EP1332282B1 - Electrovanne pour piloter une soupape d'injection de moteur a combustion interne - Google Patents

Electrovanne pour piloter une soupape d'injection de moteur a combustion interne Download PDFInfo

- Publication number

- EP1332282B1 EP1332282B1 EP01980158A EP01980158A EP1332282B1 EP 1332282 B1 EP1332282 B1 EP 1332282B1 EP 01980158 A EP01980158 A EP 01980158A EP 01980158 A EP01980158 A EP 01980158A EP 1332282 B1 EP1332282 B1 EP 1332282B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- armature

- space

- fuel

- solenoid valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M47/00—Fuel-injection apparatus operated cyclically with fuel-injection valves actuated by fluid pressure

- F02M47/02—Fuel-injection apparatus operated cyclically with fuel-injection valves actuated by fluid pressure of accumulator-injector type, i.e. having fuel pressure of accumulator tending to open, and fuel pressure in other chamber tending to close, injection valves and having means for periodically releasing that closing pressure

- F02M47/027—Electrically actuated valves draining the chamber to release the closing pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0014—Valves characterised by the valve actuating means

- F02M63/0015—Valves characterised by the valve actuating means electrical, e.g. using solenoid

- F02M63/0017—Valves characterised by the valve actuating means electrical, e.g. using solenoid using electromagnetic operating means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0014—Valves characterised by the valve actuating means

- F02M63/0015—Valves characterised by the valve actuating means electrical, e.g. using solenoid

- F02M63/0017—Valves characterised by the valve actuating means electrical, e.g. using solenoid using electromagnetic operating means

- F02M63/0021—Valves characterised by the valve actuating means electrical, e.g. using solenoid using electromagnetic operating means characterised by the arrangement of mobile armatures

- F02M63/0022—Valves characterised by the valve actuating means electrical, e.g. using solenoid using electromagnetic operating means characterised by the arrangement of mobile armatures the armature and the valve being allowed to move relatively to each other

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0031—Valves characterized by the type of valves, e.g. special valve member details, valve seat details, valve housing details

- F02M63/0033—Lift valves, i.e. having a valve member that moves perpendicularly to the plane of the valve seat

- F02M63/0036—Lift valves, i.e. having a valve member that moves perpendicularly to the plane of the valve seat with spherical or partly spherical shaped valve member ends

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/02—Fuel-injection apparatus having several injectors fed by a common pumping element, or having several pumping elements feeding a common injector; Fuel-injection apparatus having provisions for cutting-out pumps, pumping elements, or injectors; Fuel-injection apparatus having provisions for variably interconnecting pumping elements and injectors alternatively

- F02M63/0205—Fuel-injection apparatus having several injectors fed by a common pumping element, or having several pumping elements feeding a common injector; Fuel-injection apparatus having provisions for cutting-out pumps, pumping elements, or injectors; Fuel-injection apparatus having provisions for variably interconnecting pumping elements and injectors alternatively for cutting-out pumps or injectors in case of abnormal operation of the engine or the injection apparatus, e.g. over-speed, break-down of fuel pumps or injectors ; for cutting-out pumps for stopping the engine

- F02M63/022—Fuel-injection apparatus having several injectors fed by a common pumping element, or having several pumping elements feeding a common injector; Fuel-injection apparatus having provisions for cutting-out pumps, pumping elements, or injectors; Fuel-injection apparatus having provisions for variably interconnecting pumping elements and injectors alternatively for cutting-out pumps or injectors in case of abnormal operation of the engine or the injection apparatus, e.g. over-speed, break-down of fuel pumps or injectors ; for cutting-out pumps for stopping the engine by acting on fuel control mechanism

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2200/00—Details of fuel-injection apparatus, not otherwise provided for

- F02M2200/30—Fuel-injection apparatus having mechanical parts, the movement of which is damped

- F02M2200/304—Fuel-injection apparatus having mechanical parts, the movement of which is damped using hydraulic means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2547/00—Special features for fuel-injection valves actuated by fluid pressure

- F02M2547/003—Valve inserts containing control chamber and valve piston

Definitions

- the invention relates to an injection valve with a solenoid valve of an internal combustion engine according to the preamble of claim 1.

