EP1234946A2 - Porte sectionnelle - Google Patents

Porte sectionnelle Download PDFInfo

- Publication number

- EP1234946A2 EP1234946A2 EP01119612A EP01119612A EP1234946A2 EP 1234946 A2 EP1234946 A2 EP 1234946A2 EP 01119612 A EP01119612 A EP 01119612A EP 01119612 A EP01119612 A EP 01119612A EP 1234946 A2 EP1234946 A2 EP 1234946A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- plate elements

- magazine

- element gate

- guide rails

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000007789 sealing Methods 0.000 claims description 23

- 239000000463 material Substances 0.000 claims description 14

- 239000011248 coating agent Substances 0.000 claims description 7

- 238000000576 coating method Methods 0.000 claims description 7

- 238000009413 insulation Methods 0.000 claims description 7

- 238000000034 method Methods 0.000 claims description 5

- 230000007246 mechanism Effects 0.000 claims description 4

- 239000004033 plastic Substances 0.000 claims description 4

- 230000003068 static effect Effects 0.000 claims description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 4

- 238000006073 displacement reaction Methods 0.000 claims description 3

- 230000007613 environmental effect Effects 0.000 claims description 3

- 239000002184 metal Substances 0.000 claims description 3

- 244000027321 Lychnis chalcedonica Species 0.000 claims description 2

- 239000000156 glass melt Substances 0.000 claims description 2

- 238000001746 injection moulding Methods 0.000 claims description 2

- 239000011810 insulating material Substances 0.000 claims description 2

- 238000003825 pressing Methods 0.000 claims description 2

- 206010061217 Infestation Diseases 0.000 claims 1

- 238000005187 foaming Methods 0.000 claims 1

- 239000007787 solid Substances 0.000 claims 1

- 230000000694 effects Effects 0.000 abstract description 3

- 230000000149 penetrating effect Effects 0.000 abstract description 2

- 238000009434 installation Methods 0.000 description 6

- 239000012774 insulation material Substances 0.000 description 6

- 238000005452 bending Methods 0.000 description 3

- 239000000428 dust Substances 0.000 description 3

- 239000006260 foam Substances 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 238000006748 scratching Methods 0.000 description 2

- 230000002393 scratching effect Effects 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- -1 Polytetrafluoroethylene Polymers 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000003245 coal Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000005058 metal casting Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/02—Shutters, movable grilles, or other safety closing devices, e.g. against burglary

- E06B9/06—Shutters, movable grilles, or other safety closing devices, e.g. against burglary collapsible or foldable, e.g. of the bellows or lazy-tongs type

- E06B9/0607—Shutters, movable grilles, or other safety closing devices, e.g. against burglary collapsible or foldable, e.g. of the bellows or lazy-tongs type comprising a plurality of similar rigid closing elements movable to a storage position

- E06B9/0646—Shutters, movable grilles, or other safety closing devices, e.g. against burglary collapsible or foldable, e.g. of the bellows or lazy-tongs type comprising a plurality of similar rigid closing elements movable to a storage position characterised by the relative arrangement of the closing elements in the stored position

- E06B9/0676—Shutters, movable grilles, or other safety closing devices, e.g. against burglary collapsible or foldable, e.g. of the bellows or lazy-tongs type comprising a plurality of similar rigid closing elements movable to a storage position characterised by the relative arrangement of the closing elements in the stored position stored in a stacked configuration

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/02—Shutters, movable grilles, or other safety closing devices, e.g. against burglary

- E06B9/06—Shutters, movable grilles, or other safety closing devices, e.g. against burglary collapsible or foldable, e.g. of the bellows or lazy-tongs type

- E06B9/0607—Shutters, movable grilles, or other safety closing devices, e.g. against burglary collapsible or foldable, e.g. of the bellows or lazy-tongs type comprising a plurality of similar rigid closing elements movable to a storage position

- E06B9/0615—Shutters, movable grilles, or other safety closing devices, e.g. against burglary collapsible or foldable, e.g. of the bellows or lazy-tongs type comprising a plurality of similar rigid closing elements movable to a storage position characterised by the closing elements

- E06B9/0638—Slats or panels

Definitions

- Such an element gate is known from JP 07 310 483 A.

