EP1388515A2 - Schnittregister-Einstellvorrichtung - Google Patents

Schnittregister-Einstellvorrichtung Download PDFInfo

- Publication number

- EP1388515A2 EP1388515A2 EP03405563A EP03405563A EP1388515A2 EP 1388515 A2 EP1388515 A2 EP 1388515A2 EP 03405563 A EP03405563 A EP 03405563A EP 03405563 A EP03405563 A EP 03405563A EP 1388515 A2 EP1388515 A2 EP 1388515A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- web

- strand

- deflection

- cutting

- deflecting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H23/00—Registering, tensioning, smoothing or guiding webs

- B65H23/04—Registering, tensioning, smoothing or guiding webs longitudinally

- B65H23/18—Registering, tensioning, smoothing or guiding webs longitudinally by controlling or regulating the web-advancing mechanism, e.g. mechanism acting on the running web

- B65H23/188—Registering, tensioning, smoothing or guiding webs longitudinally by controlling or regulating the web-advancing mechanism, e.g. mechanism acting on the running web in connection with running-web

- B65H23/1882—Registering, tensioning, smoothing or guiding webs longitudinally by controlling or regulating the web-advancing mechanism, e.g. mechanism acting on the running web in connection with running-web and controlling longitudinal register of web

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H23/00—Registering, tensioning, smoothing or guiding webs

- B65H23/04—Registering, tensioning, smoothing or guiding webs longitudinally

- B65H23/32—Arrangements for turning or reversing webs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/41—Winding, unwinding

- B65H2301/414—Winding

- B65H2301/4148—Winding slitting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/50—Auxiliary process performed during handling process

- B65H2301/52—Auxiliary process performed during handling process for starting

- B65H2301/522—Threading web into machine

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2801/00—Application field

- B65H2801/03—Image reproduction devices

- B65H2801/21—Industrial-size printers, e.g. rotary printing press

Definitions

- the invention relates to cutting register adjusting devices in printing machines, in which an endlessly conveyed web is printed or preferably a plurality of such Webs are printed. Furthermore, the invention relates to a method for adjustment the cut register of printed web strands consisting of one or more webs were obtained by slitting.

- the printing machine is preferably one Web-fed printing press, in which the web or the several webs each from a roll be processed continuously. Particularly preferably, the invention comes in the Web-fed rotary printing of large newspaper editions.

- the web strands, each one Bundles form, are merged so that the printed images of the web strands of a Bundle between two consecutive sections in the conveying direction as possible are exactly centered.

- the web strands of a bundle are used for preserving their so-called cut register, i. for centering between cuts, by means of affected by appropriate operations.

- Related to the single web strand is in these operations targeted to the cutting register of the relevant web strand carried out changes in the path length, which is the railway line between the place of Printing and the location of the cross cutting travels. Through a targeted Path length change is thus the cut register position of the relevant strand, or in short, its cut register, set.

- Section register rollers are each looped around by a web strand, usually in order 180 °.

- a cutting register roller transversely to its longitudinal axis the path of the railway track that wraps around it is lengthened or shortened and onto it Set the cut register of the relevant web track.

- a printed web is about an arrangement of Led turning bars and turned there and / or swept. After turning and / or Sweeping with the web track are suitable for setting the cut register Operations are performed, and eventually the web is stranded with one or more further web strands merged and cut across.

- the invention relates to a printing machine with at least one printing unit for Printing a web, a slitter, a device for Merging of web strands, a cross-cutting device and a Cut register setting.

- the web is continuously with printed at least two juxtaposed printed images.

- the printed train is from the longitudinal cutting device between the printed images in a first Web strand and at least one further, second web strand cut longitudinally.

- the Longitudinal cutting device can also be arranged in front of the printing unit and the still unprinted web cut into the at least two web strands, the first subsequently printed in strands.

- the device for merging Web cords comprises a turning bar means for turning and / or sweeping the second railway line.

- the second web strand is preferably connected to the first Rail track merged. Basically, the first track and the second Brustrang but each with one or more other strands to each other Bundle bundles are merged.

- the cross-cutting device is used for Cross cutting of at least the second web strand, preferably also the first Web track, comprehensive web bundle bundle.

- the cut register adjustment device comprises a frame, a first deflection device for deflecting the first web strand about a first deflection axis and a further, second deflection device for deflecting of the second web strand about a second deflection axis.

- the second deflection is in the frame relative to the first deflecting movably mounted so that by a movement of the second deflecting device relative to the first deflecting device the length of the path the second track travels relative to the length of the path the first track is changed.

- the diverters can basically Although from along the respective deflection axis juxtaposed rollers or be formed other deflecting bodies, in particular rotatably mounted rotational bodies

- each of the diverters is a roller in the manner of the known Cut register rollers formed, particularly preferably as a circular cylindrical roller.

- the second deflection means i. the Deflection device for leading through the turning bar means second Web strand, arranged in front of the turning bar device.

- the second track can by this measure in a simple way mechanically up to the Wendenstangen thanks be recovered.

- the arrangement of the first deflection also in front of the turning bar area advantageous, for example, if the first web strand in the turning bar device turned and / or swept.

- the deflectors for the web strands the web are arranged in a preferred embodiment of the invention so that a still not cut longitudinal path around the baffles simultaneously can, whereby the machine web feed is greatly facilitated.

- too reach are between the deflection no other deflection arranged, which are looped around by only one of the web strands of the web.

- they are even arranged side by side in the sense that on the way the railway between them no other deflection devices arranged for the train are.

- the web feed is only then cut longitudinally when the web has been retracted by the cut register adjustment device thus formed.

- the arrangement of the deflection for the single or multiple turning strand the web in front of the turning bar facility has over simplifying a machine Brueinzugs addition, the further advantage that the associated deflection the Width of a simple strand and not more, as before, at least must have double strand width.

- the baffles transverse to the web strands in spatial proximity are arranged side by side, they are preferably only one at a time Supported side of the frame, while each with a free end towards the each other frame side to protrude.

