EP1161397B1 - Device and method for guiding and cutting a tapering thread when changing bobbins - Google Patents

Device and method for guiding and cutting a tapering thread when changing bobbins Download PDFInfo

- Publication number

- EP1161397B1 EP1161397B1 EP00912574A EP00912574A EP1161397B1 EP 1161397 B1 EP1161397 B1 EP 1161397B1 EP 00912574 A EP00912574 A EP 00912574A EP 00912574 A EP00912574 A EP 00912574A EP 1161397 B1 EP1161397 B1 EP 1161397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- thread

- guide

- thread guide

- catching

- winding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 16

- 238000004804 winding Methods 0.000 claims abstract description 60

- 238000012546 transfer Methods 0.000 claims description 43

- 230000008859 change Effects 0.000 claims description 18

- 230000033001 locomotion Effects 0.000 claims description 15

- 238000011144 upstream manufacturing Methods 0.000 claims description 2

- 238000012545 processing Methods 0.000 abstract description 2

- 239000011324 bead Substances 0.000 description 5

- 230000008901 benefit Effects 0.000 description 5

- 238000011161 development Methods 0.000 description 4

- 230000018109 developmental process Effects 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 238000012549 training Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000004913 activation Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/28—Traversing devices; Package-shaping arrangements

- B65H54/34—Traversing devices; Package-shaping arrangements for laying subsidiary winding, e.g. transfer tails

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H65/00—Securing material to cores or formers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H67/00—Replacing or removing cores, receptacles, or completed packages at paying-out, winding, or depositing stations

- B65H67/04—Arrangements for removing completed take-up packages and or replacing by cores, formers, or empty receptacles at winding or depositing stations; Transferring material between adjacent full and empty take-up elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Definitions

- the invention relates to a device for guiding and cutting a continuously tapering thread when changing bobbins in one Winding device according to the preamble of claim 1 and a Process for guiding and cutting a continuously running thread according to the preamble of claim 11.

- a crimped thread is continuously closed a coil wound. After the bobbin has finished winding, a Bobbin change. For this it is necessary that the thread is cut first is so that the full bobbin with loose thread end against a new empty tube can be changed. The thread end of the continuously running thread during the change by means of a pneumatic suction device recorded and discharged. After the bobbin change, the Thread caught by a catcher and on the new tube initially wound.

- the known device and the known method have the disadvantage that at the end of the bobbin trip, the loose thread end on the finished bobbin is undefined, which is particularly important for further processing when it is found of the loose thread end difficult.

- the deflection of the thread leads through the transfer device to catch the thread to significant wraps that are in relation to the winding tension lead to greater fluctuations in tensile force in the thread.

- Such fluctuations in tensile force can occur with upstream conveying elements lead to a winder formation.

- FR 22 47 906 describes a device for cutting a thread a thread guide is arranged behind a driven roller.

- Another object of the invention is to cut after the thread Ensure that the loose end of the thread lies against the binding bead of the full bobbin and that the running thread on a new sleeve without substantial slack is created.

- the invention is characterized in that the thread guide and Suction device at the beginning of the bobbin change within the bobbin area are arranged.

- the winding area is the area on the tube that of the covered thread is covered. This allows the thread to be relatively low Deflection cut and taken over by the thread suction, so that there are no significant thread tension fluctuations during the change phase occur.

- the suction device is preferably arranged stationary. at one designed to be movable essentially parallel to the coil Suction device there is the possibility of the loose thread end with the The setting bead is closed at any position within the winding area place.

- the deflection device prevents the Suction device running thread not between the surfaces of a new one Sleeve and the drive roller is clamped.

- the thread becomes tangle-free transferred from the full spool to a new tube.

- the particularly advantageous development of the device according to claim 2 enables the thread to move without further aids simply by moving the Thread guide is caught in the catching device. For this, the thread is only in Longitudinal direction deflected parallel to the sleeve. With an additional rectified movement of the deflection device can also Minimize the deflection of the thread.

- the thread can be catch easily. To do this, thread the thread in an oblique course over the Front edge of the tension plate guided so that the thread in one in the front edge of the clamping plate inserted automatically falls.

- the Arrangement of the thread guide, the deflection device and the catching device so advantageous that the thread and the tension plate are rectified Carry out movement. So there is no waste and therefore no excessive Thread tension fluctuation when catching.

