EP1544369A2 - Brandschutzfassade - Google Patents

Brandschutzfassade Download PDFInfo

- Publication number

- EP1544369A2 EP1544369A2 EP04029542A EP04029542A EP1544369A2 EP 1544369 A2 EP1544369 A2 EP 1544369A2 EP 04029542 A EP04029542 A EP 04029542A EP 04029542 A EP04029542 A EP 04029542A EP 1544369 A2 EP1544369 A2 EP 1544369A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- fire protection

- facade

- facade according

- insulating body

- glass

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B2/00—Walls, e.g. partitions, for buildings; Wall construction with regard to insulation; Connections specially adapted to walls

- E04B2/88—Curtain walls

- E04B2/96—Curtain walls comprising panels attached to the structure through mullions or transoms

- E04B2/967—Details of the cross-section of the mullions or transoms

Definitions

- the invention relates to a fire protection facade with the Features of the preamble of claim 1.

- Fire protection facades include fire protection panels that are common made of fire-resistant glass and between sealing strips are held. Between two adjacent fire protection panels There is a glass fold. In one in the facade construction frequently carried out manner is from the facade outside a Pressure profile with facade screws against a basic profile fixed, with the facade screws through the glass rebate extend and the pressure profile the fire protection panels fixed between the sealing strips.

- Fire protection facades must be prescribed Meet fire safety requirements, with a suitable Solution is sought, in addition to the requirement sufficient fire protection properties nevertheless a good one Thermal insulation achieved.

- Required fire protection requirements not only affect the desired service life under the action of high temperatures, but also avoiding the spread of smoke that Spread of flames or the production of toxic gases and optionally the limitation of the temperature increase on the side away from the brand.

- Figs. 2 and 3 fire protection facades are shown as they are used in the prior art. In both cases, it is a section through a Facade construction.

- a two-part support structure 4 shown which consists of a Basic profile 4a and a substructure 4b exists.

- the Shaping the prior art from the prior art Support structure is given only by way of example and for the Understanding of fire safety measures is not significant.

- the Base profile 4a holds inner sealing strips 5, which, as in the FIGS. 2 and 3, also in one piece can be designed.

- At the inner sealing strip 5 and lie between inner seals and outer sealing strips 6 Fire protection glasses 3 on.

- a pressure profile is under Use of facade screws 9 against the supporting structure strained and thereby fixes the fire-resistant glasses 3 between the outer sealing strip 6 and the Inner sealing strips 5.

- In the glazing rebate area between the mutually facing end faces of the two fire-resistant glasses is also a Dämmsteg arranged for better thermal insulation, in the usual manner in the art of light combustible plastic, such as PA, PP or ABS.

- intumescent strips has the disadvantage that in addition to high material costs an additional Step means.

- Another disadvantage of Intumescentstsammlung is that these are high Have thermal conductivity and the insulating effect of Reduce dam bars accordingly.

- the invention is based on the object Fire protection facade to propose, without the use of Intumescent strips achieved high thermal insulation, anyway but meets the fire protection requirements.

- the invention is based on the idea, an entrance designed fire protection façade in such a way that in the Glasfalz a Dämm redesign is made of foamed Low density material.

- a Dämmarchitecte is made of foamed Low density material.

- the Fire safety requirements with such intumescent-free, foamed insulating body made of one material meet with low density, because such a Dämmoasa has only a very small mass and therefore indeed in Dependence on the foam material used, possibly burns off early, but at the same time only a very small Amount of smoke generated and fire load represents.

- the sealing strips a one-piece inner seal.

- the Sealing strip preferably made of chloroprene or EPDM exist, the burning of the sealing material also occurs only in a temperature range or after a Duration of action, which for achieving the desired fire protection function is advantageous.

- the one-piece inner seal over the screw of the basic profile extends and a fastening receptacle for having positive reception of the insulating body, can be the insulating body in a convenient way in Glasfalz Scheme assemble by inserting this into the mounting fixture of the one-piece inner seal is fed.

- the inner gaskets is also in the Fire for a prolonged period of time sufficient Stability and as long as possible with the Fixing screw maintain a firm connection.

- the Fixing screw made of refractory metal.