- the two Bending devices are preferably placed in a position in which they aligned with each other and a preferably cylindrical, smooth, uniform surface form for the train to be recovered.

- the first deflecting device is also movably mounted in the frame.

- the movable mounting of the first deflection device is advantageous, for example, if turned in one or the other print production of the first strand of web and / or to be swept. If the first web strand is not turned before bundling still swept, but as a direct train with the second track and / or one or several other web strands is merged, is the movable storage of second deflection but also beneficial. Just for this case will be new possibilities of cut registry setting opened when the extent of the Mobility is only sufficiently large.

- a maximum length of an adjustment of the first deflection should be at least half the size of a maximum length an adjustment of the second deflection. More preferably, it is at least in essentially or as large as the maximum length of the adjustment of the second Deflection.

- the Cut register positions of the two web strands by substantially the same size, preferably exactly the same size, adjustment of the first deflection and the second deflection set. It then no longer needs the whole Position difference or at least the much larger part of the position difference at to be compensated for the second web strand, but only approximately or exactly the half position difference, while the remainder in the direct line is compensated.

- first web strand and the second Brustrang be merged with even more railway lines or the first Brustrang not with the second track, but only with another track or other web strands is combined to form a web strand bundle.

- the Cut registers of the web strands per bundle are set in such a way that the adjustment time required for setting all cutting registers of these web strands is reduced compared to the known setting method, or preferably even is minimal.

- the largest of the adjustment is proportional or at least determined by the largest of the adjustment paths, the one or more of the baffles must cover the set time and this reduces the waste.

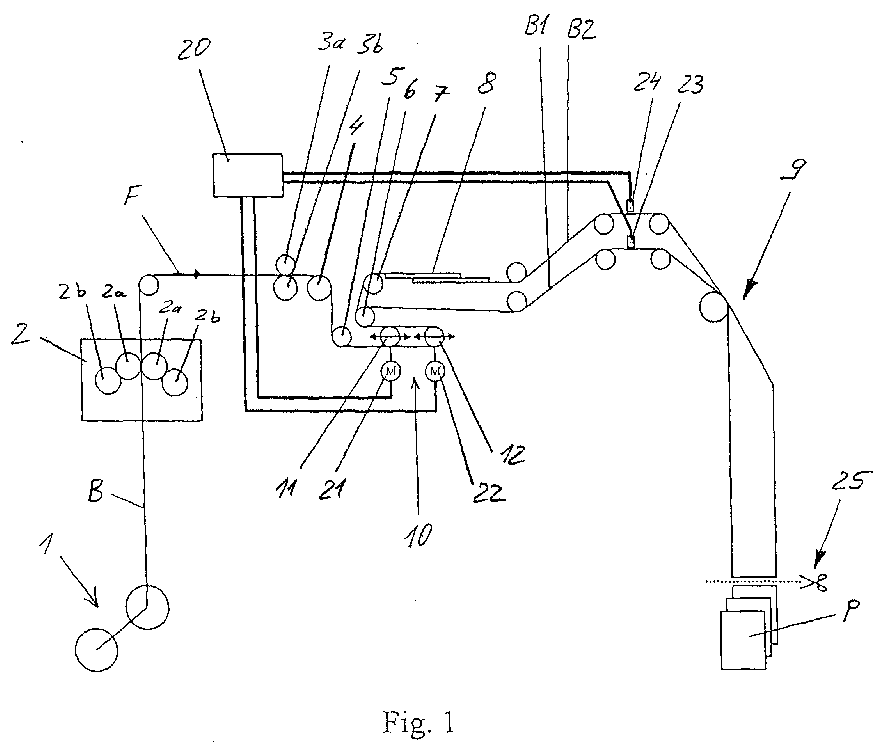

- Figure 1 shows the path of a web B through a web-fed rotary printing press for the Newsprint.

- the web B is from a role in a reel changer. 1 rotatably mounted, unwound and in a conveying direction F through a Printing unit 2 promoted. It is printed on both sides in the printing unit 2.

- the printing unit 2 comprises two blanket cylinders 2a, between which a pressure nip for the continuous web B is formed.

- the blanket cylinders 2a is ever one Associated with printing form cylinder 2b.

- the printing form cylinder 2b transmit their Printing ink imagewise occupied printed images on the blanket cylinder 2a, of which they finally printed on the web B.

- the blanket cylinders 2a are preferably mechanically not coupled with each other, but each of its own Drive motor electronically synchronized driven and in turn drive over each one mechanical transmission on the associated printing form cylinder 2b from.

- the Printing form cylinder 2b bear on its circumference in the cylinder longitudinal direction side by side at least two printing plates, their printed images on the web B accordingly be displayed side by side. In the circumferential direction, a single or it can, as usual, two printing plates or basically even more printing plates be provided one behind the other on the printing forme cylinders 2b.

- the printing forms have Seen in the cylinder longitudinal direction, the width of an open newspaper.

- Newspaper copies is the web B after printing by means of a Longitudinal cutting device between the printed images cut longitudinally.

- the Longitudinal cutting device is formed by a cutting roller 3a and a counter-roller 3b, which are each arranged to one side of the web B opposite each other.

- the Web strands B 1 and B2 are then together via a draw roller 4 to a Cut register adjustment device 10 promoted. When leaving the Cut register adjustment device 10 separates the paths of the web strands B 1 and B2.

- the first web strand B 1 is from the cutting register adjustment device 10 only via Bruleitsch without turning or Kehroperationen to a longitudinal folding device 9, which is preferably designed as a folder, guided.

- the second track B2 runs from the cutting register adjustment device 10 and into a turning bar device 8 one.

- the second web strand B2 turned and / or swept and then over an inlet roller of the Longitudinal folding device 9 with the first web strand B1 to a web strand bundle merged, in the embodiment, only from the two web strands B first and B2 exists.

- one or more other web strands another lane or several other lanes with the two lanes B1 and B2 are combined in front of the longitudinal folding device 9.

- the one in the bundle superimposed web strands B 1 and B2 are in passing through the Lssensfalz worn 9 longitudinally folded together and in a cross-cutting device 25th promoted.

