.000 claims description 22

- 238000009434 installation Methods 0.000 claims description 17

- 238000005086 pumping Methods 0.000 claims description 14

- 230000003472 neutralizing effect Effects 0.000 claims description 12

- KRHYYFGTRYWZRS-UHFFFAOYSA-N Fluorane Chemical compound F KRHYYFGTRYWZRS-UHFFFAOYSA-N 0.000 claims description 6

- 230000000694 effects Effects 0.000 claims description 4

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 claims description 3

- 238000007598 dipping method Methods 0.000 claims description 3

- 229910017604 nitric acid Inorganic materials 0.000 claims description 3

- 239000000126 substance Substances 0.000 claims description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 3

- 229910001069 Ti alloy Inorganic materials 0.000 description 4

- 238000010438 heat treatment Methods 0.000 description 4

- 238000004064 recycling Methods 0.000 description 4

- 238000011282 treatment Methods 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 238000005530 etching Methods 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 241000135309 Processus Species 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000009189 diving Effects 0.000 description 1

- 231100001261 hazardous Toxicity 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000011328 necessary treatment Methods 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23G—CLEANING OR DE-GREASING OF METALLIC MATERIAL BY CHEMICAL METHODS OTHER THAN ELECTROLYSIS

- C23G3/00—Apparatus for cleaning or pickling metallic material

Definitions

- the invention relates to a method of pickling a hollow part of revolution, in particular a hollow part of large dimensions, such as for example the wheel of a turbine having annular cavities separated by discs welded together.

- the preferred field of application of the invention relates to the chemical dissolution of the contaminated layer rich in oxygen, commonly called "alpha-case" layer which is formed on such a titanium alloy part, during the heat treatment thereof .

- a titanium alloy turbine wheel of the type indicated above is deemed difficult to access internally, given the plurality of adjacent annular cavities defined therein between the discs, welded together, which constitutes it.

- the heat treatment required for the development of this part has the effect of revealing on the surface thereof (externally as well as internally) a contaminated layer of a few tens of microns thick, rich in oxygen called "alpha-case layer ".

- alpha-case layer Currently, we are stripping the outside of the room, the interior stripping has so far been considered hazardous.

- DE 198 39 479 discloses a method of treatment, a metal piece of large diameter revolution (especially to chrome its outer surface) in which the piece is rotated in a product bath.

- US 3,420,712 describes the treatment of a tubular, cylindrical piece, by rotating it in a bath.

- the invention provides a pickling method for dissolving the contaminated layer simultaneously, both externally and internally, so that chemical dissolution occurs uniformly.

- the invention therefore relates to a method of stripping a hollow part of revolution comprising a plurality of axially adjacent coaxial annular cavities comprising the steps of rotating said part about its axis of rotation oriented horizontally, to partially immerse. said piece in a vat filled with stripping product so that it penetrates inside said part and to rotate said part during said stripping, characterized in that it comprises the steps of constantly pumping the stripping product inside of said part while maintaining substantially constant the level of stripping product with respect to said part, recycling the stripping product into said tank, by reintroducing it into the latter outside said part, the pumping being carried out by taking the stripping product in said cavities while adjusting the flow rates between them, substantially proportionally to the respective volumes of these cavities.

- the piece is extracted from the pickling product bath while continuing the pumping inside thereof. Rotation is preferably continued during part extraction. The extraction of the part takes place in a relatively short time of the order of 30 seconds. Then, the piece is transported to a bath of neutralizing product and immersed in it. Rotation is preferably continued during this rinsing phase.

- the neutralizing product may for example be water.

- the removal of the contaminated layer is carried out using a stripping product consisting, for example, of a mixture of nitric acid and hydrofluoric acid.

- the invention also relates to a pickling installation of a hollow part of revolution, having a plurality of coaxial annular cavities, axially adjacent, comprising a support provided with means for gripping and driving in rotation of said part, arranged to maintain it. and driving it in rotation about its horizontally oriented axis of rotation, a tank of stripping product, means for lowering said piece in said tank and for partially immersing it in said stripping product, characterized in that it comprises means pumping apparatus for continuously removing stripper material within said workpiece and means for maintaining a substantially constant level of stripper material relative to said workpiece. and in that said pumping means comprise a plurality of suction conduits whose end is in the vicinity of the inner wall of said part in its most deeply immersed part and plunging respectively into said cavities.

- the discharge outlet of the pumping means is arranged to reintroduce the pumped product into the tank, outside the room.

