EP1302428A1 - Yarn splicer - Google Patents

Yarn splicer Download PDFInfo

- Publication number

- EP1302428A1 EP1302428A1 EP02016537A EP02016537A EP1302428A1 EP 1302428 A1 EP1302428 A1 EP 1302428A1 EP 02016537 A EP02016537 A EP 02016537A EP 02016537 A EP02016537 A EP 02016537A EP 1302428 A1 EP1302428 A1 EP 1302428A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- thread

- splicing device

- channel

- splice

- compressed air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H69/00—Methods of, or devices for, interconnecting successive lengths of material; Knot-tying devices ;Control of the correct working of the interconnecting device

- B65H69/06—Methods of, or devices for, interconnecting successive lengths of material; Knot-tying devices ;Control of the correct working of the interconnecting device by splicing

- B65H69/061—Methods of, or devices for, interconnecting successive lengths of material; Knot-tying devices ;Control of the correct working of the interconnecting device by splicing using pneumatic means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Definitions

- the invention relates to a thread splicing device according to the Preamble of claim 1.

- Thread splicers are related to Automatic winding machines have been known for a long time and in numerous IP applications are described in detail.

- DE 39 35 536 C2 describes, for example, a pneumatic thread splicing device with a splice head that has a splice channel that is almost circular in cross section. Tangentially arranged compressed air injection openings open into the splice channel, which has a continuous slot on the top for inserting the thread ends to be spliced. The thread insertion slot and thus the splice channel is closed by a cover element during the splicing process.

- the thread ends to be spliced are prepared, that is, the thread ends are at least partially freed from their twist.

- the thread ends can either be pneumatically, as described in DE 39 35 536 C2, via so-called thread-end opening tubes or, as described for example in DE 30 29 452 C2, mechanically by means of two counter-rotating friction disks.

- the The invention is therefore based on the object Thread splicer to create that allows it too problematic yarns, especially fine and very fine yarns, connect securely.

- a splice head according to the invention with at least one preferably centrally arranged compressed air injection opening and at least two further suction openings in the region of the splice channel which can be subjected to negative pressure has the particular advantage that the fibers which are largely parallel after the preparation of the thread ends are also securely in the splice channel during the actual splicing process stay fixed. This means that the pneumatic fixing of the fibers in the splice channel enables material to accumulate in the area of the connection openings, which makes it possible to create durable splices even with fine and very fine yarns.

- suction openings under pressure in particular with mechanically prepared thread ends, that is to say with thread ends that have been turned between two counter-rotating friction disks, enable the neutralized thread rotation to be retained or stored until the actual splicing process.

- This stored thread rotation can be released after the splicing process has taken place and then brings further strength to the thread connection point.

- the individual suction openings are connected to a vacuum source via a common pneumatic line.

- suction openings are connected to a separate vacuum source.

- a pneumatic decoupling of the splicing device according to the invention from the regular vacuum system of the textile machine can ensure a largely uniform quality of the splice connections, since pressure fluctuations, which are almost inevitable in the vacuum system of a textile machine, can no longer affect the thread splicing device.

- the separate vacuum source is designed, for example, as an injector nozzle (Claim 5).

- an injector nozzle (Claim 5).

- the use of such an injector nozzle is a cost-effective way to easily implement a reliable, additional vacuum generator.

- the suction openings which can be subjected to negative pressure advantageously open into the wear channel in the region of the channel base.

- the channel base has a U-shaped or V-shaped cross section, as set out in claims 7 and 8, respectively.

- Such an advantageous shape of the splice channel base favors the parallel alignment of the fibers of the thread ends to be spliced and thereby leads to a uniform accumulation of material in the splice channel base.

- FIG. 1 shows a front view of a textile machine, generally designated with the reference number 1, which in the exemplary embodiment is an automatic winder.

- Such automatic winding machines usually have a large number of similar work stations, in the present case winding stations 2, between their end frames (not shown).

- winding stations 2 On these winding units 2, as is known and therefore not explained in more detail, spinning reels 9, which were produced, for example, on a ring spinning machine, are rewound to form large-volume cross-wound bobbins 15.

- cross-wound bobbins 15 are transferred to a machine-long cross-wound bobbin transport device 21 by means of an automatically operating service unit, preferably a cross-wound bobbin changer (not shown) and transported to a bobbin loading station or the like arranged on the machine end.

- an automatically operating service unit preferably a cross-wound bobbin changer (not shown) and transported to a bobbin loading station or the like arranged on the machine end.

- Such automatic winding machines 1 usually also have a logistic device in the form of a bobbin and tube transport system 3, in which spinning heads 9 or empty tubes circulate on transport plates 8 in a vertical orientation.

- a logistic device in the form of a bobbin and tube transport system 3, in which spinning heads 9 or empty tubes circulate on transport plates 8 in a vertical orientation.

- the cop feed path 4 the reversibly drivable storage path 5, one of the transverse transport paths 6 leading to the winding stations 2 and the core return path 7 are shown in FIG.

- Such automatic winding machines 1 generally have via a (not shown) central control unit, which via a machine bus with both the separate Workstation computers 29 of the individual winding units 2 as well connected to a control device of the service unit is.

- the delivered spinning heads 9 are in the Unwinding positions AS, which are each located in the area of the transverse transport sections 6 at the winding stations 2, are rewound to form large-volume cross-wound bobbins 15.

- Unwinding positions AS which are each located in the area of the transverse transport sections 6 at the winding stations 2, are rewound to form large-volume cross-wound bobbins 15.

- the individual winding units have various devices which ensure that these workplaces operate properly.

