EP1234603B1 - Herstellungsverfahrung eines Gleitbrett,Verstärkung und ein Gleitbrett mit solch einer Verstärkung - Google Patents

Herstellungsverfahrung eines Gleitbrett,Verstärkung und ein Gleitbrett mit solch einer Verstärkung Download PDFInfo

- Publication number

- EP1234603B1 EP1234603B1 EP02356008A EP02356008A EP1234603B1 EP 1234603 B1 EP1234603 B1 EP 1234603B1 EP 02356008 A EP02356008 A EP 02356008A EP 02356008 A EP02356008 A EP 02356008A EP 1234603 B1 EP1234603 B1 EP 1234603B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- board

- rigid reinforcement

- gliding

- reinforcements

- internal rigid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C5/00—Skis or snowboards

- A63C5/12—Making thereof; Selection of particular materials

Definitions

- the present invention relates to a method for producing a snow gliding board comprising an internal rigid reinforcement.

- the present invention also relates to an internal rigid reinforcement intended for a board for sliding on snow.

- the present invention finally relates to a snow sliding board comprising an internal rigid reinforcement.

- the rigid reinforcement can have a variable position relative to the rest of the elements, that is to say the gliding sole, the side edges and the first laminated reinforcement.

- the reinforcement rigid can be laterally offset from these same elements. More precisely, the internal rigid reinforcement will be off-center with respect to the median longitudinal axis of the snow-sliding board.

- centering defects lead to the obtaining of a ski having very poor and very variable mechanical and dimensional characteristics. During uses on the track, the behavior of the skis thus obtained will also be variable. These centering defects lead to overlaps reinforcements that cause deformations of the structures of the gliding board. These centering defects lead to a lack of homogeneity in the manufacture of boards gliding and having consequences in their behavior on the snow.

- a first problem posed consists in developing a method for making a board for gliding on snow comprising a particular step of laying a rigid reinforcement shaped to be able to be centered without any difficulty and without specific tools.

- a second problem is to design a rigid reinforcement whose own configuration allows it to focus automatically relative to the median longitudinal axis of the gliding board.

- a third problem posed is to constitute a snow sliding board having a longitudinally rigid rigid reinforcement.

- a method for making a board for gliding on snow includes the following first steps, consisting in positioning a sliding base in a mold, to border this sole with two metal side edges, to position a first layer-like reinforcement pre-impregnated by above the gliding sole, and finally to position at least one internal rigid reinforcement.

- the method is characterized in that the one or more rigid internal reinforcements comprise at least one lateral protrusion positioned exclusively at the level of the heel zone, in order to center said or said rigid reinforcements internal with respect to the median longitudinal axis of the snow gliding board.

- the protrusion (s) of the internal rigid reinforcement (s) may also have a sufficient length, so as to abut against a shoulder present in the mold and protruding laterally from the edge of the mold defining the edges of the snow gliding board.

- the internal rigid reinforcement advantageously comprises two protuberances.

- the internal rigid reinforcement consists of a metal sheet whose thickness is between 0.2 mm and 1.2 mm.

- the internal rigid reinforcement may consist of a rigid laminate plate of fiberglass and / or carbon fiber and / or aramid fiber.

- a board for gliding on snow comprises a gliding sole bordered by metal side edges, a top layer of protection and decoration and a filling core comprising on at least one of its faces, lower and / or upper, at least one reinforcement rigid internal.

- the snow gliding board is characterized in that the at least one rigid reinforcing member has at least one flush zone at the level of the heel area of the gliding board on snow, so that to allow the centering of the median longitudinal axis of said one or more internal rigid reinforcements relative to the median longitudinal axis of the snow gliding board.

- the area or zones of the rigid or internal stiffeners are flush laterally over a length of 5 mm to 30 mm.

- the Snowboarding board may comprise an internal rigid reinforcement having two flush lateral areas located on the right and left sides with respect to the median longitudinal axis of the snow board.

