EP1557249A2 - Procédé pour produire des briques thermo-isolants multicouches et telles briques - Google Patents

Procédé pour produire des briques thermo-isolants multicouches et telles briques Download PDFInfo

- Publication number

- EP1557249A2 EP1557249A2 EP20050001234 EP05001234A EP1557249A2 EP 1557249 A2 EP1557249 A2 EP 1557249A2 EP 20050001234 EP20050001234 EP 20050001234 EP 05001234 A EP05001234 A EP 05001234A EP 1557249 A2 EP1557249 A2 EP 1557249A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- shell

- thermal insulation

- outer shell

- brick

- brick according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000011449 brick Substances 0.000 title claims abstract description 60

- 238000004519 manufacturing process Methods 0.000 title claims description 15

- 238000009413 insulation Methods 0.000 claims abstract description 58

- 239000000853 adhesive Substances 0.000 claims abstract description 29

- 230000001070 adhesive effect Effects 0.000 claims abstract description 29

- 238000000034 method Methods 0.000 claims description 29

- 239000000463 material Substances 0.000 claims description 19

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 16

- 239000004033 plastic Substances 0.000 claims description 13

- 229920003023 plastic Polymers 0.000 claims description 13

- 239000011888 foil Substances 0.000 claims description 9

- 239000011521 glass Substances 0.000 claims description 8

- 238000005538 encapsulation Methods 0.000 claims description 7

- 239000007789 gas Substances 0.000 claims description 6

- 229910052751 metal Inorganic materials 0.000 claims description 6

- 239000002184 metal Substances 0.000 claims description 6

- 239000000377 silicon dioxide Substances 0.000 claims description 6

- 239000004698 Polyethylene Substances 0.000 claims description 5

- 229910052782 aluminium Inorganic materials 0.000 claims description 5

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 5

- -1 polyethylene Polymers 0.000 claims description 4

- 229920000573 polyethylene Polymers 0.000 claims description 4

- 239000000843 powder Substances 0.000 claims description 4

- 238000003466 welding Methods 0.000 claims description 4

- 229920000219 Ethylene vinyl alcohol Polymers 0.000 claims description 3

- 239000004952 Polyamide Substances 0.000 claims description 3

- 238000001816 cooling Methods 0.000 claims description 3

- UFRKOOWSQGXVKV-UHFFFAOYSA-N ethene;ethenol Chemical compound C=C.OC=C UFRKOOWSQGXVKV-UHFFFAOYSA-N 0.000 claims description 3

- 239000004715 ethylene vinyl alcohol Substances 0.000 claims description 3

- 238000002844 melting Methods 0.000 claims description 3

- 230000008018 melting Effects 0.000 claims description 3

- 229920002647 polyamide Polymers 0.000 claims description 3

- 235000019353 potassium silicate Nutrition 0.000 claims description 3

- 238000005266 casting Methods 0.000 claims description 2

- 238000001704 evaporation Methods 0.000 claims description 2

- 239000011104 metalized film Substances 0.000 claims description 2

- 229920002635 polyurethane Polymers 0.000 claims description 2

- 239000004814 polyurethane Substances 0.000 claims description 2

- 229910001220 stainless steel Inorganic materials 0.000 claims 2

- 239000010935 stainless steel Substances 0.000 claims 2

- 238000004026 adhesive bonding Methods 0.000 claims 1

- 238000010309 melting process Methods 0.000 claims 1

- 239000010410 layer Substances 0.000 description 37

- 230000006378 damage Effects 0.000 description 5

- 239000007858 starting material Substances 0.000 description 4

- 230000003068 static effect Effects 0.000 description 4

- 230000001419 dependent effect Effects 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 238000009434 installation Methods 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 238000003860 storage Methods 0.000 description 3

- 238000012549 training Methods 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 239000008187 granular material Substances 0.000 description 2

- 239000011810 insulating material Substances 0.000 description 2

- 239000004570 mortar (masonry) Substances 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 238000010943 off-gassing Methods 0.000 description 2

- 238000004382 potting Methods 0.000 description 2

- 239000004831 Hot glue Substances 0.000 description 1

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000002730 additional effect Effects 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000005465 channeling Effects 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000006735 deficit Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 239000003000 extruded plastic Substances 0.000 description 1