- the thread connecting device 10 is preferably designed as a pneumatic splicer. As indicated in FIG. 1, the pneumatic thread splicing device 10 is somewhat set back with respect to the regular thread run and, as indicated in FIG. 2, has an upper thread clamping and cutting device 11 and a lower thread clamping and cutting device 17.

- Such winding units 2 also have more, not facilities shown in greater detail, such as a thread tensioner, a thread cleaner, a waxing device, a Thread cutting device, a thread tension sensor and one Bobbin thread sensor.

- winding devices 24 have, among other things, a bobbin frame 28 which is movably mounted about a pivot axis 13 and has a device for rotatably holding a bobbin.

- the surface of the cross-wound bobbin 15, which is freely rotatably mounted in the bobbin frame 28, lies on a grooved drum 14 and is carried along by this via frictional engagement.

- each winding unit 2 has a suction nozzle 12 and a gripper tube 25.

- the suction nozzle 12 is rotatably supported to a limited extent about a pivot axis 16, the gripper tube 25 about a pivot axis 26.

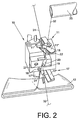

- FIG. 2 shows a perspective view of the thread connecting device 10, the suction nozzle 12 standing in a thread insertion position and the hook tube 25 arranged in a corresponding thread insertion position.

- the suction nozzle 12 has retrieved the upper thread 31 from the cheese 15 and inserted it into the splice channel 20 of the splice head 19.

- the lower thread 32 connected to the spinning cop 9 which is usually fixed in a thread tensioner (not shown) after a thread break, was picked up by the hook tube 25 and likewise inserted into the splice channel 20.

- the splice head 19 is connected, for example, via a screw connection 27 to a base body 22 which has a plurality of pneumatic connections and in which, among other things, pneumatically actuated thread preparation tubes 18 are inserted.

- a thread clamping and cutting device 11 and 17 is arranged above and below the base body 22 of the thread splicing device 10.

- the upper thread 31 lies in the cutting element 17 ′′ of the thread clamping and cutting device 17 arranged below and in the clamping element 11 ′ of the upper thread clamping and cutting device 11.

- the lower thread 32 is correspondingly in the clamping element 17 ′ of the lower thread cutting and clamping device 17 held and crosses the cutting element 11 ′′ of the upper thread cutting and clamping device 11.

- FIG. 3 shows a front view of another Embodiment of a thread splicing device 10.

- the thread splicing device 10 is within two mechanically working friction rings 42, 43 arranged, the are driven in opposite directions.

- the front friction ring according to Figure 3 42 is, for example, counterclockwise, the rear one Friction ring 43 can be rotated clockwise to a limited extent.

- the splice channel 20 of the splice head 19 has at least one compressed air injection opening 34 and at least two suction openings 33.

- the compressed air injection opening 34 is connected to a compressed air source 36 via a pneumatic line 35, into which a directional valve 37 is switched on.

- the suction openings 33 are connected via a line 39, which has a directional control valve 40, to a vacuum source 41. Both the directional control valve 37 and the directional control valve 40 can be controlled by the workstation computer 29 via a control line 38.

- FIG. 4 shows the above-described thread splicing device 10 in side view.

- the splicing head 19 which, as already indicated above, is preferably fixed to a base body 22 of the thread splicing device 10 via a screw connection 27, has a splice channel 20 which is open at the top.

- suction openings 33 In addition to at least one, as a rule centrally arranged, compressed air injection opening 34, further suction openings 33, preferably symmetrically arranged with respect to the compressed air injection opening 34, open into the channel base 30. As already indicated above, these intake air openings 33 are connected to a vacuum source 41 via a vacuum line 39.

- the suction nozzle 12 takes the accumulated on the cheese 15 Upper thread 31 and brings it to the thread splicing device 10. That is, the upper thread 31 received by the suction nozzle 12 is and in the splice channel 20 of the splice head 19 Thread splicing device 10, the clamping element 11 'of the upper and the cutting element 17 '' of the lower thread cutting and - clamping device 11 or 17 (see Fig. 2) threaded.

- the thread tensioner will held lower thread 32 picked up by the hook tube 25.

- the gripper tube 25 first swivels into the Area of the thread tensioner and sucks in the lower thread 32, which is released by the thread tensioner at the same time.

- the gripper tube 25 then pivots into the Figures 2 and 3 indicated upper working position.

- the lower thread 32 is also inserted into the splice channel 20 of the splice head 19.

- the lower thread 32 then lies in the clamping element 17 'of the lower and in the cutting element 11''of the upper thread cutting and clamping device 17 or 11.

- the thread ends of upper and lower thread 31 or 32 thus prepared are then pulled through a so-called (not shown) loop puller or the like into the splice channel 20, which, as can be seen from FIG. 5, has a channel base 30, for example U-shaped or V-shaped, in cross section , This means that the thread ends of the upper and lower thread 31, 32 slide into the channel base 30 of the splicing channel 20, where they are fixed pneumatically after opening the directional valve 40 via the suction openings 33 then subjected to negative pressure.

- a plurality of compressed air injection openings 34 which can be arranged both radially and tangentially, can also open into the channel base 30.

- the arrangement or number of suction openings 33 which can be subjected to negative pressure can also vary without thereby departing from the general inventive concept.

Landscapes

- Spinning Or Twisting Of Yarns (AREA)

Abstract

Description

Die Erfindung betrifft eine Fadenspleißvorrichtung gemäß dem

Oberbegriff des Anspruches 1.The invention relates to a thread splicing device according to the

Preamble of

Fadenspleißvorrichtungen sind im Zusammenhang mit Kreuzspulautomaten seit langem bekannt und in zahlreichen Schutzrechtsanmeldungen ausführlich beschrieben.Thread splicers are related to Automatic winding machines have been known for a long time and in numerous IP applications are described in detail.

