EP1420660B1 - Behälter für zigaretten- oder zigarilloverpackungen - Google Patents

Behälter für zigaretten- oder zigarilloverpackungen Download PDFInfo

- Publication number

- EP1420660B1 EP1420660B1 EP02779215A EP02779215A EP1420660B1 EP 1420660 B1 EP1420660 B1 EP 1420660B1 EP 02779215 A EP02779215 A EP 02779215A EP 02779215 A EP02779215 A EP 02779215A EP 1420660 B1 EP1420660 B1 EP 1420660B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- case

- cigarette

- cover

- lid

- pack

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 235000019504 cigarettes Nutrition 0.000 title claims abstract description 64

- 239000004033 plastic Substances 0.000 claims description 8

- 229920003023 plastic Polymers 0.000 claims description 8

- 239000000463 material Substances 0.000 claims description 6

- 238000002347 injection Methods 0.000 claims description 4

- 239000007924 injection Substances 0.000 claims description 4

- 229920000049 Carbon (fiber) Polymers 0.000 claims description 3

- 239000004917 carbon fiber Substances 0.000 claims description 3

- 229920001296 polysiloxane Polymers 0.000 claims description 3

- 230000000903 blocking effect Effects 0.000 claims description 2

- 238000013016 damping Methods 0.000 claims description 2

- 239000000853 adhesive Substances 0.000 claims 1

- 230000001070 adhesive effect Effects 0.000 claims 1

- 230000000295 complement effect Effects 0.000 claims 1

- 235000019506 cigar Nutrition 0.000 abstract description 3

- 238000004806 packaging method and process Methods 0.000 description 45

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 229920002430 Fibre-reinforced plastic Polymers 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 239000011151 fibre-reinforced plastic Substances 0.000 description 2

- 239000010985 leather Substances 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical group [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 230000001464 adherent effect Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000005034 decoration Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002991 molded plastic Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/07—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles

- B65D85/08—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular

- B65D85/10—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular for cigarettes

- B65D85/1036—Containers formed by erecting a rigid or semi-rigid blank

- B65D85/1045—Containers formed by erecting a rigid or semi-rigid blank having a cap-like lid hinged to an edge

- B65D85/1056—Containers formed by erecting a rigid or semi-rigid blank having a cap-like lid hinged to an edge characterized by the lid

- B65D85/10564—Containers formed by erecting a rigid or semi-rigid blank having a cap-like lid hinged to an edge characterized by the lid having means for holding the lid in a closed position

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F15/00—Receptacles or boxes specially adapted for cigars, cigarettes, simulated smoking devices or cigarettes therefor

- A24F15/12—Receptacles or boxes specially adapted for cigars, cigarettes, simulated smoking devices or cigarettes therefor for pocket use

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45C—PURSES; LUGGAGE; HAND CARRIED BAGS

- A45C13/00—Details; Accessories

- A45C13/005—Hinges

- A45C13/007—Hinges with spring means

Definitions

- the invention relates to a container with a largely accurate fit recording of cigarette or cigarillo packages provided with a hinged lid portion adapted interior, with one around one in the container integrated rotary pivoting lid, which corresponds to the corresponding cover part of the Cigarette or cigarillo packaging is adjusted, with one unfolding (Open) supporting the cover spring element and repeated with a one detachable and lockable closure element for the cover part.

- Cigarettes or groups of cigarettes are usually made in cardboard Folding boxes arranged, consisting of a box part and one with a Rear wall of the box part pivotally connected lid are arranged. Embodiments of these folding boxes are for example in the DE 43 42 523 A1 or DE 198 14 255 A1.

- the lid part is here provided on a narrow side, so that after opening the cigarettes be exposed at its mouthpiece and pulled out along its longitudinal axis can.

- Cigarillover packs consist of a bottom part with four narrow side walls and a lid part fixed to a side wall. After swinging up the lid part, the inside cigarillos over their entire Length exposed.