- 238000007765 extrusion coating Methods 0.000 description 1

- 229910021485 fumed silica Inorganic materials 0.000 description 1

- 239000003292 glue Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 238000009776 industrial production Methods 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 229920006327 polystyrene foam Polymers 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 239000006228 supernatant Substances 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C1/00—Building elements of block or other shape for the construction of parts of buildings

- E04C1/40—Building elements of block or other shape for the construction of parts of buildings built-up from parts of different materials, e.g. composed of layers of different materials or stones with filling material or with insulating inserts

- E04C1/41—Building elements of block or other shape for the construction of parts of buildings built-up from parts of different materials, e.g. composed of layers of different materials or stones with filling material or with insulating inserts composed of insulating material and load-bearing concrete, stone or stone-like material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B1/00—Producing shaped prefabricated articles from the material

- B28B1/002—Producing shaped prefabricated articles from the material assembled from preformed elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/38—Connections for building structures in general

- E04B1/41—Connecting devices specially adapted for embedding in concrete or masonry

- E04B1/4178—Masonry wall ties

- E04B1/4185—Masonry wall ties for cavity walls with both wall leaves made of masonry

Definitions

- the invention relates to a method for producing a heat-insulating multi-shell brick and a thermally insulating multi-shelled Brick.

- a known method for producing a heat-insulating multi-shell brick according to DE 101 63 994 A1 consists of the multi-shell Brick from an inner shell, an outer shell and between inner shell and outer shell arranged thermal insulation, namely a polystyrene foam sheet.

- thermal insulation namely a polystyrene foam sheet.

- inner shell, outer shell and Thermal insulation provided as prefabricated components and interconnected.

- a tie rod used and tensile strength is poured by means of a hot melt adhesive, a Adhesive mortar or the like.

- the method should be designed such that a

- Brick can be formed, which serves as thermal insulation between inner shell and Outer shell can also use vacuum panels.

- the invention is based on the idea that the inner shell and Outer shell relative to the thermal insulation have a supernatant by means of a glue mass can be covered, wherein the adhesive mass according to the thermal insulation protects outside.

- the adhesive mass reaches at least one significant contribution of the solid connection between inner shell and outer shell.

- the thermal insulation is improved, even if for static reasons

- a vacuum panel is suitable, consisting of an airtight, non-discharging, formed by a foil or the like bag-like shell, which contains inside support elements, the interior according to Closing the envelope or being evacuated during this process. It can do that Vacuum panel are brought into a plate-like shape. Become advantageous then the opposite sides of the inner shell and the outer shell facing sides of the shell of the vacuum panel with additional layers, In particular, aluminum layers, occupied, thereby creating a substantial extent "Outgassing", that is, the ingress of air into the interior of the vacuum panel is avoided.

- a vacuum panel is suitable, which during his Production obtained a glazed and thus rather insensitive surface has, without a shell and thus seams would be necessary.

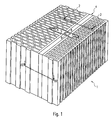

- Figure 1 shows a typical brick 1, consisting of a typical static supporting inner shell 2, a typically mechanically stable outer shell 3 and a Heat insulation 4 between inner shell 2 and outer shell 3.

- Inner shell 2 and Outer shell 3 show typical passage slots.

- the outward facing Surfaces of inner shell 2 and outer shell 3 also show projections and Recesses, which when obstructing into corresponding projections and recesses adjacent bricks can penetrate, or after the installation for better application of the inner or outer mortar are provided, as the is common practice.

- Figure 1 also shows that inner shell 2 and outer shell 3, the Thermal insulation 4 bridging, connected by a clamp 5 together are, with elastically yielding end flaps 6, 7 in corresponding slots of Inner shell 2 and outer shell 3 engage, causing the bracket 5 a solid Connection between inner shell 2 and outer shell 3 ensures.

- the bracket 5 serves the bracket 5 for stabilization during the manufacture of the brick 1, whose Warehousing and transportation and also while able to deploy during shoring and will then be removed. If the clip remains 5, it provides a thermal bridge is expediently, in the area of bridging the insulation 4 the Staple 5 an opening 8, caused by the remaining webs 9 Thermal bridge between inner shell 2 and outer shell 3 on the static necessarily to reduce the extent necessary.

- the thermal insulation 4 by a Vacuum panel 10 is formed, which is explained in more detail with reference to FIG 4.

- typical Vacuum panels are for example in EP 01 061 03 A1 and US 4,668,551 specified. Other embodiments will be more apparent from Figures 4 to 8 explained.