Die DE 39 35 536 C2 beschreibt beispielsweise eine

pneumatische Fadenspleißvorrichtung mit einem Spleißkopf, der

einen im Querschnitt nahezu kreisförmigen Spleißkanal

aufweist. In den Spleißkanal, der auf seiner Oberseite über

einen durchgehenden Schlitz zum Einlegen der zu verspleißenden

Fadenenden verfügt, münden tangential angeordnete Druckluft-Einblasöffnungen.

Der Fadeneinlegeschlitz und damit der Spleißkanal wird während

des Spleißprozesses durch ein Deckelelement verschlossen.DE 39 35 536 C2 describes, for example, a pneumatic thread splicing device with a splice head that has a splice channel that is almost circular in cross section. Tangentially arranged compressed air injection openings open into the splice channel, which has a continuous slot on the top for inserting the thread ends to be spliced.

The thread insertion slot and thus the splice channel is closed by a cover element during the splicing process.

Vor dem eigentlichen Spleißprozeß werden die zu verspleißenden

Fadenenden vorbereitet, das heißt, die Fadenenden werden

wenigstens teilweise von ihrer Garndrehung befreit.

Das Vorbereiten der Fadenenden kann dabei entweder, wie in der

DE 39 35 536 C2 dargelegt, pneumatisch über sogenannte

Fadenende-Auflöseröhrchen erfolgen oder, wie beispielsweise in

der DE 30 29 452 C2 beschrieben, mechanisch durch zwei

gegenläufige Reibscheiben. Before the actual splicing process, the thread ends to be spliced are prepared, that is, the thread ends are at least partially freed from their twist.

The thread ends can either be pneumatically, as described in

Die bekannten Fadenspleißvorrichtungen haben sich in der Praxis im Prinzip bewährt, sie offenbaren allerdings Schwächen, wenn feine und feinste Garne gespleißt werden sollen.The known thread splicing devices have in the Practice has proven itself in principle, but it does reveal Weaknesses when fine and very fine yarns are spliced should.

Ausgehend vom vorgenannten Stand der Technik liegt der Erfindung daher die Aufgabe zugrunde, eine Fadenspleißvorrichtung zu schaffen, die es ermöglicht, auch problematische Garne, insbesondere feine und feinste Garne, sicher zu verbinden.Based on the aforementioned prior art, the The invention is therefore based on the object Thread splicer to create that allows it too problematic yarns, especially fine and very fine yarns, connect securely.

Diese Aufgabe wird erfindungsgemäß durch eine

Fadenspleißvorrichtung gelöst, wie sie im Anspruch 1

beschrieben ist.This object is achieved by a

Thread splicing device solved, as in

Vorteilhafte Ausgestaltungen der Erfindung sind Gegenstand der Unteransprüche.Advantageous embodiments of the invention are the subject of Dependent claims.

Die erfindungsgemäße Ausbildung eines Spleißkopfes mit

wenigstens einer vorzugsweise mittig angeordneten Druckluft-Einblasöffnung

und wenigstens zwei weiteren mit Unterdruck

beaufschlagbaren Ansaugöffnungen im Bereich des Spleißkanales

hat insbesondere den Vorteil, daß die nach der Vorbereitung

der Fadenenden weitestgehend parallel liegenden Fasern auch

während des eigentlichen Spleißvorganges sicher im Spleißkanal

fixiert bleiben.

Das heißt, durch die pneumatische Fixierung der Fasern im

Spleißkanal kann eine Materialansammlung im Bereich der

Anschlußöffnungen erzielt werden, die es ermöglicht, haltbare

Spleiße auch bei feinen und feinsten Garnen zu erstellen.

Des weiteren ermöglichen solche unterdruckbeaufschlagte

Ansaugöffnungen, insbesondere bei mechanisch vorbereiteten

Fadenenden, das heißt bei Fadenenden, die zwischen zwei

gegenläufigen Reibscheiben aufgedreht wurden, ein Zurückhalten

bzw. Speichern der neutralisierten Fadendrehung bis zum

eigentlichen Spleißvorgang.

Diese gespeicherte Fadendrehung kann nach erfolgtem

Spleißprozeß freigegeben werden und bringt dann weitere

Festigkeit in die Fadenverbindungsstelle.The design of a splice head according to the invention with at least one preferably centrally arranged compressed air injection opening and at least two further suction openings in the region of the splice channel which can be subjected to negative pressure has the particular advantage that the fibers which are largely parallel after the preparation of the thread ends are also securely in the splice channel during the actual splicing process stay fixed.

This means that the pneumatic fixing of the fibers in the splice channel enables material to accumulate in the area of the connection openings, which makes it possible to create durable splices even with fine and very fine yarns. Furthermore, such suction openings under pressure, in particular with mechanically prepared thread ends, that is to say with thread ends that have been turned between two counter-rotating friction disks, enable the neutralized thread rotation to be retained or stored until the actual splicing process.

This stored thread rotation can be released after the splicing process has taken place and then brings further strength to the thread connection point.

Insbesondere durch die im Anspruch 2 beschriebene symmetrische

Anordnung der mit Unterdruck beaufschlagbaren Ansaugöffnungen

wird sichergestellt, daß die Fadenenden innerhalb des

Spleißkanals in einem weitestgehend gestreckten Zustand

gehalten werden, was sich sowohl auf das Aussehen und als auch

auf die Haltbarkeit der Fadenverbindung positiv auswirkt.In particular by the symmetrical described in

Wie im Anspruch 3 beschrieben, ist in bevorzugter

Ausführungsform vorgesehen, daß die einzelnen Ansaugöffnungen

über eine gemeinsame Pneumatikleitung an eine Unterdruckquelle

angeschlossen sind.

