EP1566594A1 - Procédé et dispositif pour aérer et /ou ventiler un four de cuisson - Google Patents

Procédé et dispositif pour aérer et /ou ventiler un four de cuisson Download PDFInfo

- Publication number

- EP1566594A1 EP1566594A1 EP04030589A EP04030589A EP1566594A1 EP 1566594 A1 EP1566594 A1 EP 1566594A1 EP 04030589 A EP04030589 A EP 04030589A EP 04030589 A EP04030589 A EP 04030589A EP 1566594 A1 EP1566594 A1 EP 1566594A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- door

- air

- flow channel

- flow

- oven

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/006—Arrangements for circulation of cooling air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C14/00—Stoves or ranges having self-cleaning provisions, e.g. continuous catalytic cleaning or electrostatic cleaning

- F24C14/02—Stoves or ranges having self-cleaning provisions, e.g. continuous catalytic cleaning or electrostatic cleaning pyrolytic type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/02—Doors specially adapted for stoves or ranges

- F24C15/04—Doors specially adapted for stoves or ranges with transparent panels

Definitions

- the invention relates to a method and a device for loading and / or venting a cooking oven.

- a cooking oven is known with a furnace muffle, in the Muffelwandung, preferably the muffle cover, a Wrasenaustrittsö réelle is provided, and arranged with a muffle outside the fan with at least one suction, which is connected to the Wrasenaustrittsö réelle the Muffelwandung, and with at least one blow-out area.

- At least one fresh air duct which opens into an outer space with one end and opens into the intake area of the blower at one end and at least one discharge duct connecting the blower area with the outer space for discharging the mixture of the vapors sucked out of the cooking space by the blower in its operation provided on the one hand and sucked by the fresh air passage from the outside fresh air on the other hand.

- the fresh air duct and the diversion duct preferably extend substantially horizontally above the oven muffle and are separated from one another by an air baffle plate.

- the fresh air channel is arranged below the diversion channel.

- the fan is preferably a radial fan and arranged above the Wrasenaustrittsö Maschinen Maschinen.

- the feed opening of the oven muffle is closed and is an outlet opening of the door with the entrance of the fresh air duct in flow communication, so that the fan via the fresh air duct sucks fresh air from the door interior.

- an air flow is generated in the door interior from the lower open end of the door up.

- fresh air is drawn through the door handle through an opening behind it in the door interior and then into the fresh air duct, whereby the door handle is cooled.

- This ventilation system serves, on the one hand, for cooling the cooking oven and, on the other hand, for removing the vapor from the oven muffle.

- DE 198 01 585 A1 discloses a method for cooling the outer environment of a Garofenmuffel, the muffle interior is heated while a feed opening of the open muffle is closed with a door.

- air is sucked from an outside space in an intake area below the door, the sucked air is guided around at least part of the oven muffle and the air guided around the oven muffle is at least partially blown into the door interior from above.

- Part of the air routed around the oven muffle can be directly blown out into the outdoor area in a blow-out area in an upper area or above the door.

- the door interior comprises an inner space between an inner pane and an intermediate pane of the door and an outer space between an outer pane and the intermediate pane of the door.

- a handle bar is arranged with a door handle and with three adjacent openings.

- the two outer openings are downwardly separated by a respective air guide body from the inside of the door, while behind the central opening an air deflecting body (baffle plate) is arranged, which directs a portion of the exiting an air duct cooling air from above into the door interior.

- This air deflecting body is arranged in continuation of the outer pane, so that the deflected air is mainly conducted into the outer space of the door. As a result, the outer pane of the door is cooled and the temperature is lowered there.

- a cooling fan is arranged, the in the intake area below the door cooling air from the outside sucks, then below the oven muffle and behind the oven muffle is led upwards and above the Furnace muffle in the air duct to the blow-out is guided in or above the door.

- the muffle blanket If a connection can be provided, via the vapors the muffle interior is discharged into the air duct and blown out of the blow-out area together with the cooling air becomes.

- the vapor can also be in another place be discharged and not supplied to the cooling air, for example, in a built-in cooker over the associated built-in hob.

- the two outer openings in the handle of the door together form the blow-out area through which the cooling air K coming from the air duct, possibly with the vapor, flows out into the outer space.

