EP1516954A2 - Dispositif et méthode pour déterminer l'état d'au moins une bande sans fin - Google Patents

Dispositif et méthode pour déterminer l'état d'au moins une bande sans fin Download PDFInfo

- Publication number

- EP1516954A2 EP1516954A2 EP04104210A EP04104210A EP1516954A2 EP 1516954 A2 EP1516954 A2 EP 1516954A2 EP 04104210 A EP04104210 A EP 04104210A EP 04104210 A EP04104210 A EP 04104210A EP 1516954 A2 EP1516954 A2 EP 1516954A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- measuring

- belt

- moisture

- web

- permeability

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims abstract description 15

- 230000035699 permeability Effects 0.000 claims abstract description 38

- 238000005259 measurement Methods 0.000 claims abstract description 37

- 239000000945 filler Substances 0.000 claims abstract description 13

- 238000004140 cleaning Methods 0.000 claims abstract description 6

- 239000000725 suspension Substances 0.000 claims abstract description 6

- 238000004804 winding Methods 0.000 claims abstract description 6

- 238000011109 contamination Methods 0.000 claims abstract 2

- 239000000463 material Substances 0.000 claims description 38

- 238000010790 dilution Methods 0.000 claims description 7

- 239000012895 dilution Substances 0.000 claims description 7

- 239000000835 fiber Substances 0.000 claims description 7

- 230000001105 regulatory effect Effects 0.000 claims description 6

- 238000012546 transfer Methods 0.000 claims description 6

- 239000000203 mixture Substances 0.000 claims description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 abstract 1

- 238000009736 wetting Methods 0.000 abstract 1

- 230000003750 conditioning effect Effects 0.000 description 4

- 238000011156 evaluation Methods 0.000 description 3

- 230000006866 deterioration Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000001771 impaired effect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 1

- 230000003213 activating effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21G—CALENDERS; ACCESSORIES FOR PAPER-MAKING MACHINES

- D21G9/00—Other accessories for paper-making machines

- D21G9/0009—Paper-making control systems

- D21G9/0036—Paper-making control systems controlling the press or drying section

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21F—PAPER-MAKING MACHINES; METHODS OF PRODUCING PAPER THEREON

- D21F1/00—Wet end of machines for making continuous webs of paper

- D21F1/32—Washing wire-cloths or felts

Definitions

- the invention relates to a device for assessing the nature of at least one circulating band, in particular of a water-absorbing Dewatering belt and / or a transfer belt in a paper machine, with a device for measuring the permeability of at least a circulating band.

- the invention has the object that the reliability and accuracy in the Assessment of the nature of the at least one rotating belt by the device of the type mentioned is improved.

- the invention solves the problem by a device of the aforementioned Kind, the invention, a device for measuring the in at least having a band contained moisture.

- the invention provides Device further information about the state of at least a circulating band. So if at a hole, at a crack or something like that A high permeability is measured at the hole at the crack or the like, a very low moisture detected. From the simultaneous There is a high permeability and a very low humidity can then be closed to the hole, the crack or the like. Because the Device according to the invention, the measurement of the permeability and the humidity During operation, it can provide permanent accurate information about the current state of the at least one circulating band ranem. As a constant monitoring of the nature of at least one circulating band is possible in this way can be a high quality one be ensured to be produced fibrous web.

- the time interval between the Permeability measurement and moisture measurement no more than five hours be, since the at least one rotating band changes over time.

- the time interval between the permeability measurement and the humidity measurement is too large, soiling on the at least one circumferential Band or wear on the at least one circumferential band to distort the information obtained.

- the moisture measurement and the measurement of permeability at the same Location of at least one revolving band can be performed very accurate information regarding the nature of the at least one to be won.

- the measuring points are located for this purpose for the permeability and moisture measurement in the strip running direction seen one behind the other. It makes sense that the distances between the two measuring points are relatively short, so that considering the high tape speeds a nearly simultaneous measurement of the two measured values.