- the part may in particular be a rotor wheel with welded disks.

- the suction ducts are flexible ducts communicating with a manifold connected to the same pump. These suction ducts may be provided with calibrated flow restrictions. In this case the section of each restriction is calculated as a function of the volume of the cavity into which the corresponding suction duct plunges.

- the installation may also include a tank of neutralizing product and means for transferring the part of the cleaner tank to the tank of neutralizing product.

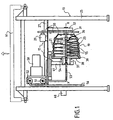

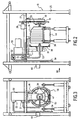

- the installation 11, shown, comprises a support 13 equipped with means for gripping and driving in rotation 17 of a hollow part of revolution 19 to be stripped.

- the wheel or central part of a turbojet turbine In this part is recognized the wheel or central part of a turbojet turbine. It is a piece of complex shape constituted by a plurality of discs 21 welded between they and internally defining coaxial annular cavities 23, axially adjacent, difficult to access. It is known that the heat treatment to which such a piece of titanium alloy is subjected reveals on the surface thereof a contaminated layer commonly known as the "alpha-case layer" which it is desirable to eliminate. Stripping of the interior surface of this room was previously considered impractical.

- the support 13 comprises a kind of gantry 25 carrying at its upper part, fixed to a platform 27, all the means (motor and electromechanical components) for gripping and driving in rotation of the part 19. More specifically, a electric motor 29 drives a support 31 of horizontal axis, carried by a post 32 extending under the platform 27. The support 31 is driven through a set of pinions 33. This support is shaped and dimensioned to fit at one end 36 of the piece. Said support 31 is widely perforated so as not to impede the circulation of a liquid inside the room, in particular a stripping product or a neutralizing or rinsing product.

- a non-motorized rotating member 37 carries three arms 38 that fit on the other end 39 of the part.

- the rotating element is carried by a vertical upright 41 mounted under the platform 27.

- the assembly moves axially to allow the establishment of the part.

- Said support 31 and said rotating element 37 admit the same horizontal axis.

- the piece is held together by being centered by the two circular ends 36 and 39. It can therefore rotate about its own axis of rotation placed in a horizontal position.

- the part is brought under the gantry 25 while being carried by a forklift truck 46 ( Figures 2 and 3 ) and it is placed between the support 31 and the arms 38. It can therefore be rotated by the motor 29.

- the platform 27 also carries a pump 50 whose input 51 is connected to a conduit whose end 53 is arranged axially (x'x axis) and connected to a collector 54, rigid and removable, may be installed axially inside the room, as shown.

- Flexible suction ducts 55 are connected to this manifold 54.

- Each duct 55 is immersed in one of the cavities 23 when the collector 54 and the part 19 are in place on the support 13, as can be seen on FIG. figure 1 .

- the length of a conduit depends on the corresponding cavity so that its lower end is in the vicinity of the inner wall of the part in its most deeply submerged part, that is to say at the bottom of said corresponding cavity .

- the pumping means (50, 54, 55) are adapted to continuously pick up the etching product inside the part and at the bottom of each cavity, when said part is partially immersed in a tank 59 of stripper ( figure 5 ). If the piece to be stripped was of another nature and did not include, in particular, several cavities, the suction system inside the room could be simplified and include, for example, only one flexible duct diving into the deepest part.

- a level detector 60 is placed on the gantry and the installation comprises means for adjusting the position of the support 13 (in height) so that said part is partially immersed to a predetermined height, for example, according to the example, up to its axis of rotation x'x.

- lifting means 61 for example part of a crane or the like, installed on the site.

- Said lifting means make it possible to adjust the position of the support 13 and consequently of the part 19 in the tank; they are for this purpose controlled by the level detector 60, which is fixed on the support at a location such that it detects the surface of the pickling product bath when the workpiece is immersed substantially up to the x'x axis.

- the lifting means can be slaved to the detected level to maintain the level detector 60 on the surface of the stripper bath.

- the installation comprises means for maintaining a substantially constant level of stripping product relative to said workpiece.

- the pump 50 is arranged to continuously recycle the pickling product in the tank, outside the part 19.

- a conduit 56 connected to the discharge outlet 52 pump plunges into the tank.

- This recycling makes it possible in practice to maintain the level of stripper product at a constant level in the tank when the support 13 has been immersed in it at a depth determined by the level detector 60.

- the stripper product is pump permanently in the cavities 23 and the bottom thereof, then recycled to the tank outside the room, the activity of the etchant product is maintained homogeneous in all points of the tank.

