EP1344985B2 - Cooking oven and oven cart - Google Patents

Cooking oven and oven cart Download PDFInfo

- Publication number

- EP1344985B2 EP1344985B2 EP03005542A EP03005542A EP1344985B2 EP 1344985 B2 EP1344985 B2 EP 1344985B2 EP 03005542 A EP03005542 A EP 03005542A EP 03005542 A EP03005542 A EP 03005542A EP 1344985 B2 EP1344985 B2 EP 1344985B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- movable

- baking

- telescopic part

- carriage

- front wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010411 cooking Methods 0.000 title claims description 9

- 230000008901 benefit Effects 0.000 description 3

- 229910000639 Spring steel Inorganic materials 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/16—Shelves, racks or trays inside ovens; Supports therefor

- F24C15/168—Shelves, racks or trays inside ovens; Supports therefor with telescopic rail systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/16—Shelves, racks or trays inside ovens; Supports therefor

- F24C15/162—Co-operating with a door, e.g. operated by the door

Definitions

- the invention relates to a baking tray according to the preamble of claim 1.

- a baking tray is from document DE-U-9 406 630 already known.

- the invention relates to a baking oven with such a baking cart. From the DE 19 817 499 C1 an oven with a device for supporting food carriers is known.

- the DE 19 949 239 A1 shows a pull-out device for Garguta in the cooking of Garöfen.

- the invention relates to a baking oven and a baking oven, which is designed for extending and retracting in a baking oven muffle and having the following features: a front wall as the oven door for closing the baking oven muffle; at least one carrying device behind the front wall for carrying and transverse method of at least one food support from a parking position behind the oven door and a transverse offset position, wherein the food support protrudes laterally at least partially over the oven door.

- the problem to be solved in an oven with a baking tray, which is arranged retractable and extendable in the oven muffle, to achieve better ease of use. Furthermore, the food support from the baking carriage should be pulled out laterally, without tipping.

- the food support does not slide on the support, but he sits on a telescopic telescopic part of the support device.

- the invention has the following advantages: better securing of the food support against tipping in the laterally protruding from the baking tray transverse offset position; the ability to make the Querversatzweg larger than in the prior art to facilitate the occupancy of the food support with food for the user person; Reduction of the movement of the food support transverse to the baking carriage required displacement force; the possibility of creating a comfortable safety catch for holding the food support in the parking position; Extractability of the movable telescopic part with the food support both to the right and to the left out of the baking tray in a Querversatzposition, without having to forego the aforementioned advantages.

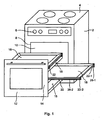

- the in Fig. 1 oven 2 shown according to the invention contains on its upper side a hob 4 (or a cooktop) and on its front panel controls above 6. Below is the muffle opening 8 of a baking oven muffle 10.

- a baking tray 12 is designed for retraction and extension into the oven muffle 10 for which purpose guide elements are provided in the baking oven muffle 10 and on the baking tray 12, for example a telescopic device which is not shown in detail here.

- the baking tray is provided behind the front wall 14 with at least one carrying device 15 for carrying and transverse process of at least one food support 18 from a parking position behind the front wall 14 and a transverse offset position, in which the food support 18 protrudes laterally at least partially over the front wall 14.

- Fig. 1 shows in two superimposed floors depending such a support device 15th

- the support device 15 includes a support frame 16, as in Fig. 2 is shown.

- the support frame 16 is not mounted on a floor or other support structure, but on the back of the front wall 14. According to the preferred embodiment shown are at the back of the Front wall 14 hook rails 20 attached to which the support frame 16 is suspended and is then held cantilevered.

- the food support 18 is for example a baking sheet or a grill or other device for carrying or holding food (food of any kind).

- the front wall may contain a viewing window made of glass or transparent plastic as known oven doors or consist entirely of such a material.

- the carrying device 15 has a telescopic device 22 arranged in the carriage transverse direction, which has a stationary telescopic part 24 mounted behind the front wall in the parking position on the supporting frame 16 and a transverse carriage offset from the parking position laterally beyond the front wall 14 into the transverse offset position movable telescopic part 26 has.

- the movable telescopic part 26 is designed to receive a food support 18.

- the movable telescopic part 26 is provided with fixing parts 30, 31, 32, and 33 for fixing the food support 18 in order to limit or block relative movements between the movable telescope part 26 and the food support 18 at least in the carriage transverse direction. This not only avoids that the food support 18 inadvertently can slide down from the movable telescopic part 26, but also achieves the advantage that the movable telescopic part 26 is movable relative to the fixed telescopic part 24 by a force acting on the food support 18 force of a user person transverse to the baking tray without the movable telescope part 26 needing to be touched by the user person.

- fixing parts 30, 31, 32 and 33 can bends of the movable telescopic part 26 or attached thereto, for. B. be welded or bolted elements, such as locating bolts.

- Fig. 2 shows four such locating bolts 30, 31, 32 and 33, wherein one is located at each corner of the food support 18. An edge region of the food support 18 rests on the locating bolt and a recessed depression area located within the edge region engages behind the locating bolts.

- According to another embodiment can be formed in the food support 18 receiving holes through which the receiving bolt can protrude through.

