EP1189004B1 - Rouleau de four que l'on peut refroidir à l'eau - Google Patents

Rouleau de four que l'on peut refroidir à l'eau Download PDFInfo

- Publication number

- EP1189004B1 EP1189004B1 EP01119488A EP01119488A EP1189004B1 EP 1189004 B1 EP1189004 B1 EP 1189004B1 EP 01119488 A EP01119488 A EP 01119488A EP 01119488 A EP01119488 A EP 01119488A EP 1189004 B1 EP1189004 B1 EP 1189004B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- shaft

- furnace

- furnace roller

- roller according

- carrier ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 title description 3

- 230000005540 biological transmission Effects 0.000 claims description 6

- 239000002826 coolant Substances 0.000 claims description 5

- 238000009749 continuous casting Methods 0.000 claims description 4

- 239000002184 metal Substances 0.000 claims description 4

- 229910052751 metal Inorganic materials 0.000 claims description 4

- 239000000463 material Substances 0.000 claims description 3

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims description 2

- 238000010276 construction Methods 0.000 claims description 2

- 239000011888 foil Substances 0.000 claims 1

- 238000001816 cooling Methods 0.000 abstract description 5

- 238000010438 heat treatment Methods 0.000 description 9

- 230000013011 mating Effects 0.000 description 6

- 238000005096 rolling process Methods 0.000 description 5

- 229910000831 Steel Inorganic materials 0.000 description 4

- 239000010959 steel Substances 0.000 description 4

- 230000035882 stress Effects 0.000 description 4

- 238000005266 casting Methods 0.000 description 3

- 230000006378 damage Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 238000004873 anchoring Methods 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000000498 cooling water Substances 0.000 description 2

- 230000012010 growth Effects 0.000 description 2

- 230000017525 heat dissipation Effects 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 102000015933 Rim-like Human genes 0.000 description 1

- 108050004199 Rim-like Proteins 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 210000003746 feather Anatomy 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000003779 heat-resistant material Substances 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 239000011819 refractory material Substances 0.000 description 1

- 238000013341 scale-up Methods 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS, OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D3/00—Charging; Discharging; Manipulation of charge

- F27D3/02—Skids or tracks for heavy objects

- F27D3/026—Skids or tracks for heavy objects transport or conveyor rolls for furnaces; roller rails

Definitions

- the invention relates to a water-coolable oven roll for conveying cargo, eg. Continuous casting of a continuous casting, by a roller hearth warming furnace, comprising a rotatable, outside the furnace mounted shaft, in particular with internal coolant channels, and arranged on the shaft by means of a receiving bore , a conveying plane forming carrier rings for the cargo.

- cargo eg. Continuous casting of a continuous casting

- roller hearth warming furnace comprising a rotatable, outside the furnace mounted shaft, in particular with internal coolant channels, and arranged on the shaft by means of a receiving bore , a conveying plane forming carrier rings for the cargo.

- roller hearth furnaces of continuous casting plants for example, thin slabs are preheated to rolling temperature.

- the promotion of the rolling stock or slabs by roller hearth furnaces is done by furnace rollers in different versions.

- the roller hearth furnace is usually in line between the casting machine and rolling train and is characterized by its function as a heating, compensation and buffer zone. Due to the types of loading of furnace rolls during furnace operation, the existing in the prior art types of furnaces have different lengths of life.

- the spatial dimensions of such a furnace and its heat-applying devices, for example, burners, are designed such that the furnace outlet Thin slabs have the required rolling temperature.

- the oven length allows the inclusion of several thin slabs, which are separated after casting - with different casting speeds - from the cast strand.

- the transport of such thin slabs takes place within the furnace via driven furnace rollers. These are arranged in a certain kiln height on a level, the transport height, at predetermined intervals from each other.

- the dimensions of the rollers are - relatively speaking - characterized in that the diameter of the support rings and the shafts is small compared to the length of the rollers.

- the transport rollers in the roller hearth furnace can be equipped with water cooling or even be arranged without a cooling device as so-called dry rollers.

- the usual construction of a water-cooled roller comprises a plurality of support rings at an axial distance on the water-cooled shaft.

- the latter is insulated between the support rings with refractory material, this insulating layer is almost as thick as the outer diameter of the support rings.

- the shaft is stored outside the furnace and provided there with connections for internal shaft cooling.

- This internal cooling is achieved by a tube with a circular cross section, which is arranged concentrically in the shaft. Through this cooling water flows, the tube passes through to the opposite side of the furnace and flows on the other side into the annular gap between the tube and shaft, flows through it and finally leaves the shaft on the inflow side.

