EP1186355A2 - Bottle cleaning machine - Google Patents

Bottle cleaning machine Download PDFInfo

- Publication number

- EP1186355A2 EP1186355A2 EP01120680A EP01120680A EP1186355A2 EP 1186355 A2 EP1186355 A2 EP 1186355A2 EP 01120680 A EP01120680 A EP 01120680A EP 01120680 A EP01120680 A EP 01120680A EP 1186355 A2 EP1186355 A2 EP 1186355A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cleaning machine

- bottle cleaning

- machine according

- swirl

- bottle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000004140 cleaning Methods 0.000 title claims abstract description 22

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 9

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- 239000007789 gas Substances 0.000 description 4

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- 239000000243 solution Substances 0.000 description 2

- 208000035415 Reinfection Diseases 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical group [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000002775 capsule Substances 0.000 description 1

- 238000009795 derivation Methods 0.000 description 1

- 239000003599 detergent Substances 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 238000003197 gene knockdown Methods 0.000 description 1

- 230000035784 germination Effects 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B15/00—Preventing escape of dirt or fumes from the area where they are produced; Collecting or removing dirt or fumes from that area

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B9/00—Cleaning hollow articles by methods or apparatus specially adapted thereto

- B08B9/08—Cleaning containers, e.g. tanks

- B08B9/20—Cleaning containers, e.g. tanks by using apparatus into or on to which containers, e.g. bottles, jars, cans are brought

Definitions

- the invention relates to a bottle washer with an opening and Dispensing station and several treatment stations arranged in the direction of flow of the bottles and a suction channel for swaths or other air masses.

- Discharge channels are provided for this purpose with the inclusion of a fan, the swaths accumulating in the machine area suck in and discharge outside. Such channels are usually immediately before Outlet of the bottles arranged from the cleaning machine, which means that in the dispensing area air is also sucked in and dispensed through the bottles is directed into the inside of the machine. Usually not biologically ongoing air also gets into the area of the bottles and can pass through their germination may lead to reinfection of the filled bottles.

- Container washing machines in particular high-performance washing machines for the winery industry, finally have a so-called essential cleaning station Alkaline station in which the containers to be cleaned are immersed in an alkaline container be filled with detergent solution.

- an aqueous one Solution of NaOH used as lye.

- the tub is heated to raise the tub temperature to, for example, 80 ° C hold.

- Containers to be cleaned often have aluminum fittings.

- three-liter bottle caps are usually in the head area with a so-called aluminum capsule provided, the majority of which still during cleaning is available.

- Labels can also consist entirely or partially of aluminum.

- Hydrogen removal devices are therefore known in the prior art which are absolutely necessary for security reasons.

- the known container washing machines of the type mentioned are for eliminating the hydrogen gas Suction devices are provided, which draw in gas while drawing in fresh air Vacuum the gas space above the tub and blow it outside.

- the object of the invention is to demonstrate a device with which in a cleaning machine accumulating and eliminating air masses more targeted and broad can be sucked in and drained.

- This task is the bottle cleaning machine of the aforementioned Art solved in that the suction channel at least partially with a slit-shaped Suction opening is formed, which is transverse and / or longitudinal in the cleaning machine housing runs and as part of a swirl hood generating a swirl flow is trained.

- the suction channel runs perpendicular to the direction of movement of the bottles and as a swirl hood is designed with a vertebral suction system.

- the air masses can be quickly and precisely along the entire width of the length or transversely installed suction channel detected and derived by this.

- the Throughput of the suction channel is appropriately automatic to the machine performance adaptable.

- a bottle washer with the feed station 1 and the delivery station 2 shown.

- the bottles 3 are in bottle cells 4 through the individual cleaning departments 5.6 and in the area of the delivery station 2, for example by rotating delivery surfaces and down on deposed or pushed onto a discharge conveyor.

- a steam extraction duct 7 arranged, the inside wall practically as a partition to Machine housing 8 can be formed.

- suction channels 9, 10 can be arranged in the individual treatment zones and departments 5.6 of such a cleaning machine be provided.