- leather cigarette cases are also known for receiving a cigarette box can serve and at its top a tab have exposed after opening and lifting the cigarette packaging lid becomes.

- leather cases have the disadvantage that the handling, to get to a cigarette, is relatively cumbersome, there first the tab and according to which the cigarette packaging lid must be opened.

- the cigarette packaging sizes are not uniform, so that such a case only for certain packaging sizes is usable.

- a hook is provided on the lid front inside, which against the Lid of cigarette packaging presses and should cause that with the Swiveling the container lid simultaneously carried along the packaging lid becomes.

- a disadvantage of this hook that the lid front wall of the cigarette packaging is strongly pressed, which can not be ruled out, that there inside cigarettes damaged, but at least pressed become. Due to the inward curvature of the lid of the cigarette packaging In addition, the swinging is made more difficult with a full package.

- US 2 954 867 shows an outer packaging box consisting of two separate parts consists.

- the first part is formed by an upwardly open cuboid

- the second part consists of a lid, at the rear wall lower edge of a tongue articulated flexibly over almost the entire width downwardly extending tongue is attached.

- the said tongue After inserting the cigarette packaging in the first part is the said tongue between the inside of the square back wall and the adjacent there Cigarette packaging wall inserted.

- the FR 950 517 shows a front open outer packaging, the lid over a Spring 6 is automatically swung off as soon as required for closing Tab has been pivoted by pressing a push button inward.

- the disadvantage of this box is that with a correspondingly high spring force the outer packaging lid unrestrained behind fast and the cigarette packaging lid this does not take along or even slightly at high spring forces damaged. When using a too weak spring, however, remains the outer packaging lid "hang", so that a manual tracking is necessary.

- the aforementioned container such that further improves its handling and its functional safety without the risk of damaging the cigarette packaging is increased.

- this container has on the inside of the cover at least one driver, the Forcibly opening the lid part of the cigarette or cigarillo packaging mitverschwenkt the lid.

- the advantage of this container is that after the Opening the lid closure the existing drivers the cigarette or Forcibly carry the cigarillo packaging lid.

- the container according to the invention has an interior, the usual cigarette or cigarillo packaging sizes is adjusted. Longer or wider cigarette or cigarillo packaging can also be included as the drivers for the original packaging lid Determine the packaging layer in the container sufficiently. Only the depth of the container, d. H.

- the distance between the back wall and the front wall should be substantially the same as the depth of the package to be received be chosen large, so that the hinge of the container lid and the break line between the packaging lid and the box body of the original packaging can be close to each other or preferably on a common line.

- inventive container is loaded by the complete cigarette or cigarillo box after removing an outer plastic foil or breaking it up the seal is pushed into the container and the lid is closed thereafter.

- the or the existing drivers lie down here so the cigarette or Cigarillo packaging lid on that already when first opening the container lid the lid is forcibly swung.

- driver Preferably serves as a driver an undercut, in whose groove the lower edge the lid part is inserted.

- a dome or more can Thorns serve as a driver, or pass through the lid part.

- the driver may also consist of an adhesion surface through which a frictional, sufficiently adherent system of the front inner lid wall at the front Cigarette or cigarillo packaging outer wall is ensured.

- drivers can also consist of springs, which pivot down slide the lid along the cigarette packaging lid front surface along and finally come to rest below the cigarette wrapper edge.

- the axis of rotation of the container is by a hinge with a spiral spring or a torsion bar formed as a spring element.

- a spiral spring or a torsion bar formed as a spring element.

- the height and preferably in addition the depth of the lid and / or the remaining container body are after a further preferred design chosen so that the packaging parts when opening the lid can make slight sliding and / or tilting movements, which is a kinematic block due to the different spatial position of the Prevent rotation axis and the hinge line of the packaging.

- the spring element is to open the lid movement damped.

- a motion damper can either when using a spring element an elastically deformable plastic compound, preferably made of silicone, in which the Spring element is embedded, or serve a motion-damped piston, the each on an inner side surface of the lid and the rest of the container body attacks.