- internals can be widely used Are located, which serve to fix the tube in the radial position and to increase the flow velocity of the water in the annular gap.

- the support rings applied to the roller axle are usually made of cast material and are made of high temperature nickel or cobalt base alloys.

- the shaft is preferably made of heat-resistant steels.

- the water-cooled rolls are used primarily but not exclusively in the heating zone of a roller hearth furnace. They are equipped in the transport direction alternately with a different number of support rings. Usually, the waves are equipped with four or five support rings, usually alternately.

- the support rings are arranged in the transport direction of a role with four support rings to the role with five support rings on different lines. For the role with four support rings is that in each case two support rings are located on a shaft half, whereas on the role with five support rings one in the middle of the roll, the others are arranged offset relative to those on the role with four support rings outwards.

- the support rings on the shaft are usually secured by welds against axial displacement.

- the torque can be achieved via known shaft-hub connections, such as e.g. Passing feathers or be transmitted via welds.

- a major reason for the failure of a furnace roll is the damage or destruction of the roll insulation, because just because the welds are directly exposed to the high furnace temperatures.

- the document DE 40 22 768 describes roller table rollers for conveying and guiding a workpiece by a heating oven comprising shafts whose ends are rotatably supported in bearings. These form wheel-like support devices in the longitudinal direction of the shaft at a distance from each other on the outer periphery are fixed, wherein the radially outermost surfaces of the wheel-like support devices serve as a support for the workpiece, while this is passed through the heating oven.

- the wheel-like support devices consist of a hub, which communicates via ribs with a rim-like, continuous wreath. The ribs are separated by open spaces to reduce their cross-sectional area and thereby impede heat flow from the rim to the hub.

- the hub consists of a plurality of angularly spaced cores comprising a nose-like portion and a head portion.

- a weld only connects the nose-like portions to the shaft so that the head portions may shift with respect to the shaft due to differential expansion and flexing.

- Means for thermally insulating the shaft are essentially the portions between adjacent wheel-like support devices and the walls of the furnace. The means for rotating the shaft are located outside the furnace.

- the post-published European patent application EP 1 134 531 A1 discloses a disk roll for roller hearth furnaces for heating Wärmgut.

- a rotatable, internally cooled support tube On a rotatable, internally cooled support tube a plurality of axially spaced from each other on the support tube arranged support rings is arranged. These sit on two lateral support elements and are detachably connected thereto.

- the support elements in the circumferential direction on rounded ridges which are distributed at a distance from each other on the circumference of the support elements and engage in correspondingly shaped recesses in the support rings.

- the document EP 0 633 815 B1 describes a furnace roll for supporting a heated workpiece having a rotatable shaft for receiving a coolant, a number of axially spaced support rings being mounted thereon.

- a thermally resistant insulating agent that surrounds the Axially mounted shaft extends axially between the support rings, wherein the insulating means has an outer surface which extends radially over at least a considerable part of the radius of a pair of support rings.

- the insulating means is secured in the shaft by anchoring means with protruding terminal ends disposed radially inwardly of the outer surface of the insulating means.

- the spacer is made of a metal which allows for the pourable insulating a voltage drop in the thermal expansion of the anchoring means and deflection of the furnace roller.

- the document DE 38 07 240 C1 describes a roller hearth furnace for heating slabs, blocks, billets, sheets and the like warm goods

- the furnace chamber is formed with a longitudinally extending roller table.

- the oven has a hot upper oven room, and a sub-furnace room, and in between a hearth with recesses.

- the roller table is stored substantially in the lower furnace space below the hearth and protrudes only with small sections of its furnace rollers through the recesses of the hearth floor above its level. At least the projecting into the hot zone roller sections with their treads on which the warm goods is transported, made of particularly heat-resistant material which, composed of segments into a ring, the furnace rollers encase on the peripheral surface.

- Cleaning devices free the running surfaces of the furnace rollers from scale caking.

- the present invention seeks to provide means for further improvement of the heat transfer between support rings and shaft, thereby increasing the heat dissipation from the support rings to the shaft and to extend the availability of the support rings with reduced growth of scale and at the same time to ensure a reliable, secure torque transmission between support rings and shaft and to achieve greater flexibility in their arrangement with reduced effort when applying the support rings on the shaft.

- a coolable furnace roller specified in the preamble of claim 1 with the invention that for the production of an optimal metallic contact for a possible unhindered heat transfer between the support ring and shaft, the contact surfaces on the inner diameter of the receiving bore of the support ring and / or on Outer diameter of the shaft in the form of a polygonal profile with mating surfaces of approximately constant diameter are designed as so-called weak equal thickness.