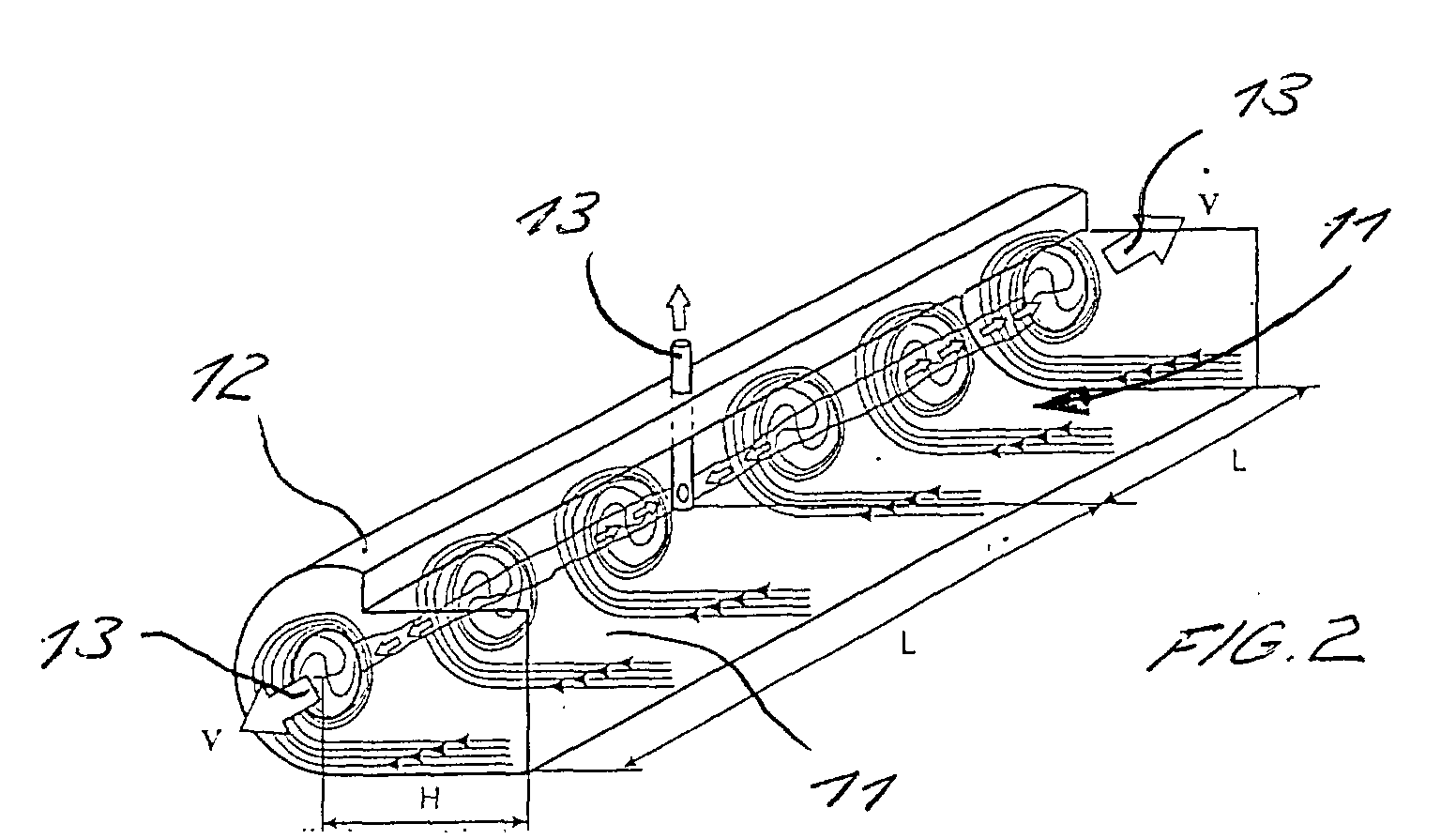

- the suction channel 7,7 'with a slot-shaped suction opening 11 equipped according to the embodiment runs transversely to the bottle conveying direction. This can also be along the bottle conveying direction run.

- the suction opening 11 is part of a swirl flow generating vortex hood 12 formed at least laterally on one side has a support tube 13 for deriving the intake air masses.

- additional support tubes 13 are provided on both sides and also in the center of the swirl hood his.

- the gap width of the intake duct 7 can be adjustable and as a function of the machine throughput can be changed.