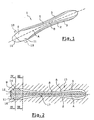

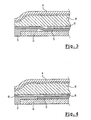

- a board for gliding on snow 1 successively comprises a gliding sole 2, bordered by metal side edges 3, an upper layer of protection and decoration 4, a filling core 6 having on at least one of its lower faces a internal rigid reinforcement 8.

- the gliding board also comprises a reinforcement 5, for example of pre-impregnated type, and positioned above the gliding base 2.

- the rigid reinforcement 8 is generally placed on top of this reinforcement of laminated type 5.

- the rigid reinforcement 8 will comprise two protuberances 9 and 11 positioned laterally on either side of the median longitudinal axis A of the gliding board 1. These two protuberances 9 and 11 are furthermore placed at the of the heel area 12 of the gliding board 1.

- the two protuberances or protruding areas 9 and 11 come flush laterally at the heel area 12 of the snow gliding board.

- a flush length at the edges varies in practice between 5 mm and 30 mm.

- a mold 13 is chosen according to the dimensions of the desired gliding board.

- the sole 2 is placed at the bottom of the mold 13.

- this sole is bordered by two metal side edges 3.

- a first reinforcement 5 of the prepreg laminated type is placed over the gliding sole 2.

- the rigid reinforcement 8 comprising these two protuberances 9 and 11 is wedged at the bottom of the mold 13.

- the rigid reinforcement 8 will be perfectly positioned at the bottom of the mold 13.

- the median longitudinal axis of the rigid reinforcement 8 will be confused with the median longitudinal axis A of the snow sliding board.

- the two protuberances 9 and 11 will come into abutment in two zones 14 and 16 respectively against the wall 17 of the mold 13. These two contact zones 14 and 16 make the rigid reinforcement 8 can not move laterally inside the mold 13.

- protuberances 18 and 19 which extend well beyond the lateral edge 17 of the mold 13 (shown in dashed lines in FIG. 1). These two protuberances 18 and 19 projecting laterally with respect to the edge of the mold 17, will abut against a shoulder (not shown) which will be present inside the mold 13 and which will be very set back with respect to the lateral edge 17 of the mold 13.

- the rigid metal reinforcement can be made of different types of materials.

- a metal sheet whose thickness is between 0.2 mm and 1.2 mm can be used.

- a rigid laminate plate made of glass fibers and / or carbon fibers and / or aramid fibers is a particularly interesting alternative.

- the gliding board may comprise several rigid reinforcements 8. each comprising the centering protrusions 9, 11, 18 and 19.

- the number of these outgrowths or projections 9, 11, 18 and 19 may be variable.

- These protuberances and projections 9, 11, 18 and 19 may have different shapes.

Landscapes

- Laminated Bodies (AREA)

- Dry Formation Of Fiberboard And The Like (AREA)

- Road Paving Structures (AREA)

- Materials Applied To Surfaces To Minimize Adherence Of Mist Or Water (AREA)

- Soil Conditioners And Soil-Stabilizing Materials (AREA)

Claims (9)

- Verfahren zur Herstellung eines Schnee-Gleitbretts (1), dadurch gekennzeichnet, daß es die folgenden ersten Schritte umfaßt, bestehend im:- Positionieren eines Gleitbelags (2) in einer Form (13);- Umranden dieses Belags (2) durch zwei seitliche metallische Kanten (3);- Positionieren einer ersten Verstärkung des vor-imprägnierten Schichttyps (5) auf dem Gleitbelag (2); und- schließlich Positionieren mindestens einer steifen inneren Verstärkung (8),

dadurch gekennzeichnet, daß die steife(n) innere(n) Verstärkung(en) (8) mindestens eine seitliche Ausstülpung (9,11,18,19) umfaßt/umfassen, welche ausschließlich im Bereich der Endzone (12) positioniert ist, um die genannte(n) steife(n) innere(n) Verstärkung(en) (8) in bezug auf die mittlere Längsachse (A) des Schnee-Gleitbretts (1) zu zentrieren. - Verfahren nach Anspruch 1, dadurch gekennzeichnet, daß man abschließend zu einem Schritt des Schneidens oder Schleifens der Ausstülpung(en) (9,11) der steifen inneren Verstärkung(en) (8) übergeht, damit die steife(n) innere(n) Verstärkung(en) (8) bündig abschließt/abschließen, ohne den Seitenrand zu überragen, der die Seitenwangen des Schnee-Gleitbretts (1) bildet.