- the cross-cutting device 25 may in particular a cutting cylinder of a Folder as commonly used in newspaper web-fed rotary printing become.

- the longitudinally folded and cross-cut single copies of printed products are denoted by P. If it, as in the embodiment, to newspaper copies After being cross-cut, they are laterally folded to finally reach the To get newspaper copies.

- the cutting register adjustment device 10 By means of the cutting register adjustment device 10 is ensured that the printed images the web strands B1 and B2 always between two successive sections of Cross cutting device 25 come to rest and between the cuts practice are appropriately centered, i. sufficient in relation to the common cut register are accurately positioned.

- the cutting register adjustment device 10 comprises two deflection devices, namely a first deflecting device 11 and a second deflecting device 12, furthermore a Deflection roller 5 at the inlet to the deflection 11 and 12 and another Deflection roller 6 at the outlet from the deflection 11 and 12th

- the two web strands B 1 and B2 wrap around the inlet guide roller 5 and the Outfeed roller 6 each in common, i. parallel next to each other. At the outlet deflection roller 6 separate the Bahnstrangwege.

- the first track B1 is without Turning or Kehroperationen by the area of the turning bar device. 8 passed.

- the first web strand B 1 can therefore also be referred to as a direct strand become.

- the second web strand B2 runs from the outlet deflection roller 6 via a Inlet roller 7 in a turning bar plane of the turning bar device 8 a, and is by appropriate web guide turned there and / or swept and ansch manend with the first web strand B1 merged.

- the second web strand B2 can therefore also be referred to as a reversing or sweeping strand.

- the first web strand is formed B 1 via the first deflection 11 and the second track B2 over the second Guided deflection 12 and the order of the respective deflection 11 or 12 deflection deflected formed.

- the inlet guide roller 5 and the outlet guide roller 6 are arranged to the deflectors 11 and 12 so that the first Web strand B1 the first deflection 11 and the second web B2 the second Umschlek responded 12 each loop by 180 °, so that the web strands B1 and B2 each run parallel to their deflection 11 or 12 and run away from it.

- the two Guide rollers 5 and 6 are stationary, but rotatably mounted roller body.

- the Deflection devices 11 and 12 are also each from a rotatably mounted Roll body formed. Both deflectors 11 and 12 are transverse to their Rotary axes, which also form the aforementioned deflection axes, linear along a common axis of movement in a common plane of motion back and forth movably mounted.

- the direction of mobility (movement axis) points parallel the incoming from the inlet guide roller 5 to the deflection 11 and 12 and from the deflecting devices 11 and 12 to the outlet guide roller 6 expiring Web strands B 1 and B2.

- the direction of the reciprocity is with the Diverter 11 and 12 each indicated by a double arrow.

- the arrangement of the cut register adjustment device 10 in the path of the second Web strand B2, i. of the turning strand, in front of the turning bar device 8 has the Advantage that its the cutting register position influencing deflection 12 in the width of the second web strand B2 can be performed and not, as in conventional arrangement behind the turning bar device 8, the double Brustrangbreite must have.

- the setting of the edit tab for the second Web strand B2 before performing the turning and / or Kehroperation allowed further the automatic entry of the web start of a new web to behind the cut register adjustment device 10 for the second track B2.

- FIG 2 is a guideway 17 of a machine and automatic in this sense Traction system drawn.

- the guideway 17 is of guide rails formed, which are arranged on one side next to the Bahnleitffenn and the leadership serve a driven pulling-in means.

- the guide track 17 leads to the Deflection devices 11 and 12 of the cutting register adjustment device 10.

- the Guideway 17 is also around the inlet guide roller 5 and the outlet guide roller 6 and further along the path of the first web strand B 1 out.

- FIG. 3 shows the web B in this state immediately after machine retraction over the complete path of the later first track B1.

- the rollers 3a and 3b of the longitudinal cutting device are moved against each other and the web B cut longitudinally between the later printed images.

- a web start was formed, for example, by manual tearing after slitting, the web start of the second web strand B2 is manually from the outlet guide roller 6 via the inlet roller 7 for the turning bar device 8, through the turning bar device 8 and over the downstream Bruleitstoff retracted.

- Manual retraction via a deflection of a Cut register adjustment device is saved, which brings time advantages and to Reduction of Einziehêtn contributes.

- Figure 4 shows the web B after slitting and before the formation of a Brutearings for the second track B2.

- a control and regulating device is shown, the Control and regulation of the adjustment movements of the two deflection 11 and 12 serves.

- the control and regulation device comprises two sensors 23 and 24, a Control and regulating member 20 and two motor actuators 21 and 22.

- the sensor 23 detects the position of the printed image on the first web strand passing under it B1, and the sensor 24 detects the position of the print image on the under it passing second track B2.

- the position signals of the sensors 23 and 24 are supplied to the control and regulating member 20.

- the control and regulating member 20 calculates the two sensor signals using a suitable algorithm and forms from this by comparison with input command signals, the control signals for the actuators 21st and 22.

- the actuator 21 is coupled to the first deflector 11 and the Actuator 22 with the second deflection 12.

- the actuators 21 and 22 act on the deflecting devices 11 and 12 corresponding to the control and regulating member 22nd formed actuating signals, i. they cause the adjustment of the Deflection devices 11 and 12 along their common axis of movement.

- the ongoing printing operation forms the control and regulating member 20 with the sensors 23 and 24th and the actuators 21 and 22 a control for the setting of the correct Cut register position for each of the web strands B 1 and B2.

- these members form a control and regulation system until the end of production Receipt of a basic setting.

- Figures 3 and 4 show the cutting register adjustment device 10 and its immediate environment each in the same view in a three-dimensional representation, however, in two different states of the cut register setting device 10.

- the states differ by the positions that the deflection 11 and 12 each to each other.

- the diverters 11 and 12 can be arranged side by side in a small space become.