- the swirl hood 12 can at least part of the swirl hood 12 directly help shape the housing or be part of the housing. Any other cross-sectional shapes can be provided his.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cleaning In General (AREA)

- Centrifugal Separators (AREA)

Abstract

Flaschenreinigungsmaschine mit einer Auf- und Abgabestation und mehreren in Durchlaufrichtung der Flaschen angeordneten Behandlungsstationen sowie mindestens einem Absaugkanal für Schwaden und/oder andere Luftmassen, bei welcher der Absaugkanal mindestens teilweise mit einer schlitzförmigen Ansaugöffnung (7, 7') ausgebildet ist, die quer und/oder längs im Reinigungsmaschinengehäuse (8) verläuft und als Teil einer eine Drallströmung erzeugenden Wirbelhaube (12) ausgebildet ist. Bottle cleaning machine with a loading and unloading station and several treatment stations arranged in the direction of flow of the bottles as well as at least one suction channel for swaths and / or other air masses, in which the suction channel is at least partially formed with a slit-shaped suction opening (7, 7 ') which is transverse and / or runs longitudinally in the cleaning machine housing (8) and is designed as part of a swirl hood (12) which generates a swirl flow.

Description

Die Erfindung bezieht sich auf eine Flaschenreinigungsmaschine mit einer Auf- und Abgabestation und mehreren in Durchlaufrichtung der Flaschen angeordneten Behandlungsstationen sowie einem Absaugkanal für Schwaden oder andere Luftmassen.The invention relates to a bottle washer with an opening and Dispensing station and several treatment stations arranged in the direction of flow of the bottles and a suction channel for swaths or other air masses.

Es ist bekannt, den Schwaden, der im Inneren von Flaschenreinigungsmaschinen verstärkt auftritt, vor der Flaschenabgabe durch entsprechende Kaltwassernachspritzungen niederzuschlagen oder den Schwaden noch vor der Flaschenabgabe aus dem Inneren der Maschine abzusaugen. Hierzu sind Abzugskanäle vorgesehen, die unter Einbindung eines Ventilators den im Maschinenbereich anfallenden Schwaden ansaugen und ins Freie abführen. Solche Kanäle sind meist unmittelbar vor dem Austritt der Flaschen aus der Reinigungsmaschine angeordnet, wodurch die im Abgabebereich anstehende Luft ebenfalls angesaugt und über die abgegebenen Flaschen hinweg in das Innere der Maschine geleitet wird. Diese meist biologisch nicht einwandfreie Luft gelangt dabei auch in den Bereich der Flaschen und kann durch ihre Keimhaltigkeit möglicherweise zu einer Reinfektion der befüllten Flaschen führen.It is known the swath that is inside bottle washers occurs more frequently before the bottle is dispensed by appropriate cold water post-injections knock down or swath out before the bottle is dispensed vacuum the inside of the machine. Discharge channels are provided for this purpose with the inclusion of a fan, the swaths accumulating in the machine area suck in and discharge outside. Such channels are usually immediately before Outlet of the bottles arranged from the cleaning machine, which means that in the dispensing area air is also sucked in and dispensed through the bottles is directed into the inside of the machine. Mostly not biologically impeccable air also gets into the area of the bottles and can pass through their germination may lead to reinfection of the filled bottles.

Behälterwaschmaschinen, insbesondere Hochleistungswaschmaschinen für die Kellereiindustrie, weisen schließlich als wesentliche Reinigungsstation eine sogenannte Laugenstation auf, in der die zu reinigenden Behälter in einen Laugenbehälter eingetaucht werden, der mit Reinigungslauge gefüllt ist. Üblicherweise wird eine wäßrige Lösung von NaOH als Lauge verwendet. Zur Steigerung der Reinigungswirkung ist der Laugenbehälter beheizt, um die Laugentemperatur auf beispielsweise 80°C zu halten.Container washing machines, in particular high-performance washing machines for the winery industry, finally have a so-called essential cleaning station Alkaline station in which the containers to be cleaned are immersed in an alkaline container be filled with detergent solution. Usually an aqueous one Solution of NaOH used as lye. To increase the cleaning effect the tub is heated to raise the tub temperature to, for example, 80 ° C hold.