- the single ones Plate elements are by rollers arranged at the top and bottom of their narrow sides guided in a vertical rail section and with the upper rollers in one stored horizontally angled rail section representing the magazine.

- the transfer into the magazine is made by falling towards the magazine Sliding surfaces on the undersides and tops of the plate elements caused by which the plate element arriving at the magazine is characterized by the Wedge pushing effect of the sliding surfaces next to the one located there and pushing it along transported to the magazine.

- the one to be overcome when pushed into the magazine Static and sliding friction depend strongly on the material and the surface pressure of which by external influences such as temperature, dust and Moisture caused wear or abrasion caused condition of the sliding surfaces.

- the object of the invention is an element gate to create the type described above, in which the sliding surfaces of the Plate elements compared to the environmental influences described above in both possible installation versions are protected and also a greater bending strength of the Plate elements is achieved, through which a harmless application of with Insulation layers or insulation panels provided with panel elements is made possible.

- the inventive Plate elements can be used in both possible built-in versions, so this are now more cost-effective to produce in larger numbers and thus a Particularly favorable cost-benefit ratio of the Element gates according to the invention can be recorded with the longest possible service life. Due to the profile shapes of the contact seals according to the invention, the dynamic rigidity of the plate elements per se and compared to that by the stresses caused by temperature-related expansion and shrinking movements significantly increased. They can therefore be used undamaged as sandwich panels or According to the invention with slightly crumbling provided in a housing cavity highly active porous insulation materials or otherwise with insulation boards be combined.

- the stability of the plate elements thus formed continues increased by the inventive concept, the plate elements with the Touch seal shapes and side guide elements and others Functional parts, if necessary, with insulation materials or insulation panels on the back receiving housing or holding forms, so to speak, in one pour by way of To produce master forms and, if necessary, also forming techniques.

- the plate elements made of light metal castings, light plate elements in Plastic pressing or injection molding process and light guide plates in the glass melt manufacture, which by their individual purpose solutions in a surprising way unifying and ensuring greater stiffness the construction Permanent stresses have grown well.

- the plate elements shown in the drawing are e.g. in the above Made from a plastic material using a master molding technique.

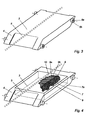

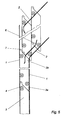

- Figure 1 is an element gate in front view of a window and in Figure 2 the Movement sequence illustrating side view of the same.

- the element gate in Figure 1 in the closed position in the vertical Guide rails 1 located plate elements 3.

- the elevator device 13 In the magazine section 2 is only the elevator device 13 indicated, which with belts on the last one Plate element or a belt strip 3c attacks.

- two upright sliding bulges 12 which have a starting slope 12a at the bottom exhibit. This is the sliding of the plate elements in the Magazine section 2 facilitates and also scratching the plate surfaces avoided.

- Such lubricants can of course also be made on other manufactured Plate elements are glued on.

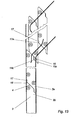

- rollers 6a, 6b and 6c as guide elements on both sides intended.

- the axes 6 of the same are formed on the plates and can can of course also be designed as slide cams 6 instead of the rollers.

- the axles 6a, 6b and 6c are the axles with one or two grooves for one Provide expansion ring to be attached.

- Figure 2 is also at the transition to Magazine section 2 a the plate elements automatically in the open and in the Locked locking mechanism 11 indicated. For this, e.g. the indicated Maltese cross with switch to forward and reverse suitable by. the belt strip 3c can be actuated and the plate elements also - if such Execution desired - can hold in intermediate positions.

- the bottom right and top rollers 6a and 6b arranged on the left of the plates guide the plate elements into the Rail guides.

- the plate elements are usually conveyed into the magazine by the sliding surfaces 5, but in this embodiment increased by this protruding thrust surfaces 4.

- the respective width and height of this depends according to the plate or push surface material and the weight of the Plate elements; their height is preferably in the micron range.

- the push surfaces 4 can also with a coating or a covering from a lower adhesion and Material with sliding friction coefficient exist or are stored Contain metal powder, sintered materials or coal. They can also be made from thin ones they are anchored to polished steel sheets of low roughness or material combinations consist.

