EP1279770A2 - Gleisunterstützungssystem für Schienen - Google Patents

Gleisunterstützungssystem für Schienen Download PDFInfo

- Publication number

- EP1279770A2 EP1279770A2 EP02447141A EP02447141A EP1279770A2 EP 1279770 A2 EP1279770 A2 EP 1279770A2 EP 02447141 A EP02447141 A EP 02447141A EP 02447141 A EP02447141 A EP 02447141A EP 1279770 A2 EP1279770 A2 EP 1279770A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- slab

- vibration

- rail

- rails

- support system

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B19/00—Protection of permanent way against development of dust or against the effect of wind, sun, frost, or corrosion; Means to reduce development of noise

- E01B19/003—Means for reducing the development or propagation of noise

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B1/00—Ballastway; Other means for supporting the sleepers or the track; Drainage of the ballastway

- E01B1/008—Drainage of track

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B2/00—General structure of permanent way

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B21/00—Track superstructure adapted for tramways in paved streets

- E01B21/02—Special supporting means; Draining of rails

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B35/00—Applications of measuring apparatus or devices for track-building purposes

- E01B35/12—Applications of measuring apparatus or devices for track-building purposes for measuring movement of the track or of the components thereof under rolling loads, e.g. depression of sleepers, increase of gauge

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B1/00—Ballastway; Other means for supporting the sleepers or the track; Drainage of the ballastway

- E01B1/001—Track with ballast

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B2203/00—Devices for working the railway-superstructure

- E01B2203/16—Guiding or measuring means, e.g. for alignment, canting, stepwise propagation

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B2204/00—Characteristics of the track and its foundations

- E01B2204/01—Elastic layers other than rail-pads, e.g. sleeper-shoes, bituconcrete

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B2204/00—Characteristics of the track and its foundations

- E01B2204/11—Embedded tracks, using prefab elements or injecting or pouring a curable material

Definitions

- the invention relates in particular to the problem of acoustic and anti-vibration insulation of railways installed on roads.

- the inventors set out to analyze the static behavior and the dynamic behavior of the railway track when a vehicle passes over the rails.

- a car traveling on the rails produces two impacts on the rails. The first is due to the mass of all the cars in the train: it is the static load transferred to the bogies; the second impact is due to the mass not suspended from the bogie: it is this mass which produces the dynamic impulses by the wheels on the rails and it is these impulses which are transmitted towards the environment.

- the first flexural resonance frequency of the wheel / rail assembly is conditioned by the dynamic stiffness of the soles placed under the rails and, if necessary, by that of the cushions placed under the saddles or crosspieces.

- This resonant frequency is inversely proportional to the anti-vibration performance of the rail fastening system.

- a low resonant frequency provides better vibration isolation than a high resonant frequency.

- Insulation performance Better antivibration is obtained by decoupling the fixing function and the insulation function.

- separating elements consisting of prefabricated elements or of a waterproof and flexible filling product, are chosen so that the static and dynamic stiffnesses of the assembly are less than those of the flanges placed under the pads of the rails.

- the rails are thus completely independent of the roads, which has the consequence of considerably reducing the transmission of vibrations to the foundations of neighboring buildings at the same time as sealing is ensured along the rails.

- a system in which the rail is coated with a very compact resilient material to give it better mechanical resistance to expansion and to the forces generated by the movement of cars on the rail does not have the static and dynamic characteristics required to ensure effective vibration isolation and, therefore, the transmission of vibration waves to the foundations of neighboring buildings is maximum.

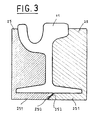

- the rails can be fixed to the slab slab in different ways: by means of saddles or crosspieces or even by direct laying on the slab slab. Under the pad of each rail is usually interposed a rigid or anti-vibration sole. Often below and underneath each saddle or cross member is an anti-vibration pad.

- the slab slab has bowls to receive the lower part of the sleepers.

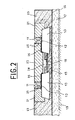

- the slab slab 15 rests on a layer of stabilized sand 17 placed on the bottom of the trunk (ground) 19.