Zu reinigende Behälter weisen häufig Aluminiumausstattungen auf. Beispielsweise sind Eindrittelliter-Kronkorkenbierflaschen üblicherweise im Kopfbereich mit einer sogenannten Aluminiumkapsel versehen, deren größter Teil bei der Reinigung noch vorhanden ist. Auch Etiketten können ganz oder teilweise aus Aluminium bestehen. Containers to be cleaned often have aluminum fittings. For example three-liter bottle caps are usually in the head area with a so-called aluminum capsule provided, the majority of which still during cleaning is available. Labels can also consist entirely or partially of aluminum.

Aluminium wird in Lauge, insbesondere in heißer Lauge, schnell aufgelöst. Dieser Effekt ist zur Entfernung der Aluminiumreste durchaus erwünscht. Es entsteht dabei aber Wasserstoffgas (H2), das aus der Lauge in den darüber befindlichen Gasraum entweicht. Mit dem dort vorhandenen Luftsauerstoff bildet sich dann sehr schnell (bei H2-Konzentrationen oberhalb etwa 4%) ein zündfähiges Knallgasgemisch, das heftige Explosionen hervorrufen kann.Aluminum is quickly dissolved in lye, especially in hot lye. This effect is quite desirable to remove the aluminum residues. However, this produces hydrogen gas (H 2 ), which escapes from the alkali into the gas space above. With the atmospheric oxygen present there, an ignitable mixture of oxyhydrogen is formed very quickly (at H 2 concentrations above about 4%), which can cause violent explosions.

Im Stand der Technik sind daher Wasserstoffbeseitigungseinrichtungen bekannt, die aus Sicherheitsgründen zwingend erforderlich sind. Bei den bekannten Behälterwaschmaschinen der eingangs genannten Art sind zur Beseitigung des Wasserstoffgases Absaugeinrichtungen vorgesehen, die unter Ansaugen von Frischluft Gas aus dem Gasraum über dem Laugenbehälter absaugen und ins Freie blasen.Hydrogen removal devices are therefore known in the prior art which are absolutely necessary for security reasons. In the known container washing machines of the type mentioned are for eliminating the hydrogen gas Suction devices are provided, which draw in gas while drawing in fresh air Vacuum the gas space above the tub and blow it outside.

Aufgabe der Erfindung ist es, eine Vorrichtung aufzuzeigen, mit der die in einer Reinigungsmaschine anfallenden und zu beseitigenden Luftmassen gezielter und breitflächiger angesaugt und abgeleitet werden können.The object of the invention is to demonstrate a device with which in a cleaning machine accumulating and eliminating air masses more targeted and broad can be sucked in and drained.

Diese Aufgabe wird bei einer Flaschenreinigungsmaschine der eingangs genannten Art dadurch gelöst, daß der Absaugkanal mindestens teilweise mit einer schlitzförmigen Ansaugöffnung ausgebildet ist, die quer und/oder längs im Reinigungsmaschinengehäuse verläuft und als Teil einer eine Drallströmung erzeugenden Wirbelhaube ausgebildet ist.This task is the bottle cleaning machine of the aforementioned Art solved in that the suction channel at least partially with a slit-shaped Suction opening is formed, which is transverse and / or longitudinal in the cleaning machine housing runs and as part of a swirl hood generating a swirl flow is trained.

In selbständiger Ausbildung der Erfindung wird ferner vorgeschlagen, daß der Absaugkanal quer zur Bewegungsrichtung der Flaschen verläuft und als Wirbelhaube mit einer Wirbelsenkenabsaugung ausgebildet ist.In an independent development of the invention it is further proposed that the suction channel runs perpendicular to the direction of movement of the bottles and as a swirl hood is designed with a vertebral suction system.

Mit der erfindungsgemäßen Ausbildung ist eine besonders vorteilhafte Ableitung der aus dem Gehäuse einer Flaschenreinigungsmaschine zu entfernenden Gase, Schwaden, Luftmassen u.dgl. gewährleistet. Durch die aufgezeigte Ausführungsform können die Luftmassen schnell und gezielt auf der gesamten Breite des längs oder quer installierten Absaugkanals erfaßt und durch diesen abgeleitet werden. Die Durchsatzleistung des Absaugkanals ist der Maschinenleistung zweckmäßig automatisch anpaßbar. With the design according to the invention, a particularly advantageous derivation of gases to be removed from the housing of a bottle washer, Swaths, air masses and the like guaranteed. By the shown embodiment the air masses can be quickly and precisely along the entire width of the length or transversely installed suction channel detected and derived by this. The Throughput of the suction channel is appropriately automatic to the machine performance adaptable.