- the two telescopic parts 24 and 26 may be plate-like body, one of which is arranged in the other and is displaceable relative to each other in the carriage transverse direction.

- a significantly lighter in weight, yet sturdy construction is that the telescopic device 22 has at least two telescopes 22-1 and 22-2 arranged parallel next to each other in the transverse direction of the wagon, each having a stationary telescopic rod 24-1 or fastened to the baking tray 12 in the parking position or fixable 24-2 and a telescopic rod 26-1 and 26-2 movable relative to the latter in the longitudinal direction of the rod, the stationary telescopic rod 24-1 and 24-2 belonging to the fixed telescopic part 24 and the movable telescopic rod 26-1 and 26-2 belongs to the movable telescopic part 26 and is designed to receive the food support 18.

- the telescopic rods may be rails or tubes.

- Each telescope 22-1 and 22-2 may have two or more movable telescopic rods instead of a single movable telescopic rod 26-1 and 26-2, respectively, which are movable relative to each other in the bar longitudinal direction to a food support 18 in a partial or preferably completely adjacent to the Front wall 14 location to move transverse offset position.

- the food support 18 is located here on the most extendable telescopic poles.

- rolling bearings 34 are arranged, on which roll the movable telescopic poles ,

- Rolling bearings can be ball bearings, roller bearings, tapered bearings or similar bearings.

- Fig. 3 of the drawings shows in a side view in the direction of an arrow III of Fig. 2

- Bearing balls 36 which are arranged in bearing cages between a stationary telescopic rod 24-1 and a relative to it in rod longitudinal direction movable telescopic rod 26-1.

- the fixing parts or receiving bolts 30, 31, 32 and 33 prevent the movable telescopic rods 26-1 and 26-2 from being displaceable relative to one another in the longitudinal direction of the rod when a food support 18 is located on them.

- the connecting element 40 is preferably located at the end of the movable telescopic rods 26-1 and 26-2 remote from the fixed telescopic rods 24-1 and 24-2. At this point, it is most easily grasped by a user person to move the movable telescope part 26 relative to the fixed telescopic part 24.

- At least one detent device 42 is provided, the locking force of which can be overcome by acting on the movable telescopic part 26 in the transverse direction of the car manual operating force.

- the detent device 42 may be provided at the front end adjacent the front wall 14 and / or at the rear end of the telescopic device 22.

- the detent device 42 may comprise a bolt which is supported by a spring, e.g. B. a leaf spring or coil spring, is pushed in the trailer longitudinal direction and can engage behind a latching surface, one of the two parts bolt or locking surface on the movable telescopic part 26 and the other part is arranged on a stationary part of the back carriage, for example, on the stationary telescopic part 24th or on the support frame 16 carrying it.

- the detent device 42 is designed such that a user person can feel the latching action on the movable telescopic part 26 or the food support 18 located thereon by a small vibration.

- the detent device 42 should hold the movable telescopic part 26 safely even in the parking position when it shakes so that it does not move laterally out of the baking tray. At the same time, the detent device 42 should be designed such that only a small force is required by a user to disengage the movable telescopic part 26 on the detent device 42 and to move it from the park position transversely out of the baking tray.

- each detent device 42 has at least one longitudinally extending in the transverse direction, longitudinally flexible in the carriage longitudinally elastic spring element 44, on which at least one detent surface is formed, and a detent element 54 for locking on the detent surface.

- spring element 44 and detent element 54 of the one part on the stationary telescopic part 26 or its support frame 16 and the other part is formed or fixed to the movable telescopic part 26.

- two spring elements 44 are arranged fixed behind the front wall 14 and two associated latching elements 54 are arranged on the movable telescopic part 26.

- the elongated spring element 44 is a leaf spring strip or preferably correspondingly Fig.

- the detent element 54 is a bolt formed or fastened to the movable telescopic part 26, which extends transversely to the shafts 48, 50, 52 of the spring element 44, whose wave peaks 48 and 50 lie in the path of movement of the detent element 54.

- the detent element 54 slides over one of the two wave peaks 42 into the wave trough 52, the detent element 54 on the wave crest 48 or 50 pushing away the spring element laterally and then entering the wave trough 52 of the spring element 44 that springs back.

- the movable telescopic part 26 can be pushed out from the parking position behind the front wall 14 selectively in one direction or in the other direction transversely out of the baking tray.

- the detent element 54 slides over the one wave crest 48, in the other direction of movement the detent element 54 slides over the other crest 50, thereby pushing the spring element 44 out of the path of movement of the detent element 54.

- the elongate spring element or spring steel wire 44 is preferably not only at one end, but both ends at a distance from the waveform 48, 50, 52 attached to the fixed telescopic part 24 or the support frame 16. As a result, in contrast to a spring element 44, which is attached only at one end, an unintentional bending of the spring element and thus a decrease in the spring force on the detent element 54 is avoided.

- Fig. 4 shows in an enlarged scale relative to the other figures, the movable telescopic part 26 with the detent element 54 formed on it or fastened and the elongated spring element 44 when the movable telescopic part 26 is located in the parking position in the center behind the front wall 14 and thereby the detent element 54 in the Wellental 52 between the two wave crests 48 and 50 is engaged. Further shows Fig. 4 by arrows 60 and 62 that the movable telescopic part 26 is displaceable in both the one arrow direction 60 and in the other direction of arrow 62 from the parking position into a transverse offset position relative to the baking tray.