- a closure element is preferably a repeatedly releasable locking or Snap closure used in an embodiment of the invention, for example is arranged in the region of the longitudinal axis of the container front side.

- the rest or Snap closure consists in a specific embodiment of the invention a tongue attached to the lid part with a protrusion in the closed state engages in a trough on the container body front.

- the container interior may further at least one, preferably two resilient have stored surfaces as room delimiters, which, because they are under spring pressure, to rest against the outer surface of the packaging.

- Such resiliently mounted surfaces makes it possible, the container according to the invention also for different packaging sizes to use.

- the lid and the rest of the container body may be made of any stable materials exist, for. Made of steel, stainless steel or light metal (eg aluminum), including such embodiments in which the surface is silver plated, nickel plated, platinum plated or engraved. Special advantages in terms of design but also The surface design, however, arise when the container is made of injection molded plastic parts wherein preferably the surface of the container carbon fibers may have, which look decorative. Injection molding plastics leave one inexpensive container manufacture and a large color variance too, so that too colored conspicuous containers can be created. In the surface can beside Fibers also be embedded color pigments or reflective particles.

- Fig. 1 is a commercially available Zigarillobox with a bottom 11 and a lid 12, which are inserted into a container according to the invention, wherein the Container itself from a bottom part 13 and a lid part hinged thereto. 14 consists.

- the bottom part with four vertical, shorter in height side walls serves for accurately fitting the cigarillobox floor; in corresponding Way is the cover part 14 of the container according to the invention with his velvet Side walls designed such that the cigar box lid 12 fit can be inserted.

- the lid part 14 has protruding edge portions 15, which are provided on the left and right at the top of the page and the undercuts form.

- a torsion bar arranged as a spring element, which is in an elastically deformable plastic material made of silicone embedded as damping material.

- This torsion bar will operated via buttons 16, which are arranged on both sides in the bottom part 13.

- buttons 16 In the closed Condition of the container according to the invention is by pressure actuation of Buttons 16 a lock released, after which the prestressed spring element, d. H. of the Torsionsstab is dearretiert and triggers the pivotal movement of the lid part becomes.

- the pressure on the keys 16 can be performed synchronously with two fingers of one hand so that the holding and opening of the container according to the invention and the eventual passing around to offer the cigarilox contained in the cigarilox Cigarillos is possible with one hand.

- the rotation or Swivel axes of the cigarillobox and the container according to the invention in one Level.

- the container according to the invention is loaded by the cigarilox 11, 12 after the breaking of the seal in the bottom part is inserted and the inventive Container is closed by pivoting down the lid part 14. in this connection presses the lid part 14, the cigarilox, if not already done so in the Floor part, so that also existing on the local side walls protruding Edges 15, which also form undercuts, on both sides of the side wall edges overlap the cigarillobox. At the same time overlap the edges 15 on the cover part 14th the lid sidewall edges of the cigarillobox.

- first opening the inventive Container by pressing the keys 16 pivots the cover part 14 around at least 90 °, preferably 135 ° from, the cigarillobox lid 12 due the edges 15 in the lid part 14 is taken.

- the container according to the invention is in terms of its receiving surfaces formed in the cover and bottom part substantially fit, wherein slight translational degrees of freedom can be provided, the one compensating sliding movement of the cigarillobox in the container according to the invention allow, so that a kinematic blockage when opening the lid by the different pivot axes of the cigarillobox and the invention Container is avoided.

- the container according to the invention is preferably made made of a high quality but very light and stable material, eg. B. from very thin steel, stainless steel, light metal or fiber-reinforced plastic. Carbon fibers in a fiber-reinforced plastic can be a visually handsome Achieve decoration effect. If the container made of injection molded parts, that is Hinge preferably directly as deformation hinge without separate movable Molded parts. Even with plastic injection molded parts decorative elements be inserted from metal, z. B. logos or other decorative elements appeal.