Im nachfolgenden wird die Erfindung anhand eines in Fig. 1 und 2 der Zeichnung dargestellten Ausführungsbeispiels näher erläutert.In the following the invention with reference to one in Fig. 1 and 2 of the drawing illustrated embodiment explained in more detail.

In der Zeichnung ist eine Flaschenreinigungsmaschine mit der Aufgabestation 1 und

der Abgabestation 2 dargestellt. Die Flaschen 3 werden in Flaschenzellen 4 durch

die einzelnen Reinigungsabteilungen 5,6 geführt und im Bereich der Abgabestation

2, beispielsweise durch rotierende Abgabeflächen unterfangen und nach unten auf

einen Ablauftransporteur abgesetzt bzw. auf diesen abgedrängt. Gemäß dem dargestellten

Ausführungsbeispiel ist kopfseitig an der Abgabestation 2 ein Schwadenabzugskanal

7 angeordnet, dessen innenseitige Wand praktisch als Trennwand zum

Maschinengehäuse 8 ausgebildet sein kann.In the drawing is a bottle washer with the feed station 1 and

the

Wie aus der Zeichnung Figur 1 ersichtlich, können weitere Absaugkanäle 9,10 in den

einzelnen Behandlungszonen und -Abteilungen 5,6 einer solchen Reinigungsmaschine

vorgesehen sein. Zweckmäßig ist dabei der Absaugkanal 7,7' mit einer

schlitzförmigen Ansaugöffnung 11 ausgestattet, die gemäß dem Ausführungsbeispiel

quer zur Flaschenförderrichtung verläuft. Diese kann aber auch längs zur Flaschenförderrichtung

verlaufen. Die Ansaugöffnung 11 ist dabei als Teil einer eine Drallströmung

erzeugende Wirbelhaube 12 ausgebildet, die mindestens seitlich einseitig

ein Stützrohr 13 zur Ableitung der angesaugten Luftmassen aufweist. Insbesondere

bei sehr breiten Reinigungsmaschinen oder langen Wirbelhauben 12 können seitlich

auf beiden Seiten und auch mittig der Wirbelhaube 12 weitere Stützrohre 13 vorgesehen

sein.As can be seen from the drawing in FIG. 1, further suction channels 9, 10 can be arranged in the

individual treatment zones and departments 5.6 of such a cleaning machine

be provided. The

Die Spaltbreite des Ansaugkanals 7 kann einstellbar sein und in Abhängigkeit von

der Maschinendurchsatzleistung verändert werden.The gap width of the

Je nach Ausbildung des Reinigungsmaschinengehäuses 8 und dort, wo es sich anbietet,

kann mindestens ein Teil der Wirbelhaube 12 direkt das Gehäuse mitgestalten

oder Teil des Gehäuses sein. Im übrigen können beliebige Querschnittsformen vorgesehen

sein.Depending on the design of the cleaning machine housing 8 and where it is appropriate,

can at least part of the

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10045083 | 2000-09-12 | ||

| DE10045083A DE10045083A1 (en) | 2000-09-12 | 2000-09-12 | Bottle washer |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1186355A2 true EP1186355A2 (en) | 2002-03-13 |

| EP1186355A3 EP1186355A3 (en) | 2003-08-20 |

| EP1186355B1 EP1186355B1 (en) | 2004-07-21 |

Family

ID=7655933

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01120680A Expired - Lifetime EP1186355B1 (en) | 2000-09-12 | 2001-09-03 | Bottle cleaning machine |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1186355B1 (en) |

| AT (1) | ATE271427T1 (en) |

| DE (2) | DE10045083A1 (en) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB514293A (en) * | 1937-05-06 | 1939-11-03 | Cherry Burrell Corp | Improvements in or relating to machines for washing bottles or similar containers |

| US4208761A (en) * | 1978-01-24 | 1980-06-24 | New England Machinery, Inc. | Bottle conveying and cleaning apparatus |

| DE3914412A1 (en) * | 1989-04-29 | 1990-10-31 | Seitz Enzinger Noll Masch | Heat recycling system for bottle cleaning machines - has two circuits with heat exchangers, hydrogen gas suction unit and fluid pipe to remove condensation |

| DE4232986C2 (en) * | 1992-10-01 | 1996-10-31 | Khs Masch & Anlagenbau Ag | Bottle washer with a loading and unloading station |