- Such a solenoid valve of an injection valve which is known for example from DE 196 50 865 A1, is used to control the fuel pressure in the control pressure chamber of an injection valve, for example an injector of a common-rail injection system.

- the fuel pressure in the control pressure chamber controls the movement of a valve piston with which an injection opening of the injection valve is opened or closed.

- the known solenoid valve has a solenoid disposed in a housing part, a movable armature and a moving with the armature and acted upon by a closing spring in the closing direction control valve member which cooperates with a valve seat of the solenoid valve and thus controls the fuel drain from the control pressure chamber.

- the armature is made in two parts with an anchor bolt and an armature plate slidably mounted on the anchor bolt anchor plate.

- solenoid valves with one-piece anchor for controlling injectors known in which the anchor bolt is firmly connected to the anchor plate.

- a disadvantage of the known solenoid valves of injection valves is the so-called anchor bounce.

- the anchor plate is slidably mounted on the anchor bolt, so that the armature plate on impact of the control valve member on the valve seat against the clamping force of a return spring moves on.

- the armature plate can oscillate after closing the solenoid valve on the anchor bolt, so that additional measures are required to the unwanted Nachschwingen to dampen the anchor plate.

- an armature leading slider in the armature space of the solenoid valve is arranged such that the armature space is divided into a connected to a fuel low-pressure port relief space and a hydraulic damping chamber, in which the fuel drain passage from the Control pressure chamber opens.

- the damping chamber is connected via at least one provided with a throttle connection channel with the discharge chamber.

- the control valve member moves in the damping chamber to the valve seat.

- the resulting rapid displacement of the fuel in the damping chamber which can not escape immediately through the throttle provided with the connecting channel in the discharge chamber, thereby advantageously the formation of a fuel pressure pad, which counteracts the movement of the control valve member and this brakes together with the armature, so that the pulse transmitted to the valve seat when the control valve member abuts the valve seat is reduced.

- the armature bouncing, or the bouncing movement of the control valve member on the valve seat can be reduced.

- main injection and post-injection can be advantageously set because the anchor takes less time to take a defined rest position. This is especially true for solenoid valves, in which the anchor plate is formed integrally with the anchor bolt.

- One-piece anchors can be advantageously manufactured with less effort and allow a significant reduction in costs.

- the pressure pad generated in the damping chamber advantageously reduces the seat load of the valve seat at high closing forces.

- the slider comprises an armature sleeve guiding the armature and a flange forming a partition between the damping chamber and the relief space, with which the slider is clamped in the armature space stationary.

- the at least one connecting channel through a passage opening provided with a throttle in the flange region of the slider, since the production of the connecting channel in the slider is particularly easy to carry out in terms of manufacturing technology.

- the at least one passage opening is disposed within the projection of the armature plate in the direction of movement of the armature, it is achieved that the fuel flowing from the damping chamber into the discharge space fuel flows against the armature plate and thereby supports the braking operation of the armature.

- the throttle portion of the at least one connecting channel is formed by a slot in the damping chamber and provided with the valve seat end face of a valve inserted into the housing of the injector valve piece, wherein the slot covered by a damping chamber partially limiting support member becomes.

- the support member may for example be a valve member in the housing chucking screw member.

- a portion of the connecting channel which connects the damping chamber with the discharge chamber formed by a formed in the housing of the injection valve leakage channel.

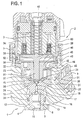

- Fig. 1 shows the upper part of a fuel injection valve 1, which is intended for use in a fuel injection system, which is equipped with a high-pressure fuel storage, which is continuously supplied by a high-pressure feed pump with high-pressure fuel.

- the fuel injection valve 1 shown has a valve housing 4 with a longitudinal bore 5, in which a valve piston 6 is arranged, which acts with its one end to a valve needle, not shown, in a nozzle body, not shown.

- the valve needle is arranged in a pressure chamber in the lower part of the injection valve 1, not shown, which is supplied via a pressure bore 8 with fuel under high pressure.