- the small deviation of the direct dodge from the ideal round, the circular shape causes an automatic tightening of the support ring seat on the shaft during torque transmission.

- the contact surface of both the support ring, and the shaft is plastically and elastically deformed, which has a significant increase in the contact surfaces result, and as a further advantage results in a significantly improved heat conduction or a significantly improved heat transfer between the support ring and shaft.

- the inner diameter of the support ring which becomes larger as a result of thermal expansion, is also compensated by the relative rotation with respect to the shaft.

- the surface temperature of the furnace roll is reduced in the design according to the invention due to the increased contact surface of the support ring and shaft and more intimate metallic contact and increases their availability, and reduces the risk of pick-up formation on the surface.

- the structure of the furnace roller is extremely flexible and can be optimally adapted to the respective stresses.

- the heat transfer can be further improved.

- Fig. 1 shows the support ring 7 with cut shaft 3 in the assembled starting state with snug fit 6 with a slight deviation of a polygonal profile of the circular shape of a few millimeters. It is a so-called weak "equal thickness”.

- the shaft 3 has in its tubular cavity a central coolant channel 4, and a peripheral coolant ring channel 5.

- Fig. 2 shows the support ring 7 with the cut shaft 3 in the operating state under load by torsional stress, as well as in the heated state.

- the preferred embodiment of the same thickness provides that the deviation of the mating surfaces 6, 6 'from the ideal round, the circular shape, a self-locking in a torque transmission between the support ring 7 and shaft 3 corresponds.

- This deviation of the mating surfaces 6, 6 'from the ideal round can - depending on the design and stress in mechanical and / or thermal nature - be about 1 to 5 mm.

- the support ring 7 is about Gleichdick-fitting tolerances 6, 6 'purely mechanically pushed onto the shaft 3 and jammed by relative rotation with the shaft 3, wherein the attachment of the support ring 7 on the shaft 3 according to the principle of surface enlargement by deformation of the contact surfaces 6, 6 'takes place.

- At least the deviation of the mating surfaces 6, 6 'from Idealrund should be slightly larger than the thermal expansion of the inner diameter of the receiving bore 1 of the support ring 7 during operation of the furnace.

- This receiving bore 1 forms the inner contact surface 6 with the mating surface 6 'of the shaft third

- the support ring 7 may be one or more pieces, or be made of individual rings.

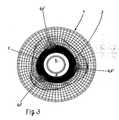

- Fig. 3 shows an embodiment of the invention, according to which formed as a polygon profile with constant diameter equal thickness so weak fitting tolerances between the contact surfaces on the inner diameter of the support ring 7 and the outer diameter of the shaft 3, that a rotation of support ring 7 and shaft 3 due to the transfer of a Torque leads to a comparatively large elastic-plastic deformation.

Claims (8)

- Rouleau de four refroidi à l'eau pour le convoyage d'un produit transporté, par exemple un matériau d'extrusion dans une installation d'extrusion, à travers un four de chauffage avec foyer à rouleaux, comprenant un arbre (3) susceptible d'être entraîné en rotation et supporté à l'extérieur du four, en particulier avec des canaux (4, 5) pour agent de refroidissement situés à l'intérieur, et avec des bagues portantes (7) agencées sur l'arbre (3) au moyen d'un perçage de réception (1) et formant un plan de convoyage,

caractérisé en ce que

les surfaces de contact au niveau du diamètre intérieur du perçage de réception (1) de la bague portante (7) et/ou au niveau du diamètre extérieur de l'arbre (3) sont réalisées sous la forme d'un profil polygonal avec des surfaces d'ajustage (6, 6') de diamètre approximativement constant à la manière d'un "orbiforme faible" ("Gleichdick"). - Rouleau de four selon la revendication 1,

caractérisé en ce que la déviation des surfaces d'ajustage (6, 6') par rapport à la forme idéale ronde ou circulaire correspond à un autocoincement lors de la transmission de couples de rotation entre la bague portante (7) et l'arbre (3). - Rouleau de four selon la revendication 1 ou 2,

caractérisé en ce que la déviation des surfaces d'ajustage (6, 6') par rapport à la forme idéale ronde est d'environ 4 à 5 %. - Rouleau de four selon l'une ou plusieurs des revendications 1 à 3,

caractérisé en ce que la déviation des surfaces d'ajustage (6, 6') par rapport à la forme idéale ronde correspond au moins à l'amplitude de la dilatation thermique du diamètre intérieur du perçage de réception (1) de la bague portante (7) lors du fonctionnement du four. - Rouleau de four selon l'une ou plusieurs des revendications 1 à 4,