- the arrangement and movable mounting of the deflectors 11 and 12 is such that they are in a first state, shown in Figure 3, with respect to Direction F of the web B occupy the same height and even, as this is particularly is preferred axially continuous form a smooth, uniform roll body.

- the two deflection devices 11 and 12 together formed roller body when pulling the web start of a new web a simple guide roller.

- the unavoidable clear gap between the free ends of the roll body is inside tolerances kept so narrow that he neglected for the entry of the web B. can be. In this sense, the roll body is uniform.

- the of the Deflection devices 11 and 12 formed deflection axes are aligned in the first state. In the first state, the deflecting devices 11 and 12 each take relative to each other its initial base position, in which a web is retracted with free web start.

- the deflecting means 11 and 12 by means of Actuators 21 and 22 are moved apart in opposite directions, For example, in the second state shown in Figure 4, in which their deflection axes in a maximum distance are offset parallel to each other.

- the second shown State take the baffles 11 and 12 positions in which the Trajectory of the first track B1 a minimum length and the track path of the second Brustrangs B2 has a maximum track length.

- the deflecting devices 11 and 12 can move from the position they take in the first state to their two other extreme positions are moved, if required by the cut register control.

- Intermediate states are of course also adjustable, preferably continuously.

- the frame side, at the first Bearing 11 is mounted, is denoted by 14, and the frame side on which the second deflecting device 12 is mounted, is designated 16.

- the frame sides 14 and 16 each form a parallel to the axis of movement guideway.

- the Deflection devices 11 and 12 are each on one of two carriages 13 and 15 rotatably mounted along the guideway formed by its frame side 14 or 16 is guided linearly. Through the two carriages 13 and 15 is for a rigid mounting the deflecting devices 11 and 12 provided on their respective frame side 14 or 16.

- the deflecting axes formed by the deflecting devices 11 and 12 each have one right angle to the guideways formed by the frame sides 14 and 16.

- the adjustability of the deflectors 11 and 12 is by their storage and the Coupling with the actuators 21 and 22 designed so that for the positioning of the Cutting register of the two web strands B1 and B2 required adjustment movements the deflecting devices 11 and 12 can be divided, preferably at least essentially half each, more preferably exactly half of each. Corresponding the maximum lengths of the adjustment of the deflectors 11 and 12 equal. Due to the advantageous storage of the deflectors 11 and 12 directly side by side, the adjustment paths are even the same, i. from the first Deflection 11 formed deflecting axis and that of the second deflection 12 formed deflection axis can between the two same outer Extreme positions are moved back and forth. The two deflection 11 and 12 are therefore equivalent in the ideal case described by way of example.

- the adjustability of the first deflection 11 opens up new possibilities for the Adjusting the cut registers of the direct strand and the turning strand, i. for the Control and / or regulation of the web strands B 1 and B2.

- Path length of a strand is in the context of the invention, the length of the path of the relevant Strangs from its formation, this is the place of the strands B1 and B2 Longitudinal cutting, understood until merging.

- the direct strand is in the known setting method of the strand of the bundle on which the other web strands of the bundle.

- This type of cut register setting requires the other web strand or the several other web strands of the bundle big Adjustment paths for their adjustment serving deflection.

- the adjustment paths are typically on the order of 200 to 400 mm.

- a linear register like any of the Turning 11 and 12 represents a, the strand path experience, order extend a maximum of 1 mm per meter.

- the first web strand B 1 can now be required for the cut register setting Adjustment be split on both web strands B 1 and B2.

- the adjustment path for the turning strand of the web-strand bundle is reduced, by a part thereof, preferably half of the adjustment path for the turning strand of the Thomasregistereinstellglied for the direct strand, in the embodiment, the first Turning 11, is taken over.

- the total required Verwellweg is preferably evenly divided. If the direct strand with multiple web strands to bundled together, the adjustment paths are preferably so evenly as possible divided on the web strands to be joined together. The adjustment takes place Advantageously, under the optimization strategy that assumes the positioning time same adjustment speeds for the setting of the cut register is minimal.

- the way of the first Web strand B 1 is extended to the same extent as the web path of the second Brustrangs B2 is shortened.

- the Path length changes that should be made can also be one Adjustment in the reverse direction, i. a shortening of the way of the first Brustrangs B 1 and extension of the path of the second web strand B2 be advantageous.

- the reduction in the length of the displacement of the second deflection 12 is especially when switching from one printed product to another ongoing printing production advantageous because the waste is significantly reduced can.

- the new cut registry setting may result in the first Brustrang B 1 due to the change in length of his path not with the cut in the Register is also if the color register (s) before adjustment with the cut in Registers were.

- the direct, first web strand B 1 is otherwise in the register with the Cut brought, for example by means of a register roller for the web B or preferably by a coordinated adjustment of the circumferential register of the color the web B transferring cylinders.

- the transverse cutting device in Adjustment to the path length changes of the web strands B 1 and B2 are adjusted.

- both the circumferential register of the color-transmitting cylinder as also the cross cutting device can be adjusted adjusted.

- the invention is already advantageous for a printing press for a one-sided, monochrome printing or two-sided printing in a single printing nip of a Printing unit, as will be described for purposes of explanation of a reference to the figure 1.

- the printing machine may include a plurality of printing units of this type, i. Rubber-rubber printing units, and / or of other types, for example satellite printing units, wherein the different types of printing units are arranged and operated be that the web B multicolored or a plurality of orbits B or is printed or colored in multiple colors.

- each of the web contacting and color on the web-printing cylinder each driven by its own motor, whereby the required synchronization of the respective cylinders is not mechanical, but signal technology, for example, electronically made.

- each a cut register adjustment device 10 is arranged according to the invention and also preferably has the on further features of this adjustment.

- the largest strand path length change and the largest adjustment path length of the relevant Bypass would be required for the third track B3. Whose Bypass would have to the largest Verstellwegmati from its original position to be moved.

- the total required setup time would be the time required would order the diverter for the third track B3 from its front of the Setting assumed starting position by the for a strand path length change 400 mm required Verstellwegm to proceed.