- valve needle In an opening stroke of the valve piston 6, the valve needle is raised by the constantly acting on a pressure shoulder of the valve needle high fuel pressure in the pressure chamber against the closing force of a spring, not shown. By then connected to the pressure chamber injection port, the injection of the fuel takes place in the combustion chamber of the internal combustion engine. By lowering the valve piston 6, the valve needle is pressed in the closing direction in the valve seat, not shown, of the injection valve and the injection process terminated.

- valve piston 6 is guided at its end facing away from the valve needle in a cylinder bore 11 which is incorporated in a valve member 12 which is inserted into the valve housing 4.

- the end face 13 of the valve piston 6 includes a control pressure chamber 14, which is connected via an inlet channel with a high-pressure fuel connection is.

- the inlet channel is formed substantially in three parts.

- a radially through the wall of the valve member 12 leading bore whose inner walls form part of their length an inlet throttle 15 is connected to the valve member 12 peripherally surrounding annular space 16 is constantly connected, which in turn via an inserted into the inlet channel fuel filter 31 in constant communication with the high-pressure fuel connection of a screwed into the valve housing 4 connecting piece 9 is.

- the annular space 16 is sealed by a sealing ring 39 to the longitudinal bore 5.

- About the inlet throttle 15 of the control pressure chamber 14 is exposed to the ruling in high-pressure fuel storage high fuel pressure.

- Coaxially to the valve piston 6 branches off from the control pressure chamber 14 extending in a valve piece 12 bore, which forms a provided with an outlet throttle 18 fuel drain passage 17.

- the outlet of the fuel discharge channel 17 from the valve piece 12 takes place in the region of a conically countersunk portion 21 of the outer end face 20 of the valve piece 12.

- the valve piece 12 is clamped with a screw member 23 in a flange 22 fixed to the valve housing 4.

- the opening and closing of the injection valve is controlled by means of a solenoid valve which opens and closes the fuel drain passage 17 and thereby controls the pressure in the control pressure chamber.

- a solenoid valve which opens and closes the fuel drain passage 17 and thereby controls the pressure in the control pressure chamber.

- With closed fuel drain passage 17 of the control pressure chamber 14 is closed to the discharge side, so that very quickly builds up there on the inlet channel of high pressure, which is also present in the high-pressure fuel storage.

- Over the surface of the end face 13 of the pressure in the control pressure chamber 14 generates a closing force on the valve piston 6 and the valve needle associated therewith, which is greater than the forces acting on the other hand in the opening direction due to the upcoming high pressure.

- control pressure chamber 14 by opening the solenoid valve open to the discharge side, the pressure in the small volume of the control pressure chamber 14 builds up very quickly, since it is decoupled via the inlet throttle 15 from the high pressure side.

- the force acting on the valve needle in the opening direction outweighs the force applied to the valve needle high pressure fuel, so that it moves upward while the at least one injection port is opened for injection.

- closes the solenoid valve 30, the fuel drain passage 17, the pressure in the control pressure chamber 14 can be rebuilt by the inflowing over the inlet channel 15 fuel so that the original closing force is present and the valve needle of the fuel injection valve closes.

- a preferred embodiment of the injection valve according to the invention with a solenoid valve 2 is shown, which is shown below.

- a valve seat 24 is formed with which a control valve member 25, 26 of a solenoid valve 2 controlling the injection valve cooperates.

- the control valve member of the solenoid valve 2 comprises a ball 25 and a ball-receiving guide piece 26 which is coupled to an armature 29 which cooperates with an electromagnet 34 of the solenoid valve.

- the solenoid valve 2 further comprises a housing part 60 which shelters the electromagnet 34 and which is fixedly connected to the valve housing 4 via screwable connection means 7.

- the armature 29 is integrally formed with an anchor plate 28 and an anchor bolt 27 and arranged in an armature space 51,52 of the solenoid valve 2.

- the armature 29 and coupled to the anchor bolt 27 control valve member 25,26 are constantly acted upon by a housing firmly supporting closing spring 3 in the closing direction of the solenoid valve so that the control valve member 25,26 normally rests in the closed position on the valve seat 24 and the fuel drain passage 17 closes.

- a slider 40 is arranged in the armature space, which guides the movable armature 29.