- the two measuring points across the Be arranged strip running direction in which case the distances of Both measuring points should be relatively short in order to obtain reliable information about the nature of the at least one circulating belt receive.

- the humidity and the permeability at different points of the be measured at least one circumferential band and the distances of the two measuring points are relatively short, one can mathematically the one measuring point, For example, the measuring point where the humidity is measured, the other Measuring point, for example the measuring point at which the permeability is measured will assign.

- the device according to the invention can also be a device to measure the strip temperature.

- the temperature of the at least one circulating belt are measured.

- the determined belt temperature also provides information about the condition of the at least one circulating band. This is how the belt temperature differs at dirty places, holes, cracks and the like of the Belt temperature at clean or faultless belt locations.

- the measured strip temperature for tempering one for the permeability measurement necessary measuring fluids.

- the device is connected to a winding machine a device for moisture measurement of a material web, in particular a fibrous web, on. It is also possible that the device according to the invention after a press section a device for moisture measurement of the material web, in particular the fibrous web, has. If that's at least one circulating band is a drainage tape, affects its texture directly the moisture of the material web to be produced. Thus, the measured Moisture of the material web on the winding machine and / or in the press section an explanation of the nature of the at least one circulating Band.

- the device may be provided with means for determining the Basis weight of the material web, in particular the fibrous web, provided be. If the at least one circulating belt is a drainage belt, its quality also directly influences the basis weight of the product to be produced Web. Thus, the basis weight of the web gives a Information about the nature of the at least one circulating belt.

- the apparatus may also include means for measuring a hall temperature, along the width of the at least one circumferential band prevails.

- the hall temperature especially in the nourishing environment of the at least one circulating Tape measured.

- Heat to the hall environment gives the distribution of the hall temperature along its width information about its nature.

- the heat radiation varies.

- you can with the device for measuring the temperature of the hall and the device for Measuring the belt temperature the difference between the two temperatures along the width of the at least one circulating belt are determined, which statements about its nature can also be made.

- the device for measuring the hall temperature a cleaning unit for cleaning the at least one circulating Bandes be arranged.

- the device can be a device for measuring the thickness of the at least one circumferential band. deposits increase its thickness, whereas belt abrasions reduce its thickness.

- the nature of the at least one circulating band also depends directly with the tension prevailing in him together. That's why it is makes sense the device with a device for measuring in at least to equip a circulating band of prevailing tension.

- a strong one Bandabrieb, dirt on the at least one rotating belt and other influences can increase the tension.

- the device with a device for Measurement of the filler content of the material web to be equipped may be the pores of at least one circulating Tape clog.

- the at least one circulating band are closed.

- the device has a device for Measuring a pressure that prevails in a nip between two rolls, and / or a device for measuring the thickness of the material web. Since that At least one revolving band as a drainage tape, also the thickness of the influenced material web is also of its nature The amount of pressure that prevails in the nip between two rolls depends. Consequently The pressure in the nip between two rollers provides information about the condition of the at least one circulating band. Measuring the thickness of the Material web can advantageously by measuring the web tension, in the web prevails done.

- the device has a device for Measurement of at least one surface property of the material web, in particular roughness, soiling (pigments, cloth) and the like.

- the device has a steam blower box and / or a humidifier.

- the amount of steam leaving and / or amount of moisture depends on the nature of the at least one circulating Bandes along the material web width adjustable.

- the steam box and / or the humidifier the quality of the material to be produced be compensated if this is due to a deterioration of the state of the at least one band was impaired.

- the steam box and / or the humidifier the nature of at least to influence a band.

- the mixing ratio of a fiber and filler suspension and a dilution stream on a headbox along the width of an exit port a nozzle from which the mixture emerges depending on the nature the at least one circumferential band along the web width be managed.

- Fibers and fillers pollute the at least one circulating belt can, by increasing the dilution flow the Mixing ratio can be changed in such a way that the pollution of the at least one circulating band is reduced.