- a connection area is formed, via which the inner space and the outer space of the door are in fluid communication.

- the washer protrudes further down than the inner pane.

- an oven is known with at least one heat source and a microwave generator for heating the food and with a provided on an overhead muffle Wrasenö réelle. On the Wrasenö réelle a provided with two separated by a partition suction chambers suction housing is placed and in the suction chambers each a fan of a common fan drive is arranged, wherein a suction chamber suction side with the Ofenmuffel and the other suction chamber communicates with the housing space and both suction chambers discharge side in a common discharge channel, wherein the flow path of the housing chamber associated with the suction chamber is separated or separable from the flow path of the other suction chamber by a closure flap.

- a baking and roasting oven is known with a Wrasenabzug in the region of a device for measuring the moisture contained in the withdrawing vapor is arranged, wherein the moisture measuring device is part of a control device, as a function of measured by the measuring device Moisture content adjusted a control of the vapor outlet flap or the speed of the fan motor of a hot air blower for circulating the heating air in the baking and frying room is changed.

- DE 35 19 423 C2 discloses a cooking appliance with a closable cooking space, in which a grill element is arranged and the further heating means are assigned, as well as with a cooling fan, from which an air stream flows through the cooking chamber, wherein the air flow through an air damper at the entrance is arranged as a setting depending on the operating mode of the cooking appliance in the intermediate position adjustable by means of a manually operable selector, with the different operating modes and possibly different temperature ranges are adjustable, the adjusting member in the dialing range outgoing from the cooling fan and entering into the cooking chamber the selector for cooking operation by means of thermal radiator in at least one intermediate-open position is adjustable, in which the grill element is turned on.

- an oven in particular with a pyrolytic self-cleaning, which has a vapor opening in the muffle cover, through which the steam produced in the oven operation is sucked outwards by a blower and blown outwards.

- the flow cross section of the vapor opening itself or a subsequent flow channel is automatically adjustable by a throttle as a function of temperature and / or humidity of Wrasens.

- a cooking oven is known with a furnace muffle, in the muffle wall, preferably the muffle cover, a Wrasenaustrittsö réelle is provided, and arranged with a muffle outside the fan with at least one suction, which is connected to the Wrasenaustrittsö Maschinen the Muffelwandung, and with at least one blow-out area.

- At least one fresh air duct which opens into an outer space with one end and opens into the intake area of the blower at one end and at least one discharge duct connecting the blower area with the outer space for discharging the mixture of the vapors sucked out of the cooking space by the blower in its operation provided on the one hand and sucked by the fresh air passage from the outside fresh air on the other hand.

- the fresh air duct and the diversion duct preferably extend substantially horizontally above the oven muffle and are separated from one another by an air baffle plate.

- the fresh air channel is arranged below the diversion channel.

- the fan is preferably a radial fan and arranged above the Wrasenaustrittsö Maschinen Maschinen.

- the feed opening of the oven muffle is closed and is an outlet opening of the door with the entrance of the fresh air duct in flow communication, so that the fan via the fresh air duct sucks fresh air from the door interior.

- an air flow is generated in the door interior from the lower open end of the door up.

- fresh air is drawn through the door handle through an opening behind it in the door interior and then into the fresh air duct, whereby the door handle is cooled.

- This ventilation system serves, on the one hand, for cooling the cooking oven and, on the other hand, for removing the vapor from the oven muffle.

- the invention is based on the object, a new Method and a new device for loading and / or venting of a cooking oven.

- the invention is based on the consideration, in cooking mode and in pyrolysis operation of a Garofens different air ducts through the door of the oven.

- pyrolysis operation The air is sucked in from below and through the door interior headed upstairs and out the door again discharged. Because the air in a room in the area of the floor usually colder than in an area about it, especially over the oven muffle of the oven, and the Air above the oven muffle in pyrolysis mode high temperatures of over 500 ° C particularly strong heated, is thus according to the invention colder air to Cooling the door used to cool the door.

- the cooking mode are the temperatures occurring in the oven muffle significantly lower than in pyrolysis and are typically between 100 ° C and 250 ° C, in grill mode sometimes even up to 300 ° C. Therefore, the cooking operation is air from the top into the door and down again into the outside space blown out.

- the flow direction of the air in the door So in cooking mode is just opposite to the pyrolysis operation.