- the vacuum panel 10 consists essentially of a single or multi-walled, usually two-walled shell 11, which is (or should be) gas or airtight and the one, symbolized by a honeycomb representation filling of grainy or powdery degassed support elements 12, preferably microporous silica, contains.

- the interior of the shell 11 is evacuated, whereby the support members 12 closely approach each other and are surrounded by the shell 11 close fitting.

- the Material of the supporting elements 12 is of course made of a heat-insulating material, as well as the shell 11.

- the advantage here are the sections of the shell 11, in the brick in the first installed state against the opposite sides of the inner shell 2 and Outer shell 3 come to rest, with an additional layer 14 each at least partially provided.

- this layer 14 is essential that they are the Gas-tightness of the shell 11 substantially increased at the corresponding sections, while a contribution to thermal insulation does not have to be made. It may therefore be to deal with compact materials, such as metal foils or metal layers, for example, an aluminum foil. Such a material is also relatively little vulnerable to injury during shoring, that is, in terms of risk, to be damaged during shoring so that the tightness of the shell 11th is impaired.

- This design also allows an adhesive bond between them additional layer 14 and the opposite side of the associated the provide against each other heat-insulating surfaces, not in detail is shown.

- the above-mentioned adhesive bond may be a ceremoniverklebung exclusively for assembly purposes, when the mutually heat-insulating surfaces having brick shells ( Figure 1) connected in a different manner are, appropriately thermally decoupled interconnected.

- the seam 13 is vulnerable to damage in a special way, at least during installation. It is therefore expedient, as shown in Fig. 4, and the Seam formed by two interconnected flaps 25 and 26, also additionally provided with an additional layer 27 or 28, wherein expedient the arrangement is such that the coated tabs 25, 26 on the additional layer 14 are foldable. Appropriately (also) in the assigned to each other heat-insulating surfaces a corresponding Well be provided.

- an arrangement may be provided in which one, alternatively two, seams 19 and 20 are provided such that they Continue side of the shell on which the additional layer 14 is applied.

- the welds or seams 19 or 20 can be represented as in Fig. 5 by dashed lines, against the be folded additional layer 14, but also against the region of the shell 11, the is not provided with an additional layer 14 (in dash-dot lines ) Indicated. In the latter case, a coating must be avoided.

- Fig. 6 shows in perspective an arrangement in which the through the vacuum panel 10th formed thermal insulation is essentially cuboid, so a clear Thickness dimension has.

- a comparatively elastic shell instead of a comparatively rigid box or box-like sheath arrangement 21 is selected be evacuated via a nozzle or the like (not shown).

- an embodiment of a vacuum panel may also be used be, in which by a glazing of a surface on the one hand very hard-wearing surface is created, on the other hand gas and thus also is vacuum-tight, as will be explained below with reference to FIGS 7 and 8.

- An amount of starting material 31, for example, a powder or granular material is first pressed in a first step S1 into a mold, For example, a plate or cuboid shape, as in later Use cases is to use.

- a mold For example, a plate or cuboid shape, as in later Use cases is to use.

- a shaping the total for the later arrangement is suitable, so one to the course of each other heat-insulating surfaces of the brick shells adapted course. Consequently If necessary, the surfaces could also be curved.

- a molded plate obtained by pressing in the first step S1 is then inserted into an evacuated space is introduced and heated, so that a melting is reached in step S2 of the surface, by merging the individual particles of the pressed starting material. This forms an im Essentially liquid glass layer.

- this glass layer is solidified by cooling in accordance with step S5, then the Glass layer and thus provides a closure for that within the glass layer, that is, inside the plate, between the unmelted ones arranged there Particles of the starting material reached vacuum.

- melts typically attempt to contain them inside Gas residues and / or residual liquid to escape and lead to unwanted Openings. It is therefore expedient, after melting in accordance with step S2 to selectively provide openings 33 (FIG. 8) in the glassy surface such that evaporating moisture and gases can escape easily, like that through the Steps S3 and S4 is shown.

- step S6 After cooling according to step S5, only the openings 33 are required to close, which is shown in Figure 8 by closure elements 34.

- This Closing has, as shown by step S6, after an evacuation, if necessary, to be evacuated again.