- the detent element 54 (bolt) slides over the one corrugation peak 48 or the other corrugation peak 50, wherein the corrugation peak and thus the spring element 44 is pushed away in the direction of arrow 64.

- the spring element returns to a neutral position by means of its spring force in accordance with an arrow 66.

- Fig. 4 is the spring in the region of the corrugation 48, 50, 52 as far as the side bent against the movable telescopic part 26 that the trough 52 is biased against the detent element 54 with resilient bias.

Abstract

Description

Die Erfindung betrifft einen Backwagen gemäß dem Oberbegriff von Anspruch 1. Ein solcher Backwagen ist aus Dokument

Demgemäß betrifft die Erfindung einen Backofen und einen Backofen-Wagen, welcher zum Ein- und Ausfahren in einer Backofenmuffel ausgebildet ist und folgende Merkmale aufweist: eine Frontwand als Backofentür zum Verschließen der Backofenmuffel; mindestens eine Tragvorrichtung hinter der Frontwand zum Tragen und Querverfahren von mindestens einem Gargutträger von einer Parkposition hinter der Backofentür und einer Querversatzposition, bei welcher der Gargutträger mindestens teilweise über die Backofentür seitlich hinausragt.Accordingly, the invention relates to a baking oven and a baking oven, which is designed for extending and retracting in a baking oven muffle and having the following features: a front wall as the oven door for closing the baking oven muffle; at least one carrying device behind the front wall for carrying and transverse method of at least one food support from a parking position behind the oven door and a transverse offset position, wherein the food support protrudes laterally at least partially over the oven door.

Beim Stand der Technik eines solchen Backofens gleitet das Backblech direkt auf einem Drahtrahmen, welcher in Hakenschienen eingehängt ist. Die Hakenschienen sind an der Rückseite einer Frontwand des Backwagens befestigt. Das Backblech kann sowohl nach rechts als auch nach links herausgezogen werden. Das Backblech ist gegen Abkippen nur schlecht gesichert. Sein Auszugsweg nach links oder nach rechts ist daher auf ungefähr drei Viertel der Backblechbreite beschränkt. Backöfen dieser Art sind aus der DE-Gebrauchsmusterschrift G 94 06 630.2 und aus der

Ferner sind aus der

Durch die Erfindung soll die Aufgabe gelöst werden, bei einem Backofen mit einem Backwagen, welcher in der Backofenmuffel einfahrbar und ausfahrbar angeordnet ist, einen besseren Benutzungskomfort zu erzielen. Ferner soll der Gargutträger aus dem Backwagen seitlich ausziehbar sein, ohne abzukippen.By the invention, the problem to be solved, in an oven with a baking tray, which is arranged retractable and extendable in the oven muffle, to achieve better ease of use. Furthermore, the food support from the baking carriage should be pulled out laterally, without tipping.

Diese Aufgabe wird gemäß der Erfindung durch Patentanspruch 1 gelöst.This object is achieved according to the invention by claim 1.

Der Gargutträger gleitet hierbei nicht auf der Tragvorrichtung, sondern er sitzt auf einem ausziehbaren Teleskopteil der Tragvorrichtung.The food support does not slide on the support, but he sits on a telescopic telescopic part of the support device.

Die Erfindung hat folgende Vorteile: bessere Sicherung des Gargutträgers gegen Abkippen in der seitlich aus dem Backwagen herausragenden Querversatzposition; die Möglichkeit, den Querversatzweg größer als beim Stand der Technik zu machen, um die Belegung des Gargutträgers mit Gargut für die Benutzerperson zu erleichtern; Reduzierung der zur Bewegung des Gargutträgers quer zum Backwagen erforderlichen Verschiebekraft; die Möglichkeit der Schaffung einer komfortablen Rastensicherung zum Halten des Gargutträgers in der Parkposition; Ausziehbarkeit des beweglichen Teleskopteiles mit dem Gargutträger sowohl nach rechts als auch nach links aus dem Backwagen heraus in eine Querversatzposition, ohne auf die vorgenannten Vorteile verzichten zu müssen. Damit ergibt sich eine wesentliche Komfortverbesserung gegenüber dem Stand der Technik; bereits bestehende Backöfen und Backwagen können auf einfache Weise mit geringem Kostenaufwand mit der Erfindung versehen werden; ein Vollauszug, bei welchem der Gargutträger aus dem Backwagen in eine vollständig neben der Frontwand gelegene Querversatzposition ausziehbar ist ist mit geringem Aufwand realisierbar.The invention has the following advantages: better securing of the food support against tipping in the laterally protruding from the baking tray transverse offset position; the ability to make the Querversatzweg larger than in the prior art to facilitate the occupancy of the food support with food for the user person; Reduction of the movement of the food support transverse to the baking carriage required displacement force; the possibility of creating a comfortable safety catch for holding the food support in the parking position; Extractability of the movable telescopic part with the food support both to the right and to the left out of the baking tray in a Querversatzposition, without having to forego the aforementioned advantages. This results in a significant improvement in comfort over the prior art; Existing ovens and baking cars can be provided in a simple manner with low cost with the invention; a full extension, in which the food support from the baking tray in a completely adjacent to the front wall located Querversatzposition is extendable with little effort feasible.