- the insulating body from a hydrocarbon-based polymer foam.

- This has the advantage that when burning off the polymer foam exclusively or predominantly hydrogen and Carbon dioxide, but not highly toxic gases released become.

- the insulating body made of PE foam because polyethylene is completely hydrogen and Carbon dioxide burns.

- the fire protection behavior of the fire protection facade can additionally improve on the pressure profile one or more additional steel supports on the outside of the facade or stainless steel.

- This additional measure is particularly advantageous if the Antikprofil off Aluminum is made.

- the pressure profile made of aluminum can be Produce cost-effectively in the extrusion process and with the suitable attachment geometries for the Outer sealing strips but also the facade outside as Decorative element attached cover strips provided. Only in Fire will take over after the melting of the Aluminum pressure profile on or over the length distributed several facades outside in the area of Fixing screws arranged additional elements made of steel or stainless steel the function of the pressure profile.

- the fire protection facade according to the invention has a Glasfalz Scheme on, in which only one one-piece inner gasket, the insulating body, the Façade screws and optionally glass blocks for the Fire protection panels are located. In other words, they are No intumescent strips in the glazing rebate area.

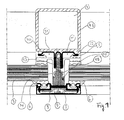

- FIG. 1 that is deliberately portrayed as being a far-reaching one

- FIG. 1 that is deliberately portrayed as being a far-reaching one

- the fire protection facade shown in Fig. 1 is in a Sectional view shown. In the illustrated section are no glass blocks for the fire protection panels shown. It should but be clear that in the bar area the Fire protection panels are supported on glass blocks.

- the support structure is in this case in two parts provided and includes a basic profile 4a made of steel or Stainless steel and one in the present case as a hollow profile shown substructure 4b, which has a different shape can own and also from a solid material profile body can exist.

- materials for the substructure come in addition to steel and stainless steel and aluminum and wood in Question.

- a one-piece Support structure 4 made of steel or stainless steel conceivable.

- the basic profile is in the present embodiment with connected to the substructure, wherein at reference numeral 11 both a screw connection or even with suitable Material pairing a weld is conceivable.

- the Basic profile has attachment lugs 12 for a one-piece provided inner sealing strip 5, which in the Befest Trentsan accounts 12 is hooked and above the im Basic profile trained screw 13 extends.

- To the Inner seal strips 5 are applied to the fire-resistant glasses 3, the facade outside again from outer seals. 6 being held.

- Both the inner seals as well as the Outer seals are preferably made of chloroprene or EPDM, as these materials are suitable for Fire protection facades have proven.

- the outer seals 6 be in suitable receiving geometries of a Andruckprofils 7 recorded, the pressure profile 7 off Steel, stainless steel or aluminum.

- Especially at the Use of a pressure profile 7 are made of aluminum additionally one or more additional holders 8 are provided.

- the Additional holders are made of steel or stainless steel and are either in the field of fastening screws 9 piecewise or continuously

- the fixing screws are made of high-melting Metal, like steel or stainless steel and grab in the Screw 13 a.

- the inner gasket 5 is in the area by being over the screw extends with a mounting receptacle 14th provided by a hook-like ledges limited reception space exists and feeding a Insulating body 18 is used in the Glasfalz Scheme between the Inner seal 5 and the pressure profile 7 is arranged.

- the Insulating body 18 consists of an optimized insulation material without the use of intumescent material. As suitable Insulating material has low density foam material proven, preferably PE foam is used.

- PE foam is used.

- the Insulating body 18 is with a hammerhead-like approach 15th provided, which is shaped so that it is positively in the Attachment receptacle 14 of the one-piece inner seal 5 can be included.

- the insulating body 18 made of a foamed material with low density has only a very small mass, burns the insulating body with only a small amount of smoke, so that The required fire protection properties also under Use of the insulating body 18 can still reach.

- the insulating body 18 is a very good Thermal insulation achieved.