- the slider 40 includes a flange portion 42 and a sleeve 41 in which the anchor bolt 27 of the armature 29 is slidably mounted.

- the flange portion 42 of the slider 40 is firmly clamped together with a spacer ring 38 between the housing part 60 and a shoulder 32 of the housing part 4 of the injection valve.

- the slider 40 divides the armature space in a relief space 52 which is connected to a fuel low-pressure port 10 of the injection valve, and a hydraulic damping chamber 51, in which the fuel drain passage 17 opens.

- the flange region 42 forms a partition wall between the damping chamber 51 and the relief chamber 52, wherein a first side 45 of the flange region 42 faces the damping chamber 51 and a second side 46 faces the relief chamber 52.

- the sliding sleeve 41 projects toward the valve seat 24 in such a way that an annular space formed between the sliding sleeve 41 and the screw member 23 is connected to the conically countersunk portion 21 of the valve piece 12.

- the volume of the annular space is more than twice as large as the inner volume of the tapered portion 21 and comprises most of the damping chamber 51.

- the flange portion 41 is further provided with two through holes 44, each having a throttle 43 and a respective connecting channel between the Damping chamber 51 and the discharge chamber 52 form.

- the passage openings 44 are diametrically opposite with respect to the anchor bolt 27 and are preferably formed as bores.

- the diameter of the two throttle bodies 43 is for example 0.6 mm.

- the armature plate 28 When opening the solenoid valve, the armature plate 28 is attracted by the electromagnet 34 and thereby open the fuel drain passage 17 to the armature space 51,51 out.

- the from the with The throttle 18 provided fuel drain passage 17 flowing fuel first passes into the damping chamber 51 and from there via the throttles 43 provided through holes 44 in the discharge chamber 52 which is connected to the fuel low-pressure port 10, which in turn in a manner not shown with a fuel return of the injector 1 is connected.

- the volume of the damping chamber 51 and the throttles 43 are matched to one another such that when the solenoid valve is open, an approximately constant fuel pressure in the damping chamber 51 prevails.

- the closing spring 3 moves the anchor bolt 27 with the control valve member 25,26 toward the valve seat 24. Due to the control valve member penetrating into the damping chamber, fuel is displaced in the damping chamber, which can not immediately escape completely into the relief chamber 52 through the throttle passage 44, so that the pressure in the damping chamber increases and the movement of the control valve member is limited by a fuel pressure. Pressure pad is braked, which acts on the control valve member 25,26 and the lower part of the anchor bolt 27 against the closing direction of the anchor bolt. As a result, the armature is braked so that the pulse transmitted to the valve seat 24 at the stop of the control valve member 25, 26 is reduced.

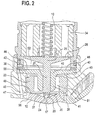

- FIG. 2 A further embodiment of the injection valve according to the invention with a solenoid valve 2 is shown in Fig. 2. Identical parts are provided with the same reference numerals.

- the embodiment in Fig. 2 differs from the embodiment in Fig. 1 in particular in that the flange portion 42 has no through holes.

- the connecting channel between the damping chamber 51 and the relief chamber 52 is in this embodiment by a slot 48 in the provided with the valve seat 24 end face 20 of the valve member 12, a valve member surrounding the annular space 56, a transverse bore 47 in the housing part 4 of the injector, a leakage Channel 49 and a recess 55 in the second side 46 of the flange portion 42 of the slider 40 is formed.

- the slot 48 is covered by a cushioning space 51 partially limiting support member 23.

- the support member is a valve member 12 in the housing part 4 chucking screw member.

- the covered by the screw member 23 slot 48, which connects the countersunk portion 21 on the end face 20 of the valve member 12 with the annular space 56 is formed as a throttle channel.

- the throttle channel formed by the slot 48 and the screw member 23 has in the in Fig 2, the same function as the chokes 43 in the first embodiment shown in FIG.

- the leakage channel 49 serves to return leaking fuel from the longitudinal bore 5 in the fuel return of the injector and is provided anyway in most injectors.

- the leakage channel 49 advantageously also forms a section of the connecting channel between the damping chamber 51 and the relief space 52.

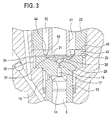

- a third embodiment is shown.