- a draining layer 16 intended to drain water infiltration towards draining pipes 18 arranged at intervals along the track with a diameter and a spacing which are a function of the geographical location of the road.

- the slab slab ensures the stability of the installation.

- a layer of anti-vibration material can also be placed between the stabilized sand bed and the slab slab.

- the vacuum between the road slab 22 and the slab slab 15 is preferably filled by injection of a suitable filling product 28 chosen according to the degree of insulation required by the environment.

- the successive supports along the track are made so as to alternately constitute a support relatively rigid and relatively flexible support.

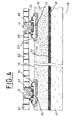

- FIG. 4 illustrates a case where the rail 11 is fixed to saddles 33 sealed in the slab slab 15, using an epoxy mortar, for example.

- the reference 31 designates a device for fixing a rail with joint bars.

- On the stabilized sand 17 are arranged, for example, a draining layer 35 and an anti-vibration isolation mat 37.

- the spaces between each rail 11 and the road slabs 21 and 22 are filled with separation elements 25 made of material having predetermined static and dynamic rigidities.

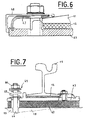

- FIG. 7 illustrates the fixing of a rail 11 on a saddle 43 which is itself fixed to the slab slab 15 by means of an adjustable fixing device 41 applying an adjustable preload to the anti-vibration sole 42 disposed under the saddle 43

- This fixing device provides antivibration isolation at low resonance frequency.

- the fixing device illustrated comprises a prestressing spring 45 held between two abutment washers around a threaded rod 44.

- the spring 45 is compressed by the clamping nut 46 which adjusts the prestressing force.

- the fixing device may also include two springs having rigidities different and held between two washers around the threaded rod 44, the springs being compressed by the clamping nut 46 which adjusts the prestressing force.

- the inventors have devised a measurement method by which the effects of the total static load applied to an axle of a vehicle having to travel on a railway track are decoupled from the equivalent of the unsprung mass of a bogie.

- the implementation of this method can be carried out, for example, using a test bench as shown diagrammatically in FIG. 9.

- the supports 61 are produced with static and dynamic stiffness chosen according to the actual operating conditions and the desired level of performance. For example, in the case where it is desired to optimize the antivibration isolation and limit the deflection of the rail, the supports 61 will be produced with alternating stiffnesses so as to be alternately a relatively rigid support R and a relatively flexible support S.

- load cell 64 By applying to load cell 64, a load in stages ranging from 0 to 250 kN, for example, and by moving the carriage along the section of track, it is possible to detect the static deflection of the rail to the right of each support.

- the natural frequency of the track system can be noted, the deflections in line with the supports and vibration damping of the rails to the right of each support.

- the analyzes thus carried out allow the designer of a railway track to be installed to determine in an optimal manner the particularities of the acoustic and anti-vibration insulation elements to be incorporated in the railroad support system in order to optimize the acoustic and anti-vibration insulation. and reduce the transmission of vibration waves to the environment.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Railway Tracks (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BE200100502 | 2001-07-25 | ||

| BE2001/0502A BE1014311A5 (fr) | 2001-07-25 | 2001-07-25 | Systeme de support de rails pour voie ferree en voirie et systeme d'analyse pour une telle voie ferree. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1279770A2 true EP1279770A2 (de) | 2003-01-29 |

| EP1279770A3 EP1279770A3 (de) | 2003-03-05 |

Family

ID=3897065

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02447141A Withdrawn EP1279770A3 (de) | 2001-07-25 | 2002-07-23 | Gleisunterstützungssystem für Schienen |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1279770A3 (de) |

| BE (1) | BE1014311A5 (de) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1460175A1 (de) * | 2003-03-17 | 2004-09-22 | Régie Autonome des Transports Parisiens | Verfahren zum Einlegen einer Verkehrs- und Gleisplattform, und eine derart hergestellte Plattform |

| WO2005124027A1 (de) * | 2004-06-22 | 2005-12-29 | Gmundner Fertigteile Gesellschaft M.B.H. & Co. Kg. | Leiterschwellengleis |