- the advantages of the invention Insulating body compared to those described in the prior art Solutions are that significant Achieve cost savings. Especially in the Comparison to the solution using a Dämmsteges with attached Intumescentst Shape are the Material costs significantly lower and the introduction of the Intumescent strips deleted. At the same time, however, can be improved using the foam pad 18 Realize heat insulation, because both in Fig.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Special Wing (AREA)

- Building Environments (AREA)

Abstract

Description

- Fig. 1

- zeigt einen Schnitt durch eine erfindungsgemäße Brandschutzfassade.

- Fig. 2

- zeigt einen Schnitt durch eine Brandschutzfassade im Stand der Technik unter Verwendung eines mit Intumescentstreifen versehenen zusätzlichen Dämmkörpers.

- Fig. 3

- zeigt einen Schnitt durch eine im Stand der Technik bekannte Brandschutzfassade unter Verzicht auf ein zusätzliches, wärmedämmendes Bauteil im Glasfalzbereich.

Claims (13)

- Brandschutzfassade, umfassenddadurch gekennzeichnet, dassBrandschutzpanele (3) oder Brandschutzgläser, die zwischen Dichtstreifen (5, 6) gehalten sind, wobei zwischen zwei angrenzenden Brandschutzpanelen (3) oder Brandschutzgläsern ein Glasfalz besteht;ein Andruckprofil (7), das mit Fassadenschrauben (9), die sich durch den Glasfalz erstrecken, gegen ein Grundprofil (4; 4a, 4b) fixiert ist;

sich im Glasfalz ein Dämmkörper (18) befindet, der aus intumescentfreiem, geschäumten Material mit geringer Dichte besteht. - Brandschutzfassade nach Anspruch 1,

dadurch gekennzeichnet, dass

das Grundprofil integral oder separat mit einer Tragkonstruktion (4b) vorgesehen ist und einen Schraubkanal (13) aufweist. - Brandschutzfassade nach Anspruch 2,

dadurch gekennzeichnet, dass

das Grundprofil weiterhin Befestigungsansätze (12) für die Innendichtung (5) aufweist. - Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

die Dichtstreifen eine einteilige Innendichtung (5) umfassen. - Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

die Dichtstreifen (5, 6) aus Chloroprene oder EPDM bestehen. - Brandschutzfassade nach einem der Ansprüche 1 bis 5, sofern diese auf Anspruch 2 rückbezogen ist,

dadurch gekennzeichnet, dass

sich die einteilige Innendichtung (5) über den Schraubkanal (13) erstreckt und eine Befestigungsaufnahme (14) zur formschlüssigen Aufnahme des Dämmkörpers (18) aufweist. - Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

die Brandschutzpanele Brandschutzgläser (3) umfassen. - Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

der Dämmkörper aus einem Kohlenwasserstoff-basierten Polymerschaum besteht. - Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

der Dämmkörper (18) aus PE-Schaum besteht. - Brandschutzfassade nach einem der vorhergehenden Ansprüche, weiter umfassend einen oder mehrere fassadenaußenseitig auf dem Andruckprofil (7) angeordneten Zusatzhalter (8) aus Stahl oder Edelstahl.

- Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

die Befestigungsschrauben (9) aus hochschmelzendem Metall bestehen. - Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

sich im Glasfalzbereich ausschließlich eine einteilige Innendichtung (5), der Dämmkörper (18), die Fassadenschrauben (9) sowie gegebenenfalls Glasklötze befinden. - Brandschutzfassade nach einem der vorhergehenden Ansprüche,

dadurch gekennzeichnet, dass

keine Intumescentstreifen im Glasfalz vorgesehen sind.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20319566U | 2003-12-17 | ||

| DE20319566U DE20319566U1 (de) | 2003-12-17 | 2003-12-17 | Brandschutzfassade |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1544369A2 true EP1544369A2 (de) | 2005-06-22 |

| EP1544369A3 EP1544369A3 (de) | 2006-05-31 |

| EP1544369B1 EP1544369B1 (de) | 2009-11-04 |

Family

ID=32731273

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04029542A Expired - Lifetime EP1544369B1 (de) | 2003-12-17 | 2004-12-14 | Brandschutzfassade |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1544369B1 (de) |

| AT (1) | ATE447646T1 (de) |

| DE (2) | DE20319566U1 (de) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1754841A3 (de) * | 2005-08-17 | 2008-01-09 | Raico Bautechnik GmbH | Isolatorprofil |