- the guided through the sliding sleeve 41 anchor 29 is not shown.

- the sliding sleeve 41 for guiding the armature is in this embodiment on the side remote from the valve piece second side 46 of the flange of this from.

- the screw member 23 biases the sliding sleeve 41 together with the valve member 12 in the housing part. 4 on.

- at least one recess 54 is provided on the end face 20 of the valve piece, which connects the conical, countersunk portion 21 on the end face 20 of the valve piece 12 with the annular space 56.

- the at least one recess 54 is formed so large that, unlike the embodiment shown in FIG. 2, it does not act as a throttle.

- the damping space is formed by the annulus 56 and the tapered volume above the countersunk portion 21.

- the volume of the annular space 56 is more than twice as large as the volume above the countersunk portion 21.

- the damping chamber 51 via two through holes 44, each having a throttle 43, with the discharge chamber 52nd connected.

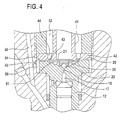

- a fourth embodiment of the injection valve according to the invention with a solenoid valve 2 is shown in Fig. 4.

- the flange portion 42 of the sliding sleeve 41 has through holes.

- the damping chamber 51 is formed as in the embodiment shown in FIG. 3 by the conical volume over the countersunk portion 21 and the annular space 56, which are interconnected by at least one recessed into the end face of the valve piece 12 recess 54.

- the at least one recess 54 is sufficiently large so as not to act as a throttle.

- One in the side wall of the housing part 4 provided throttle 43 connects the annular space 56 with a leakage channel 49, which in turn is connected to the discharge chamber 52.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Fluid Mechanics (AREA)

- Fuel-Injection Apparatus (AREA)

Abstract

Claims (10)

- Injecteur comportant une soupape électromagnétique (2) formée d'un électroaimant (34), d'un induit mobile (29), d'un organe de commande (25, 26) coopérant avec un siège de soupape (24) pour ouvrir et fermer un canal de sortie de carburant (17) d'une chambre de pression de commande (14) de l'injecteur ainsi qu'une pièce de glissement (40) guidant l'induit (29) et logée avec l'induit (29) et l'organe de commande (25, 26) dans une chambre d'induit (51, 52),

caractérisé en ce que

la pièce de glissement (40) subdivise la chambre d'induit en une chambre de décharge (52) reliée au branchement basse pression de carburant (10) et une chambre d'amortissement hydraulique (51) dans laquelle débouche le canal de sortie de carburant (17), cette chambre d'amortissement pouvant être déchargée par l'intermédiaire d'au moins un canal de liaison (44, 47) muni d'un organe d'étranglement (43, 48) vers la chambre de décharge (52),

la vitesse de l'organe de commande de soupape (25, 26), lors de la fermeture de l'électrovanne (2), avant sa butée contre le siège de soupape (24), étant diminuée par un coussin de carburant sous pression dans la chambre d'amortissement (51) et agissant sur l'organe de commande de soupape (25, 26). - Injecteur comportant une électrovanne selon la revendication 1,

caractérisé en ce que

le volume de la chambre d'amortissement (51) et celui d'au moins un organe d'étranglement (43) sont définis l'un par rapport à l'autre de façon que lorsque l'électrovanne est ouverte, il règne une pression de carburant sensiblement constante dans la chambre d'amortissement (51). - Injecteur comportant une électrovanne selon les revendications 1 ou 2,

caractérisé en ce que

la pièce de glissement (40) comporte une chemise (41) guidant l'induit (29) et une zone de bride (42) formant une cloison entre la chambre d'amortissement (51) et le chambre de décharge (52), par laquelle la pièce de glissement (41) est bloquée dans la chambre d'induit (51, 52). - Injecteur comportant une électrovanne selon la revendication 3,

caractérisé en ce qu'

au moins un canal de liaison est réalisé par un orifice de passage (44) muni d'un organe d'étranglement (43) dans la zone de bride (42) de la pièce de glissement (40). - Injecteur comportant une électrovanne selon la revendication 4,

caractérisé en ce que

l'orifice de passage (44) est prévu dans la projection du plateau d'induit (28) dans la direction de déplacement de l'induit (29). - Injecteur comportant une électrovanne selon la revendication 3,