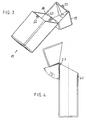

- the container of Fig. 3 is for receiving a commercial cigarette box educated.

- the container 17 has a bottom, a front, a back and two left and right side walls, with the front and the Rear side wall of different heights and the connecting these side walls can be appropriately bevelled, as is known with cigarette packs is.

- a cover part 19th attached, in size and shape about the lid part of known cigarette packaging corresponds to the largely accurate and accurate recording Cover is formed.

- As a driver for the cover part of a cigarette packaging serve here also protruding edges 20, which as undercut the lower lid edge a cigarette pack when pivoting the lid part 19 detect and carry.

- a hook 21 is further formed, in a corresponding opening 22 with a corresponding undercut can engage, so that the hook and the opening 22 form a snap closure.

- the container 17 and the lid member 19 made of slightly deformable plastic, allowing by slight pressure on the front side surface the lock between the hook 21 and opening 22 is released.

- the joint 18 is formed by a spring 23, which is also the axis of rotation and the same time due to their bias after loosening the lock 21, 22 pivoting cause the lid part 19.

- the height, width and depth of the container 17 and the lid part 19 accordingly preferably fit the exact fit of the cigarette pack, but the Height of the container 17 and the height of the lid part 19 also larger than the corresponding Heights of the cigarette pack parts be there after inserting the Cover the cigarette box in the lid part 19, the respective pivot axes of the cigarette packaging lid part to the cigarette packaging as well as the container 17 abut the lid portion 19 at the same height and the edges 20 also at Closing the lid member 19, a sliding down of the cigarette box effectively prevent.

- the cigarette box After breaking up or Release the original closure or remove the plastic wrap into the container 17 introduced and inserted the cigarette box lid in the lid part 19, the cigarette box lid lower edge are held by the edges 20 can.

- the lid part 19 Upon the respective opening of the lock 21, 22 pivots the lid part 19, as shown in Fig. 3, to the rear, the lid part of the cigarette box entrained becomes.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packaging Of Annular Or Rod-Shaped Articles, Wearing Apparel, Cassettes, Or The Like (AREA)

- Control And Other Processes For Unpacking Of Materials (AREA)

- Closures For Containers (AREA)

Description

- Fig. 1

- eine perspektivische Darstellung eines Zigarillo-Behälters mit geöffnetem Deckel,

- Fig. 2

- eine Detailansicht des Deckels und

- Fig. 3,4

- einen Behälter zur Aufnahme von Zigaretten-Schachteln in einer perspektivischen und einer teilgeschnittenen Ansicht

Claims (10)

- Behälter mit einem zur weitgehend passgenauen Aufnahme von mit einem abschwenkbaren Deckelteil versehenen Zigaretten- oder Zigarillo-Verpackungen angepassten Innenraum, mit einem um eine in den Behälter integrierte Drehachse schwenkbaren Deckel, der dem entsprechenden Deckelteil der Zigaretten- oder Zigarillo-Verpackung angepasst ist, mit einem das Aufklappen (Öffnen) des Deckels unterstützenden Federelement und mit einem eine wiederholt lösbaren und verriegelbaren Verschlusselement für das Deckelteil,

dadurch gekennzeichnet, dass an der Deckelinnenseite des Behälters mindestens ein Mitnehmer (15, 20) angeordnet ist, der den Deckelteil der Zigaretten- oder Zigarillo-Verpackung zwangsweise beim Öffnen des Deckels (14, 19) mit verschwenkt, wobei das Federelement (23) vorzugsweise bewegungsgedämpft ist. - Behälter nach Anspruch 1, dadurch gekennzeichnet, dass der Mitnehmer (15, 20) entweder ein Hinterschnitt ist, in dessen Nut die Unterkante des Deckelteils einschiebbar ist oder ein Dorn ist, der das Deckelteil (14, 19) durchgreift oder eine an der Außenfläche des Deckelteils reibschlüssig anliegende Adhäsionsfläche oder eine Feder ist.