- the invention relates to a method for assessing the nature the at least one circulating belt, in particular of the water-absorbing Dewatering belt and / or transfer belt in the paper machine, wherein the permeability of the at least one circulating belt is measured, and in accordance with the invention also in the at least one circulating band contained moisture is measured.

- the strip temperature to eat.

- the mixing ratio of the fiber and filler suspension and the dilution flow at the headbox along the width of the outlet opening of Nozzle from which the mixture exits, depending on the nature of the at least a band along the material web width are regulated.

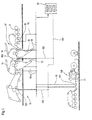

- Fig. 1 shows a side view of a paper machine 10, with a web of material 11 is produced.

- the web 11 may be a paper, board or tissue or be other fibrous web.

- the paper machine 10 has various circumferential bands 12, 13, 14 and 15 on.

- the band 12 takes over in the illustrated Example, the function of a material web 11 receiving first Oberfilzes, the band 13 the function of a first Unterfilzes, the band 14 the Function of a second upper felt and the band 15, the function of a second Bottom felt.

- the band 15 is a transfer band.

- the bands 12, 13, 14 and 15 are provided with measuring devices 20, 21, 22 and 23 (see Fig. 2).

- the measuring devices 20, 21, 22 and 23 are not with here shown in more detail devices for measuring the permeability and / or Humidity of bands 12, 13, 14 and 15 equipped. This way can be reliable Information about the nature of bands 12, 13, 14 and 15 be won. If a high permeability is measured then it can point to clean bands 12, 13, 14 or 15. But it can also be that the bands 12, 13, 14 or 15 have a hole, a crack or the like, so that even in this case a high permeability is measured. To misinterpret, which can result from the permeability measurement, exclude In addition, the humidity measurement is carried out.

- the measurement result reliable information, it is useful to moisture measurement and the permeability measurement at the same measuring point or close to each other lying measuring points on the circulating belts 12, 13, 14 or 15 perform.

- a high permeability is measured, and in the humidity measurement, a very low humidity then leave those measurements on a hole, or on a crack or the like in the bands 12, 13, 14 or 15 close.

- the moisture measurement a useful supplement to the permeability measurement, the nature the bands 12, 13, 14 or 15 to judge. Except holes, cracks and The same can also be done by the combined permeability and moisture measurement Pollution of the bands 12, 13, 14 or 15 are detected. Then by means of conditioning devices 25, 26, 27 and 28, the soiled Bands 12, 13, 14 or 15 are cleaned.

- the measuring devices 20, 21, 22 and 23 via measuring signal lines 19 with a Evaluation unit 16 which, if necessary for cleaning the belts 12, 13, 14 or 15 activates the conditioning devices 25, 26, 27 or 28. If that Band 15 is a transfer belt, eliminates the conditioning 28.

- a device for Measurement of the temperature of the bands 12, 13, 14 and 15 may be provided.

- the paper machine 10 has a device 18 at the end of a press section 17 for measuring the moisture of the material web 11 and on a winding machine 100 a measuring device 101 for measuring the moisture of the material web 11.

- the Moisture measured by means 18 and 101 provides information the nature of the bands 12, 13, 14 and 15. Of the devices 18 and 101 measured humidity value is via measuring signal lines 19 to the evaluation unit 16 transmitted.

- the mixing ratio of a fiber and Filler suspension and a dilution stream along the headbox 103 along the width of an outlet not shown here a nozzle from which the Blend exits, depending on the nature of the bands 12, 13, 14 and 15 regulated along the width of the material web 11.

- a pollution of the Bands 12, 13, 14 and 15 to avoid by the fiber and fillers is at this control process increases the dilution flow.

- the steam outlet quantity is dependent governed by the nature of the bands 12, 13, 14 and 15.

- the quality of the material to be produced be compensated, if this by a deterioration of the condition the bands 12, 13, 14 and 15 was impaired.

- the belts 12, 13, 14 and 15 are kept in a state that ensures the production of a qualitatively flawless material web.