- the deflection 11 by 100 mm for a Extension and the deflection for the third track B3 also 100 mm for an equal amount of shortening of the relevant strand path be adjusted.

- the largest of the strand path length changes and the largest of Verstellwegenburgn minimized.

- the invention is at such an absolute Minimization is not limited, but also includes suboptimal design variants of the adjustment procedure. So it would also correspond to the invention, if, based on the For example, the path of the first web strand B1 only by 150 mm, for example is extended and, accordingly, the path of the second web track B2 by 150 mm and the path of the third track B3 be shortened by 250 mm, all three Web strands B1, B2 and B3 to bring the same cutting register position.

- the third web strand B3 may be at the third web strand B3 to act a web strand, obtained by slitting from the same web B. becomes like the first web B1 and the second web B2.

- the third track B3 But does not have the same track B as the two other railway lines B1 and B2, but may have been obtained from another web by slitting. He In fact, it can even be handled directly in web strand width from a roll have been.

- the Inventive adjustment method the inventive arrangement of individual or all Thomasregistereinstellglieder for the web strands in front of the turning bars and the Arrangement of the rail register adjustment members provided for each of their strands in mutual spatial proximity are in many different web guides, leading to the Formation of web strand bundles lead, advantageous.

Landscapes

- Inking, Control Or Cleaning Of Printing Machines (AREA)

- Controlling Rewinding, Feeding, Winding, Or Abnormalities Of Webs (AREA)

- Collation Of Sheets And Webs (AREA)

- Details Of Cutting Devices (AREA)

- Advance Control (AREA)

- Harvester Elements (AREA)

- Registering, Tensioning, Guiding Webs, And Rollers Therefor (AREA)

- Processing Of Stones Or Stones Resemblance Materials (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Confectionery (AREA)

- Handling Of Sheets (AREA)

Abstract

Description

- Figur 1

- eine Druckmaschine mit einer Schnittregister-Einstellvorrichtung, die vor einer Wendestangeneinrichtung angeordnet ist,

- Figur 2

- eine Ansicht der in einem ersten Zustand befindlichen Schnittregister-Einstellvorrichtung,

- Figur 3

- eine perspektivische Darstellung der in einem ersten Zustand befindlichen Schnittregister-Einstellvorrichtung und

- Figur 4

- eine perspektivische Darstellung der in einem zweiten Zustand befindlichen Schnittregister-Einstellvorrichtung.

Claims (21)

- Schnittregister-Einstellvorrichtung in einer Druckmaschine, die Druckmaschine umfassend:a) wenigstens ein Druckwerk (2) zum Bedrucken einer Bahn (B),b) eine Längsschneideinrichtung (3a, 3b) zum Längsschneiden der Bahn (B) in einen ersten Bahnstrang (B1) und wenigstens einen weiteren, zweiten Bahnstrang (B2),e) eine Einrichtung (8, 9) zum Zusammenführen der Bahnstränge (B1, B2) oder zum Zusammenführen der Bahnstränge (B1, B2) je mit wenigstens einem anderen Bahnstrang umfassend eine Wendestangeneinrichtung (8),d) eine Querschneideinrichtung (25) zum Querschneiden der zusammengeführten Bahnstränge (B1, B2)e) und eine Schnittregister-Einstellvorrichtung (10), die zum Einstellen eines auf das Querschneiden bezogenen Schnittregisters der Bahnstränge (B1, B2) zum Umlenken des ersten Bahnstrangs (B1) um eine erste Umlenkachse eine erste Umlenkeinrichtung (11) und zum Umlenken des zweiten Bahnstrangs (B2) um eine zweite Umlenkachse eine zweite Umlenkeinrichtung (12) umfasst, die relativ zu der ersten Umlenkeinrichtung (11) in einem Gestell (14, 16) bewegbar so gelagert ist, dass die Länge des Wegs des zweiten Bahnstrangs (B2) relativ zu der Länge des Wegs des ersten Bahnstrangs (B1) durch eine Bewegung der zweiten Umlenkeinrichtung (12) relativ zu der ersten Umlenkeinrichtung (11) veränderbar ist,f) wobei die Schnittregister-Einstellvorrichtung (10) in Förderrichtung (F) der Bahn (B) vor der Wendestangeneinrichtung (8) angeordnet ist.

- Schnittregister-Einstellvorrichtung nach Anspruch 1, dadurch gekennzeichnet, dass die erste Umlenkeinrichtung (11) und die zweite Umlenkeinrichtung (12) quer zu dem zweiten Bahnstrang (B2) in dem Gestell (14, 16) nebeneinander angeordnet sind.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die zweite Umlenkeinrichtung (12) quer zu der von ihr gebildeten Umlenkachse bewegbar, vorzugsweise geradgeführt, gelagert ist.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die erste Umlenkeinrichtung (11) relativ zu dem Gestell (14, 16) und der zweiten Umlenkeinrichtung (12) quer zu der von ihr gebildeten Umlenkachse bewegbar, vorzugsweise geradgeführt, gelagert ist, um auch die Länge des Wegs des ersten Bahnstrangs (B1) verändern zu können.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die erste Umlenkeinrichtung (11) um eine erste maximale Verstellweglänge und die zweite Umlenkeinrichtung (12) um eine zweite maximale Verstellweglänge bewegbar sind und die erste maximale Verstellweglänge wenigstens halb so groß, vorzugsweise zumindest im wesentlichen so groß, wie die zweite maximale Verstellweglänge ist.

- Schnittregister-Einstellvorrichtung nach einem der zwei vorhergehenden Ansprüche, dadurch gekennzeichnet, dass eine Steuerungs- und/oder Regelungseinrichtung (20-24) mit einer Stelleinrichtung (21, 22) vorgesehen ist, mittels der die Umlenkeinrichtungen (11, 12) so bewegt werden können, dass für einen der Bahnstränge (B1, B2) die Länge seines Wegs vergrößert und für den anderen der Bahnstränge (B1, B2) die Länge seines Wegs verkleinert wird.