Eine solche Ausbildung gewährleistet nicht nur eine

gleichmäßige Beaufschlagung der zu verspleißenden Fadenenden,

sondern stellt auch eine konstruktiv vorteilhafte, weil

einfache Bauweise des Spleißkopfes dar.As described in

Such a design not only ensures a uniform loading of the thread ends to be spliced, but also represents a structurally advantageous, because simple construction of the splicing head.

Wie im Anspruch 4 dargelegt, ist in vorteilhafter

Ausführungsform vorgesehen, daß die Ansaugöffnungen an eine

separate Unterdruckquelle angeschlossen sind.

Durch eine solche pneumatische Abkopplung der

erfindungsgemäßen Spleißvorrichtung vom regulären

Unterdrucksystem der Textilmaschine kann eine weitestgehend

gleichmäßige Qualität der Spleißverbindungen gewährleistet

werden, da sich Druckschwankungen, wie sie im Unterdrucksystem

einer Textilmaschine nahezu unvermeidlich sind, nicht mehr auf

die Fadenspleißvorrichtung auswirken können.As stated in

Such a pneumatic decoupling of the splicing device according to the invention from the regular vacuum system of the textile machine can ensure a largely uniform quality of the splice connections, since pressure fluctuations, which are almost inevitable in the vacuum system of a textile machine, can no longer affect the thread splicing device.

Die separate Unterdruckquelle ist dabei beispielsweise als

Injektordüse ausgebildet (Anspr.5).

Der Einsatz einer solchen Injektordüse stellt eine

kostengünstige Möglichkeit dar, auf einfache Weise einen

zuverlässigen, zusätzlichen Unterdruckerzeuger zu realisieren.The separate vacuum source is designed, for example, as an injector nozzle (Claim 5).

The use of such an injector nozzle is a cost-effective way to easily implement a reliable, additional vacuum generator.

Gemäß Anspruch 6 münden die mit Unterdruck beaufschlagbaren

Ansaugöffnungen vorteilhafterweise im Bereich des Kanalgrundes

in den Schleißkanal ein.

Der Kanalgrund weist dabei, wie in den Ansprüchen 7 bzw. 8

dargelegt, in bevorzugter Ausführungsform einen U- oder V-förmigen

Querschnitt auf.

Eine solche vorteilhafte Form des Spleißkanalgrundes

begünstigt die parallele Ausrichtung der Fasern der zu

verspleißenden Fadenenden und führt dadurch zu einer

gleichmäßigen Materialansammlung in Spleißkanalgrund.According to

In a preferred embodiment, the channel base has a U-shaped or V-shaped cross section, as set out in

Such an advantageous shape of the splice channel base favors the parallel alignment of the fibers of the thread ends to be spliced and thereby leads to a uniform accumulation of material in the splice channel base.

Die Erfindung wird nachfolgend anhand eines in den Zeichnungen dargestellten Ausführungsbeispieles erläutert.The invention is described below with reference to the drawings illustrated embodiment explained.

Es zeigt:

- Fig. 1

- in Seitenansicht eine Arbeitsstelle eines Kreuzspulautomaten, mit einer erfindungsgemäßen Fadenspleißvorrichtung,

- Fig. 2

- in perspektivischer Ansicht eine erfindungsgemäße Fadenspleißvorrichtung mit pneumatisch beaufschlagbarem Spleißkopf sowie pneumatischen arbeitenden Fadenende-Vorbereitungsröhrchen,

- Fig. 3

- in Vorderansicht die erfindungsgemäße Fadenspleißvorrichtung mit besaugbarem Spleißkopf sowie mechanischen Reibscheiben zum Vorbereiten der Fadenenden,

- Fig. 4

- die Fadenspleißvorrichtung gemäß Fig.3, in Seitenansicht,

- Fig. 5

- den pneumatisch beaufschlagbaren Spleißkopf einer erfindungsgemäßen Fadenspleißvorrichtung in einem größeren Maßstab.

- Fig. 1

- in side view a work station of a cheese winder, with a thread splicing device according to the invention,

- Fig. 2

- a perspective view of a thread splicing device according to the invention with a pneumatically actuated splice head and pneumatic working thread end preparation tube,

- Fig. 3

- in front view the thread splicing device according to the invention with suction-absorbing splicing head and mechanical friction disks for preparing the thread ends,

- Fig. 4

- the thread splicing device according to Figure 3, in side view,

- Fig. 5

- the pneumatically actuated splice head of a thread splicing device according to the invention on a larger scale.

In Figur 1 ist in Vorderansicht schematisch eine insgesamt mit

der Bezugszahl 1 gekennzeichnete Kreuzspulen herstellende

Textilmaschine, im Ausführungsbeispiel ein Kreuzspulautomat,

dargestellt.

Derartige Kreuzspulautomaten weisen üblicherweise zwischen

ihren (nicht dargestellten) Endgestellen eine Vielzahl

gleichartiger Arbeitsstellen, im vorliegenden Fall

Spulstellen 2, auf.

Auf diesen Spulstellen 2 werden, wie bekannt und daher nicht

näher erläutert, Spinnkopse 9, die beispielsweise auf einer

Ringspinnmaschine produziert wurden, zu großvolumigen

Kreuzspulen 15 umgespult.