Landscapes

- Paper (AREA)

- Treatment Of Fiber Materials (AREA)

- Preliminary Treatment Of Fibers (AREA)

- Lubrication Of Internal Combustion Engines (AREA)

- Devices For Conveying Motion By Means Of Endless Flexible Members (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10343418A DE10343418A1 (de) | 2003-09-19 | 2003-09-19 | Vorrichtung und Verfahren zur Beurteilung der Beschaffenheit mindestens eines umlaufenden Bandes |

| DE10343418 | 2003-09-19 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1516954A2 true EP1516954A2 (fr) | 2005-03-23 |

| EP1516954A3 EP1516954A3 (fr) | 2006-03-29 |

| EP1516954B1 EP1516954B1 (fr) | 2008-03-19 |

Family

ID=34177837

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04104210A Expired - Lifetime EP1516954B1 (fr) | 2003-09-19 | 2004-09-02 | Dispositif pour déterminer l'état d'au moins une bande sans fin |

Country Status (4)

| Country | Link |

|---|---|

| US (2) | US20050103095A1 (fr) |

| EP (1) | EP1516954B1 (fr) |

| AT (1) | ATE389744T1 (fr) |

| DE (2) | DE10343418A1 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITMI20101698A1 (it) * | 2010-09-17 | 2012-03-18 | Giuseppe Cristini S P A Sa | Apparecchio portatile di controllo delle condizioni di un nastro circolante in una macchina di fabbricazione della carta |

| ITMI20101699A1 (it) * | 2010-09-17 | 2012-03-18 | Giuseppe Cristini S P A Sa | Apparecchiatura e metodo di controllo delle condizioni di un nastro circolante in una macchina di fabbricazione della carta |

| WO2013171195A1 (fr) * | 2012-05-16 | 2013-11-21 | Voith Patent Gmbh | Procédé de détection de l'encrassement d'un habillage de machine à papier et habillage de machine à papier |

| ITMI20132213A1 (it) * | 2013-12-27 | 2015-06-28 | Giuseppe Cristini S P A Sa | Apparecchiatura e metodo per controllare le condizioni di almeno un nastro circolante in una macchina di fabbricazione della carta e macchina di fabbricazione della carta comprendente detta apparecchiatura |

| IT201900018350A1 (it) * | 2019-10-09 | 2021-04-09 | Binet Sul Liri Eng Fabrics S P A | Sistema e metodo di rilevamento di una zona di criticità in un feltro |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7938935B2 (en) * | 2007-10-11 | 2011-05-10 | Honeywell Asca Inc. | Infrared measurement of paper machine clothing condition |

| US9540769B2 (en) | 2013-03-11 | 2017-01-10 | International Paper Company | Method and apparatus for measuring and removing rotational variability from a nip pressure profile of a covered roll of a nip press |

| FI125811B (en) * | 2013-05-29 | 2016-02-29 | Valmet Automation Oy | Track measurement |

| US9797788B2 (en) | 2014-05-02 | 2017-10-24 | International Paper Company | Method and system associated with a sensing roll including pluralities of sensors and a mating roll for collecting roll data |

| US10378980B2 (en) | 2014-05-02 | 2019-08-13 | International Paper Company | Method and system associated with a sensing roll and a mating roll for collecting roll data |

| US9804044B2 (en) | 2014-05-02 | 2017-10-31 | International Paper Company | Method and system associated with a sensing roll and a mating roll for collecting data including first and second sensor arrays |

| US10370795B2 (en) | 2015-06-10 | 2019-08-06 | International Paper Company | Monitoring applicator rods and applicator rod nips |

| US9816232B2 (en) | 2015-06-10 | 2017-11-14 | International Paper Company | Monitoring upstream machine wires and felts |

| US9863827B2 (en) | 2015-06-10 | 2018-01-09 | International Paper Company | Monitoring machine wires and felts |

| US9677225B2 (en) | 2015-06-10 | 2017-06-13 | International Paper Company | Monitoring applicator rods |