caractérisé en ce que

la chemise (41) guidant l'induit (29) s'écarte de la zone de bride (42) en direction du siège de soupape (24). - Injecteur comportant une électrovanne selon l'une des revendications 1 à 3,

caractérisé en ce que

le segment d'étranglement d'au moins un canal de liaison est formé par une fente (48) dans une face frontale (20) tournée vers la chambre d'amortissement (51) et munie d'un siège de soupape (24), appartenant à une pièce de soupape (12) placée dans le corps (4) de l'injecteur (1), la fente (48) étant couverte par une pièce d'appui (23) délimitant partiellement la chambre d'amortissement (51). - Injecteur comportant une électrovanne selon la revendication 7,

caractérisé en ce que

la pièce d'appui (23) est un élément vissé serrant la pièce de soupape (12) dans le corps (4). - Injecteur comportant une électrovanne selon les revendications 7 ou 8,

caractérisé en ce que

la fente (48) relie un segment (21) en retrait, muni du siège de soupape (24) de la face frontale (20) de la pièce de soupape (12), à un volume annulaire (56) entourant la pièce de soupape (12), ce volume annulaire étant relié à la chambre de décharge (52) par d'autres segments (47, 49, 55) du canal de liaison. - Injecteur comportant une électrovanne selon la revendication 9,

caractérisé en ce qu'

un segment du canal de liaison est formé par un canal de fuite (49) réalisé dans le corps (4) de l'injecteur (1).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10052604A DE10052604A1 (de) | 2000-10-24 | 2000-10-24 | Magnetventil zur Steuerung eines Einspritzventils einer Brennkraftmaschine |

| DE10052604 | 2000-10-24 | ||

| PCT/DE2001/003396 WO2002035080A2 (fr) | 2000-10-24 | 2001-09-05 | Electrovanne pour piloter une soupape d'injection de moteur a combustion interne |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1332282A2 EP1332282A2 (fr) | 2003-08-06 |

| EP1332282B1 true EP1332282B1 (fr) | 2006-11-29 |

Family

ID=7660822

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01980158A Expired - Lifetime EP1332282B1 (fr) | 2000-10-24 | 2001-09-05 | Electrovanne pour piloter une soupape d'injection de moteur a combustion interne |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6820858B2 (fr) |

| EP (1) | EP1332282B1 (fr) |

| JP (1) | JP5044090B2 (fr) |

| DE (2) | DE10052604A1 (fr) |

| WO (1) | WO2002035080A2 (fr) |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10131125A1 (de) * | 2001-06-28 | 2002-09-12 | Bosch Gmbh Robert | Magnetventil mit gedämpftem, einteiligem Ankerelement |

| JP4052258B2 (ja) * | 2003-05-01 | 2008-02-27 | 株式会社デンソー | 内燃機関用インジェクタ |

| DE10325442A1 (de) * | 2003-06-05 | 2004-12-23 | Robert Bosch Gmbh | Magnetventil mit reduzierten Schaltgeräuschen |

| US20050104301A1 (en) * | 2003-11-18 | 2005-05-19 | Carter Stephen A. | Sealing system for a solenoid |

| US7337768B2 (en) * | 2004-05-07 | 2008-03-04 | Philip Morris Usa Inc. | Multiple capillary fuel injector for an internal combustion engine |

| DE102004028523A1 (de) * | 2004-06-11 | 2005-12-29 | Robert Bosch Gmbh | Kraftstoffinjektor mit Spannhülse als Anschlag für Ventilnadel |

| ATE503105T1 (de) * | 2005-01-07 | 2011-04-15 | Delphi Technologies Holding | Kraftstoffeinspritzvorrichtung |

| ES2335596T3 (es) * | 2005-02-08 | 2010-03-30 | Robert Bosch Gmbh | Fijacion de una armadura a una aguja de valvula en una valvula de control de inyector de combustible. |

| DE102005024045A1 (de) * | 2005-05-25 | 2006-11-30 | Robert Bosch Gmbh | Injektor für ein Kraftstoffeinspritzsystem |