Nach ihrer Fertigstellung werden diese Kreuzspulen 15 mittels

eines selbsttätig arbeitenden Serviceaggregates, vorzugsweise

eines (nicht dargestellten) Kreuzspulenwechslers, auf eine

maschinenlange Kreuzspulentransporteinrichtung 21 übergeben

und zu einer maschinenendseitig angeordneten

Spulenverladestation oder dergleichen transportiert.FIG. 1 shows a front view of a textile machine, generally designated with the

Such automatic winding machines usually have a large number of similar work stations, in the present

On these

After their completion, these

Üblicherweise weisen solche Kreuzspulautomaten 1 außerdem eine

Logistikeinrichtung in Form eines Spulen- und

Hülsentransportsystems 3 auf, in dem, auf Transporttellern 8

in vertikaler Ausrichtung, Spinnkopse 9 beziehungsweise

Leerhülsen umlaufen.

Von diesem Sulen-und Hülsentransportsystem 3 sind in Figur 1

lediglich die Kopszuführstrecke 4, die reversierend

antreibbare Speicherstrecke 5, eine der zu den Spulstellen 2

führenden Quertransportstrecken 6 sowie die

Hülsenrückführstrecke 7 dargestellt.Such

Of this column and

Des weiteren verfügen solche Kreuzspulautomaten 1 in der Regel

über eine (nicht dargestellte) Zentralsteuereinheit, die über

einen Maschinenbus sowohl mit den separaten

Arbeitsstellenrechnern 29 der einzelnen Spulstellen 2 als auch

mit einer Steuereinrichtung des Serviceaggregates verbunden

ist.Furthermore, such

Die angelieferten Spinnkopse 9 werden in den

Abspulstellungen AS, die sich jeweils im Bereich der

Quertransportstrecken 6 an den Spulstellen 2 befinden, zu

großvolumigen Kreuzspulen 15 umgespult.

Die einzelnen Spulstellen verfügen zu diesem Zweck, wie

bekannt und daher nur angedeutet, über verschiedene

Einrichtungen, die einen ordnungsgemäßen Betrieb dieser

Arbeitsstellen gewährleisten. The delivered spinning

Unwinding positions AS, which are each located in the area of the

For this purpose, as is known and therefore only hinted at, the individual winding units have various devices which ensure that these workplaces operate properly.

Diese Einrichtungen sind beispielsweise eine Saugdüse 12, ein

Greiferrohr 25 sowie eine Fadenverbindungseinrichtung 10.

Die Fadenverbindungseinrichtung 10 ist dabei vorzugsweise als

pneumatischer Spleißer ausgebildet.

Wie in Figur 1 angedeutet ist die pneumatische

Fadenspleißvorrichtung 10 dabei bezüglich des regulären

Fadenlaufes etwas zurückgesetzt und besitzt beispielsweise,

wie in Figur 2 angedeutet, eine obere Fadenklemm- und

-schneideinrichtung 11 und eine untere Fadenklemm- und

-schneideinrichtung 17.These devices are, for example, a

The

As indicated in FIG. 1, the pneumatic

Solche Spulstellen 2 verfügen außerdem über weitere, nicht

näher dargestellte Einrichtungen, wie einen Fadenspanner,

einen Fadenreiniger, eine Paraffiniereinrichtung, eine

Fadenschneideinrichtung, einen Fadenzugkraftsensor sowie einen

Unterfadensensor.

Das Wickeln der Kreuzspulen 15 erfolgt dabei auf sogenannten

Spulvorrichtungen 24. Derartige Spulvorrichtung 24 verfügen

unter anderem über einen Spulenrahmen 28, der um eine

Schwenkachse 13 beweglich gelagert ist und eine Einrichtung

zum drehbaren Haltern einer Kreuzspulenhülse aufweist.

Während des Spulprozesses liegt die im Spulenrahmen 28 frei

drehbar gelagerte Kreuzspule 15 mit ihrer Oberfläche auf einer

Nuttrommel 14 und wird von dieser über Reibschluß mitgenommen.The winding of the

During the winding process, the surface of the

Wie vorstehend bereits angedeutet, verfügt jede Spulstelle 2

über eine Saugdüse 12 sowie ein Greiferrohr 25.

Die Saugdüse 12 ist dabei um eine Schwenkachse 16, das

Greiferrohr 25 um eine Schwenkachse 26 begrenzt drehbar

gelagert. As already indicated above, each

The

Die Figur 2 zeigt in perspektivischer Ansicht die

Fadenverbindungseinrichtung 10, die in einer

Fadeneinlegeposition stehende Saugdüse 12 sowie das in einer

entsprechenden Fadeneinlegeposition angeordnete

Greiferrohr 25.

Die Saugdüse 12 hat dabei den Oberfaden 31 von der

Kreuzspule 15 zurückgeholt und in den Spleißkanal 20 des

Spleißkopfes 19 eingelegt. Außerdem wurde der mit dem

Spinnkops 9 verbundene Unterfaden 32, der nach einem

Fadenbruch in der Regel in einem (nicht dargestellten)

Fadenspanner fixiert ist, durch das Greiferrohr 25 abgeholt

und ebenfalls in den Spleißkanal 20 eingelegt.FIG. 2 shows a perspective view of the

The

Wie in Figur 2 angedeutet, ist der Spleißkopf 19 zum Beispiel

über eine Schraubverbindung 27 an einen Grundkörper 22

angeschlossen, der mehrere pneumatische Anschlüsse aufweist

und in den unter anderem pneumatisch beaufschlagbare

Fadenende-Vorbereitungsröhrchen 18 eingelassen sind.

Ober- und unterhalb des Grundkörpers 22 der

Fadenspleißvorrichtung 10 ist dabei jeweils eine Fadenklemmund

-schneideinrichtung 11 beziehungsweise 17 angeordnet.