- the necessary treatment time taking into account the activity of the stripping product (which gradually wears out), it suffices to strip beforehand a specimen which has undergone the same heat treatment as the workpiece and to deduce from it a stripping time. for said piece.

- suction ducts 55 are provided with calibrated flow restrictions 65 (upstream of the manifold 54), the section of each restriction being calculated as a function of the volume of the cavity in which the suction duct plunges. corresponding. This makes it possible to keep the level of stripping product constant in the part itself, in particular at the end of stripping during the time when said part is extracted from the tank and continues to be emptied.

- the pumping is balanced between the cavities, which makes it possible to standardize the stripping in these cavities.

- the installation also comprises a tank of neutralizing product 62, located near the tank 59 and means for transferring the piece 19 (in this case, here, the entire piece and the frame 25) from the tank 59 up to the tank 62.

- a tank of neutralizing product 62 located near the tank 59 and means for transferring the piece 19 (in this case, here, the entire piece and the frame 25) from the tank 59 up to the tank 62.

- These means are constituted by the lifting means 61 previously mentioned.

- the etchant is a mixture of nitric acid and hydrofluoric acid.

- the neutralizing product is water.

- Stripping takes place externally and internally, as shown on the figure 5 with permanent recycling of the pumped cleaner product in the cavities.

- the flow rates of stripping product taken from the cavities are adjusted relative to each other substantially in proportion to the respective volumes of these cavities. This adjustment of the flow rates is obtained thanks to the flow restrictions 65, which are differently calibrated.

- the piece of bath is extracted by raising again the support 13 while continuing the pumping inside the room so that the level of stripping product remaining inside the room decreases gradually through pumping but remains substantially equal in all cavities.

- the part is completely extracted and emptied of the paint remover ( figure 6 ) it is transferred to the tank 62 of neutralizing product and again immersed in it.

- the rotation of the part is advantageously continued throughout the rinsing phase, as is the recycling.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Cleaning And De-Greasing Of Metallic Materials By Chemical Methods (AREA)

- Cleaning By Liquid Or Steam (AREA)

- Cleaning In General (AREA)

- ing And Chemical Polishing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0405332A FR2870142B1 (fr) | 2004-05-17 | 2004-05-17 | Procede de decapage d'une piece creuse de revolution et dispositif mettant en oeuvre un tel procede |

| FR0405332 | 2004-05-17 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1598447A1 EP1598447A1 (fr) | 2005-11-23 |

| EP1598447B1 true EP1598447B1 (fr) | 2012-06-20 |

Family

ID=34942294

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05291048A Active EP1598447B1 (fr) | 2004-05-17 | 2005-05-16 | Procédé de décapage d'une pièce creuse de révolution et dispositif mettant en oeuvre un tel procédé |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7703463B2 (zh) |

| EP (1) | EP1598447B1 (zh) |

| JP (1) | JP4619194B2 (zh) |

| CN (1) | CN1699626B (zh) |

| CA (1) | CA2507164C (zh) |

| ES (1) | ES2387986T3 (zh) |

| FR (1) | FR2870142B1 (zh) |

| RU (1) | RU2367527C2 (zh) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2961598B1 (fr) * | 2010-06-21 | 2012-07-27 | Snecma | Procede de controle d'une piece en titane ou en alliage de titane en vue de la detection de defauts d'usinage |

| CN102311231A (zh) * | 2011-08-06 | 2012-01-11 | 海宁伊满阁太阳能科技有限公司 | 真空集热管罩玻璃管酸洗蒙砂设备 |

| FR3056605B1 (fr) * | 2016-09-29 | 2020-12-18 | Safran Aircraft Engines | Dispositif de traitement chimique d'une piece de turbomachine munie d'un element de surface metallique |

| CN108714587A (zh) * | 2018-06-06 | 2018-10-30 | 南京采孚汽车零部件有限公司 | 一种泵类产品内部清洗装置 |

| FR3084673A1 (fr) * | 2018-08-02 | 2020-02-07 | Safran Aircraft Engines | Dispositif d'immersion d'au moins une piece de turbomachine dans un bain de decapage chimique |

| CN110129809B (zh) * | 2019-04-09 | 2021-04-23 | 上海老凤祥首饰研究所有限公司 | 一种千足金双套项链表面无损处理工艺 |

| CN112030174A (zh) * | 2020-09-04 | 2020-12-04 | 海盐金鼎钢管股份有限公司 | 一种酸洗效率高的钢管酸洗装置 |