- a vacuum panel 32 ( Figure 8), inside by the particles the starting material 31 formed, closely adjacent support elements 12th contains, between which prevails vacuum, the arrangement of the support elements 12 is sealed gas-tight to the outside through a glass layer 35 and possibly provided openings 33 are closed by closure elements 34.

- the thus formed vacuum panel 32 is characterized by a glass skin and has no seams. This glass skin forms a very hard-wearing layer 35. Vacuum panels 32 thus formed can therefore be easily obtained be further processed.

- Particularly suitable as support elements 12 are silica particles.

- the outwardly facing surface is without Impairment of the thermal insulation behavior compared to mechanical Significantly improved damage and outgassing.

- thermal insulation 4 of the brick according to the invention. 1 not limited to this type of thermal insulation.

- the Dimensions of the thermal insulation 4 are smaller than that of the inner shell 2 and the Outer shell 3 of the type that a shallow or shallow channel-like space 15 between inner shell 2, insulation 4 and outer shell 3 is formed with an adhesive mass 16 is filled, wherein the adhesive of the adhesive mass 16 so is selected that he at least inner shell 2 and outer shell 3 fixed together to connect.

- each one Recess 17 and 18 may be provided, which is also of the adhesive mass 16th is filled.

- This recess 17 and / or 18 may be additional Undercuts, grooves or the like (not in detail shown), the solid connection between inner shell 2 and outer shell. 3 to improve by means of the adhesive mass 16.

- the adhesive mass 16 may also be introduced in another way In particular, it may also be strip material. It is essential only that the adhesive mass 16 on the one hand good adhesion between the inner shell. 2 and outer shell 3 achieved, further with the material of the thermal insulation 4, especially the material of the shell 11, is compatible and finally better Thermal insulation has as metallic brackets for the connection of Inner shell 2 and outer shell 3, such as the clip 5.

- connection force exerted by the adhesive mass 16 between Inner shell 2 and outer shell 3 for production, storage, transport and shoring is not static enough, in addition to the mentioned brackets. 5 be provided, wherein depending on the mentioned holding force or Connecting force the dimension of the bridges or webs 9 correspondingly smaller can be measured as a brick without adhesive mass.

- Figure 9 shows in perspective an arrangement similar to Figure 5, in which the through a vacuum panel 22 formed thermal insulation is substantially cuboid, So has a significant thickness.

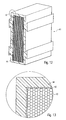

- the inner wall 24 (FIG. 10 and FIG. 11) of the gas-tight envelope of the vacuum panel 22 in a special way is formed, namely rib-like elevations 29 and channel-like recesses 30th having.

- the filling, not shown here, of granular or powdery Degassed support elements, preferably microporous silica, is in any case usually close to the projections 29 and will probably, at least in Significant extent also penetrate into the channel-like recesses 30.

- Figure 10 and Figure 11 show that the entire wall structure of the shell multi-layered, starting from the inner wall 24 further layers 25, 26 and 27, 28. The number and type of material of each layer will be judge according to the respective application.

- the lid 32 has one of the walls of the extruded tube corresponding multilayer structure with an inner wall 34 and successive layers 35, 36 and 37, 38.

- the lid 32 may be glued or welded or glued or be welded on. It may also be partially shown in FIG. 11 engaging in training.

- the evacuation port 31 evacuates carried out, after which this evacuation port 31 is sealed.

- a vacuum panel 22 designed in this way has very high inherent rigidity and is therefore more usable in many applications than vacuum panels with only small thickness and thin bag-like casing, even if these, such as explained above, is coated by an additional layer. Further suitable Such an embodiment is better for industrial production with high Quantities.

- suitable for the layer 24 is a polyamide

- for the layers 25 and 27 is an EVOH and for layers 26 and 28 is a PE (polyethylene).

- the vacuum panels next to the desired heat-insulating property an additional property in the to give special dimensions, namely, that the materials of the shell and of the support material targeted to improve the Schalldämmconcees the Overall arrangement in which the vacuum panel is used to improve.

- vacuum panels can not only increase the thermal insulation, but also to improve the sound insulation, even together be used.

- FIG. 12 shows a partial section of a vacuum panel 41, which initially has a vacuum inside Arrangement of a shell 42 and a filling 43, for example, from a powdery or granular material, eg. Fumed silica, has, wherein this arrangement is evacuated.

- This arrangement 42, 43 is as shown Figure 12 seen completely surrounded by a plastic material, wherein this plastic material is designed as an encapsulation or encapsulation 44.