Wie ersichtlich liegt der Oberfaden 31 im Schneidelement 17''

der unten angeordneten Fadenklemm- und -schneideinrichtung 17

sowie im Klemmelement 11' der oberen Fadenklemm- und

-schneideinrichtung 11. Der Unterfaden 32 ist entsprechend im

Klemmelement 17' der unteren Fadenschneid- und

-klemmeinrichtung 17 gehalten und kreuzt das Schneidelement

11'' der oberen Fadenschneid- und -klemmeinrichtung 11.As indicated in FIG. 2, the

A thread clamping and cutting

Die Fig.3 zeigt eine Vorderansicht auf eine weitere

Ausführungsform einer Fadenspleißvorrichtung 10. 3 shows a front view of another

Embodiment of a

Die Fadenspleißvorrichtung 10 ist dabei innerhalb zweier

mechanisch arbeitender Reibringe 42, 43 angeordnet, die

gegenläufig antreibbar sind. Der gemäß Fig.3 vordere Reibring

42 ist beispielsweise im Gegenuhrzeigersinn, der hintere

Reibring 43 im Uhrzeigersinn begrenzt drehbar.The

Wie aus Figur 3 weiter ersichtlich, weist der Spleißkanal 20

des Spleißkopfes 19 mindestens eine Druckluft-Einblasöffnung

34 sowie wenigstens zwei Ansaugöffnungen 33 auf.

Die Druckluft-Einblasöffnung 34 ist dabei über eine

Pneumatikleitung 35, in die ein Wegeventil 37 eingeschaltet

ist, mit einer Druckluftquelle 36 verbunden.

Die Ansaugöffnungen 33 sind über eine Leitung 39, die ein

Wegeventil 40 aufweist, an eine Unterdruckquelle 41

angeschlossen.

Sowohl das Wegeventil 37 als auch das Wegeventil 40 sind durch

den Arbeitsstellenrechner 29 über eine Steuerleitung 38

ansteuerbar.As can also be seen from FIG. 3, the

The compressed air injection opening 34 is connected to a

The

Both the

Die Fig.4 zeigt die vorbeschriebene Fadenspleißvorrichtung 10

in Seitenansicht.4 shows the above-described

In Fig.5 ist der konstruktive Aufbau des erfindungsgemäßen

Spleißkopfes 19 näher dargestellt.

Der Spleißkopf 19, der, wie vorstehend bereits angedeutet,

vorzugsweise über eine Schraubverbindung 27 an einem

Grundkörper 22 der Fadenspleißvorrichtung 10 festgelegt ist,

verfügt über einen nach oben offenen Spleißkanal 20.5 shows the structural design of the

The

Der Spleißkanal 20, der über ein gestrichelt dargestelltes

Deckelelement 23 verschließbar ist, weist einen Kanalgrund 30

mit einem im Ausführungsbeispiel U-förmigen Querschnitt auf. The

In den Kanalgrund 30 münden neben wenigstens einer, in der

Regel mittig angeordneten Druckluft-Einblasöffnung 34 weitere,

vorzugsweise bezüglich der Druckluft-Einblasöffnung 34

symmetrisch angeordnete Ansaugöffnungen 33 ein.

Diese Ansaugluftöffnungen 33 sind, wie vorstehend bereits

angedeutet, über eine Unterdruckleitung 39 an eine

Unterdruckquelle 41 angeschlossen.In addition to at least one, as a rule centrally arranged, compressed air injection opening 34,

As already indicated above, these

Wenn es an einer der Spulstellen 2 des Kreuzspulautomaten 1 zu

einer Spulunterbrechung gekommen ist, beispielsweise aufgrund

eines regulären Reinigerschnittes oder eines Fadenbruches,

nimmt die Saugdüse 12 den auf die Kreuzspule 15 aufgelaufene

Oberfaden 31 auf und bringt ihn zur Fadenspleißeinrichtung 10.

Das heißt, der durch die Saugdüse 12 aufgenommene Oberfadem 31

wird und in den Spleißkanal 20 des Spleißkopfes 19 der

Fadenspleißvorrichtung 10 , das Klemmelement 11' der oberen

und das Schneidelement 17'' der unteren Fadenschneid- und -

klemmeinrichtung 11 beziehungsweise 17 ein (siehe Fig.2)

eingefädelt.If it is at one of the winding

Gleichzeitig oder anschließend wird der im Fadenspanner

gehaltene Unterfaden 32 durch das Greiferrohr 25 abgeholt.

Das Greiferrohr 25 schwenkt zu diesem Zweck zunächst in den

Bereich des Fadenspanners und saugt dort den Unterfaden 32 an,

der gleichzeitig vom Fadenspanner freigegeben wird.

Das Greiferrohres 25 schwenkt anschließend in die in den

Figuren 2 und 3 angedeutete obere Arbeitsposition. At the same time or afterwards, the thread tensioner will

held

Während dieser Schwenkbewegung wird der Unterfaden 32, wie

beispielsweise in den Figur 2 und 3 dargestellt, ebenfalls in

den Spleißkanal 20 des Spleißkopfes 19 eingelegt.

Außerdem liegt der Unterfaden 32 dann im Klemmelement 17' der

unteren und im Schneidelement 11'' der oberen Fadenschneidund

-klemmeinrichtung 17 beziehungsweise 11.During this pivoting movement, the

In addition, the

Nach dem Verschließen des Spleißkopfes 19 mit dem

Deckelelement 23 werden die in den Fadenschneid- und -

klemmeinrichtungen 11 und 17 fixierten Fäden 31, 32

geschnitten, wobei das abgeschnittene Fadenende des

Unterfadens 32 durch das Greiferrohr 25 und das abgeschnittene

Fadenende des Oberfadens 31 durch die Saugdüse 12 entsorgt

wird.After closing the

Gleichzeitig werden die aus dem Spleißkanal 20 herausragenden

Fadenenden von Oberfaden 31 und Unterfaden 32 jeweils in eins

der unterdruckbeaufschlagten Fadenende-Vorbereitungsröhrchen

18 eingesaugt und dort, vorzugsweise

pneumatisch, wenigstens teilweise von ihrer Fadendrehung

befreit.At the same time, the protruding from the

Anschließend werden die so vorbereiteten Fadenenden von Oberund

Unterfaden 31 bzw. 32 durch einen sogenannten (nicht

dargestellten) Schlaufenzieher oder dergleichen in den

Spleißkanal 20 gezogen, der, wie aus Figur 5 ersichtlich,

einen im Querschnitt beispielsweise U- oder V-förmigen

Kanalgrund 30 aufweist.