| CN114000158B (zh) * | 2021-10-28 | 2023-11-28 | 泰安航天特种车有限公司 | 一种适用于钢管内壁的自动酸洗设备 |

| CN114011790A (zh) * | 2021-11-25 | 2022-02-08 | 桂林电子科技大学 | 一种用于机械零件的自动化酸洗加工设备 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3420712A (en) * | 1964-07-10 | 1969-01-07 | Parsons Corp | Method for treating elongated metal workpieces with a succession of treating liquids |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE480102A (zh) * | 1944-01-06 | |||

| GB731569A (en) * | 1953-04-24 | 1955-06-08 | Alfred George Honey | Improvements relating to apparatus for cleaning ball or roller bearings |

| US2849097A (en) * | 1954-08-05 | 1958-08-26 | Udylite Corp | Automatic apparatus for chemical treatment of metal articles in bulk |

| GB1023402A (en) * | 1964-02-29 | 1966-03-23 | A T Juniper Ltd | Improvements in or relating to apparatus for dispensing liquid under pressure for use for example in the washing of compressor blades of gas turbine engines |

| SE387720B (sv) * | 1974-12-30 | 1976-09-13 | Stal Laval Turbin Ab | Tvettapparat for tvastegskompressor |

| JPS52130155A (en) * | 1976-04-26 | 1977-11-01 | Hitachi Ltd | Method of and apparatus for pickling elongated small-diametered metal tube |

| JP2604650B2 (ja) * | 1991-06-07 | 1997-04-30 | 本田技研工業株式会社 | 表面処理方法 |

| CN2139128Y (zh) * | 1992-06-01 | 1993-07-28 | 天津市自行车钢材改制厂 | 单轴带钢酸洗机 |

| US5318683A (en) * | 1993-02-01 | 1994-06-07 | Quad/Tech, Inc. | Electrodeposition system |

| EP0694090B1 (de) * | 1994-02-15 | 1997-04-23 | Ecograph Ag | Verfahren und vorrichtung zur elektrolytischen oberflächenbeschichtung von werkstücken |

| JPH08101206A (ja) * | 1994-09-29 | 1996-04-16 | Horiba Ltd | 洗浄ノズルおよびそれを用いる容器の洗浄方法 |

| JP3703842B2 (ja) * | 1994-11-22 | 2005-10-05 | ユナイテッド テクノロジーズ コーポレイション | タービンエアフォイルの超音波洗浄の方法 |

| DE19839479A1 (de) * | 1998-08-29 | 2000-03-02 | Schaeffler Waelzlager Ohg | Verfahren zur chemischen oder elektrochemischen Behandlung eines rotationssymmetrischen Hohlkörpers und zugehörige Halte- und Drehvorrichtung |

| US6503334B2 (en) * | 2001-03-14 | 2003-01-07 | Hydrochem Industrial Services, Inc. | Forced mist cleaning of combustion turbines |

| DE10308731B4 (de) * | 2003-02-28 | 2005-09-01 | Contitech Luftfedersysteme Gmbh | Verfahren und Vorrichtung zur galvanischen Beschichtung von Hohlkörpern |

-

2004

- 2004-05-17 FR FR0405332A patent/FR2870142B1/fr not_active Expired - Lifetime

-

2005

- 2005-05-11 US US11/126,283 patent/US7703463B2/en active Active

- 2005-05-11 CA CA2507164A patent/CA2507164C/fr active Active

- 2005-05-12 JP JP2005139595A patent/JP4619194B2/ja active Active

- 2005-05-16 RU RU2005114871/12A patent/RU2367527C2/ru active

- 2005-05-16 ES ES05291048T patent/ES2387986T3/es active Active

- 2005-05-16 EP EP05291048A patent/EP1598447B1/fr active Active

- 2005-05-17 CN CN2005100728895A patent/CN1699626B/zh active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3420712A (en) * | 1964-07-10 | 1969-01-07 | Parsons Corp | Method for treating elongated metal workpieces with a succession of treating liquids |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2387986T3 (es) | 2012-10-05 |