Weitere Merkmale der Erfindung sind in den Unteransprüchen enthalten.Further features of the invention are contained in the subclaims.

Die Erfindung wird im folgenden mit Bezug auf die Zeichnungen anhand von bevorzugten Ausführungsformen als Beispiele beschrieben. In den Zeichnungen zeigen

- Fig.

- 1 schematisch einen Backofen gemäß der Erfindung,

- Fig. 2

- schematisch einen Teil eines Backofen-Backwagens von

Fig. 1 , - Fig. 3

- ein Detail von

Fig. 2 , - Fig. 4

- ein weiteres Detail von

Fig. 2 .

- FIG.

- 1 schematically shows an oven according to the invention,

- Fig. 2

- schematically a part of an oven-baking cart of

Fig. 1 . - Fig. 3

- a detail of

Fig. 2 . - Fig. 4

- another detail from

Fig. 2 ,

Der in

Eine Frontwand 14 des Backwagens 12 bildet eine Backofentür zum Verschließen der Muffelöffnung 8. Der Backwagen ist hinter der Frontwand 14 mit mindestens einer Tragvorrichtung 15 zum Tragen und Querverfahren von mindestens einem Gargutträger 18 von einer Parkposition hinter der Frontwand 14 und einer Querversatzposition versehen, bei welcher der Gargutträger 18 mindestens teilweise über die Frontwand 14 seitlich hinausragt.

Die Tragvorrichtung 15 enthält einen Tragrahmen 16, wie er in

Der Gargutträger 18 ist beispielsweise ein Backblech oder ein Grillrost oder eine andere Vorrichtung zum Tragen oder Halten von Gargut (Speisen jeder Art).The

Die Frontwand kann wie bekannte Backofentüren ein Sichtfenster aus Glas oder durchsichtigem Kunststoff enthalten oder insgesamt aus einem solchen Material bestehen.The front wall may contain a viewing window made of glass or transparent plastic as known oven doors or consist entirely of such a material.

Die Tragvorrichtung 15 weist eine in Wagenquerrichtung angeordnete Teleskopvorrichtung 22 auf, welche einen im Backwagen 12 hinter der Frontwand in der Parkposition am Tragrahmen 16 befestigten oder befestigbaren ortsfesten Teleskopteil 24 und einen relativ dazu in Wagenquerrichtung von der Parkposition seitlich über die Frontwand 14 hinaus in die Querversatzposition bewegbaren Teleskopteil 26 hat. Der bewegbare Teleskopteil 26 ist zur Aufnahme eines Gargutträgers 18 ausgebildet.The carrying

Der bewegliche Teleskopteil 26 ist mit Fixierteilen 30, 31, 32, und 33 zur Fixierung des Gargutträgers 18 versehen, um Relativbewegungen zwischen dem beweglichen Teleskopteil 26 und dem Gargutträger 18 mindestens in Wagenquerrichtung zu begrenzen oder zu sperren. Damit wird nicht nur vermieden, dass der Gargutträger 18 unbeabsichtigt vom beweglichen Teleskopteil 26 herunter rutschen kann, sondern auch der Vorteil erzielt, dass der bewegliche Teleskopteil 26 durch eine auf den Gargutträger 18 wirkende Kraft einer Benutzerperson quer zum Backwagen relativ zum feststehenden Teleskopteil 24 bewegbar ist, ohne dass der bewegliche Teleskopteil 26 von der Benutzerperson berührt zu werden braucht.The movable

Diese Fixierteile 30, 31, 32 und 33 können Abwinkelungen des beweglichen Teleskopteiles 26 oder daran befestigte, z. B. angeschweißte oder angeschraubte Elemente sein, beispielsweise Aufnahmebolzen.

Die beiden Teleskopteile 24 und 26 können plattenartige Körper sein, von welchen der eine im anderen angeordnet ist und relativ zueinander in Wagenquerrichtung verschiebbar ist. Eine gewichtsmäßig wesentlich leichtere und trotzdem stabile Konstruktion besteht darin, dass die Teleskopvorrichtung 22 mindestens zwei in Wagenquerrichtung parallel nebeneinander angeordnete Teleskope 22-1 und 22-2 aufweist, die je eine am Backwagen 12 in der Parkposition befestigte oder befestigbare ortsfeste Teleskopstange 24-1 bzw. 24-2 und eine relativ zu dieser in Stangenlängsrichtung bewegbare Teleskopstange 26-1 bzw. 26-2 aufweisen, wobei die ortsfeste Teleskopstange 24-1 und 24-2 zum ortsfesten Teleskopteil 24 gehört und die bewegliche Teleskopstange 26-1 und 26-2 zum beweglichen Teleskopteil 26 gehört und zur Aufnahme des Gargutträgers 18 ausgebildet ist. Die Teleskopstangen können Profilschienen oder Rohre sein.The two