caractérisé en ce que le contact métallique est établi via l'orbiforme soit sur la totalité de la largeur du rouleau de four soit sur des zones partielles de celui-ci. - Rouleau de four selon l'une ou plusieurs des revendications 1 à 5,

caractérisé en ce que la bague portante (7) est réalisée en une ou plusieurs pièces, ou respectivement à partir de bagues individuelles. - Rouleau de four selon l'une ou plusieurs des revendications 1 à 6,

caractérisé en ce que des rondelles minces sont interposées entre la bague portante (7) et l'arbre (3), en particulier lorsque la bague est réalisée en plusieurs pièces, rondelles qui sont constituées par exemple par une feuille d'argent ou une feuille d'un métal réfractaire et présentant une forte conductibilité thermique, comme par exemple CuNiBe. - Rouleau de four selon l'une ou plusieurs des revendications 1 à 7,

caractérisé en ce que l'orbiforme réalisé comme un profil polygonal avec diamètre constant présente des tolérances d'ajustement si faibles entre les surfaces de contact au niveau du diamètre intérieur des perçages de réception (1) de la bague portante (7) et le diamètre extérieur de l'arbre (3), qu'une rotation de la bague portante (7) et de l'arbre (3) suite à la transmission d'un couple de rotation mène à une déformation élastique-plastique comparativement considérable.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10045251A DE10045251A1 (de) | 2000-09-13 | 2000-09-13 | Wasserkühlbare Ofenrolle zum Fördern von bspw. Stranggußmaterial-Werkstücken durch einen Rollenherdofen |

| DE10045251 | 2000-09-13 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1189004A1 EP1189004A1 (fr) | 2002-03-20 |

| EP1189004B1 true EP1189004B1 (fr) | 2006-12-13 |

Family

ID=7656043

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01119488A Expired - Lifetime EP1189004B1 (fr) | 2000-09-13 | 2001-08-14 | Rouleau de four que l'on peut refroidir à l'eau |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6547557B2 (fr) |

| EP (1) | EP1189004B1 (fr) |

| JP (1) | JP5170924B2 (fr) |

| AT (1) | ATE348307T1 (fr) |

| DE (2) | DE10045251A1 (fr) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108607788A (zh) * | 2018-05-20 | 2018-10-02 | 苏州锌富化工有限公司 | 一种滚筒式加热装置 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB317433A (en) * | 1928-08-16 | 1929-08-16 | Int Nickel Co | Improvements in or relating to carrier wheel devices |

| JPS522369B2 (fr) * | 1971-08-20 | 1977-01-21 | ||

| DE2413270C2 (de) * | 1974-03-20 | 1975-08-21 | Ludwig-Ofag-Indugas Industrieofenanlagen Gmbh, 4300 Essen | Gekülte Ofentransportrolle |

| JPS5596236A (en) * | 1979-01-12 | 1980-07-22 | Kubota Ltd | Preparation of compound roll for continuous casting |

| JPS5759237Y2 (fr) * | 1979-01-20 | 1982-12-17 | ||

| JPS6121162Y2 (fr) * | 1980-08-11 | 1986-06-25 | ||

| US4991276A (en) | 1989-07-31 | 1991-02-12 | Bricmanage, Inc. | Flexible conveyance and guidance roller for use in metalworking furnace structures |

| DE4142941A1 (de) * | 1991-12-24 | 1993-07-01 | Kabelmetal Ag | Verwendung einer aushaertbaren kupferlegierung |

| US5230618A (en) * | 1992-02-24 | 1993-07-27 | Bricmanage, Inc. | Insulated furnace roller |

| US5362230A (en) * | 1993-03-24 | 1994-11-08 | Italimpianti Of America, Inc. | Rolls for high temperature roller hearth furnaces |

| US5370530A (en) * | 1993-03-24 | 1994-12-06 | Italimpianti Of America, Inc. | Rolls for high temperature roller hearth furnaces |

| JPH10181835A (ja) * | 1996-12-27 | 1998-07-07 | Kubota Corp | 分割形タイヤローラ |

| JP3678899B2 (ja) * | 1998-01-29 | 2005-08-03 | 株式会社クボタ | スラブ搬送用ローラ |

| DE10012940A1 (de) * | 2000-03-16 | 2001-09-20 | Loi Thermprocess Gmbh | Scheibenrolle für Rollenherdöfen |