Das heißt, die Fadenenden des Ober- und Unterfadens 31, 32

gleiten in den Kanalgrund 30 des Spleißkanals 20, wo sie nach

Öffnen des Wegeventiles 40 über die dann mit Unterdruck

beaufschlagten Ansaugöffnungen 33 pneumatisch fixiert werden. The thread ends of upper and

This means that the thread ends of the upper and

Die im Kanalgrund 30 des Spleißkanales 20 zunächst nahezu

parallel angeordneten Einzelfasern der Fadenenden von

Unterfaden 31 und Oberfaden 32 werden anschließend durch einen

Spleißluftstoß, der aus der Druckluft-Einblasöffnung 34

austritt und durch Öffnen des Wegeventiles 37 initiiert wird,

miteinander verwirbelt.

Das heißt, die beiden Fadenenden von Unterfaden 32 und

oberfaden 31 werden pneumatisch verspleißt.The individual fibers of the thread ends of the

This means that the two thread ends of the

Die Erfindung ist nicht auf die dargestellten

Ausführungsbeispiele beschränkt.

In den Kanalgrund 30 können beispielsweise auch mehrere

Druckluft-Einblasöffnungen 34 einmünden, die sowohl radial als

auch tangential angeordnet sein können.

Auch die Anordnung oder Anzahl der unterdruckbeaufschlagbaren

Ansaugöffnungen 33 kann variieren, ohne daß dadurch der

allgemeine Erfindungsgedanke verlassen wird.The invention is not restricted to the exemplary embodiments shown.

A plurality of compressed

The arrangement or number of

Claims (8)

dadurch gekennzeichnet, daß der Spleißkanal (20) über wenigsten zwei zusätzliche mit Unterdruck beaufschlagbare Ansaugöffnungen (33) verfügt, die beidseitig der Druckluft-Einblasöffnung (34) angeordnet sind.Thread splicing device for the pneumatic connection of two thread ends, with a splicing head which can be fixed on a base body and which has a splicing channel with at least one compressed air injection opening which can be acted upon in a defined manner,

characterized in that the splice channel (20) has at least two additional suction openings (33) which can be subjected to negative pressure and which are arranged on both sides of the compressed air injection opening (34).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10150578A DE10150578A1 (en) | 2001-10-12 | 2001-10-12 | yarn splicing |

| DE10150578 | 2001-10-12 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1302428A1 true EP1302428A1 (en) | 2003-04-16 |

Family

ID=7702391

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02016537A Withdrawn EP1302428A1 (en) | 2001-10-12 | 2002-07-24 | Yarn splicer |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20030070411A1 (en) |

| EP (1) | EP1302428A1 (en) |

| JP (1) | JP2003119627A (en) |

| CN (1) | CN1412363A (en) |

| DE (1) | DE10150578A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007048466A1 (en) * | 2005-10-29 | 2007-05-03 | Oerlikon Textile Gmbh & Co. Kg | Thread-connection apparatus |

| DE102006000824A1 (en) * | 2006-01-05 | 2007-07-12 | Saurer Gmbh & Co. Kg | Yarn splicing device for a cross-wound textile machine |

| CZ301752B6 (en) * | 2005-12-20 | 2010-06-16 | Rieter Cz S.R.O. | Method for recovery of component yarn spinning, particularly on rotor spinning machine, using a splicer, and apparatus for making the same |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10230760A1 (en) * | 2002-07-09 | 2004-01-22 | Saurer Gmbh & Co. Kg | yarn splicing |

| ITMI20050605A1 (en) * | 2005-04-11 | 2006-10-12 | Savio Macchine Tessili Spa | WIRE MANAGEMENT DEVICE FOR SERVICE TROLLEYS FOR OPEN-END YARN |

| CN100999844B (en) * | 2006-01-11 | 2010-12-08 | 上海梅花刺轴有限公司 | Process to yarn making non-knot twist contecting and thread rolling device using said method |

| DE102012005861A1 (en) * | 2012-03-22 | 2013-09-26 | Oerlikon Textile Gmbh & Co. Kg | Yarn splicing device for a cross-wound textile machine |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4322943A (en) * | 1980-01-19 | 1982-04-06 | W. Schlafhorst & Co. | Device for joining an upper thread to a lower thread |

| JPS5874470A (en) * | 1981-10-27 | 1983-05-04 | Murata Mach Ltd | Pneumatic yarn ending device |

| CH660722A5 (en) * | 1982-11-12 | 1987-06-15 | Schweiter Ag Maschf | METHOD AND DEVICE FOR SPLICING TWO YARNS. |

| EP0246686A1 (en) * | 1986-05-16 | 1987-11-25 | S. BIGAGLI & C. SpA | Device to piece-up rovings of textile fibres |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3040662C2 (en) * | 1980-10-29 | 1985-02-21 | W. Schlafhorst & Co, 4050 Mönchengladbach | Thread splicing device |

| DE3405304A1 (en) * | 1984-02-15 | 1985-08-29 | W. Schlafhorst & Co, 4050 Mönchengladbach | COMPRESSED AIR THREAD SPLICING DEVICE |