- Verfahren nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß die seitliche(n) Ausstülpung(en) (18,19) der steifen inneren Verstärkung(en) (8) eine ausreichende Länge aufweisen, um zur Anlage gegen eine Schulter zu gelangen, welche in der Form vorhanden ist und seitlich den Rand der Form überragt, welcher die Seitenwangen des Schnee-Gleitbretts (1) definiert.

- Verfahren nach einem beliebigen der vorangehenden Ansprüche, dadurch gekennzeichnet, daß die steife(n) innere(n) Verstärkung(en) (8) zwei seitliche Ausstülpungen (9,11) umfaßt/umfassen.

- Verfahren nach einem beliebigen der vorangehenden Ansprüche, dadurch gekennzeichnet, daß die steife(n) innere(n) Verstärkung(en) (8) von einem metallischen Blech gebildet werden, dessen Dicke zwischen 0,2 mm und 1,2 mm liegt.

- Verfahren nach einem beliebigen der vorangehenden Ansprüche, dadurch gekennzeichnet, daß die steife(n) innere(n) Verstärkung(en) (8) von einer steifen Schichtplatte aus Glasfasern und/oder aus Karbonfasern und/oder aus Aramidfasern gebildet wird/werden.

- Schnee-Gleitbrett mit einem Gleitbelag (2), der durch zwei seitliche metallische Kanten (3) umrandet ist, einer oberen Schutz- und Dekorationsschicht (4) und einem Füllungskern (6), der auf mindestens einer seiner Seiten, der unteren und/oder der oberen, mindestens eine steife innere Verstärkung (8) umfaßt, dadurch gekennzeichnet, daß die steife(n) innere(n) Verstärkung(en) (8) mindestens eine seitlich bündig abschließende Zone (9,11) ausschließlich im Bereich der Endzone (12) des Schnee-Gleitbretts (1) aufweist/aufweisen, um die Zentrierung der mittleren Längsachse der genannten inneren Verstärkung(en) (8) in bezug auf die mittlere Längsachse (A) des Schnee-Gleitbretts (1) zu erlauben.

- Schnee-Gleitbrett nach Anspruch 7, dadurch gekennzeichnet, daß die Zone(n) der steifen inneren Verstärkung(en) (8) seitlich über eine Länge von 5 mm bis 30 mm bündig abschließt/abschließen.

- Schnee-Gleitbrett nach Anspruch 6 oder 7, dadurch gekennzeichnet, daß es eine steife innere Verstärkung (8) umfaßt, welche zwei seitlich bündig abschließende Zonen (9,11) aufweist, die auf der rechten Seite und auf der linken Seite in bezug auf die mittlere Längsachse (A) des Schnee-Gleitbretts (1) angeordnet sind.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0102413 | 2001-02-22 | ||

| FR0102413A FR2820981B1 (fr) | 2001-02-22 | 2001-02-22 | Procede pour realiser une planche de glisse sur neige, renfort et planche de glisse sur neige comprenant un tel renfort |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1234603A1 EP1234603A1 (de) | 2002-08-28 |

| EP1234603B1 true EP1234603B1 (de) | 2006-03-15 |

| EP1234603B8 EP1234603B8 (de) | 2006-06-14 |

Family

ID=8860317

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02356008A Expired - Lifetime EP1234603B8 (de) | 2001-02-22 | 2002-01-17 | Herstellungsverfahrung eines Gleitbrett,Verstärkung und ein Gleitbrett mit solch einer Verstärkung |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6755434B2 (de) |