- Schnittregister-Einstellvorrichtung nach dem vorhergehenden Anspruch, dadurch gekennzeichnet, dass die Längen der Wege der Bahnstränge (B1, B2) mittels der Steuerungs- und/oder Regelungseinrichtung (20-24) gleichzeitig veränderbar sind.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die zweite Umlenkeinrichtung (12) und/oder die erste Umlenkleinrichtung (11) in eine Position bewegbar ist oder sind, in der die Umlenkeinrichtungen (11, 12) von der Bahn (B) gemeinsam umschlungen werden können.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die erste Umlenkeinrichtung (11) ein erster Walzenkörper und die zweite Umlenkeinrichtung (12) ein zweiter Walzenkörper ist und die Walzenkörper in einer ersten Position gemeinsam eine Umlenkwalze und in einer zweiten Position je eine separate Umlenkwalze bilden.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass das Gestell (14, 16) eine erste Gestellseite (14) und eine der ersten Gestellseite (14) quer zu der Bahn (B) beabstandet gegenüberliegende zweite Gestellseite (16) aufweist, dass die erste Umlenkeinrichtung (11) an der ersten Gestellseite (14) gelagert ist und ein der zweiten Gestellseite (16) zugewandtes, freies Ende aufweist und dass die zweite Umlenkeinrichtung (12) an der zweiten Gestellseite (16) gelagert ist und ein der ersten Gestellseite (14) zugewandtes, freies Ende aufweist.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass eine in Richtung der ersten Umlenkachse gemessene Breite der ersten Umlenkeinrichtung (11) der Breite des ersten Bahnstrangs (B1) entspricht.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass eine in Richtung der zweiten Umlenkachse gemessene Breite der zweiten Umlenkeinrichtung (12) der Breite des zweiten Bahnstrangs (B2) entspricht.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass eine in den Wegen der Bahnstränge (B1, B2) auf die erste Umlenkeinrichtung (11) und die zweite Umlenkeinrichtung (12) nächstfolgende Auslauf-Umlenkeinrichtung (6) der ersten Umlenkeinrichtung (11) und der zweiten Umlenkeinrichtung (12) gemeinsam zugeordnet ist, indem sie von dem ersten Bahnstrang (B1) und dem zweiten Bahnstrang (B2) gemeinsam umschlingbar ist.

- Schnittregister-Einstellvorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass eine in dem Weg der Bahn (B) oder den Wegen der Bahnstränge (B1, B2) der ersten Umlenkeinrichtung (11) und der zweiten Umlenkeinrichtung (12) nächst benachbart vorgeordnete Einlauf-Umlenkeinrichtung (5) der ersten Umlenkeinrichtung (11) und der zweiten Umlenkeinrichtung (12) gemeinsam zugeordnet ist, indem sie von der Bahn (B) oder von dem ersten Bahnstrang (B1) und dem zweiten Bahnstrang (B2) gemeinsam umschlingbar ist.

- Verfahren für eine Einstellung des Schnittregisters für eine und/oder in einer Druckproduktion, bei dema) eine Bahn (B) mit wenigstens zwei quer zu einer Förderrichtung (F) der Bahn (B) nebeneinander angeordneten Druckbildern fortlaufend bedruckt,b) die Bahn (B) zwischen den aufgedruckten oder noch aufzudruckenden Druckbildern in einen ersten Bahnstrang (B1) und einen zweiten Bahnstrang (B2) längsgeschnitten undc) wenigstens der zweite Bahnstrang (B2) gewendet und/oder gekehrt wird,d) die Bahnstränge (B1, B2) nach dem Wenden und/oder Kehren des zweiten Bahnstrangs (B2) zusammengeführt oder je mit einem anderen bedruckten Bahnstrang zusammengeführt unde) die zusammengeführten Bahnstränge (B1, B2) zwischen in Förderrichtung (F) aufeinanderfolgenden Druckbildern quergeschnitten werden, um einzelne Druckprodukte (P) zu erhalten,f) und bei dem eine auf das Querschneiden bezogene Schnittregisterposition wenigstens des zweiten Bahnstrangs (B2) in einer Schnittregister-Einstellvorrichtung (10), die eine von dem ersten Bahnstrang (B1) umschlungene erste Umlenkeinrichtung (11) und eine von dem zweiten Bahnstrang (B2) umschlungene zweite Umlenkeinrichtung (12) umfasst, vor dem Wenden und/oder Kehren des zweiten Bahnstrangs (B2) durch eine die Länge des Wegs des zweiten Bahnstrangs (B2) verändernde Bewegung der zweiten Umlenkeinrichtung (12) eingestellt wird.

- Verfahren nach dem vorhergehenden Anspruch, dadurch gekennzeichnet, dass eine auf das Querschneiden bezogene Schnittregisterposition auch des ersten Bahnstrangs (B1) in der Schnittregister-Einstellvorrichtung (10) durch eine die Länge des Wegs des ersten Bahnstrangs (B1) verändernde Bewegung der ersten Umlenkeinrichtung (11) eingestellt wird.

- Verfahren nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der erste Bahnstrang (B1) direkt, nämlich ungewendet, mit dem zweiten Bahnstrang (B2) oder wenigstens einem anderen Bahnstrang zusammengeführt und quergeschnitten wird.

- Verfahren nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der erste Bahnstrang (B1) und der zweite Bahnstrang (B2) allein oder mit wenigstens einem weiteren Bahnstrang zu einem Bündel zusammengeführt und die Schnittregisterpositionen der Bahnstränge (B1, B2) des Bündels durch eine Bewegung sowohl der ersten Umlenkeinrichtung (11) als auch der zweiten Umlenkeinrichtung (12) je um eine Verstellweglänge aufeinander abgestimmt eingestellt werden.

- Verfahren nach dem vorhergehenden Anspruch, dadurch gekennzeichnet, dass die Schnittregisterpositionen der Bahnsträngen (B1, B2) des Bündels gleichzeitig eingestellt werden, um eine für die Einstellung der Schnittregister der Bahnstränge (B1, B2) benötigte Einstellzeit zu minimieren.