- the door in the cooking mode can blow out air on the door standing at the door of the user or even the face as in the prior art reduced or even be completely avoided, which on the one hand the associated Inconvenience and on the other hand the sounds e.g. the fan can be reduced.

- pyrolysis mode is against assume that a user person usually will not be in front of the oven for a long time, allowing the blowing out of the hot exhaust air even in a blow-out area can be done above the door, as in the state of the technique.

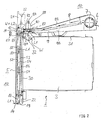

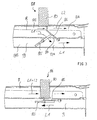

- the cooking oven 2 according to FIG. 1 and 2 comprises a furnace muffle 3 with a loading opening 30 which is closed by a door 5 is.

- the door 5 is substantially perpendicular to Ground or arranged parallel to gravity and lies while a seal on a housing front 22 of the oven 2, which surrounds the feed opening 30.

- the door 5 has according to Figures 1 and 2, an outer pane 50, a Inner disk 51 and two intermediate disks 52 and 53.

- the outer and inner spaces 55 and 56 of the door 5 are via sealing elements or Closures 15 and 16 below and 25 and 26 sealed above.

- the middle gap 54 is above and open at the bottom and serves as a door interior for air guidance.

- an air guide part 11 is provided, that on an inner side a first passage opening 13 of the door 5, which in a flow channel 81st opens inside the air guide part 11.

- a separate Air guide 19 attached, the one initially above substantially parallel to the outer pane 50 extending and then bent outward flow channel 17 below has, which adjoins the middle gap 54 or this continues and in a second passage opening 14 below the outer pane 50 in the outer space 10 opens. This will, depending on the bend of the flow channel 17 an obliquely or horizontally directed air flow achieved through the second passage opening 14.

- a fan 7 arranged which may be formed in a known manner can, for example, one of an electric drive motor driven impeller or fan roller include and / or designed as a radial fan or axial fan can be.

- the fan 7 sucks in the pyrolysis of the cooking oven 2 provided embodiment of the ventilation As shown in FIG 1 air L1 from the door 5 via a suction connected first flow channel 9 and air L2 from a Outside 10 and blows the sucked air through L1 + L2 a pressure side connected second flow channel. 8 towards the front of the device.

- the first flow channel 9 opens according to Figures 1 and 2 at the Housing front 22 in an opening, the first passage opening 13 in the air guide part 11 of the door 5 is opposite.

- the fan 7 is a Air flow of fresh air L1 from the exterior 10 of down through the second passage opening 14 of the door 5, through the central gap 54 between the two Washers 52 and 53 in the door 5 upwards, through the flow channel 81 in the air guide part 11 and the first Passage opening 13 from the door 5 and finally by generates the first flow channel 9 to the fan 7 out.

- a flow channel 82 formed in a blow-out area (blow-out slot) 12 above the outer pane 50 of the door 5 in the outer space 10 opens.

- this flow channel 82 opens the second flow channel 8.

- a flow adjuster 88 the Flow control in the two flow channels 8 and 9 changed or switched by both flow channels 8 and 9 in each case a front, first portion 8A and 9A and a rear, second portion 8B and 9B, respectively and these subregions 8A, 8B, 9A and 9B fluidically be interconnected differently.

- the Flow adjuster 88 is except in FIGS 1 and 2 in an enlarged view in Figures 3 and 4 shown. 3 corresponds to the setting or the state the flow adjuster 88 in the cooking mode according to 3 and FIG 4 of the setting or the state in pyrolysis according to FIG. 1

- the flow adjuster 88 includes a first closure member 85, which is pivotally mounted in a center is and is in the form of a rotary flap, and a second closure member 86 pivotable at one end is stored and at another end in a closing element 80 engages, as well as one in the partition between the two flow channels 8 and 9 provided opening (or: Flow passage) 84.

- the closing element 80 is of a Actuator 89 (shown only in Figures 1 and 2) operable, by being outside in a first state according to FIG of the second flow channel 8 is arranged and in a second state shown in FIG 4 down now moves in the flow channel 8 is arranged.

- the adjusting device 89 may e.g. electromagnetically (e.g., relay, coil) or thermoelectric (e.g., bimetal) or mechanically (e.g. Pushbutton with slider, e.g. on the control panel 21) the Press closing element 80.