- Behälter nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass die Drehachse des Behälters (18) durch ein Scharnier mit einer Spiralfeder oder einem Torsionsstab als Federelement gebildet wird.

- Behälter nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass die Drehachse des Behälters und die Gelenklinie zwischen dem Deckelteil und dem übrigen Körper der Zigaretten- oder Zigarillo-Verpackung liegt auf einer gemeinsamen Linie oder unmittelbar nebeneinander liegen.

- Behälter nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, dass die Höhe und vorzugsweise zusätzlich die Tiefe des Deckels und/oder des übrigen Behälterkörpers größer ist bzw. sind, als die jeweilige Höhe und/oder Tiefe der aufzunehmenden Verpackung, so dass die Verpackungsteile beim Öffnen des Deckels geringfügige Gleit- und/oder Kippbewegungen ausführen, die eine kinematische Blockierung durch die unterschiedliche räumliche. Lage der Drehachse und der Gelenklinie der Verpackung verhindern.

- Behälter nach einem der Ansprüche 1 bis 5, gekennzeichnet durch einen bewegungsgedämpften Hubkolben als Federelement, der jeweils an einer Innenseitenfläche des Deckels und des übrigen Behälterkörpers angreift oder durch ein Federelement, das in eine elastisch verformbare Kunststoffmasse, vorzugsweise aus Silikon als Dämpfungsmaterial, eingebettet ist.

- Behälter nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, dass das Verschlusselement (21, 22) aus einem wiederholt lösbaren Rast- oder Schnappverschluss besteht, der vorzugsweise etwa im Bereich der Mittellängsachse an der Behältervorderseite angeordnet ist, und/oder aus einer an dem Deckelteil befestigten Zunge (21) mit einer Erhebung besteht, die im Verschlusszustand in eine Mulde (22) an der Behälterkörpervorderseite eingreift.

- Behälter nach einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, dass der Innenraum durch mindestens eine, vorzugsweise zwei federnd gelagerte Flächen so begrenzt wird, dass gegen den Federdruck der Flächen gegen den Innenraum an die Verpackungsgröße variabel anpassbar ist.

- Behälter nach einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, dass der Deckel (19) und der übrige Behälterkörper (17) aus Spritzgussteilen bestehen.

- Behälter nach einem der Ansprüche 1 bis 9, dadurch gekennzeichnet, dass die Oberfläche des Behälters Karbonfasern aufweist.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10156764 | 2001-11-19 | ||

| DE10156764A DE10156764A1 (de) | 2001-11-19 | 2001-11-19 | Zigarren- und Zigarettenbox |

| PCT/DE2002/004211 WO2003045173A1 (de) | 2001-11-19 | 2002-11-14 | Behälter für zigaretten- oder zigarilloverpackungen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1420660A1 EP1420660A1 (de) | 2004-05-26 |

| EP1420660B1 true EP1420660B1 (de) | 2005-01-26 |

Family

ID=7706246

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02779215A Expired - Lifetime EP1420660B1 (de) | 2001-11-19 | 2002-11-14 | Behälter für zigaretten- oder zigarilloverpackungen |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US20040251148A1 (de) |

| EP (1) | EP1420660B1 (de) |

| JP (1) | JP2005510224A (de) |

| KR (1) | KR20040066820A (de) |

| CN (1) | CN1585608A (de) |

| AT (1) | ATE287650T1 (de) |

| AU (1) | AU2002342561A1 (de) |

| CA (1) | CA2466669A1 (de) |

| DE (2) | DE10156764A1 (de) |

| ES (1) | ES2236596T3 (de) |

| WO (1) | WO2003045173A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101287387B (zh) * | 2005-10-14 | 2010-05-26 | 朴相奎 | 香烟包装盒 |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW569888U (en) * | 2002-09-09 | 2004-01-01 | Stanley Chiro Int Ltd | Tool box with thermal shrunk and integrated nameplate unit |