| US9696226B2 (en) | 2015-06-10 | 2017-07-04 | International Paper Company | Count-based monitoring machine wires and felts |

| US9534970B1 (en) | 2015-06-10 | 2017-01-03 | International Paper Company | Monitoring oscillating components |

| CN106442232B (zh) * | 2016-09-18 | 2018-12-14 | 上海理工大学 | 基于动态称重的颗粒物料分类装置和方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5349845A (en) * | 1992-04-07 | 1994-09-27 | Tamfelt Oy Ab | Apparatus for measuring the condition of a felt in a paper machine |

| DE19860567A1 (de) * | 1997-06-25 | 2000-06-29 | Voith Sulzer Papiermasch Gmbh | Verfahren und Vorrichtung zum Reinigen eines Transportbandes |

| EP1225270A2 (fr) * | 2001-01-18 | 2002-07-24 | Voith Paper Patent GmbH | Procédé pour le conditionnement d' une bande en mouvement |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US129914A (en) * | 1872-07-30 | Improvement in friction-clutches | ||

| US1550993A (en) * | 1924-02-08 | 1925-08-25 | Vickery Ltd | Felt-reconditioning apparatus |

| FI77119C (fi) * | 1987-09-23 | 1989-01-10 | Valmet Paper Machinery Inc | Foerfarande och anordning foer maetning av luftgenomslaeppningsfoermaogan hos luftgenomslaeppliga vaevnader i synnerhet en vira eller en filt i en pappersmaskin. |

| FI100099B (fi) * | 1988-11-17 | 1997-09-30 | Valmet Paper Machinery Inc | Menetelmä ja laite paperirainan rullauksessa |

| US5725737A (en) * | 1996-09-18 | 1998-03-10 | Pulp And Paper Research Institute Of Canada | Apparatus for the detection of holes and plugged spots |

| US6284100B1 (en) * | 1997-01-24 | 2001-09-04 | Valmet Corporation | Method and apparatus for controlling a headbox in a paper machine |

| FI111283B (fi) * | 1997-10-20 | 2003-06-30 | Metso Paper Inc | Paperikoneen tai paperin jälkikäsittelykoneen nipin läpi kulkevan pinnan likaantumisen ja/tai vaurioitumisen havaitsemismenetelmä |

| DE19911395A1 (de) * | 1999-03-15 | 2000-09-21 | Voith Sulzer Papiertech Patent | Vorrichtung zum Bestimmen von Eigenschaften einer laufenden Materialbahn und/oder einer Maschine zu deren Herstellung und/oder Veredelung |

| FI20012175A (fi) * | 2001-11-09 | 2003-05-10 | Metso Paper Automation Oy | Menetelmä ja laitteisto viiraosan toiminnan säätämiseksi |

| DE10249385A1 (de) * | 2002-10-23 | 2004-05-06 | Voith Paper Patent Gmbh | Verfahren und Einrichtung zur Überwachung des Zustandes einer Bespannung |

| DE10343516A1 (de) * | 2003-09-19 | 2005-05-04 | Voith Paper Patent Gmbh | Verfahren und Vorrichtung zur Bestimmung wenigstens einer Eigenschaft einer bewegten Bespannung |

-

2003

- 2003-09-19 DE DE10343418A patent/DE10343418A1/de not_active Withdrawn

-

2004

- 2004-09-02 EP EP04104210A patent/EP1516954B1/fr not_active Expired - Lifetime

- 2004-09-02 DE DE502004006557T patent/DE502004006557D1/de not_active Expired - Lifetime