- the closing element 80 by the adjusting device 89 moves out of the flow channel 8 and the first Closing element 85 rotates by its aysmmetric mass distribution and that from the action of gravity resulting torque itself in a position in the one opening in the first closing element 85 a flow passage between the second flow channel 8 and the first flow channel 9 through in the Partition provided opening 84 creates and a continuous Area of the first closing element 85, the first Flow channel 9 closes and in the two sections 9A and 9B separates.

- the second closing element 86 has openings on or is smaller than the flow cross-section of the second flow channel 8 to a part of the incoming air as the second airflow L2 in the front forward first portion 8A of the flow channel 8.

- the main part of the air flow from the second Flow channel 8 is on the other hand as the first air flow L1 the rear second portion 8 B of the flow channel eighth in the front first portion 9A of the first flow channel 9 passed and then through the passage opening 13th (see FIG 2) introduced into the door. After flowing through the Flow channel 81 in the air guide part 11 and the gap 54 down this first air flow L1 flows through the flow channel 17 and the second passage opening 14th again out into the outer space 10.

- the door 5 flows in the Essentially only pure air L1.

- the closing element 80 of the adjusting device 89 introduced into the flow channel 8 and thereby pushes the second closing element 86 down, wherein this during the pivoting movement and the first closing element 85 brings in a horizontal open position, so that through the now again through the second flow channel 8 the air flow L1 according to FIG 1 and 4 flow can.

- the second closing element 86 now closes the Opening 84, so that the second flow channel 8 and the first flow channel 9 separated by the partition again are. Since the closing element 80 has openings or is smaller than the flow cross-section of second flow channel 8, can now according to FIG 1 and 4 of Air flow L1 + L2 flow in the second flow channel 8.

- the Width of the openings 12 and 13 can be chosen differently his and / or himself almost over the whole device width or Door width extend.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electric Ovens (AREA)

- Electric Stoves And Ranges (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200410008463 DE102004008463B3 (de) | 2004-02-20 | 2004-02-20 | Verfahren und eine Vorrichtung zum Be- und/oder Entlüften eines Garofens |

| DE102004008463 | 2004-02-20 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1566594A1 true EP1566594A1 (fr) | 2005-08-24 |

Family

ID=34178111

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04030589A Withdrawn EP1566594A1 (fr) | 2004-02-20 | 2004-12-23 | Procédé et dispositif pour aérer et /ou ventiler un four de cuisson |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1566594A1 (fr) |

| DE (1) | DE102004008463B3 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2108891A1 (fr) * | 2008-04-10 | 2009-10-14 | Whirpool Corporation | Four intégré avec système de refroidissement amélioré |

| US7708007B2 (en) * | 2005-12-02 | 2010-05-04 | Lg Electronics Inc. | Door assembly for home appliance, electric oven using the same, and method for operating electric oven |

| EP2741013A1 (fr) * | 2012-12-04 | 2014-06-11 | BSH Bosch und Siemens Hausgeräte GmbH | Appareil de cuisson avec un ventilateur et un dispositif de réglage |

| EP2846100A1 (fr) * | 2013-09-10 | 2015-03-11 | Electrolux Appliances Aktiebolag | Système de refroidissement et d'échappement destiné à un four de cuisson |

| EP2980491A3 (fr) * | 2014-08-01 | 2016-04-27 | Samsung Electronics Co., Ltd. | Four |

| EP3091291A1 (fr) * | 2015-05-08 | 2016-11-09 | Electrolux Appliances Aktiebolag | Four de cuisson avec une cavité de four et une porte de four |

| EP3058282B1 (fr) * | 2013-10-18 | 2018-09-26 | Whirlpool EMEA S.p.A | Appareil electromenager de cuisson |

| US10502431B2 (en) | 2014-08-01 | 2019-12-10 | Samsung Electronics Co., Ltd. | Oven and door assembly applied to the oven |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TR200703263T1 (tr) * | 2004-12-13 | 2008-03-21 | Ar�El�K Anon�M ��Rket� | Bir pişirici cihaz |

| ITVR20060001A1 (it) * | 2006-01-10 | 2007-07-11 | Societa Europea Componenti Elettrici Spa | Ventilatore, particolarmente per la ventilazione di forni da cucina |