- Verfahren nach einem der zwei vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die Schnittregisterpositionen der Bahnstränge (B1, B2) des Bündels in einer Weise eingestellt werden, dass eine größte aus den Verstellweglängen minimiert wird.

- Verfahren nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dassder erste Bahnstrang (B1) mit wenigstens zwei weiteren Bahnsträngen, von denen der eine vorzugsweise der zweite Bahnstrang (B2) ist, zu einem Bahnstrangbündel zusammengeführt und im Bündel quergeschnitten wird,jeder der Bahnstränge des Bündels über je wenigstens eine Umlenkeinrichtung gefördert wird, die um eine Verstellweglänge verstellbar ist, um das Schnittregister des von ihr umgelenkten Bahnstrangs verstellen zu könnenund dass die Schnittregister der Bahnstränge des Bündels in solch einer Weise abgestimmt eingestellt werden, dass die hierfür erforderlichen Verstellweglängen der Umlenkeinrichtungen auf die Bahnstränge verteilt sind.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10236657 | 2002-08-09 | ||

| DE10236657A DE10236657A1 (de) | 2002-08-09 | 2002-08-09 | Schnittregister-Einstellvorrichtung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1388515A2 true EP1388515A2 (de) | 2004-02-11 |

| EP1388515A3 EP1388515A3 (de) | 2005-04-06 |

| EP1388515B1 EP1388515B1 (de) | 2008-05-28 |

Family

ID=30128805

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03405563A Expired - Lifetime EP1388515B1 (de) | 2002-08-09 | 2003-07-28 | Schnittregister-Einstellvorrichtung |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6748857B2 (de) |

| EP (1) | EP1388515B1 (de) |

| JP (1) | JP4212425B2 (de) |

| AT (1) | ATE396944T1 (de) |

| DE (2) | DE10236657A1 (de) |

| DK (1) | DK1388515T3 (de) |

| ES (1) | ES2310233T3 (de) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10154003A1 (de) * | 2001-11-02 | 2003-05-15 | Heidelberger Druckmasch Ag | Vorrichtung und Verfahren zur Positionierung eines Querschnitts auf einem Bedruckstoff in Rollendruckmaschinen |

| DE10236658B4 (de) * | 2002-08-09 | 2012-11-29 | Wifag Maschinenfabrik Ag | Schnittregister-Aufteilung |

| DE10337248B4 (de) * | 2003-08-13 | 2009-12-17 | Maschinenfabrik Wifag | Bahnspreizverfahren und Bahnspreizvorrichtung |

| US7523705B2 (en) * | 2004-03-08 | 2009-04-28 | Goss International Americas, Inc. | Web printing press and method for controlling print-to-cut and circumferential register |

| TWI283651B (en) * | 2004-04-23 | 2007-07-11 | Bobst Sa | Device for transferring a foil matter from outside to inside of a machine |

| DE102004051635A1 (de) * | 2004-10-23 | 2006-05-18 | Man Roland Druckmaschinen Ag | Verfahren zur Schnittregistereinstellung bei einer Rollenrotationsdruckmaschine |

| WO2007112017A2 (en) * | 2006-03-23 | 2007-10-04 | Goss International Americas, Inc. | Tabloid printing press and retrofitting method |

| DE102006031681B4 (de) * | 2006-07-08 | 2020-02-13 | Manroland Goss Web Systems Gmbh | Verfahren zum Betreiben eines Falzapparats einer Druckmaschine |

| DE102006037946A1 (de) * | 2006-08-12 | 2008-02-14 | Man Roland Druckmaschinen Ag | Verfahren zur Schnittregisterregelung an einer Rollenrotationsdruckmaschine |

| DE102007035432A1 (de) * | 2007-07-28 | 2009-01-29 | Manroland Ag | Rollenrotationsdruckmaschine |

| DE102007039372B4 (de) * | 2007-08-21 | 2010-08-12 | Koenig & Bauer Aktiengesellschaft | Schnittregisterregelung in einem Trichteraufbau sowie Verfahren zur Schnittregisterregelung |

| DE102007040678A1 (de) * | 2007-08-29 | 2009-03-05 | Manroland Ag | Wendestangeneinheit einer Rollendruckmaschine |

| KR102398583B1 (ko) | 2015-11-06 | 2022-05-17 | 호야 가부시키가이샤 | 마스크 블랭크, 위상 시프트 마스크의 제조 방법 및 반도체 디바이스의 제조 방법 |

| IT202100018878A1 (it) * | 2021-07-16 | 2023-01-16 | Futura Spa | Sistema di guida per la movimentazione di materiale cartaceo. |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4063505A (en) * | 1975-07-21 | 1977-12-20 | Ikegsi Iron Works, Ltd. | Papering apparatus in rotary printing press |

| DE3515626A1 (de) * | 1984-04-27 | 1985-10-24 | Mitsubishi Jukogyo K.K., Tokio/Tokyo | Verfahren zum steuern des rasters der schneidvorrichtung in rotationsdruckmaschinen |

| ATE74553T1 (de) * | 1988-02-19 | 1992-04-15 | Asea Brown Boveri | Verfahren zur schnittlagebestimmung fuer druckmaschinen. |

| US5048810A (en) * | 1990-11-19 | 1991-09-17 | Harris Graphics Corporation | Apparatus for adjusting an anglebar or a compensator roller in a folder of a printing press |

| US5320334A (en) * | 1992-06-23 | 1994-06-14 | Deangelis Andrew V | Method of printing a book having pages of newsprint and pages of coated enamel pages |

| US5289770A (en) * | 1992-09-18 | 1994-03-01 | Heidelberg Harris Gmbh | Device for presetting a cut-off register in a folder of a web-fed printing press |

| US5458062A (en) * | 1994-02-28 | 1995-10-17 | Goldberg; Ira B. | Continuous web printing press with page cutting control apparatus and method |

| JP2943101B2 (ja) * | 1997-05-07 | 1999-08-30 | 株式会社ミヤコシ | ターンバー装置 |

| DE19728207A1 (de) * | 1997-07-02 | 1999-01-07 | Wifag Maschf | Wendeturmanordnung |

| DE19834725A1 (de) * | 1998-07-31 | 2000-02-03 | Wifag Maschf | Bahnspannungsregeleinrichtung |

| JP3032763B1 (ja) * | 1999-06-17 | 2000-04-17 | 株式会社東京機械製作所 | 輪転機におけるウエブ紙走行張力制御装置を備えた給紙部 |

| EP1080887A1 (de) * | 1999-08-19 | 2001-03-07 | Quad/Tech, Inc. | Bahnlagekontrollsystem |

| JP3212298B2 (ja) * | 1999-12-21 | 2001-09-25 | 株式会社東京機械製作所 | 輪転機の同期制御装置及びその方法 |