- the magazine guides 2a-2b-1a-1b naturally have one towards the magazine lower height.

- the Plate element according to Figure 4 is a housing for receiving insulation material educated. At the back there is a cavity 7 receiving this, which is attached to it by an edge 8 or a step seat Cover layer 10 is to be completed.

- the one introduced into the cavity here, for example or glued-in insulating material layer consists of a film 9a under vacuum pressed-in insulation material 9, which is enveloped by a further foam film 9b, which in the exemplary embodiment consists essentially of highly disperse silica consists. You can also insulate in the cavity in the manner of sandwich panels foam, which are glued to the top layer.

- the housing can also be used as a guide that can be inserted laterally at the top and bottom be trained ..

- FIG. 8 shows a particularly simple sealing form in which the step-shaped recess 14c and the strip-shaped lip 15c have a wedge angle corresponding to the sliding surfaces 5 at the top.

- the vertical wall of the recess 14b is here provided with a sealing coating 16 against which the cheek of the sealing strip 15b is pressed in the vertical guide 1 and thus also provides a good sealing closure.

- the same contact seal can also be seen in the reverse arrangement in FIG.

- the sealing means according to the invention can, as usual, be completed by sealing means comprising resilient sealing strips, brushes or ball bearing strips in the vertical guide rails 1-1.

- FIG. 10 shows, according to the invention the partial task of preventing rainwater from penetrating can also be solved in a different way by drip edges 17a, which are provided on an arch 17 at the bottom of the plate elements 3 above the sliding or pushing surfaces 4-5.

- drip edges 17a which are provided on an arch 17 at the bottom of the plate elements 3 above the sliding or pushing surfaces 4-5.

- the drip edges 17a can be assigned a chamfer 18 on the upper sides of the respectively following plate elements, which chamfer has a drainage surface which is directed downwards from the inside to the outside.

- a density — here primarily to avoid an air bridge — can also be applied to the other inward side of the plate elements by means of a projecting sealing strip 15c here each upper plate element can be achieved, which is fitted into a sealing niche 14c provided with a sealing coating 16 on the underside of the respective following plate. All touch seals shown can, of course, be carried out figuratively on the other side of the plate.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

Applications Claiming Priority (11)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2001108702 DE10108702A1 (de) | 2001-06-12 | 2001-02-23 | Abschirm-und/oder Schutzvorrichtung für Gebäudeöffnungen |

| DE10108702 | 2001-02-23 | ||

| DE10118928 | 2001-04-18 | ||

| DE2001118928 DE10118928A1 (de) | 2001-04-18 | 2001-04-18 | Abschirm- und Schutzvorrichtung für Wandöffnungen in Form eines Elementtores |

| DE10121094 | 2001-04-23 | ||

| DE10121094 | 2001-04-23 | ||

| DE10121084 | 2001-04-28 | ||

| DE10122819 | 2001-05-11 | ||

| DE10122819 | 2001-05-11 | ||

| DE10127603 | 2001-06-12 | ||

| DE2001127603 DE10127603A1 (de) | 2001-02-23 | 2001-06-12 | Elementtor |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1234946A2 true EP1234946A2 (fr) | 2002-08-28 |

| EP1234946A3 EP1234946A3 (fr) | 2003-08-20 |

Family

ID=27512406

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01119612A Withdrawn EP1234946A3 (fr) | 2001-02-23 | 2001-08-20 | Porte sectionnelle |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1234946A3 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10329798A1 (de) * | 2003-07-01 | 2005-02-24 | Guido Langenbach | Sektionaltor |

| US10125540B2 (en) | 2014-01-29 | 2018-11-13 | Gmp Nv | Sectional door with lifting mechanism |

| US20220074262A1 (en) * | 2018-12-28 | 2022-03-10 | Simon-Andreas MAURER | Retractable Partition Wall |

| WO2022072395A1 (fr) | 2020-09-30 | 2022-04-07 | Cornellcookson, Llc | Porte de panneau à empilement vertical dotée de leviers de came |

| US11927055B2 (en) | 2020-10-05 | 2024-03-12 | Cornellcookson, Llc | Vertically stacking panel door with a lifting cam |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07310483A (ja) | 1994-04-15 | 1995-11-28 | Shinko Ind:Kk | シャッター |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL8502956A (nl) * | 1985-10-30 | 1987-05-18 | Carmen Francisca Maria Van Vil | Afscherming. |

| DE19519529C1 (de) * | 1995-05-27 | 1996-06-05 | Top Form Gmbh Fenster Tueren U | Hubstaffeltor |

| EP0991844B1 (fr) * | 1997-06-25 | 2002-08-21 | Gregory H. Cook | Systeme de fermeture ameliore |