-

2000

- 2000-09-13 DE DE10045251A patent/DE10045251A1/de not_active Withdrawn

-

2001

- 2001-08-14 AT AT01119488T patent/ATE348307T1/de active

- 2001-08-14 DE DE50111623T patent/DE50111623D1/de not_active Expired - Lifetime

- 2001-08-14 EP EP01119488A patent/EP1189004B1/fr not_active Expired - Lifetime

- 2001-09-07 JP JP2001272271A patent/JP5170924B2/ja not_active Expired - Fee Related

- 2001-09-13 US US09/952,025 patent/US6547557B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US20020048740A1 (en) | 2002-04-25 |

| DE50111623D1 (de) | 2007-01-25 |

| JP2002172453A (ja) | 2002-06-18 |

| ATE348307T1 (de) | 2007-01-15 |

| US6547557B2 (en) | 2003-04-15 |

| DE10045251A1 (de) | 2002-03-21 |

| JP5170924B2 (ja) | 2013-03-27 |

| EP1189004A1 (fr) | 2002-03-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1197721B1 (fr) | Rouleau refroidi de four, en particulier pour un four à sole à rouleaux | |

| EP1397522B1 (fr) | Rouleau de ligne de rouleaux, destine en particulier au transport de bandes de materiau metallique sortant du four | |

| EP1937430B1 (fr) | Cylindre guide-boyau | |

| EP1646463B1 (fr) | Galet de guidage de barre refroidi par l'interieur | |

| DE4022768C2 (de) | Rollengangrolle und deren Verwendung | |

| EP2473298B1 (fr) | Rouleaux et assemblage de rouleaux pour une installation de coulée continue | |

| WO2004039588A1 (fr) | Corps rotatifs d'une presse a imprimer constitues d'un cylindre | |

| EP0037549B1 (fr) | Rouleaux de guidage coaxial à proximité de billettes pour une installation de coulée continue pour l'acier | |

| DE2216982A1 (de) | Anordnung zur befestigung eines laufringes auf dem mantel eines drehrohres, insbesondere eines drehrohrofens | |

| DE4041217A1 (de) | Durchlaufofen und verfahren zur wartung der rollen eines durchlaufofens | |

| EP1189004B1 (fr) | Rouleau de four que l'on peut refroidir à l'eau | |

| DE3704744A1 (de) | Transportrolle fuer glaskuehlkanaele | |

| DE10007383B4 (de) | Wasserkühlbare Ofenrolle zum Fördern von Werkstücken durch einen Aufwärmofen | |

| WO2005102558A2 (fr) | Installation pour traiter des barres de coulee continue ou des axes de coulee continue | |

| EP1940572B1 (fr) | Galet de guidade de barre | |

| DE3515856C1 (de) | Tunnelförmiger Industrieofen | |

| EP0331937B1 (fr) | Four à sole à rouleaux pour réchauffer des brames, des lingots, des billettes, des tôles et des matériaux similaires | |

| DE4005900A1 (de) | Scheibenrolle fuer rollenherdoefen | |

| DE10250690A1 (de) | Rotationskörper einer Druckmaschine mit einem Ballen | |

| DE10104032A1 (de) | Lageranordnung für Hochtemperatur-Anwendungen | |

| DE2734230C2 (de) | Auslässe eines Drehrohrofens in Satelliten-Kühlerrohre | |

| EP1032716B1 (fr) | Four pour caisse a rouleau | |

| DE10250691A1 (de) | Rotationskörper einer Druckmaschine mit einem Grundkörper | |

| DE2919207A1 (de) | Ofen zum erhitzen durchlaufender, zylindrischer teile | |

| DE2340722A1 (de) | Aus mehreren am verwendungsort durch schweissung miteinander verbundenen einzelstahlrohren hergestellter rohrleitungsstrang, sowie verfahren und vorrichtung zum vergueten der beim aufbau dieses rohrleitungsstranges verwendeten einzelstahlrohres |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20010814 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17Q | First examination report despatched |

Effective date: 20050402 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL PT SE TR |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061213 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061213 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061213 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061213 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50111623 Country of ref document: DE Date of ref document: 20070125 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070324 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070321 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070514 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070914 |

|

| BERE | Be: lapsed |

Owner name: SMS DEMAG AG Effective date: 20070831 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070831 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070314 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070814 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061213 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20120821 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120906 Year of fee payment: 12 Ref country code: IT Payment date: 20120822 Year of fee payment: 12 Ref country code: DE Payment date: 20120822 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20120813 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50111623 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 348307 Country of ref document: AT Kind code of ref document: T Effective date: 20130814 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130814 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130814 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130814 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130814 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130902 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50111623 Country of ref document: DE Effective date: 20140301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140301 |