| WO2005092129A1 (en) * | 2004-03-29 | 2005-10-06 | Hayat Nicholas Haddad | A case for a cigarette packet |

| DE202004008197U1 (de) * | 2004-05-21 | 2005-09-29 | Knobloch, Joerg | Zigarettenschachtel-Hülle |

| US8554042B2 (en) * | 2009-02-18 | 2013-10-08 | Commscope, Inc. | Optical fiber management shelf including door with push-push fastener |

| GB201001944D0 (en) * | 2010-02-05 | 2010-03-24 | Kind Consumer Ltd | A simulated smoking device |

| CN101919594A (zh) * | 2010-09-26 | 2010-12-22 | 吴永 | 便携式烟盒 |

| USD668142S1 (en) * | 2011-08-31 | 2012-10-02 | Camo Pack IP, LLC | Slip covering for a tobacco product package |

| JP5960723B2 (ja) | 2011-12-02 | 2016-08-02 | 日本たばこ産業株式会社 | ボックス型パッケージ |

| GB2498732A (en) * | 2012-01-25 | 2013-07-31 | British American Tobacco Co | Pack for smoking articles |

| US20150274351A1 (en) * | 2012-10-17 | 2015-10-01 | Fireless Oy | Container with self opening lid |

| CN104070588A (zh) * | 2013-03-25 | 2014-10-01 | 厦门开源进汇创意设计产业有限公司 | 一种包装盒生产方法 |

| KR101464594B1 (ko) * | 2013-03-25 | 2014-11-24 | 김연동 | 내부에 보관된 담뱃갑의 뚜껑이 자동으로 열리도록 구성된 담뱃갑 케이스 |

| WO2014193849A1 (en) * | 2013-05-28 | 2014-12-04 | Axton Ryan Christopher | Carbon fiber equestrian tack trunk |

| WO2015000151A1 (zh) * | 2013-07-03 | 2015-01-08 | 吉瑞高新科技股份有限公司 | 电子烟烟盒 |

| USD863953S1 (en) * | 2016-02-29 | 2019-10-22 | Focke & Co. (Gmbh & Co. Kg) | Cigarette pack |

| US20200385183A1 (en) * | 2016-06-07 | 2020-12-10 | Paq Holdings, Llc | Airtight child resistant case with elongated compartments |

| US10773862B2 (en) * | 2016-06-07 | 2020-09-15 | Paq Holdings, Llc | Airtight child resistant case with elongated compartments |

| US10414553B2 (en) * | 2016-06-07 | 2019-09-17 | Paq Holdings, Llc | Airtight child resistant case with elongated compartments |

| CN106240994A (zh) * | 2016-10-12 | 2016-12-21 | 中国电子科技集团公司第二十六研究所 | 文物保护专用碳纤维囊匣 |

| KR200492858Y1 (ko) * | 2017-04-18 | 2020-12-23 | 주식회사 인비토 | 담뱃갑 가리개 |

| EP3939467A1 (de) * | 2020-07-17 | 2022-01-19 | Samsonite IP Holdings S.àr.l | Äussere schutzhülle, insbesondere für tragbare audiovorrichtungssysteme |

| KR102714684B1 (ko) * | 2021-12-30 | 2024-10-11 | 주식회사 지니컵 | 쌍안정성 구조를 적용한 원터치 오픈형 케이스 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE665306C (de) * | 1938-09-22 | Garbaty Cigarettenfabrik Komm | Als Etui ausgebildete Zigarettenschachtel | |

| US1830583A (en) * | 1928-01-13 | 1931-11-03 | Woller Oliver C Ritz | Cigarette case |

| FR762082A (fr) * | 1932-12-28 | 1934-04-03 | Ind Des Comprimes De L Ouest | étui à cigarettes |

| FR858121A (fr) * | 1939-07-21 | 1940-11-18 | étui à cigarettes | |

| US2286389A (en) * | 1939-09-29 | 1942-06-16 | Sowin George | Cigarette case |

| US2411946A (en) * | 1944-07-28 | 1946-12-03 | Vogel Max | Container for cigarette packages or the like |