| DE102005045856A1 (de) * | 2005-09-26 | 2007-04-05 | Siemens Ag | Injektor mit außenöffnendem Servoventil |

| DE102005057948A1 (de) * | 2005-12-05 | 2007-06-06 | Robert Bosch Gmbh | Brennstoffeinspritzventil |

| US8127791B2 (en) * | 2005-12-21 | 2012-03-06 | Saturn Electronics & Engineering, Inc. | Solenoid operated fluid control valve |

| DE102006003040A1 (de) * | 2006-01-23 | 2007-07-26 | Robert Bosch Gmbh | Kraftstoffinjektor |

| DE102006050162A1 (de) | 2006-10-25 | 2008-04-30 | Robert Bosch Gmbh | Kraftstoffeinspritzventileinrichtung |

| DE102007001550A1 (de) * | 2007-01-10 | 2008-07-17 | Robert Bosch Gmbh | Injektor zum Einspritzen von Kraftstoff |

| US7871058B2 (en) * | 2007-07-25 | 2011-01-18 | Illinois Tool Works Inc. | Dual inline solenoid-actuated hot melt adhesive dispensing valve assembly |

| DE102007047152A1 (de) * | 2007-10-02 | 2009-04-09 | Robert Bosch Gmbh | Injektor mit einem Ringraum getrennten Ankerraum |

| DE102008000907A1 (de) * | 2008-04-01 | 2009-10-08 | Robert Bosch Gmbh | Magnetventil mit mehrteiligem Anker ohne Ankerführung |

| DE102008000929A1 (de) * | 2008-04-02 | 2009-10-08 | Robert Bosch Gmbh | Hydraulische Dämpfung |

| DE102008000926A1 (de) * | 2008-04-02 | 2009-10-08 | Robert Bosch Gmbh | Kraftstoffinjektor mit Magnetventil |

| DE102008001281A1 (de) * | 2008-04-21 | 2009-10-22 | Robert Bosch Gmbh | Injektor |

| DE102010043092A1 (de) * | 2010-10-29 | 2012-05-03 | Robert Bosch Gmbh | Druckregelventil |

| DE102012209226A1 (de) * | 2012-05-31 | 2013-12-05 | Robert Bosch Gmbh | Druckregelventil |

| EP2778386B1 (fr) * | 2013-03-13 | 2016-03-09 | Delphi International Operations Luxembourg S.à r.l. | Ensemble soupape de commande et injecteur de carburant comprenant un ensemble soupape de commande |

| US9644589B2 (en) * | 2013-11-20 | 2017-05-09 | Stanadyne Llc | Debris diverter shield for fuel injector |

| DE102015204037A1 (de) * | 2015-03-06 | 2016-09-08 | Robert Bosch Gmbh | Verfahren zur Steuerung eines Common-Rail-Einspritzsystems |

| DE102016209546A1 (de) * | 2016-06-01 | 2017-12-07 | Robert Bosch Gmbh | Kraftstoffeinspritzventil |

| US20230078232A1 (en) * | 2020-02-13 | 2023-03-16 | Padmini Vna Mechatronics Pvt. Ltd. | Oil solenoid valve with real time monitoring of plunger position |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8729087D0 (en) * | 1987-12-12 | 1988-01-27 | Lucas Ind Plc | Control valve |

| JPH0688559A (ja) * | 1992-09-08 | 1994-03-29 | Toyota Motor Corp | 燃料噴射弁 |

| IT227711Y1 (it) * | 1992-12-29 | 1997-12-15 | Elasis Sistema Ricerca Fiat | Valvola di dosaggio a comando elettromagnetico per un iniettore di combustibile |

| IT1276503B1 (it) * | 1995-07-14 | 1997-10-31 | Elasis Sistema Ricerca Fiat | Perfezionamenti ad una valvola di dosaggio a comando elettromagnetico, per un iniettore di combustibile. |

| JPH1082356A (ja) * | 1996-09-09 | 1998-03-31 | Denso Corp | 蓄圧式燃料噴射装置 |

| DE19650865A1 (de) * | 1996-12-07 | 1998-06-10 | Bosch Gmbh Robert | Magnetventil |

| DE19708104A1 (de) * | 1997-02-28 | 1998-09-03 | Bosch Gmbh Robert | Magnetventil |