- the deflection device from a movable deflection thread guide and one controllable drive.

- the deflecting thread guide is made by means of the drive moved out of a rest position outside the thread path.

- the guide thread guide remains in its first Rest. There are no significant deflections of the thread and thus no significant wrapping.

- the guide thread is guided by the Actuator activated to catch and deflect the thread.

- the movement of the Deflecting thread guide can be advantageous with the movement of the thread guide Guide the thread in a catch area be coordinated such that for example the actuation of the drives by a common one Control device is made. So that the thread guide in carry out the further course of the bobbin change particularly gently.

- the guide thread between the Rest position and a deflection position moves.

- the guide thread guide passes through a trajectory transverse to the thread path, so that the Deflection thread guide with a guide edge penetrating the thread running plane can seize and deflect the thread safely.

- the advantage of this training is that the thread from the defined position of the safety gear to Catch can be offered. A superimposed relative movement between In this case, there is no safety gear and deflection thread guide.

- the thread guide and the suction device in a transfer plane arranged so that the loose end of the thread on the full spool securely on the Tying wrapping can be stored. Furthermore, by simple Swiveling movement of the thread transfer device into the cutting device the suction device. Here is only a deflection in the transfer level is required.

- the gripper arm of the transfer device detects the thread in the thread path between the already lifted bobbin and the Yarn guide. This training also has the advantage that when Lifting the bobbin from the drive roller of the thread through the transfer device remains safely guided in the thread guide.

- the transfer level is here preferably formed as the normal plane of the coil and contains the Tying reel of the spool.

- the execution of the device according to claim 7 ensures that the thread before entering the cutting device from the pneumatic Suction port is detected.

- the thread end of the incoming thread is thus safely taken after cutting in the cutter and dissipated.

- the cutting device preferably has a knife blade on that cooperates with the gripper arm of the transfer device such that the thread is cut cleanly and quickly by the knife blade.

- the Thread guide is preferably carried out with a drive that the Thread guide moved in the longitudinal direction parallel to the sleeve and the movement of the Thread guide executes at variable speed regardless of direction.

- the drive could be designed as a linear drive, for example his.

- the thread guide executed as a traversing thread guide of a traversing device.

- This can the traversing thread guide the thread outside and inside the winding area Run lengthways parallel to the sleeve.

- This version has the advantage that no additional control unit for controlling the traversing device is required. All operations during winding, during Bobbin change and while catching are controlled by a control device Traversing device controlled.

- the actual winding travel i.e. winding the spool.

- the thread from the Suction device taken over.

- the thread leading remains Traversing thread guide stand on a transfer level.

- the full coil wound a binding bead the full coil already from the Driving roller is lifted ..

- the transfer device then leads the thread in the suction device. Now that the bobbin has been changed and the Empty sleeve in the bobbin holder between the clamping plates begins the threading.

- the traversing thread guide and the deflection device guides the thread out of the Contact area between the sleeve and the drive roller.

- the sleeve is on the Driving roller attached and at a speed required for the application accelerated. As soon as the speed is reached, the drive of the Traversing thread guide activated, and the traversing thread guide leads the thread in a catch position in which the thread is inclined over a catch plane of the Catcher runs, for example an end edge of the clamping plate.

- the inventive method is particularly characterized by fast and precise bobbin changes.

- the thread can be positioned very precisely, so that the thread securely and without substantial slack from the catching device is caught.

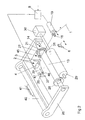

- FIG. 1 and Fig. 2 is a first embodiment of an inventive Device shown within a take-up device, such as, for example can be used in a texturing machine.

- a take-up device such as, for example can be used in a texturing machine.

- the following description therefore applies to FIGS. 1 and 2, unless stated otherwise.

- the winding device has a pivotable spool holder 26 which a pivot axis 40 is mounted.

- the pivot axis 40 is at one Machine frame 41 attached.

- two opposing clamping plates 27 and 28 are rotatable stored.

- Between the clamping plates 27 and 28 is a sleeve 13 for receiving a coil tensioned.

- the clamping plates 27 and 28 each have one conical centering shoulder that partially protrudes into the sleeve end.