- 2004-09-02 AT AT04104210T patent/ATE389744T1/de active

- 2004-09-16 US US10/942,164 patent/US20050103095A1/en not_active Abandoned

-

2007

- 2007-12-06 US US11/951,439 patent/US7506550B2/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5349845A (en) * | 1992-04-07 | 1994-09-27 | Tamfelt Oy Ab | Apparatus for measuring the condition of a felt in a paper machine |

| DE19860567A1 (de) * | 1997-06-25 | 2000-06-29 | Voith Sulzer Papiermasch Gmbh | Verfahren und Vorrichtung zum Reinigen eines Transportbandes |

| EP1225270A2 (fr) * | 2001-01-18 | 2002-07-24 | Voith Paper Patent GmbH | Procédé pour le conditionnement d' une bande en mouvement |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITMI20101698A1 (it) * | 2010-09-17 | 2012-03-18 | Giuseppe Cristini S P A Sa | Apparecchio portatile di controllo delle condizioni di un nastro circolante in una macchina di fabbricazione della carta |

| ITMI20101699A1 (it) * | 2010-09-17 | 2012-03-18 | Giuseppe Cristini S P A Sa | Apparecchiatura e metodo di controllo delle condizioni di un nastro circolante in una macchina di fabbricazione della carta |

| WO2012035521A1 (fr) * | 2010-09-17 | 2012-03-22 | S.A. Giuseppe Cristini S.P.A. | Appareil portatif permettant de contrôler la condition d'une bande en circulation dans une machine à papier |

| CN103328721A (zh) * | 2010-09-17 | 2013-09-25 | S.A.朱塞佩克里斯蒂尼有限公司 | 用于控制造纸机中的循环带的状况的手持设备 |

| US8778141B2 (en) | 2010-09-17 | 2014-07-15 | S.A. Giuseppe Cristini S.P.A. | Hand-held apparatus for controlling the condition of a circulating band in a papermaking machine |

| CN103328721B (zh) * | 2010-09-17 | 2015-11-25 | S.A.朱塞佩克里斯蒂尼有限公司 | 用于控制造纸机中的循环带的状况的手持设备 |

| WO2013171195A1 (fr) * | 2012-05-16 | 2013-11-21 | Voith Patent Gmbh | Procédé de détection de l'encrassement d'un habillage de machine à papier et habillage de machine à papier |

| CN104302833A (zh) * | 2012-05-16 | 2015-01-21 | 福伊特专利公司 | 用于检测造纸机绷网的污染的方法和造纸机绷网 |

| ITMI20132213A1 (it) * | 2013-12-27 | 2015-06-28 | Giuseppe Cristini S P A Sa | Apparecchiatura e metodo per controllare le condizioni di almeno un nastro circolante in una macchina di fabbricazione della carta e macchina di fabbricazione della carta comprendente detta apparecchiatura |

| WO2015097682A1 (fr) * | 2013-12-27 | 2015-07-02 | S.A. Giuseppe Cristini S.P.A. | Appareil et procédé de contrôle des conditions d'au moins une bande circulant dans une machine de fabrication du papier et machine de fabrication du papier comprenant ledit appareil |

| US10132035B2 (en) | 2013-12-27 | 2018-11-20 | S.A. Giuseppe Cristini S.P.A. | Method for controlling the conditions of at least one band circulating in a paper making machine |

| IT201900018350A1 (it) * | 2019-10-09 | 2021-04-09 | Binet Sul Liri Eng Fabrics S P A | Sistema e metodo di rilevamento di una zona di criticità in un feltro |

Also Published As

| Publication number | Publication date |

|---|---|

| US7506550B2 (en) | 2009-03-24 |

| US20050103095A1 (en) | 2005-05-19 |

| DE502004006557D1 (de) | 2008-04-30 |

| ATE389744T1 (de) | 2008-04-15 |

| EP1516954A3 (fr) | 2006-03-29 |

| EP1516954B1 (fr) | 2008-03-19 |

| DE10343418A1 (de) | 2005-04-21 |

| US20080087073A1 (en) | 2008-04-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1516954B1 (fr) | Dispositif pour déterminer l'état d'au moins une bande sans fin | |

| DE3854843T2 (de) | Verfahren und Anordnung zur kontinuierlichen Bestimmung der Papierfestigkeit | |