| ITTV20080136A1 (it) * | 2008-10-27 | 2010-04-28 | Unieldom Group S Cons A R L | Forno per la cottura d'alimenti, con dispositivo di controllo a flusso d'aria della dispersione di calore dalla camera di cottura attraverso la luce d'accesso, e sistema integrato di ventilazione per l'isolamento termico con barriera termica della lu |

| IT1395265B1 (it) * | 2009-07-30 | 2012-09-05 | Indesit Co Spa | Forno di cottura, in particolare di uso domestico, di tipologia migliorata |

| IT1395264B1 (it) * | 2009-07-30 | 2012-09-05 | Indesit Co Spa | Forno di cottura, in particolare di uso domestico |

| WO2011013088A2 (fr) * | 2009-07-30 | 2011-02-03 | Indesit Company S.P.A. | Four de cuisson, en particulier à usage ménager |

| ES2386560B1 (es) * | 2009-11-25 | 2013-07-08 | BSH Electrodomésticos España S.A. | Procedimiento para accionar un aparato doméstico para preparar alimentos, y aparato doméstico de tal tipo. |

| ITRN20100013A1 (it) * | 2010-04-02 | 2011-10-03 | Indesit Co Spa | Forno di cottura. |

| ITTO20110191A1 (it) * | 2011-03-03 | 2012-09-04 | Indesit Co Spa | Forno di cottura, in particolare di uso domestico |

| EP2505924A1 (fr) * | 2011-03-30 | 2012-10-03 | Electrolux Home Products Corporation N.V. | Four de cuisson avec cadre frontal et pivot de porte de four assemblé sur ce cadre frontal |

| KR20220014508A (ko) * | 2020-07-29 | 2022-02-07 | 삼성전자주식회사 | 조리기기 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1022517A1 (fr) | 1999-01-25 | 2000-07-26 | CANDY S.p.A. | Porte pour four pyrolytique |

| DE10047016A1 (de) * | 2000-09-22 | 2002-04-18 | Aeg Hausgeraete Gmbh | Verfahren zum Kühlen einer Ofenmuffeltür und Garofen mit Kühlung |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2856094C2 (de) * | 1978-12-23 | 1986-05-22 | Licentia Patent-Verwaltungs-Gmbh, 6000 Frankfurt | Back- und Bratofen |

| DE3519423A1 (de) * | 1985-05-30 | 1986-12-04 | Bosch-Siemens Hausgeräte GmbH, 7000 Stuttgart | Gargeraet mit verschliessbarem garraum |

| DE8706668U1 (de) * | 1987-05-08 | 1987-07-02 | Bosch-Siemens Hausgeräte GmbH, 8000 München | Backofen |

| DE4238660C2 (de) * | 1992-11-16 | 1994-09-01 | Bosch Siemens Hausgeraete | Backofen, insbesondere mit einer Einrichtung für pyrolytische Selbstreinigung |

| DE19801585A1 (de) * | 1998-01-19 | 1999-07-22 | Aeg Hausgeraete Gmbh | Verfahren zum Kühlen der Außenumgebung einer Ofenmuffel und Garofen mit Kühleinrichtung |

| DE19920345C1 (de) * | 1999-05-04 | 2000-12-21 | Aeg Hausgeraete Gmbh | Garofen mit Wrasenabführung und Frischluftbeimischung |

-

2004

- 2004-02-20 DE DE200410008463 patent/DE102004008463B3/de not_active Expired - Fee Related

- 2004-12-23 EP EP04030589A patent/EP1566594A1/fr not_active Withdrawn

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1022517A1 (fr) | 1999-01-25 | 2000-07-26 | CANDY S.p.A. | Porte pour four pyrolytique |

| DE10047016A1 (de) * | 2000-09-22 | 2002-04-18 | Aeg Hausgeraete Gmbh | Verfahren zum Kühlen einer Ofenmuffeltür und Garofen mit Kühlung |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7708007B2 (en) * | 2005-12-02 | 2010-05-04 | Lg Electronics Inc. | Door assembly for home appliance, electric oven using the same, and method for operating electric oven |

| EP2108891A1 (fr) * | 2008-04-10 | 2009-10-14 | Whirpool Corporation | Four intégré avec système de refroidissement amélioré |