-

2002

- 2002-08-09 DE DE10236657A patent/DE10236657A1/de not_active Withdrawn

-

2003

- 2003-07-28 DE DE50309907T patent/DE50309907D1/de not_active Expired - Lifetime

- 2003-07-28 ES ES03405563T patent/ES2310233T3/es not_active Expired - Lifetime

- 2003-07-28 US US10/629,073 patent/US6748857B2/en not_active Expired - Fee Related

- 2003-07-28 DK DK03405563T patent/DK1388515T3/da active

- 2003-07-28 EP EP03405563A patent/EP1388515B1/de not_active Expired - Lifetime

- 2003-07-28 AT AT03405563T patent/ATE396944T1/de not_active IP Right Cessation

- 2003-07-31 JP JP2003283552A patent/JP4212425B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP4212425B2 (ja) | 2009-01-21 |

| JP2004090635A (ja) | 2004-03-25 |

| EP1388515A3 (de) | 2005-04-06 |

| EP1388515B1 (de) | 2008-05-28 |

| US6748857B2 (en) | 2004-06-15 |

| ES2310233T3 (es) | 2009-01-01 |

| US20040025725A1 (en) | 2004-02-12 |

| DE10236657A1 (de) | 2004-02-26 |

| DE50309907D1 (de) | 2008-07-10 |

| ATE396944T1 (de) | 2008-06-15 |

| DK1388515T3 (da) | 2008-09-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1466730B1 (de) | Rollenrotationsdruckmaschine | |

| EP1742796B1 (de) | Rollenrotationsdruckmaschinen mit einem einstellbaren falzaufbau | |

| EP1388516B1 (de) | Schnittregister-Einstellvorrichtung | |

| EP0683123B1 (de) | Rotations-Rollendruckmaschine mit einer Registervorrichtung zum Ausrichten der Papierbahn | |

| DE4435429A1 (de) | Rollenrotationsdruckmaschine | |

| EP0888887B1 (de) | Wendeturmanordnung | |

| EP1388515B1 (de) | Schnittregister-Einstellvorrichtung | |

| DE10052015A1 (de) | Bewegbarer Falzapparat und Falztrichteranordnung | |

| EP1386869A2 (de) | Bahnspreizvorrichtung | |

| EP1742794A1 (de) | Druckformen einer druckmaschine und rollenrotationsdruckmaschinen | |

| DE19856422A1 (de) | Warenbahnzuführung für einen Falzapparat | |

| EP1401661B1 (de) | Druckmaschine mit mehreren sektionen | |

| DE102004033912A1 (de) | Offsetdruckwerk und Rollenrotationsdruckmaschine | |

| EP1693324B1 (de) | Vorrichtung zum Führen einer teilbreiten Bahn in einer Bearbeitungsmaschine | |

| DE3515626C2 (de) | ||

| DE102005037731B4 (de) | Druckmaschinenanlagen | |

| EP0518053A1 (de) | Verfahren zur Herstellung bedruckter Wellpappe in grosser Arbeitsbreite sowie Anlage zur Durchführung des Verfahrens | |

| EP2223806A1 (de) | Vorrichtung und Verfahren zum Spreizen von quer zur Maschinenlängsachse laufenden Teilbahnen in einer Rollenrotationsdruckmaschine | |

| EP1930163B1 (de) | Vorrichtung zum Einziehen mindestens einer Materialbahn bzw. mindestens eines Bahnstrangs in einen Falzapparat | |

| DE102005048246B4 (de) | Rotationsdruckmaschine mit Längendehnungs-Kompensator und Verfahren zum Bedrucken einer längsgeschnittenen Bahn | |

| DE102008042085B4 (de) | Verfahren und Vorrichtung zum Führen von Bahnen in einer Rollenrotationsdruckmaschine | |

| EP2085222A1 (de) | Druckeinheit, Falzapparat oder Rotationsdruckmaschine mit Mittels Schlitten gelagerten Komponenten | |

| DE102004043417A1 (de) | Druckmaschine | |

| EP1634831A1 (de) | Bahnspreizverfahren und Bahnspreizvorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20051006 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20060824 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: WIFAG MASCHINENFABRIK AG |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50309907 Country of ref document: DE Date of ref document: 20080710 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2310233 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081028 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080828 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080731 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080828 |

|

| 26N | No opposition filed |

Effective date: 20090303 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20090723 Year of fee payment: 7 Ref country code: ES Payment date: 20090724 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20090723 Year of fee payment: 7 Ref country code: GB Payment date: 20090724 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080728 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081129 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080528 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080829 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100728 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110818 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100802 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20130722 Year of fee payment: 11 Ref country code: FI Payment date: 20130722 Year of fee payment: 11 Ref country code: NL Payment date: 20130722 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20150201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140728 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140731 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENT- UND MARKENANWAELTE, CH Ref country code: CH Ref legal event code: PFA Owner name: WIFAG-POLYTYPE HOLDING AG, CH Free format text: FORMER OWNER: WIFAG MASCHINENFABRIK AG, CH |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20190723 Year of fee payment: 17 Ref country code: IT Payment date: 20190723 Year of fee payment: 17 Ref country code: FR Payment date: 20190724 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20190711 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50309907 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200728 |