| US2454455A (en) * | 1945-12-04 | 1948-11-23 | James W Irwin | Telescoping cigarette case |

| US2483304A (en) * | 1945-12-11 | 1949-09-27 | Vogel Rudolf | Container |

| US2460427A (en) * | 1946-01-26 | 1949-02-01 | Henry E Musselman | Combined cigarette case and lighter |

| FR950517A (fr) * | 1947-07-30 | 1949-09-29 | étui pour paquets de cigarettes | |

| FR987041A (fr) * | 1949-03-26 | 1951-08-08 | Procédé de fermeture d'une boîte telle qu'un poudrier, une tabatière, un portecigarettes, etc., et boîte en comportant application | |

| US2897958A (en) * | 1957-04-04 | 1959-08-04 | Black Starr & Gorham | Cigarette case |

| US2954867A (en) * | 1958-12-08 | 1960-10-04 | Enger Kress Company | Cigarette case |

| US3165225A (en) * | 1963-03-27 | 1965-01-12 | Drescher & Kiefer | Box cover support |

| DE3842817A1 (de) * | 1988-12-20 | 1990-06-21 | Leis Franz Josef | Programmierbarer zigarettenspender |

| DE4342523C2 (de) * | 1993-12-14 | 2003-03-27 | Focke & Co | Klappschachtel für Zigaretten |

| US5632373A (en) * | 1995-04-03 | 1997-05-27 | Khyber Technologies Corporation | Protective case for portable computer |

| FR2766164B1 (fr) * | 1997-07-17 | 1999-09-24 | Davy Cruchet | Etui pour boite de produits consommables preconditionnes |

| DE29922719U1 (de) * | 1998-12-23 | 2000-03-16 | Benkhardt, Axel, 22587 Hamburg | Zigarette, Zigarre oder Zigarillo und Verpackung hierfür |

| DE10007406A1 (de) * | 2000-02-18 | 2001-08-23 | Volkswagen Ag | Schließbarer Behälter, insbesondere Humidor |

-

2001

- 2001-11-19 DE DE10156764A patent/DE10156764A1/de not_active Withdrawn

-

2002

- 2002-11-14 CN CNA02822583XA patent/CN1585608A/zh active Pending

- 2002-11-14 JP JP2003546685A patent/JP2005510224A/ja active Pending

- 2002-11-14 AU AU2002342561A patent/AU2002342561A1/en not_active Abandoned

- 2002-11-14 DE DE50202135T patent/DE50202135D1/de not_active Expired - Lifetime

- 2002-11-14 US US10/495,152 patent/US20040251148A1/en not_active Abandoned

- 2002-11-14 KR KR10-2004-7007517A patent/KR20040066820A/ko not_active Application Discontinuation

- 2002-11-14 ES ES02779215T patent/ES2236596T3/es not_active Expired - Lifetime

- 2002-11-14 WO PCT/DE2002/004211 patent/WO2003045173A1/de active IP Right Grant

- 2002-11-14 CA CA002466669A patent/CA2466669A1/en not_active Abandoned

- 2002-11-14 EP EP02779215A patent/EP1420660B1/de not_active Expired - Lifetime

- 2002-11-14 AT AT02779215T patent/ATE287650T1/de active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101287387B (zh) * | 2005-10-14 | 2010-05-26 | 朴相奎 | 香烟包装盒 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20040251148A1 (en) | 2004-12-16 |

| JP2005510224A (ja) | 2005-04-21 |

| KR20040066820A (ko) | 2004-07-27 |

| WO2003045173A1 (de) | 2003-06-05 |

| ATE287650T1 (de) | 2005-02-15 |

| EP1420660A1 (de) | 2004-05-26 |

| DE50202135D1 (de) | 2005-03-03 |

| DE10156764A1 (de) | 2003-05-28 |

| CA2466669A1 (en) | 2003-06-05 |

| CN1585608A (zh) | 2005-02-23 |

| AU2002342561A1 (en) | 2003-06-10 |

| ES2236596T3 (es) | 2005-07-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1420660B1 (de) | Behälter für zigaretten- oder zigarilloverpackungen | |