| EP2741013A1 (fr) * | 2012-12-04 | 2014-06-11 | BSH Bosch und Siemens Hausgeräte GmbH | Appareil de cuisson avec un ventilateur et un dispositif de réglage |

| AU2014320631B2 (en) * | 2013-09-10 | 2018-05-10 | Electrolux Appliances Aktiebolag | Cooling and exhaust system for a cooking oven |

| WO2015036274A1 (fr) * | 2013-09-10 | 2015-03-19 | Electrolux Appliances Aktiebolag | Système de refroidissement et d'échappement pour four de cuisson |

| EP2846100A1 (fr) * | 2013-09-10 | 2015-03-11 | Electrolux Appliances Aktiebolag | Système de refroidissement et d'échappement destiné à un four de cuisson |

| EP3058282B1 (fr) * | 2013-10-18 | 2018-09-26 | Whirlpool EMEA S.p.A | Appareil electromenager de cuisson |

| US11092344B2 (en) | 2013-10-18 | 2021-08-17 | Whirlpool Emea S.P.A. | Household cooking appliance |

| EP2980491A3 (fr) * | 2014-08-01 | 2016-04-27 | Samsung Electronics Co., Ltd. | Four |

| US9784457B2 (en) | 2014-08-01 | 2017-10-10 | Samsung Electronics Co., Ltd. | Oven, door assembly applied to the same, and method for controlling the oven |

| US10502431B2 (en) | 2014-08-01 | 2019-12-10 | Samsung Electronics Co., Ltd. | Oven and door assembly applied to the oven |

| EP3091291A1 (fr) * | 2015-05-08 | 2016-11-09 | Electrolux Appliances Aktiebolag | Four de cuisson avec une cavité de four et une porte de four |

| WO2016180684A1 (fr) * | 2015-05-08 | 2016-11-17 | Electrolux Appliances Aktiebolag | Four de cuisson pourvu d'une cavité de four et d'une porte de four |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102004008463B3 (de) | 2005-03-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1566594A1 (fr) | Procédé et dispositif pour aérer et /ou ventiler un four de cuisson | |

| EP0752561B1 (fr) | Fuir de cuisson | |

| DE3839657C2 (de) | Luftführungssystem für einen Backofen | |

| DE19939673B4 (de) | Garofen mit Auslaßphase | |

| DE10245773C1 (de) | Vorrichtung zur Wärmebehandlung von Lebensmitteln | |

| EP1589287B1 (fr) | Procédé et dispositif pour la ventilation d'un four | |

| DE3519423C2 (fr) | ||

| DE10047016B4 (de) | Garofen | |

| EP0732549A2 (fr) | Four pour le traitement thermique d'aliments et méthode de cuisson | |

| EP2476960A1 (fr) | Dispositif de commutation pour une hotte aspirante destiné à commuter entre un fonctionnement à air ambiant et un fonctionnement à air d'évacuation | |

| EP1979683B1 (fr) | Porte d'appareil de cuisson | |

| EP0947776B1 (fr) | Four à dispositif de refroidissement | |

| DE20221100U1 (de) | Dunstabsaugvorrichtung für ein Kochfeld o.dgl. und insbesondere dafür geeigneter Fettfilter | |

| CH678913A5 (en) | Oven for forced cooling - with heat transferred to air which flows along channels in oven walls and door | |

| EP2818800B1 (fr) | Appareil de cuisson | |

| CH630240A5 (en) | Hot-air circulating, baking, frying and grilling oven, and method of operating it | |

| EP0641976B1 (fr) | Four électrique pour cuire au four et rotir | |

| DE9309989U1 (de) | Backofen | |

| EP0499803B1 (fr) | Porte de four avec poignée | |

| EP1639299A1 (fr) | Four de cuisson | |

| DE3144493A1 (de) | Gargeraet, insbesondere backofen | |

| EP1201999A2 (fr) | Four pour la cuisson et le rôtissage | |

| DE3441191C2 (fr) | ||

| EP0482602B1 (fr) | Four | |

| DE10219348B4 (de) | Gargerät |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050613 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ELECTROLUX HOME PRODUCTS CORPORATION N.V. |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070608 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ELECTROLUX HOME PRODUCTS CORPORATION N.V. |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ELECTROLUX HOME PRODUCTS CORPORATION N.V. |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20140701 |