| EP1835084A3 (de) * | 2006-03-16 | 2009-02-18 | Johann Henkenjohann | Isolator für eine aus Profilen bestehende Pfosten/Riegel-Fassadenkonstruktion |

| DE102012112279A1 (de) * | 2012-12-14 | 2014-07-03 | SCHÜCO International KG | Fassade oder Lichtdach, Isoliersteg und Verfahren zum Herstellen eines Isoliersteges |

| CN107700771A (zh) * | 2017-08-30 | 2018-02-16 | 湖南省金为新材料科技有限公司 | 一种防火护栏 |

| US20180283003A1 (en) * | 2017-03-30 | 2018-10-04 | Tanglewood Conservatories, Ltd. | System and method for attaching glass panels to a substructure |

| CN111456265A (zh) * | 2020-05-18 | 2020-07-28 | 余卫平 | 钢制龙骨玻璃隔断和玻璃幕墙节点的防火结构 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104481069B (zh) * | 2014-12-27 | 2017-12-08 | 湖南省金为型材有限公司 | 一种拟态防火玻璃幕墙系统 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3739741A1 (de) * | 1987-11-24 | 1989-06-08 | August Eich | Glasdach |

| DE3807426A1 (de) * | 1987-12-16 | 1989-06-29 | Gartner & Co J | Brandsicheres verglasungssystem |

| DE4107933C2 (de) * | 1991-03-08 | 1995-09-07 | Mannesmann Ag | Brandschutzkonstruktion für ein Fassadensystem |

| DE29918219U1 (de) * | 1999-04-09 | 2000-08-17 | Raico Bautechnik GmbH, 87746 Erkheim | Fassade für ein Niedrig-Energiehaus |

| DE10008370C2 (de) * | 2000-02-23 | 2003-12-24 | Evg Bauprofil System Entwicklungs & Vermarktungsgesellschaft Mbh | Rahmenkonstruktion mit verbesserter Wärmedämmung |

-

2003

- 2003-12-17 DE DE20319566U patent/DE20319566U1/de not_active Expired - Lifetime

-

2004

- 2004-12-14 AT AT04029542T patent/ATE447646T1/de active

- 2004-12-14 DE DE502004010318T patent/DE502004010318D1/de not_active Expired - Lifetime

- 2004-12-14 EP EP04029542A patent/EP1544369B1/de not_active Expired - Lifetime

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1754841A3 (de) * | 2005-08-17 | 2008-01-09 | Raico Bautechnik GmbH | Isolatorprofil |

| EP1835084A3 (de) * | 2006-03-16 | 2009-02-18 | Johann Henkenjohann | Isolator für eine aus Profilen bestehende Pfosten/Riegel-Fassadenkonstruktion |

| DE102012112279A1 (de) * | 2012-12-14 | 2014-07-03 | SCHÜCO International KG | Fassade oder Lichtdach, Isoliersteg und Verfahren zum Herstellen eines Isoliersteges |

| US20180283003A1 (en) * | 2017-03-30 | 2018-10-04 | Tanglewood Conservatories, Ltd. | System and method for attaching glass panels to a substructure |

| CN107700771A (zh) * | 2017-08-30 | 2018-02-16 | 湖南省金为新材料科技有限公司 | 一种防火护栏 |

| CN111456265A (zh) * | 2020-05-18 | 2020-07-28 | 余卫平 | 钢制龙骨玻璃隔断和玻璃幕墙节点的防火结构 |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE447646T1 (de) | 2009-11-15 |

| EP1544369A3 (de) | 2006-05-31 |

| DE20319566U1 (de) | 2004-07-15 |

| EP1544369B1 (de) | 2009-11-04 |

| DE502004010318D1 (de) | 2009-12-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3008659C2 (de) | Feuersicheres Glasfenster | |

| DE9422023U1 (de) | Rahmenwerk aus Metallprofilen in Brandschutzausführung für Fenster, Türen, Fassaden oder Glasdächer | |