| EP1830002A1 (de) * | 2006-03-02 | 2007-09-05 | BTE Stelcon Deutschland GmbH | Gleiselement für Straßenbahnschienen und dergleichen |

| EP2295635A3 (de) * | 2009-08-14 | 2013-03-13 | edilon)(sedra GmbH | Schienenlagerung mit Deckkörpern für flexible Bustrasse und Verfahren zur deren Herstellung |

| FR2993582A1 (fr) * | 2012-07-17 | 2014-01-24 | Regie Autonome Transports | Procede de pose d'une voie comportant un support avec du beton |

| CN111395072A (zh) * | 2020-03-25 | 2020-07-10 | 江苏锡沂钢模有限公司 | 一种抗水平垂直振动的高速铁路轨枕 |

| CN113756138A (zh) * | 2021-10-08 | 2021-12-07 | 重庆交通职业学院 | 一种防沉降的地铁轨道 |

| WO2024114401A3 (zh) * | 2022-11-28 | 2024-08-02 | 中国铁道科学研究院集团有限公司铁道建筑研究所 | 高程可调整路基结构及其高程调整方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1997013037A1 (de) * | 1995-10-03 | 1997-04-10 | Gmundner Fertigteile Gesellschaft Mbh & Co. Kg | Schienengleicher bahnübergang |

| NL1001542C2 (nl) * | 1995-10-31 | 1997-05-02 | Stichting Geluidarme Spoorbrug | Spoorwegconstructie. |

| US5756903A (en) * | 1995-11-22 | 1998-05-26 | Holland Company | Track strength testing vehicle with a loaded gage axle and loaded gage axle apparatus |

| WO1998051863A1 (en) * | 1997-05-13 | 1998-11-19 | Mecno-Rail S.R.L. | Track superstructure, in particular for tramway, tram-railway and underground railway lines |

| DE19822178A1 (de) * | 1998-05-16 | 1999-12-02 | Weiss Gmbh & Co Leonhard | Gleiskörper in Endlosbauweise |

| DE29918842U1 (de) * | 1998-10-26 | 2000-02-17 | Dresdner Verkehrsbetriebe AG, 01129 Dresden | Gleisoberbau für Straßenbahnen, insbesondere in einer Fahrbahn für Straßenfahrzeuge |

-

2001

- 2001-07-25 BE BE2001/0502A patent/BE1014311A5/fr not_active IP Right Cessation

-

2002

- 2002-07-23 EP EP02447141A patent/EP1279770A3/de not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1997013037A1 (de) * | 1995-10-03 | 1997-04-10 | Gmundner Fertigteile Gesellschaft Mbh & Co. Kg | Schienengleicher bahnübergang |

| NL1001542C2 (nl) * | 1995-10-31 | 1997-05-02 | Stichting Geluidarme Spoorbrug | Spoorwegconstructie. |

| US5756903A (en) * | 1995-11-22 | 1998-05-26 | Holland Company | Track strength testing vehicle with a loaded gage axle and loaded gage axle apparatus |

| WO1998051863A1 (en) * | 1997-05-13 | 1998-11-19 | Mecno-Rail S.R.L. | Track superstructure, in particular for tramway, tram-railway and underground railway lines |

| DE19822178A1 (de) * | 1998-05-16 | 1999-12-02 | Weiss Gmbh & Co Leonhard | Gleiskörper in Endlosbauweise |

| DE29918842U1 (de) * | 1998-10-26 | 2000-02-17 | Dresdner Verkehrsbetriebe AG, 01129 Dresden | Gleisoberbau für Straßenbahnen, insbesondere in einer Fahrbahn für Straßenfahrzeuge |