| DE69630650T2 (de) | Verfahren und vorrichtung zur erfassung und regelung der oberflächenbeschaffenheit von bandförmigen materialien,wie papier | |

| DE3539354A1 (de) | Verfahren und vorrichtung zum lokalisieren von funktionsstoerungen an den maschinenelementen einer papiermaschine | |

| EP0815315B1 (fr) | Procede et dispositif de conduite du processus dans la production de cellulose et/ou de papier | |

| DE69911187T2 (de) | Verfahren zur feststellung einer irreversibelen ausdehnung und eines dynamischen elastizitätsmoduls | |

| DE4311402A1 (de) | Meßvorrichtung zum Messen des Zustands eines Papiermaschinenfilzes | |

| DE69915647T2 (de) | Verfahren zur herstellung von kalandriertem papier | |

| DE3404571C2 (fr) | ||

| WO2009010343A1 (fr) | Procédé et système de détection en ligne d'au moins une propriété d'extension d'une bande de papier ou de carton en mouvement | |

| DE4221395C2 (de) | Verfahren zum zerstörungsfreien Bestimmen eines mit der breitenbezogenen Bruchkraft korrelierenden Kennwertes an einer laufenden Papierbahn | |

| EP1596002B1 (fr) | Machine à papier | |

| DE19917553A1 (de) | Verfahren und Vorrichtung zum Messen der Permeabilität von lagenförmigen, wasserdurchlässigen Materialien | |

| EP1521075A2 (fr) | Dispositif et procédé pour déterminer la perméabilité d'une bande de circulation | |

| EP3717695B1 (fr) | Procédé de détermination de la teneur en matière sèche d'une bande de matière fibreuse et procédé de commande ou de régulation d'une machine de production d'une bande de papier, ainsi que programme informatique permettant la mise en oeuvre des procédés | |

| WO2012130694A2 (fr) | Dispositif et procédé de nettoyage et/ou de conditionnement d'un habillage | |

| DE69923082T2 (de) | Verfahren und vorrichtung zur messung des retentionsprofil und zur reglung der retention in einer papier/pappemaschine | |

| DE10108517A1 (de) | Feuchtequerprofil | |

| EP1780333A2 (fr) | Méthode et machine pour produire une bande de matériau fibreux | |

| AT11309U1 (de) | Vorrichtung zum ermitteln der menge an beschichtungsmittel in einzelnen beschichtungsmittelschichten beim mehrschichtigen vorhangbeschichten | |

| EP1524363A1 (fr) | Procédé et arrangement pour la détermination de la perméabilité d'un habillage | |

| DE19631637A1 (de) | Pressenanordnung | |

| DE202008011131U1 (de) | Aufroller mit geschlossenem Bahnzug | |

| WO2012034992A1 (fr) | Dispositif de mesure | |

| WO2020249343A1 (fr) | Procédé et dispositif pour déterminer l'encrassement d'un cylindre aspirant d'une machine pour produire une bande de matière fibreuse |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: D21G 9/00 20060101ALI20060209BHEP Ipc: D21F 1/32 20060101AFI20041221BHEP |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: VOITH PATENT GMBH |

|

| 17P | Request for examination filed |

Effective date: 20060929 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20061122 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: DEVICE FOR DETERMINING THE CONDITION OF AT LEAST ONE ENDLESS BAND |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502004006557 Country of ref document: DE Date of ref document: 20080430 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080826 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080630 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 |

|

| EN | Fr: translation not filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 |

|

| 26N | No opposition filed |

Effective date: 20081222 |

|

| BERE | Be: lapsed |

Owner name: VOITH PATENT G.M.B.H. Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080619 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20080902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080902 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080920 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080620 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20110926 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120902 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20230920 Year of fee payment: 20 Ref country code: AT Payment date: 20230921 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20230920 Year of fee payment: 20 Ref country code: DE Payment date: 20230920 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 502004006557 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 389744 Country of ref document: AT Kind code of ref document: T Effective date: 20240902 |