- Such a vacuum panel 41 can be by introducing the assembly 42, 43 in a mold and by molding or encapsulation in this form by means of a produce relatively suitable plastic material such as polyurethane comparatively easy. It is advantageous if the shell 42 is formed by a metallized film.

- the ease of manufacture of the vacuum panel 41 allows the Outer side surfaces of the extrusion coating or Umg electung 44 to an application adapted to form, for example by casting or molding of Vorsprügen.

- Centresbeipiel strip-like projections 45 are with Dovetail-shaped cross-section on opposite sides Outer side surfaces of the Umg electung or the enclosure 44 of the vacuum panel 41st formed. This makes it possible in a simple manner, the vacuum panel 41st between introducing elements to be insulated against each other.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Thermal Insulation (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200410003602 DE102004003602A1 (de) | 2004-01-23 | 2004-01-23 | Verfahren zum Herstellen eines wärmedämmenden mehrschaligen Mauersteins sowie solcher Mauerstein |

| DE102004003602 | 2004-01-23 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1557249A2 true EP1557249A2 (fr) | 2005-07-27 |

Family

ID=34625787

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20050001234 Withdrawn EP1557249A2 (fr) | 2004-01-23 | 2005-01-21 | Procédé pour produire des briques thermo-isolants multicouches et telles briques |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1557249A2 (fr) |

| DE (1) | DE102004003602A1 (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007138625A1 (fr) * | 2006-06-01 | 2007-12-06 | Stahl Beton S.R.L. | Bloc de béton comportant une couche interne de matériau isolant |

| EP1876309A1 (fr) * | 2006-07-06 | 2008-01-09 | Stamford Consulting Limited | Assemblage de blocs pour des bâtiments et méthode de fabrication correspondante |

| DE102007013584A1 (de) | 2006-12-13 | 2008-09-25 | Woschko Winlite Gmbh | Verfahren zur Herstellung eines Vakuumpaneels, derartiges Vakuumpaneel sowie ein dieses verwendender Mauerstein |

| EP1988228A3 (fr) * | 2007-05-03 | 2009-08-26 | Matthias Rimmele | Blocs et systèmes de construction avec isolation thermique hydrophobe et microporeuse |

| EP2116663A1 (fr) * | 2008-05-08 | 2009-11-11 | Stamford Consulting Limited | Bloc composite isolé pour l'industrie de la construction, et procédé de fabrication de ce bloc |

| WO2011134677A1 (fr) * | 2010-04-30 | 2011-11-03 | Va-Q-Tec Ag | Structure plane sous vide pour l'isolation thermique |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10058566C2 (de) * | 2000-08-03 | 2002-10-31 | Va Q Tec Ag | Folienumhüllter, evakuierter Wärmedämmkörper und Herstellungsverfahren für diesen |

| DE10101689A1 (de) * | 2001-01-15 | 2003-11-13 | Woschko Gabriele | Fenster, Mauerstein, Wand- und Deckenverkleidung mit Vakuumdämmeinlage |

| DE10160214A1 (de) * | 2001-12-07 | 2003-06-18 | Veit Dennert Kg Baustoffbetr | Wärmedämmender mehrschaliger Mauerstein und Verfahren zu dessen Herstellung |

-

2004

- 2004-01-23 DE DE200410003602 patent/DE102004003602A1/de not_active Ceased

-

2005

- 2005-01-21 EP EP20050001234 patent/EP1557249A2/fr not_active Withdrawn

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007138625A1 (fr) * | 2006-06-01 | 2007-12-06 | Stahl Beton S.R.L. | Bloc de béton comportant une couche interne de matériau isolant |

| EP1876309A1 (fr) * | 2006-07-06 | 2008-01-09 | Stamford Consulting Limited | Assemblage de blocs pour des bâtiments et méthode de fabrication correspondante |

| DE102007013584A1 (de) | 2006-12-13 | 2008-09-25 | Woschko Winlite Gmbh | Verfahren zur Herstellung eines Vakuumpaneels, derartiges Vakuumpaneel sowie ein dieses verwendender Mauerstein |

| EP1988228A3 (fr) * | 2007-05-03 | 2009-08-26 | Matthias Rimmele | Blocs et systèmes de construction avec isolation thermique hydrophobe et microporeuse |