Non-Patent Citations (1)

| Title |

|---|

| HAMMARLUND S ET AL: "GOOSE HILL MEASUREMENTS CONFIRM X2000'S LOW DYNAMIC TRACK FORCES" RAILWAY GAZETTE INTERNATIONAL, IPC TRANSPORT PRESS LTD. LONDON, GB, vol. 150, no. 7, 1 juillet 1994 (1994-07-01), pages 439,441-444, XP000452232 ISSN: 0373-5346 * |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1460175A1 (de) * | 2003-03-17 | 2004-09-22 | Régie Autonome des Transports Parisiens | Verfahren zum Einlegen einer Verkehrs- und Gleisplattform, und eine derart hergestellte Plattform |

| FR2852614A1 (fr) * | 2003-03-17 | 2004-09-24 | Regie Autonome Transports | Procede de pose d'une plate-forme de circulations ferroviaire et routiere, et plate-forme obtenue par ce procede |

| WO2005124027A1 (de) * | 2004-06-22 | 2005-12-29 | Gmundner Fertigteile Gesellschaft M.B.H. & Co. Kg. | Leiterschwellengleis |

| EP1830002A1 (de) * | 2006-03-02 | 2007-09-05 | BTE Stelcon Deutschland GmbH | Gleiselement für Straßenbahnschienen und dergleichen |

| EP2295635A3 (de) * | 2009-08-14 | 2013-03-13 | edilon)(sedra GmbH | Schienenlagerung mit Deckkörpern für flexible Bustrasse und Verfahren zur deren Herstellung |

| FR2993582A1 (fr) * | 2012-07-17 | 2014-01-24 | Regie Autonome Transports | Procede de pose d'une voie comportant un support avec du beton |

| CN111395072A (zh) * | 2020-03-25 | 2020-07-10 | 江苏锡沂钢模有限公司 | 一种抗水平垂直振动的高速铁路轨枕 |

| CN113756138A (zh) * | 2021-10-08 | 2021-12-07 | 重庆交通职业学院 | 一种防沉降的地铁轨道 |

| WO2024114401A3 (zh) * | 2022-11-28 | 2024-08-02 | 中国铁道科学研究院集团有限公司铁道建筑研究所 | 高程可调整路基结构及其高程调整方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1279770A3 (de) | 2003-03-05 |

| BE1014311A5 (fr) | 2003-08-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Ouakka et al. | Railway ground vibration and mitigation measures: benchmarking of best practices | |

| CA2598637C (fr) | Traverse de chemin de fer | |

| Nelson | Recent developments in ground-borne noise and vibration control | |

| CA2987083A1 (fr) | Appui d'un panneau de section de voie de transport guide | |

| EP1279770A2 (de) | Gleisunterstützungssystem für Schienen | |

| US20010023897A1 (en) | Rail support | |

| BE1017257A5 (fr) | Assise a niveau vibratoire reduit pour voie ferree. | |

| KR101938294B1 (ko) | 롤링저감을 위한 비틀림에 저항하는 강재빔을 이용한 철도용 방진궤도 시스템 | |

| KR101815652B1 (ko) | 진동저감형 철도역사 및 그 시공방법 | |

| AU2006212686B2 (en) | Level crossing | |

| Butorina et al. | Reduction of vibroacoustic effect of high-speed trains | |

| BE1014836A6 (fr) | Banc d'essai pour voie ferree. | |

| EP1251204B1 (de) | Schwingungsdämpfungssystem für Eisenbahngleise | |

| BE1015814A5 (fr) | Systeme de pose de voie ferree et traverse pour un tel systeme. | |

| KR100613412B1 (ko) | 콘크리트 도상의 방진침목 교체 시공방법 | |

| JPH06248606A (ja) | 防振軌道 | |

| Esveld | Track structures in an urban environment | |

| Wang et al. | Railway bridge noise control with resilient baseplates | |

| WO2000046448A1 (fr) | Dispositif de support pour rails de voie ferree | |

| JP3676112B2 (ja) | 高架橋の下部構造及びその設計方法 | |

| FR2901814A1 (fr) | Ensemble pour passage a niveau | |

| BE1009576A6 (fr) | Systeme de pose de voie ferree. | |

| EP1118711B1 (de) | Gleisschienenstützeinrichtung | |

| BE1008607A3 (fr) | Etouffeur de vibrations pour une voie ferree ou autre construction destinee a supporter un trafic. | |

| CA1328097C (fr) | Systeme de supports anti-vibratoires pour voie ferree |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20030808 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20041013 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20050224 |