| RU2367527C2 (ru) | 2009-09-20 |

| FR2870142A1 (fr) | 2005-11-18 |

| CN1699626B (zh) | 2010-06-09 |

| JP4619194B2 (ja) | 2011-01-26 |

| CA2507164A1 (fr) | 2005-11-17 |

| EP1598447A1 (fr) | 2005-11-23 |

| US7703463B2 (en) | 2010-04-27 |

| CA2507164C (fr) | 2012-10-16 |

| CN1699626A (zh) | 2005-11-23 |

| RU2005114871A (ru) | 2006-11-20 |

| JP2005329402A (ja) | 2005-12-02 |

| US20050252530A1 (en) | 2005-11-17 |

| FR2870142B1 (fr) | 2007-02-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1598447B1 (fr) | Procédé de décapage d'une pièce creuse de révolution et dispositif mettant en oeuvre un tel procédé | |

| EP2872878B1 (fr) | Dispositif de pulvérisation d'un produit de ressuage sur une pièce | |

| EP2678120B1 (fr) | Installation et procede pour le depot d'un film de particules ordonnees sur un substrat en defilement | |

| EP1305147B1 (fr) | Procede et dispositif de recyclage de pneus | |

| FR2961598A1 (fr) | Procede de controle d'une piece en titane ou en alliage de titane en vue de la detection de defauts d'usinage | |

| EP3408589B1 (fr) | Installation de redressage automatisé d'une mèche de bougie et procédé de redressage automatisé associé | |

| FR3085598A1 (fr) | Procede nomade d'extraction douce de constituants de pellicules de raisin en phase de maceration en vinification en rouge ou de brassage des vins blancs par insufflage a basse pression de gaz carbonique ou d'air ambiant | |

| EP1733868B1 (fr) | Dispositif et procédé de refroidissement d'un noyau | |

| FR2975072A1 (fr) | Procede d'evacuation du liquide d'une cuve d'un navire sinistre | |

| FR2771654A1 (fr) | Procede et appareillage a fonctions multiples pour la maintenance des liquides metastables | |

| CA1219813A (fr) | Procede et dispositif d'evacuation et de degazage d'une bouillie d'une cuve d'attaque | |

| FR2795979A1 (fr) | Procede et machine pour le traitement de petites pieces avec un fluide de traitement liquide | |

| EP3091142B1 (fr) | Appareil pour l'application d'un produit liquide de ragréage | |

| FR2878531A1 (fr) | Procede d'emiettage d'un chapeau de marc dans une cuve de fermentation, et cuve de fermentation permettant de mettre en oeuvre un tel procede | |

| EP1629874B1 (fr) | Extracteur de boues pour stations d'épuration | |

| FR2494716A1 (fr) | Perfectionnements aux appareils de traitement des vendanges par maceration dans du vin chaud | |

| EP0956005B1 (fr) | Dispositif et procede de fabrication d'une capsule tubulaire segmentee contenant un milieu biologiquement actif | |

| EP4170316A1 (fr) | Appareil et dispositif de prelevement d'echantillon | |

| EP0192509B1 (fr) | Procédé et dispositif pour la préparation du lait destiné à la fabrication du fromage | |

| EP1808415A1 (fr) | Dispositif de désembouage électro-magnétique | |

| FR2481716A1 (fr) | Appareil pour recuperer l'argent des produits chimiques pour photographie | |

| FR3067344A1 (fr) | Installation de decontamination comprenant une cuve de traitement thermique et procede de decontamination associe | |

| EP0943375A1 (fr) | Procédé et installation d'assainissement de sol | |

| EP2806053A2 (fr) | Electrolyseur, anode pour cet électrolyseur et procédé d'électrolyse dans cet électrolyseur | |

| FR2666959A1 (fr) | Procede et dispositif destines au traitement de fromages, notamment a leur saumurage. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050523 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070309 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 563130 Country of ref document: AT Kind code of ref document: T Effective date: 20120715 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602005034817 Country of ref document: DE Effective date: 20120816 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2387986 Country of ref document: ES Kind code of ref document: T3 Effective date: 20121005 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20120620 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 563130 Country of ref document: AT Kind code of ref document: T Effective date: 20120620 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D Effective date: 20120620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120921 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121020 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121022 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 |

|

| 26N | No opposition filed |

Effective date: 20130321 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602005034817 Country of ref document: DE Effective date: 20130321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120920 |

|

| BERE | Be: lapsed |

Owner name: SNECMA Effective date: 20130531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130531 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130516 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20140613 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20050516 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130516 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: SAFRAN AIRCRAFT ENGINES, FR Effective date: 20170717 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240419 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240418 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240418 Year of fee payment: 20 Ref country code: FR Payment date: 20240418 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20240418 Year of fee payment: 20 |