| EP (1) | EP1234603B8 (de) |

| AT (1) | ATE320288T1 (de) |

| DE (1) | DE60209865T2 (de) |

| FR (1) | FR2820981B1 (de) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2841479B1 (fr) * | 2002-06-26 | 2007-04-13 | Salomon Sa | Engin de glisse comprenant deux parois |

| FR2882269A1 (fr) * | 2005-02-23 | 2006-08-25 | Skis Rossignol Sa Sa | Planche de glisse sur neige a element superieur de decoration et de protection |

| AT504800B1 (de) * | 2007-02-02 | 2010-05-15 | Atomic Austria Gmbh | Schi oder snowboard mit einem plattenartigen kraftübertragungselement |

| DE102017125770A1 (de) * | 2016-12-29 | 2018-07-05 | Völkl Sports GmbH & Co. KG | Untergurt mit Klammereffekt |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT313136B (de) * | 1971-07-07 | 1974-02-11 | Christine Nowak | Zur Aufnahme der Laufkanten sowie des Sohlenbelages dienender Skibauteil aus thermoplastischem Material |

| US3902732A (en) * | 1973-02-14 | 1975-09-02 | Jr Albert A Fosha | Advanced composition ski |

| US4068861A (en) * | 1976-02-26 | 1978-01-17 | Hexcel Corporation | Lightweight, flexible ski |

| US4647061A (en) * | 1985-11-21 | 1987-03-03 | Girard Donald A | Ski stiffened in torsion by a bellows-like member |

| FR2678543B1 (fr) * | 1991-07-04 | 1996-03-01 | Rossignol Sa | Procede pour la realisation d'une structure moulee complexe, et notamment d'un ski et ski obtenu par la mise en óoeuvre de ce procede. |

| FR2679821B1 (fr) * | 1991-07-31 | 1993-10-22 | Rossignol Sa Skis | Procede pour la fabrication d'une structure moulee complexe, et notamment d'un ski, et structure moulee complexe ainsi obtenue. |

| FR2683733B1 (fr) * | 1991-11-19 | 1994-03-18 | Rossignol Sa Skis | Ski en forme, de section non rectangulaire. |

| FR2683734B1 (fr) * | 1991-11-19 | 1994-01-07 | Rossignol Sa | Ski en forme, de section non rectangulaire. |

| FR2692158B1 (fr) * | 1992-06-11 | 1994-12-16 | Rossignol Sa | Ski à profil perfectionné. |

| USRE36453E (en) * | 1993-04-16 | 1999-12-21 | Skis Rossignol S.A. | Ski including sides and an upper shell |

| JPH07265483A (ja) * | 1994-03-31 | 1995-10-17 | Kazama Sports Hanbai Kk | スキー板の製造方法並びにスキー板 |

| FR2734492B1 (fr) * | 1995-05-22 | 1997-06-27 | Rossignol Sa | Planche de glisse sur neige comportant un dispositif pour le montage d'une fixation d'une chaussure |

| FR2734491B1 (fr) * | 1995-05-22 | 1997-06-27 | Rossignol Sa | Planche de glisse sur neige comportant un dispositif pour le montage d'une fixation d'une chaussure |

| FR2773997B1 (fr) * | 1998-01-28 | 2000-02-25 | Rossignol Sa | Planche de glisse dont les chants sont equipes d'elements de renforcement presents sur une partie de la longueur portante de la planche |

| FR2780294B1 (fr) * | 1998-06-25 | 2000-08-11 | Rossignol Sa | Planche de glisse sur neige |

| US6102428A (en) * | 1998-12-04 | 2000-08-15 | Skis Rossignol, S.A. | Assembly for gliding on snow |

| DE19917992A1 (de) * | 1999-04-21 | 2000-11-02 | Uwe Emig | Alpinski |

| US6612605B2 (en) * | 1999-09-29 | 2003-09-02 | K-2 Corporation | Integrated modular glide board |