-

2001

- 2001-08-20 EP EP01119612A patent/EP1234946A3/fr not_active Withdrawn

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07310483A (ja) | 1994-04-15 | 1995-11-28 | Shinko Ind:Kk | シャッター |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10329798A1 (de) * | 2003-07-01 | 2005-02-24 | Guido Langenbach | Sektionaltor |

| DE10329798B4 (de) * | 2003-07-01 | 2009-04-09 | Guido Langenbach | Sektionaltor |

| US10125540B2 (en) | 2014-01-29 | 2018-11-13 | Gmp Nv | Sectional door with lifting mechanism |

| US20220074262A1 (en) * | 2018-12-28 | 2022-03-10 | Simon-Andreas MAURER | Retractable Partition Wall |

| US12398592B2 (en) * | 2018-12-28 | 2025-08-26 | Simon-Andreas MAURER | Retractable partition wall |

| WO2022072395A1 (fr) | 2020-09-30 | 2022-04-07 | Cornellcookson, Llc | Porte de panneau à empilement vertical dotée de leviers de came |

| EP4222333A4 (fr) * | 2020-09-30 | 2024-10-30 | Cornellcookson, Llc | Porte de panneau à empilement vertical dotée de leviers de came |

| US11927055B2 (en) | 2020-10-05 | 2024-03-12 | Cornellcookson, Llc | Vertically stacking panel door with a lifting cam |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1234946A3 (fr) | 2003-08-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE202008013043U1 (de) | Hebe-Schiebe-Fenster oder -Tür sowie Abdichtelement | |

| EP1554455A1 (fr) | Element pour espacer des vitres de vitrages isolants multiples | |

| EP1431501B1 (fr) | Installation de porte coulissante | |

| EP2317054B1 (fr) | Porte coulissante | |

| DE60306623T2 (de) | Kombination aus dichtungsrahmen, lichtsperre und verschleisseinsatz für kipptorplatte | |

| DE29808292U1 (de) | Abschlußprofil für ein Torblatt | |

| EP2546448B1 (fr) | Dispositif de décalage d'un objet de décalage | |

| AT392327B (de) | Strangfoermige fluegelfalzdichtung fuer fenster, tueren oder dgl. raumabschlussorgane | |

| EP1354545B1 (fr) | Joint pour une cloison de séparation de douche | |

| EP0370324A2 (fr) | Vantail de porte | |

| EP1234946A2 (fr) | Porte sectionnelle | |

| EP1659254B1 (fr) | Vantail de porte ou fenêtre | |

| DE102019125204A1 (de) | Rolltor | |

| DE9206018U1 (de) | Sectionaltor | |

| DE8632855U1 (de) | Elastisches Dichtungsprofil als Anschlagprofil für Türen od. dgl. | |

| DE19829783A1 (de) | Schiebetür- oder Trennwandanlage | |

| DE19806123A1 (de) | Lamellenfenster | |

| EP0730068A1 (fr) | Lucarne | |

| DE3310230A1 (de) | Fenster | |

| EP2487313A1 (fr) | Construction de cadre pour une fenêtre ou une porte | |

| EP2466051A2 (fr) | Porte à isolation thermique | |

| DE19911022A1 (de) | Fenster für ein Kraftfahrzeug | |

| DE202019102768U1 (de) | Dachfenster-Konstruktionssystem | |

| DE10250284A1 (de) | Elementtor | |

| DE69415002T2 (de) | Vorrichtung für ein zu öffnendes dach |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20040115 |

|

| AKX | Designation fees paid |

Designated state(s): DE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20040302 |