| DE19900793C2 (de) | Brandschutzleiste | |

| DE2731979C3 (de) | Fenster mit erhöhter Feuerwiderstandsfähigkeit | |

| DE102004008414A1 (de) | Profilrahmenkonstruktion | |

| EP0384418B1 (de) | Brandsichere Halterung mindestens einer Scheibe | |

| EP1544369A2 (de) | Brandschutzfassade | |

| EP1793073B1 (de) | Gebäudeelement in brandgeschützter Ausführung | |

| DE3508078A1 (de) | Feuerhemmende trennwand | |

| DE8706051U1 (de) | Verglaste und/oder mit Füllungen versehene Brandschutztüre | |

| EP2749724A1 (de) | Verbundprofil für Brandschutztüren und -Fenster | |

| EP2199524B1 (de) | Brandschutzelement | |

| DE2507244C2 (de) | Lichtdurchlässige Brandschutz-Verbundscheibe, bestehend aus mindestens zwei Glasplatten und einer Zwischenschicht aus einem bei Hitzeeinwirkung expandierenden Ma terial | |

| EP0093265A2 (de) | Metallfenster | |

| EP3636869A1 (de) | Mehrkammerhohlprofil für brandschutztüren oder -fenster und verfahren sowie vorrichtung zum herstellen eines solchen mehrkammerhohlprofils | |

| DE3719803A1 (de) | Feuerhemmende verglaste trennwand | |

| EP0646212B1 (de) | Feuerschutzabschluss im gebäudebereich insbesondere feuerschutz-tür oder -fenster | |

| DE102004036265A1 (de) | Befestigungselement für mehrteilige Rahmen für Fenster oder dergl. | |

| EP1571283A2 (de) | Verbinder von Abstandshalteprofilleisten zwischen Isolierglasscheiben | |

| EP0782657B2 (de) | Feuerschutz-tür | |

| DE19508075A1 (de) | Verglasung mit einer eine Gebäudeöffnung abdeckenden Doppel- oder Mehrfachscheibe und brandsicherer Schraubhalterung | |

| DE202007007114U1 (de) | Sprengwirkungshemmendes Fassadensystem | |

| DE69305224T2 (de) | Ventil für Brandschutzverglasung | |

| DE202010003492U1 (de) | Horizontale Brandschutzverglasung | |

| DE2419161A1 (de) | Brandschutztuer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20061108 |

|

| AKX | Designation fees paid |

Designated state(s): AT CH DE FR IT LI PL |

|

| 17Q | First examination report despatched |

Effective date: 20071120 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR IT LI PL |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502004010318 Country of ref document: DE Date of ref document: 20091217 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: E. BLUM & CO. AG PATENT- UND MARKENANWAELTE VSP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091104 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: SCHUECO INTERNATIONAL KG Effective date: 20100729 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100104 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091104 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 20130312 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R100 Ref document number: 502004010318 Country of ref document: DE Effective date: 20130312 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004010318 Country of ref document: DE Representative=s name: HOFFMANN - EITLE, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20140109 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502004010318 Country of ref document: DE Owner name: RP TECHNIK GMBH PROFILSYSTEME, DE Free format text: FORMER OWNER: EVG BAUPROFIL-SYSTEM ENTWICKLUNGS- UND VERMARKTUNGSGESELLSCHAFT MBH, EUGENDORF, AT Effective date: 20140409 Ref country code: DE Ref legal event code: R082 Ref document number: 502004010318 Country of ref document: DE Representative=s name: HOFFMANN - EITLE, DE Effective date: 20140409 Ref country code: DE Ref legal event code: R082 Ref document number: 502004010318 Country of ref document: DE Representative=s name: HOFFMANN - EITLE PATENT- UND RECHTSANWAELTE PA, DE Effective date: 20140409 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20140113 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: RP TECHNIK GMBH PROFILSYSTEME, DE Free format text: FORMER OWNER: EVG BAUPROFIL-SYSTEM ENTWICKLUNGS- UND VERMARKTUNGSGESELLSCHAFT MBH, AT |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 447646 Country of ref document: AT Kind code of ref document: T Effective date: 20141214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141214 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004010318 Country of ref document: DE Representative=s name: FRITZ PATENT- UND RECHTSANWAELTE PARTNERSCHAFT, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20201231 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004010318 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220701 |