-

2000

- 2000-09-12 DE DE10045083A patent/DE10045083A1/en not_active Withdrawn

-

2001

- 2001-09-03 DE DE50102907T patent/DE50102907D1/en not_active Expired - Lifetime

- 2001-09-03 EP EP01120680A patent/EP1186355B1/en not_active Expired - Lifetime

- 2001-09-03 AT AT01120680T patent/ATE271427T1/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| EP1186355B1 (en) | 2004-07-21 |

| DE10045083A1 (en) | 2002-03-28 |

| EP1186355A3 (en) | 2003-08-20 |

| ATE271427T1 (en) | 2004-08-15 |

| DE50102907D1 (en) | 2004-08-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3486589B1 (en) | Crates drying and/or cleaning device | |

| DE102011119171B3 (en) | Apparatus for treating containers with a suction device | |

| EP0213532B1 (en) | Device for drying cleaned glass plates | |

| EP2688689B1 (en) | Device for blowing off bottle bottoms | |

| EP0775534A2 (en) | Automatic installation for cleaning workpieces | |

| EP1186355A2 (en) | Bottle cleaning machine | |

| DE102020129774A1 (en) | Device for conveying and cleaning small parts with an open cavity | |

| DE202013103829U1 (en) | Drying device and vehicle treatment system | |

| DE102008049296A1 (en) | Blowing or drying device for container i.e. box, has drying station with nozzle head, which is insertable for blowing and/or sucking into container, where nozzle head is movable relative to container arranged at respective drying station | |

| EP0387526B1 (en) | Apparatus for the electrolytic treatment of work-pieces through a succession of baths | |

| DE60026397T2 (en) | Vacuum cleaner with liquid bath | |

| DE2248220A1 (en) | BOTTLE WASHING MACHINE | |

| EP1782890B1 (en) | Pretreatment installation and method for the pretreatment by spraying | |

| WO2023089004A1 (en) | Air blade device | |

| EP0590509B1 (en) | Bottle cleaning machine with a load and an unload section | |

| EP1792666A2 (en) | Automated cleaning of open containers | |

| DE9210531U1 (en) | Device for inspecting vessels | |

| DE1801797A1 (en) | Bottle washing machine | |

| EP0918974B1 (en) | Device for intermittent dispensing of an agent for treating surfaces | |

| DE2212777A1 (en) | DEVICE FOR TREATMENT OF LOCKING SCREWS | |

| DE102013109139A1 (en) | Drying device, vehicle treatment system and method for drying a vehicle | |

| DE102010062976A1 (en) | Centrifugal fan with mist eliminator function | |

| DE7214760U (en) | BOTTLE WASHING MACHINES WITH A DEVICE TO PREVENT THE SPILLAGE | |

| DE1904777A1 (en) | Method and device for cleaning and disinfecting bottle washing machines | |

| DE102005008700A1 (en) | Bottle case conveying and cleaning section, has conveyor belt with attachment, which causes rotation of case from normal position into inclined position, during transportation of case along section in cooperation with guide |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20010926 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040721 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50102907 Country of ref document: DE Date of ref document: 20040826 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040903 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041101 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050422 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: RN |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: FC |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061002 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: FR Effective date: 20071017 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: TD Effective date: 20111114 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: KHS GMBH Effective date: 20111121 Ref country code: FR Ref legal event code: CD Owner name: KHS GMBH Effective date: 20111122 |

|

| BECN | Be: change of holder's name |

Owner name: KHS G.M.B.H. Effective date: 20120314 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20170921 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20170921 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20181001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180903 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20200914 Year of fee payment: 20 Ref country code: DE Payment date: 20200925 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20200925 Year of fee payment: 20 Ref country code: IT Payment date: 20200922 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50102907 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MK Effective date: 20210903 |