| DE2318291C2 (de) | Behälter | |

| DE60313038T2 (de) | Flaschenverschluss mit kontrollierter öffnungsbewegung | |

| DE69312716T2 (de) | Spendergerät mit hebewerk und gewindestange für stiftförmiges gut und ersatzpatrone dafür | |

| DE60124309T2 (de) | Steife packung mit gelenkdeckel für tabakprodukte | |

| DE2649218A1 (de) | Abgabeverschluss | |

| DE3850169T2 (de) | Gerät zum Unterbringen von behälterartigen Gegenständen. | |

| EP2548467A2 (de) | Kosmetikbehältnis für ein flüssiges oder pastöses Kosmetikmittel mit arretierbarer Verschlusskappe | |

| DE60302218T2 (de) | Ausgabegerät zur aufnahme einer kartusche mit zurückschiebbaren stiften | |

| EP2070832B1 (de) | Verpackungsbehälter für Gebäckteile | |

| DE102008037953A1 (de) | Versandverpackung mit Originalitätsverschluss | |

| EP2602067B1 (de) | Behälter für Kleinteile mit Dosierscheibe | |

| WO2008119421A1 (de) | Behälter für mehrere teststreifen | |

| DE8816560U1 (de) | Dose mit Drückerverschluß | |

| CH685550A5 (de) | Oeffnungsvorrichtung am Deckel einer Fliessmittelpackung. | |

| EP1280706B1 (de) | Verpackungsschachtel für tabletten | |

| EP0575764A1 (de) | Vorratsbehälter für streufähiges oder fliessfähiges Gut | |

| DE3414214A1 (de) | Verpackung fuer laengliche gegenstaende, insbesondere zigaretten oder zigarillos | |

| WO2002085758A2 (de) | Müllbehälter mit sekundärdeckel | |

| EP3083428A1 (de) | Verschluss für ein behältnis | |

| DE202012008816U1 (de) | Behälter, insbesondere zur Aufnahme von Erste-Hilfe-Materialien | |

| DE3120264A1 (de) | Kapselheber | |

| EP1820753A1 (de) | Zusatzbehälter für einen Sammelbehälter sowie Sammelbehälter | |

| DE2820879C2 (de) | Behälter zum dosierten Abgeben von pulverförmigen Materialien, insbesondere Schnupftabak | |

| DE20317270U1 (de) | Wiederverwendbare Hülle für Verpackungen von Tabakwaren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| 17P | Request for examination filed |

Effective date: 20031021 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050126 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050126 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050126 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050126 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050126 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050126 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| REF | Corresponds to: |

Ref document number: 50202135 Country of ref document: DE Date of ref document: 20050303 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20050319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050426 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050426 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20050401283 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2236596 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051130 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051130 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| ET | Fr: translation filed | ||

| 26N | No opposition filed |

Effective date: 20051027 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050626 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20071112 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20071126 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090603 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20101112 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20100920 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20101124 Year of fee payment: 9 Ref country code: GB Payment date: 20101118 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20111124 Year of fee payment: 10 Ref country code: ES Payment date: 20111125 Year of fee payment: 10 Ref country code: FR Payment date: 20111130 Year of fee payment: 10 Ref country code: CH Payment date: 20111123 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20111110 Year of fee payment: 10 |

|

| BERE | Be: lapsed |

Owner name: *KRIMPMANN MANFRED Effective date: 20121130 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20130601 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 287650 Country of ref document: AT Kind code of ref document: T Effective date: 20121114 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20121114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121114 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121114 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130601 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50202135 Country of ref document: DE Effective date: 20130601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121114 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20140527 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121115 |