| DE4331553C2 (en) * | 1993-09-16 | 1997-01-30 | Saxonia Umformtechnik Gmbh | Method for connecting threads and thread processing machine with thread changing device, in particular for carrying out the method |

| DE19824210A1 (en) * | 1998-05-29 | 1999-12-02 | Saxonia Umformtechnik Gmbh | Thread connection expanded |

| IT1316370B1 (en) * | 2000-02-15 | 2003-04-10 | Mesdan Spa | DEVICE AND PROCEDURE FOR JOINTING TEXTILE THREADS BY COMPRESSED AND LIQUID MEDIUM |

| DE10124832A1 (en) * | 2001-05-22 | 2002-11-28 | Schlafhorst & Co W | Pneumatic thread splicing assembly has arresting unit located between clamps and elastic strand separation jets |

-

2001

- 2001-10-12 DE DE10150578A patent/DE10150578A1/en not_active Withdrawn

-

2002

- 2002-07-24 EP EP02016537A patent/EP1302428A1/en not_active Withdrawn

- 2002-10-09 JP JP2002296365A patent/JP2003119627A/en active Pending

- 2002-10-11 CN CN02143586.3A patent/CN1412363A/en active Pending

- 2002-10-11 US US10/269,420 patent/US20030070411A1/en not_active Abandoned

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4322943A (en) * | 1980-01-19 | 1982-04-06 | W. Schlafhorst & Co. | Device for joining an upper thread to a lower thread |

| JPS5874470A (en) * | 1981-10-27 | 1983-05-04 | Murata Mach Ltd | Pneumatic yarn ending device |

| CH660722A5 (en) * | 1982-11-12 | 1987-06-15 | Schweiter Ag Maschf | METHOD AND DEVICE FOR SPLICING TWO YARNS. |

| EP0246686A1 (en) * | 1986-05-16 | 1987-11-25 | S. BIGAGLI & C. SpA | Device to piece-up rovings of textile fibres |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 007, no. 169 (M - 231) 26 July 1983 (1983-07-26) * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007048466A1 (en) * | 2005-10-29 | 2007-05-03 | Oerlikon Textile Gmbh & Co. Kg | Thread-connection apparatus |

| DE102005051935A1 (en) * | 2005-10-29 | 2007-05-03 | Saurer Gmbh & Co. Kg | Yarn splicing device |

| CZ301752B6 (en) * | 2005-12-20 | 2010-06-16 | Rieter Cz S.R.O. | Method for recovery of component yarn spinning, particularly on rotor spinning machine, using a splicer, and apparatus for making the same |

| DE102006000824A1 (en) * | 2006-01-05 | 2007-07-12 | Saurer Gmbh & Co. Kg | Yarn splicing device for a cross-wound textile machine |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10150578A1 (en) | 2003-04-17 |

| CN1412363A (en) | 2003-04-23 |

| US20030070411A1 (en) | 2003-04-17 |

| JP2003119627A (en) | 2003-04-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4420979B4 (en) | Fadenendevorbereitungseinrichtung for cross-wound textile machinery manufacturing | |

| DE10139074B4 (en) | Open-end rotor spinning machine | |

| DE102011101629A1 (en) | Thread splicing device for automatic cheese winder, has smoothening zone extending over length in thread longitudinal direction, where length corresponds to thread ends projecting from channel during splicing process | |

| EP1331192A2 (en) | Apparatus for pneumatically connecting the ends of yarns | |

| DE10124832A1 (en) | Pneumatic thread splicing assembly has arresting unit located between clamps and elastic strand separation jets | |

| DE102016002695A1 (en) | Thread splicing device for a workstation of a cross-wound textile machine | |

| EP1971545B1 (en) | Thread splicing apparatus for a textile machine producing cross-wound bobbins | |

| DE102017114707A1 (en) | Thread splicer for pneumatically connecting thread ends | |

| DE102016119542A1 (en) | Thread splicing device for a workstation of a cross-wound textile machine | |

| DE10224080A1 (en) | Textile machine has cross-wound bobbin winder with thread splicing unit having a separate drive for a predefined drive control | |

| DE102016115732A1 (en) | Thread splicing device for a workstation of a cross-wound textile machine | |

| DE102006039735A1 (en) | Suction nozzle for a job of a cheese-producing textile machine | |

| EP1544147A2 (en) | Apparatus for splicing yarns pneumatically | |

| EP1380529B1 (en) | Thread-splicing apparatus | |

| EP1076028B1 (en) | Yarn connecting device for a textile machine making cross-wound bobbins | |

| DE102011111033A1 (en) | Thread splicing device for cross coil-producing textile machine with pneumatic loadable splicing prism in textile industry, has actuators for lower thread clamp and cutting device and upper thread clamp and cutting device | |

| EP1127831B1 (en) | Apparatus for starting a workstation of a textile machine producing cross-wound bobbins | |

| DE102018108151A1 (en) | Thread splicing device for a workstation of a cross-wound textile machine | |

| DE102018120457A1 (en) | Thread splicing device for a work station of a textile machine producing cross-wound bobbins | |

| DE102017124729A1 (en) | yarn splicing | |

| DE102020132458A1 (en) | Thread splicing device for a work station of a textile machine producing cross-wound bobbins | |

| EP1302428A1 (en) | Yarn splicer | |

| DE102017102438A1 (en) | Thread splicing device for a workstation of a cross-wound textile machine | |

| EP1302427B1 (en) | Thread-splicing apparatus | |

| DE102017129580A1 (en) | Rotation splicer for a job on a textile machine producing cross-wound bobbins |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SAURER GMBH & CO. KG |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20031017 |