-

2000

- 2000-10-24 DE DE10052604A patent/DE10052604A1/de not_active Withdrawn

-

2001

- 2001-09-05 US US10/168,671 patent/US6820858B2/en not_active Expired - Fee Related

- 2001-09-05 DE DE50111569T patent/DE50111569D1/de not_active Expired - Lifetime

- 2001-09-05 WO PCT/DE2001/003396 patent/WO2002035080A2/fr active IP Right Grant

- 2001-09-05 JP JP2002538036A patent/JP5044090B2/ja not_active Expired - Fee Related

- 2001-09-05 EP EP01980158A patent/EP1332282B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1332282A2 (fr) | 2003-08-06 |

| US6820858B2 (en) | 2004-11-23 |

| WO2002035080A3 (fr) | 2002-07-18 |

| DE50111569D1 (de) | 2007-01-11 |

| JP5044090B2 (ja) | 2012-10-10 |

| US20030127614A1 (en) | 2003-07-10 |

| JP2004512457A (ja) | 2004-04-22 |

| DE10052604A1 (de) | 2002-05-02 |

| WO2002035080A2 (fr) | 2002-05-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1332282B1 (fr) | Electrovanne pour piloter une soupape d'injection de moteur a combustion interne | |

| EP1259729B1 (fr) | Electrovanne destinee a la commande d'une soupape d'injection d'un moteur a combustion interne | |

| DE19650865A1 (de) | Magnetventil | |

| WO2002053905A1 (fr) | Electrovanne destinee a commander la soupape d'injection d'un moteur a combustion interne | |

| EP1342005B1 (fr) | Systeme d'injection de carburant pour moteurs a combustion interne | |

| EP1387937B1 (fr) | Soupape d'injection de carburant pour moteurs a combustion, comprenant une chambre d'amortissement reduisant les oscillations de pression | |

| EP1390614B1 (fr) | Electrovanne de commande de soupape d'injection de moteur a combustion interne | |

| EP1348074A1 (fr) | Electrovalve pour la commande d'une soupape d'injection d'un moteur a combustion interne | |

| WO2000019089A1 (fr) | Soupape d'injection de carburant pour moteurs a combustion interne | |

| EP1339969B1 (fr) | Electrovanne destinee a la commande d'un injecteur d'un moteur a combustion interne | |

| DE10335059A1 (de) | Schaltventil für einen Kraftstoffinjektor mit Druckübersetzer | |

| DE102007043538A1 (de) | Injektor mit hydraulischem Dämpfer | |

| EP2743493B1 (fr) | Injecteur de carburant | |

| WO2007141094A1 (fr) | Dispositif d'injection de carburant pour un moteur à combustion interne | |

| EP1135606B1 (fr) | Soupape d'injection de carburant pour moteurs a combustion interne | |

| EP1483498A1 (fr) | Dispositif d'injection de carburant pour un moteur a combustion interne | |

| DE10009037A1 (de) | Steuerventil für eine Kraftstoff-Einspritzdüse | |

| EP1537300A1 (fr) | Actionneur hydraulique de soupape servant a actionner une soupape d'echange de gaz | |

| DE102007005382A1 (de) | Leckagefreier Injektor | |

| EP1483499A1 (fr) | Systeme pour moduler en pression le comportement d'injection | |

| DE10132249A1 (de) | Kraftstoffinjektor mit kraftausgeglichenem Steuerventil | |

| DE102007034319A1 (de) | Injektor | |

| EP1911966A2 (fr) | Injecteur de carburant pour un moteur à combustion interne | |

| DE10132248A1 (de) | Kraftstoffinjektor mit 2-Wege-Ventilsteuerung | |

| WO2009138279A1 (fr) | Vanne magnétique à fentes d'induit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20030526 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE FR IT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR IT |

|

| REF | Corresponds to: |

Ref document number: 50111569 Country of ref document: DE Date of ref document: 20070111 Kind code of ref document: P |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070830 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20120926 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20121008 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R084 Ref document number: 50111569 Country of ref document: DE Effective date: 20130617 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130905 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20161125 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50111569 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180404 |