Jedes Teleskop 22-1 und 22-2 kann anstelle einer einzigen bewegbaren Teleskopstange 26-1 bzw. 26-2 zwei oder mehr bewegbare Teleskopstangen haben, die relativ zueinander in Stangenlängsrichtung bewegbar sind, um einen Gargutträger 18 in eine teilweise oder vorzugsweise vollständig neben der Frontwand 14 gelegene Querversatzposition bewegen zu können. Der Gargutträger 18 befindet sich hierbei auf den am weitesten ausfahrbaren Teleskopstangen.Each telescope 22-1 and 22-2 may have two or more movable telescopic rods instead of a single movable telescopic rod 26-1 and 26-2, respectively, which are movable relative to each other in the bar longitudinal direction to a

Gemäß der bevorzugten Ausführungsform der Erfindung sind zwischen den Teleskopstangen 24-1 und 26-1 des einen Teleskops 22-1 und zwischen den Teleskopstangen 24-2 und 26-2 des anderen Teleskops 22-2 Wälzlager 34 angeordnet, auf welchen die beweglichen Teleskopstangen rollen. Wälzlager können Kugellager, Rollenlager, Kegellager oder ähnliche Lager sein.

Die Fixierteile oder Aufnahmebolzen 30, 31, 32 und 33 verhindern, dass sich die beweglichen Teleskopstangen 26-1 und 26-2 in Stangenlängsrichtung relativ zueinander verschieben können, wenn sich auf ihnen ein Gargutträger 18 befindet. Um eine solche Relatiwerschiebung der beweglichen Teleskopstangen 26-1 und 26-2 relativ zueinander auch dann zu verhindern, wenn sie keinen Gargutträger 18 tragen, ist es vorteilhaft, wenn sie durch mindestens ein Verbindungselement 40 miteinander verbunden sind, so dass sie auch ohne Gargutträger 18 nur gemeinsam relativ zu den ortsfesten Teleskopstangen 24-1 und 24-2 beweglich sind. Das Verbindungselement 40 befindet sich vorzugsweise an dem von den ortsfesten Teleskopstangen 24-1 und 24-2 entfernten Ende der beweglichen Teleskopstangen 26-1 und 26-2. An dieser Stelle ist es von einer Benutzerperson am einfachsten greifbar, um den beweglichen Teleskopteil 26 relativ zum ortsfesten Teleskopteil 24 zu bewegen.The fixing parts or receiving

Zur automatischen Arretierung des beweglichen Teleskopteils 26 in der Parkposition ist mindestens eine Rastenvorrichtung 42 vorgesehen, deren Arretierkraft durch eine auf den beweglichen Teleskopteil 26 in Wagenquerrichtung wirkende manuelle Betätigungskraft überwindbar ist.For automatic locking of the movable

Die Rastenvorrichtung 42 kann am vorderen, der Frontwand 14 benachbarten Ende und/oder am hinteren Ende der Teleskopvorrichtung 22 vorgesehen sein. Die Rastenvorrichtung 42 kann einen Bolzen aufweisen, welcher von einer Feder, z. B. einer Blattfeder oder Schraubenfeder, in Backwagenlängsrichtung gedrängt wird und hinter einer Einrastfläche einrasten kann, wobei einer der beiden Teile Bolzen oder Einrastfläche am beweglichen Teleskopteil 26 und der betreffende andere Teil an einem ortsfesten Teil des Backwagens angeordnet ist, beispielsweise an dem ortsfesten Teleskopteil 24 oder an dem ihn tragenden Tragrahmen16. Die Rastenvorrichtung 42 ist derart ausgebildet, dass eine Benutzerperson den Einrastvorgang an dem bewegbaren Teleskopteil 26 oder dem darauf liegenden Gargutträger 18 durch eine kleine Erschütterung spüren kann. Die Rastenvorrichtung 42 sollte den bewegbaren Teleskopteil 26 auch bei Erschütterungen in der Parkposition sicher halten, damit er nicht seitlich aus dem Backwagen sich herausbewegt. Gleichzeitig sollte die Rastenvorrichtung 42 derart ausgebildet sein, dass von einer Benutzerperson nur eine geringe Kraft erforderlich ist, um den beweglichen Teleskopteil 26 an der Rastenvorrichtung 42 auszurasten und von der Parkposition quer aus dem Backwagen heraus zu bewegen.The

Gemäß der bevorzugten Ausführungsform der Erfindung hat jede Rastenvorrichtung 42 mindestens ein sich in Wagenquerrichtung erstreckendes, in Wagenlängsrichtung federelastisch biegsames, längliches Federelement 44, an welchem mindestens eine Rastfläche gebildet ist, und ein Rastenelement 54 zum Einrasten an der Rastenfläche. Von den beiden Teilen Federelement 44 und Rastenelement 54 ist der eine Teil am ortsfesten Teleskopteil 26 oder dessen Tragrahmen 16 und der andere Teil am beweglichen Teleskopteil 26 geformt oder befestigt ist. Bei der Ausführungsform von