| EP2116663A1 (fr) * | 2008-05-08 | 2009-11-11 | Stamford Consulting Limited | Bloc composite isolé pour l'industrie de la construction, et procédé de fabrication de ce bloc |

| WO2011134677A1 (fr) * | 2010-04-30 | 2011-11-03 | Va-Q-Tec Ag | Structure plane sous vide pour l'isolation thermique |

| CN102859251A (zh) * | 2010-04-30 | 2013-01-02 | 瓦克技术股份公司 | 用于隔热的抽真空的扁平成型件 |

| CN102859251B (zh) * | 2010-04-30 | 2015-11-25 | 瓦克技术股份公司 | 用于隔热的抽真空的扁平成型件及其制造方法 |

| US9321237B2 (en) | 2010-04-30 | 2016-04-26 | Va-Q-Tec Ag | Evacuated sheet material for thermal insulation |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102004003602A1 (de) | 2005-08-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2276961B1 (fr) | Plaque d'isolation sous vide et son procédé de production | |

| EP1177879B1 (fr) | Corps thermoisolant conditionné sous vide et procédé d'obtention | |

| EP1557249A2 (fr) | Procédé pour produire des briques thermo-isolants multicouches et telles briques | |

| WO2011032299A1 (fr) | Élément à structure alvéolaire | |

| DE10058566A1 (de) | Folienumhüllter, evakuierter Wärmedämmkörper und Herstellungsverfahren für diesen | |

| EP1557504A2 (fr) | Procédé de fabrication d'un panneau isolant sous vide, et panneau isolant sous vide notamment pour l'isolation thermique | |

| EP2119842B1 (fr) | Elément d'isolation et procédé de fabrication d'un élément d'isolation | |

| EP2089586B1 (fr) | Procédé de fabrication d'un panneau à vide intérieur, panneau à vide intérieur ainsi obtenu et maçonnerie réalisée à l'aide de ce panneau | |

| EP3049603B1 (fr) | Entretoise d'écartement des vitres d'une fenêtre à vitrage multiple, fenêtre à vitrage multiple, film pare-vapeur pour une entretoise, procédé de fabrication d'un film pare-vapeur, ainsi que procédé de fabrication d'une entretoise | |

| WO2004001149A2 (fr) | Panneau a isolation par le vide, procede pour isoler thermiquement des objets et elements auxiliaires associes | |

| EP2119841B1 (fr) | Elément d'isolation et procédé de fabrication d'un élément d'isolation | |

| DE102004050549B4 (de) | Folienumhüllte Vakuumdämmplatte und Verfahren zur Herstellung derselben | |

| EP2406454A1 (fr) | Ecarteur pour vitrages isolants | |

| DE102004003603A1 (de) | Verfahren zum Herstellen eines Vakuumpaneels, sowie Vakuumpaneel, insbesondere für Wärmedämmzwecke | |

| WO2017207253A1 (fr) | Bande d'étanchéité destinée à assurer l'étanchéité de joints entre des éléments de construction ainsi que procédé de fabrication d'une telle bande d'étanchéité | |

| DE102007056837A1 (de) | Vorrichtung und Herstellungsverfahren für ein Vakuum-Isolier-Element besthend aus einem mehrere Kammern definierendes Dämmmaterial | |

| EP0753638A1 (fr) | Ecarteur pour vitrage isolant | |

| DE102018112075A1 (de) | Verfahren zur Herstellung eines Bauelemlents sowie Bauelement zur wärmebrückenarmen Anbindung eines vorkragenden Außenteils an eine Gebäudehülle | |

| EP2165110B1 (fr) | Panneau isolant sous vide et son procédé de production | |

| DE102011050632A1 (de) | Wabenelement zur Dämmung | |

| EP1734197B1 (fr) | Elément de paroi avec panneau à vide isolant disposé entre deux éléments préfabriqués en béton | |

| DE102015112152A1 (de) | Verfahren zur Herstellung eines Dämmelements sowie ein entsprechendes Dämmelement | |

| EP1898014B1 (fr) | Panneau d'isolation sous vide doté d'un évidement dans une pièce d'appui de matériau isolant | |

| DE102011119219A1 (de) | Wärmedämmendes Isolationselement für Hochtemperaturanwendungen und ein Verfahren zu seiner Herstellung | |

| DE102015112154A1 (de) | Verfahren zur Herstellung eines Dämmelements sowie ein entsprechendes Dämmelement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Effective date: 20100824 |