-

2001

- 2001-02-22 FR FR0102413A patent/FR2820981B1/fr not_active Expired - Fee Related

-

2002

- 2002-01-17 AT AT02356008T patent/ATE320288T1/de not_active IP Right Cessation

- 2002-01-17 DE DE60209865T patent/DE60209865T2/de not_active Expired - Fee Related

- 2002-01-17 EP EP02356008A patent/EP1234603B8/de not_active Expired - Lifetime

- 2002-02-20 US US10/079,335 patent/US6755434B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| FR2820981B1 (fr) | 2003-03-28 |

| DE60209865T2 (de) | 2006-08-10 |

| DE60209865D1 (de) | 2006-05-11 |

| US6755434B2 (en) | 2004-06-29 |

| EP1234603B8 (de) | 2006-06-14 |

| US20020113409A1 (en) | 2002-08-22 |

| ATE320288T1 (de) | 2006-04-15 |

| EP1234603A1 (de) | 2002-08-28 |

| FR2820981A1 (fr) | 2002-08-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1475303B1 (de) | Surfbrett und Verfahren zu seiner Herstellung | |

| EP0577947B1 (de) | Ski mit einer Rippe und einer Stützvorrichtung | |

| EP0620027B1 (de) | Ski mit Seitenwangen und Oberschale | |

| EP0620028A1 (de) | Ski mit Seitenwangen und Oberschale | |

| EP1234603B1 (de) | Herstellungsverfahrung eines Gleitbrett,Verstärkung und ein Gleitbrett mit solch einer Verstärkung | |

| EP1321358A2 (de) | Strukturuntereinheit und Surfbrett sowie Herstellungsverfahren hierfür | |

| EP0976427B1 (de) | Gleitbrett für Alpineski oder Snowboarding | |

| EP3305378A1 (de) | Schläger, insbesondere struktur eines padel-schlägers | |

| EP0120521B1 (de) | Schichtski mit Einbau von metallischer Folie | |

| EP1440712A1 (de) | Gleit- oder Rollbrett | |

| EP1484091B1 (de) | Ski für Alpineskifahren | |

| EP1279419B1 (de) | Alpinski | |

| EP2353672B1 (de) | Gleitbrett für Schnee mit Seitenwange variabler Breite | |

| WO2005065912A1 (fr) | Procede de fabrication d’une planche de glisse et planche obtenue par un tel procede | |

| EP3251730B1 (de) | Ski mit gewichtsreduziertem kern | |

| EP2055358B1 (de) | Snowboard, dessen Gleitseite eine Rille aufweist | |

| EP1082977A1 (de) | Ski, oder andere Gleitbretter mit verstärkten und separaten Seitenwangen und dazugehöriges Verfahren | |

| FR2818915A1 (fr) | Planche de glisse | |

| EP4176945B1 (de) | Skikern und ski mit einem solchen kern | |

| FR2713100A1 (fr) | Ski. | |

| EP1774995A1 (de) | Gleit- oder Rollbrett | |

| EP3415206B1 (de) | Gleitbrett | |

| EP2921210B1 (de) | Snowboard und herstellungsmethode eines solchen snowboards | |

| FR2825646A1 (fr) | Ski prevu pour la pratique du ski alpin | |

| FR3084596A1 (fr) | Ski alpin |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20021202 |

|

| AKX | Designation fees paid |

Designated state(s): AT DE FR |

|

| 17Q | First examination report despatched |

Effective date: 20050415 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE FR |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: SKIS ROSSIGNOL |

|

| REF | Corresponds to: |

Ref document number: 60209865 Country of ref document: DE Date of ref document: 20060511 Kind code of ref document: P |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20061215 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20070110 Year of fee payment: 6 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20061218 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20070131 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080117 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20081029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080131 |