Gemäß der Erfindung ist der bewegbare Teleskopteil 26 von der Parkposition hinter der Frontwand 14 wahlweise in der einen Richtung oder in der anderen Richtung quer aus dem Backwagen herausschiebbar. In der einen Richtung gleitet das Rastenelement 54 über den einen Wellenberg 48, in der anderen Bewegungsrichtung gleitet das Rastenelement 54 über den anderen Wellenberg 50, und drückt dabei das Federelement 44 aus der Bewegungsbahn des Rastenelements 54.According to the invention, the movable

Das längliche Federelement bzw. Federstahldraht 44 ist vorzugsweise nicht nur an einem Ende, sondern beiden Enden mit Abstand von der Wellenform 48, 50, 52 an dem ortsfesten Teleskopteil 24 oder dessen Tragrahmen 16 befestigt. Dadurch wird im Gegensatz zu einem Federelement 44, welches nur an einem Ende befestigt ist, ein unbeabsichtigtes Verbiegen des Federelements und damit ein Nachlassen der Federkraft auf das Rastenelement 54 vermieden.The elongate spring element or

Claims (11)

- Baking carriage with a front wall (14) as baking oven door for closing a baking oven muffle (10) and at least one carrier device (15) behind the front wall (14) for carrying and transverse movement of at least one cooking stock carrier (18) from a parked position behind the front wall (14) to a transversely offset position in which the cooking stock carrier projects laterally at least partly beyond the front wall (14), and which carrier device (15) comprises a telescopic device (22), which is arranged in carriage transverse direction and which comprises a stationary telescopic part (24) and at least one telescopic part (27), which is movable relative thereto in carriage transverse direction from the parked position laterally beyond the front wall (14) to the transversely offset position and which is constructed for reception of the cooking stock carrier (18), characterised in that the telescopic device (22) comprises at least two telescopes (22-1, 22-2), which are arranged parallelly adjacent to one another in carriage transverse direction and which comprise a stationary telescope rod (24-1, 24-2), which is fastened or fastenable to the bakery carriage in the parked position, and a telescope rod (26-1, 26-2), which is movable relative thereto in rod longitudinal direction, wherein the stationary telescope rod (24-1, 24-2) belongs to the stationary telescopic part (24) and the movable telescope rod (26-1, 26-2) belongs to the movable telescopic part (26) and is constructed for reception of the cooking stock carrier (18), which movable telescopic part (26) is movable relative to the stationary telescopic part (24) from the parked position selectably in one or the other carriage transverse direction into a transversely offset position out of the baking carriage in which the movable telescopic part projects at least partly laterally beyond the front wall (14), and that the carrier device (15) has a carrier frame (16) to which the stationary telescope rods (24-1, 24-2) are fastened and which is fastened or fastenable to the rear side of the front wall (14).

- Baking carriage according to claim 1, characterised in that the movable telescopic part has fixing parts (30, 31, 32, 33) for fixing the cooking stock carrier (18) in order to limit or block relative movements between the movable telescopic part (26) and the cooking stock carrier (18) at least in carriage transverse direction.

- Baking carriage according to one of the preceding claims, characterised in that roller bearings on which the movable telescope rods (26-1, 26-2) roll are arranged between the telescope rods (24-1, 26-1; 24-2, 26-2).

- Baking carriage according to at least one of claims 2 and 3, characterised in that the fixing parts (30, 31, 32, 33) are pins at which the cooking stock carrier (18) is positionable.

- Baking carriage according to at least one of the preceding claims, characterised in that the movable telescope rods (26-1, 26-2) are connected together by at least one connecting element (40) so that they are movable only in common relative to the stationary telescope rods (24-1, 24-2).

- Baking carriage according to at least one of the preceding claims, characterised in that at least one detent device (42) by which the movable telescopic part (26) is lockable in the parked position is provided.

- Baking carriage according to claim 6, characterised in that the movable telescopic part (26) can be released by a force, which is exerted on it in carriage transverse direction by a user, from detenting at the detent device (42) so as to be moved from the parked position in direction towards the transversely offset position.

- Baking carriage according to claim 6 or 7, characterised in that the at least one detent device (42) comprises at least one elongate spring element (44), which extends in carriage transverse direction and which is resiliently flexible in carriage longitudinal direction, with at least one detent surface (48, 50, 52) at which a detent element (54) can be detented, wherein of the two parts of spring element (44) and detent element (54) one part is arranged to be stationary and the other part is provided at the movable telescopic part (26).

- Baking carriage according to claim 8, characterised in that the spring element (44) is arranged to be stationary and the detent element (54) is provided at the movable telescopic part (26).

- Baking carriage according to at least one of the preceding claims, characterised in that the rear side of the front wall (14) has a hook device (20) at which the carrier device (15) can be hung.

- Baking oven characterised by a baking carriage according to at least one of the preceding claims.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10211519A DE10211519A1 (en) | 2002-03-15 | 2002-03-15 | Oven and baking cart |

| DE10211519 | 2002-03-15 |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP1344985A2 EP1344985A2 (en) | 2003-09-17 |

| EP1344985A3 EP1344985A3 (en) | 2006-08-23 |

| EP1344985B1 EP1344985B1 (en) | 2007-11-14 |

| EP1344985B2 true EP1344985B2 (en) | 2011-10-26 |

Family

ID=27762935

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03005542A Expired - Lifetime EP1344985B2 (en) | 2002-03-15 | 2003-03-11 | Cooking oven and oven cart |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1344985B2 (en) |

| AT (1) | ATE378555T1 (en) |

| DE (2) | DE10211519A1 (en) |

| ES (1) | ES2295476T5 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015108806A1 (en) | 2015-06-03 | 2016-12-08 | Miele & Cie. Kg | Electric stove with a baking cart |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004031723A1 (en) * | 2004-06-30 | 2006-01-26 | BSH Bosch und Siemens Hausgeräte GmbH | pull-out system |

| DE102004031724B4 (en) * | 2004-06-30 | 2018-10-31 | BSH Hausgeräte GmbH | Pull-out system for household appliances |

| DE102005019956A1 (en) * | 2005-04-29 | 2006-11-02 | Electrolux Home Products Corporation N.V. | Garofenmuffel |

| ES2284331B1 (en) * | 2005-06-15 | 2009-01-01 | Bsh Electrodomesticos España, S.A. | APPLIANCE APPLIANCE. |

| EP2063184B1 (en) | 2007-11-26 | 2010-01-20 | Electrolux Home Products Corporation N.V. | Self cleaning cooking oven |

| EP2090832B1 (en) | 2008-02-15 | 2013-06-12 | Electrolux Home Products Corporation N.V. | Door system for closing a feeding opening of the cooking cavity of a cooking oven |

| DE202008010190U1 (en) * | 2008-07-30 | 2009-12-10 | Paul Hettich Gmbh & Co. Kg | Extractor for a household appliance |

| WO2010076142A2 (en) * | 2008-12-29 | 2010-07-08 | Arcelik Anonim Sirketi | An oven with telescopic rails |

| DE202011105786U1 (en) | 2011-09-16 | 2012-12-17 | Hörauf & Kohler Verwaltungs KG | Rotary damper with freewheel |

| DE102011113617A1 (en) | 2011-09-16 | 2013-03-21 | Hörauf & Kohler Verwaltungs KG | Rotary damper with freewheel |

| EP2830945A4 (en) * | 2012-03-28 | 2015-12-23 | Be Aerospace Inc | Oven having slidable drawer mechanism |

| DE202012104877U1 (en) * | 2012-12-14 | 2013-01-31 | Hans Giesbert Gmbh & Co. Kg | Telescopic rail extension for a drawer-like appliance or furniture body |

| DE202018100849U1 (en) * | 2018-02-15 | 2018-05-02 | Accente Limited | grill |

| DE202018106399U1 (en) * | 2018-11-12 | 2020-02-13 | Grass Gmbh | Guide device for guiding a product carrier in a housing |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7507245U (en) † | 1974-04-02 | 1975-08-07 | De Dietrich & Cie | PULL-OUT SUPPORT FOR COOKER AND BUILT-IN OVEN O DGL |

| DE3924588A1 (en) † | 1989-07-25 | 1991-01-31 | Bosch Siemens Hausgeraete | Food trays for ovens - are hooked behind cooking oven door to slide along rails of open door for individual dish removal from any level |

| DE3628763C2 (en) † | 1986-08-25 | 1993-02-04 | Bosch-Siemens Hausgeraete Gmbh, 8000 Muenchen, De | |

| DE4106809C2 (en) † | 1991-03-04 | 1994-10-27 | Huwil Werke Gmbh | Guide for a drawer |

| DE19817499C1 (en) † | 1998-04-20 | 1999-12-09 | Bsh Bosch Siemens Hausgeraete | Oven with telescopic pull-out |

| DE19949239A1 (en) † | 1999-10-13 | 2001-04-26 | Aeg Hausgeraete Gmbh | Extraction device for at least one cooking item bearer in cooker oven has bearings for rails with bearing balls or rollers consisting of self-lubricating material, at least one their surfaces |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE9406630U1 (en) * | 1994-04-20 | 1994-06-23 | Bosch Siemens Hausgeraete | Oven with a drawer-like oven door |

| DE4444316C2 (en) * | 1994-12-13 | 1999-08-05 | Bosch Siemens Hausgeraete | stove |

| DE20210598U1 (en) * | 2002-07-09 | 2002-09-05 | Moll System & Funktionsmoebel Gmbh | Device for guiding a drawer |

-

2002

- 2002-03-15 DE DE10211519A patent/DE10211519A1/en not_active Withdrawn

-

2003

- 2003-03-11 AT AT03005542T patent/ATE378555T1/en not_active IP Right Cessation

- 2003-03-11 ES ES03005542T patent/ES2295476T5/en not_active Expired - Lifetime

- 2003-03-11 DE DE50308571T patent/DE50308571D1/en not_active Expired - Lifetime

- 2003-03-11 EP EP03005542A patent/EP1344985B2/en not_active Expired - Lifetime

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7507245U (en) † | 1974-04-02 | 1975-08-07 | De Dietrich & Cie | PULL-OUT SUPPORT FOR COOKER AND BUILT-IN OVEN O DGL |

| DE3628763C2 (en) † | 1986-08-25 | 1993-02-04 | Bosch-Siemens Hausgeraete Gmbh, 8000 Muenchen, De | |

| DE3924588A1 (en) † | 1989-07-25 | 1991-01-31 | Bosch Siemens Hausgeraete | Food trays for ovens - are hooked behind cooking oven door to slide along rails of open door for individual dish removal from any level |

| DE4106809C2 (en) † | 1991-03-04 | 1994-10-27 | Huwil Werke Gmbh | Guide for a drawer |

| DE19817499C1 (en) † | 1998-04-20 | 1999-12-09 | Bsh Bosch Siemens Hausgeraete | Oven with telescopic pull-out |

| DE19949239A1 (en) † | 1999-10-13 | 2001-04-26 | Aeg Hausgeraete Gmbh | Extraction device for at least one cooking item bearer in cooker oven has bearings for rails with bearing balls or rollers consisting of self-lubricating material, at least one their surfaces |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015108806A1 (en) | 2015-06-03 | 2016-12-08 | Miele & Cie. Kg | Electric stove with a baking cart |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10211519A1 (en) | 2003-09-25 |

| EP1344985B1 (en) | 2007-11-14 |

| EP1344985A2 (en) | 2003-09-17 |

| EP1344985A3 (en) | 2006-08-23 |

| ATE378555T1 (en) | 2007-11-15 |

| ES2295476T5 (en) | 2012-02-23 |

| DE50308571D1 (en) | 2007-12-27 |

| ES2295476T3 (en) | 2008-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1344985B2 (en) | Cooking oven and oven cart | |

| EP1537365B2 (en) | Baking oven having a linear pull-out element | |

| EP2325565B1 (en) | Guide rail | |

| EP1353128B1 (en) | A width adjustable support frame for use in an household appliance, specially in a cooking- and backing oven | |

| EP1840473A2 (en) | Telescopic device for attachment to a supporting frame in the operational area of a domestic appliance | |

| DE202010008825U1 (en) | Pull-out device for a drawer-like device in a device or furniture body | |

| DE102018132802A1 (en) | Sliding tilt mechanism of a storage of a piece of furniture or household appliance and furniture or household appliance | |

| EP3624637B1 (en) | Lifting mechanism, piece of furniture or domestic appliance, and drawer | |

| EP1459014A1 (en) | Extraction system for a domestic appliance, especially a cooking device | |

| AT401854B (en) | DRAWER | |

| DE19504251A1 (en) | Television transmission vehicle | |

| DE102010029768A1 (en) | Telescopic sliding-out device for household appliance i.e. cooking device, has movable rail provided with support surface on which load carrier is provided, where lowering unit is arranged between front and end sections of support surface | |

| EP2988068A1 (en) | Telescopic drawer system and household cooking appliance | |

| DE202019104414U1 (en) | Pull-out system for especially mobile homes | |

| DE102019217365A1 (en) | Food receptacle for a household refrigerator with coupling rail for coupling with different guide devices, as well as arrangement, system and household refrigerator | |

| DE102006027703A1 (en) | Domestic oven with a horizontally sliding door has extending baking tray carriers mounted on the rear of the door to facilitate loading of the food items | |

| EP0774627B1 (en) | Cooker with a drawer | |

| DE3221926C2 (en) | Pull-out device for a cabinet provided with a furniture body | |

| DE102019124130B4 (en) | Drawer catch that can be deactivated for mounting on a front panel that covers several drawers | |

| DE102020215682A1 (en) | Baking tray and food carrier with specific guide systems, as well as cooking device | |

| DE102004025755A1 (en) | Drawer, has rack with guide devices having projection running in installation position of rack opposite to module direction of drawer, and cooperating with strength transfer of storage linear track | |

| DE202015106729U1 (en) | Pair of rails for a manually longitudinally adjustable vehicle seat | |

| DE102022113764A1 (en) | Quick attachment system for a telescopic extension | |

| EP1506727B1 (en) | Drawer guide | |

| DE2840090A1 (en) | Drawer guide with runners for smooth easy inward movement - has guide rails on drawer sides with three runners preventing jamming |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BSH BOSCH UND SIEMENS HAUSGERAETE GMBH |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20070223 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50308571 Country of ref document: DE Date of ref document: 20071227 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2295476 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080214 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080214 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| 26 | Opposition filed |

Opponent name: AEG HAUSGERAETE GMBH Effective date: 20080729 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| BERE | Be: lapsed |

Owner name: BSH BOSCH UND SIEMENS HAUSGERATE G.M.B.H. Effective date: 20080331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080414 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080829 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080311 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080515 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080311 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: ELECTROLUX ROTHENBURG GMBH FACTORY AND DEVELOPMENT Effective date: 20080729 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20111026 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 50308571 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 50308571 Country of ref document: DE Effective date: 20111026 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2295476 Country of ref document: ES Kind code of ref document: T5 Effective date: 20120223 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 50308571 Country of ref document: DE Owner name: BSH HAUSGERAETE GMBH, DE Free format text: FORMER OWNER: BSH BOSCH UND SIEMENS HAUSGERAETE GMBH, 81739 MUENCHEN, DE Effective date: 20150407 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: BSH HAUSGERATE GMBH Effective date: 20150527 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20180423 Year of fee payment: 16 Ref country code: DE Payment date: 20180331 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50308571 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191001 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190312 |