- the sleeve 13 In order to the sleeve 13 is centered between the clamping plates 27 and 28.

- On the surface the sleeve 13 is a drive roller 29.

- the drive roller 29 is on one Drive shaft 31 attached.

- the drive shaft 31 is at one end with the Roller motor 30 coupled.

- the roller motor 30 drives the drive roller 29 in the substantially constant speed.

- the sleeve 13 is now over friction driven by the drive roller 29 to a winding speed, so that the thread 1 is wound on the sleeve 13 into a coil.

- the traversing thread guide is coupled to a traversing drive which guides the traversing thread guide 6 drives oscillating within the winding area.

- the traversing drive can for example, formed by a reverse thread shaft or a belt drive his.

- the thread guide 18 is with a drive 19 coupled, which the thread guide 18 in a parallel plane to the sleeve 13th so back and forth that the thread guide 18 both within the Spooling area is positioned as well as outside of the winding area.

- the drive 19 is connected to a control device 8.

- the control device 8 also serves to control a deflection device 2.

- the deflection device 2 is on the opposite to the thread guide 18 Side of the drive roller 29 or a sleeve 13 abutting the drive roller arranged.

- the deflection device 2 has a drive 4, which with the Control device 8 is connected.

- the drive 4 is with a Deflection thread guide 3 coupled.

- the guide thread guide 3 is by an L-shaped Rod formed.

- One leg of the guide thread 3 is with the Drive 4 connected, the rotary motion when activated on the Deflection thread guide 3 exercises.

- the free leg of the guide thread guide 3 has a leading edge 5, which by rotating the guide guide 3 from a Rest position is pivotable into an operating position.

- the runs through Deflecting thread guide 3 a path of movement that the thread run one in one Suction device 37 crosses incoming thread 1.

- 1 is the Deflection device 2 with the deflection thread guide 3 in the rest position shown. 2, the deflection device 2 with the deflection thread guide 3 is in shown the operating position.

- the suction device 37 On the opposite side to the sleeve 13 or for Driving roller 29, the suction device 37 is arranged.

- the suction device 37 here consists of a cutting device 38 and a suction connection 39.

- the suction port 39 is here between the cutting device 38 and the sleeve 13 arranged.

- the suction port 39 has a slot-shaped Suction opening 46, which is aligned with a knife 47 of the cutting device 38 is arranged.

- Fig. 1 In the situation shown in Fig. 1 is in the take-up device Reel change immediately before.

- the Thread guide 18 via the drive 19 in the bobbin area in a transfer plane positioned.

- the auxiliary device can do this in a simple manner be designed as a ramp parallel to the movement of the traversing thread guide 6 is introduced into the winding area. So that the thread 1 could automatically from the Traversing thread guide 6 are guided.

- the ramp would be beneficial with that Thread guide 18 coupled so that the thread sliding on the ramp automatically in the guide groove of the thread guide 18 occurs.

- Thread 1 continues wound as a binding bead 23. Now one becomes the side of the coil area arranged transfer device 42 activated.

- the transfer device 42 has a gripper arm 43 which has the free end of the transfer plane penetrates.

- the gripping arm 43 is rotatably mounted on a pivot axis 25 and is moved parallel to the transfer level via a drive, not shown here.

- the gripping arm 43 is dimensioned such that the free end of the gripping arm 43 the Grips thread between the thread guide 18 and the bobbin 24 and the thread 1 in the transfer level leads to the suction device 37.

- the suction device 37 lies within that described by the free end of the gripping arm 43 Trajectory. This ensures that the thread 1 in the cutting device 38 immersed and cut by the knife 47. Shortly before or at the same time the thread 1 enters the slit-shaped suction opening 46 of the Suction port 39. The thread end of the incoming thread is thus aspirated immediately after cutting.

- the loose thread end of the bobbin is deposited on the binding reel 23 by the outgoing coil 24.

- the Transfer device 42 is in her after cutting the thread 1 Starting position moved back.

- the deflection device 2 remains during this Phase in their rest position, so that the guide thread guide 3 none Thread contact.

- the thread 1 is fed through the suction opening 46 of the suction connection 39 continuously removed by means of a suction stream.

- the coil 24 was through replaced a new empty tube, which is driven by the drive roller 29.

- the thread 1 of the suction device 37 through the deflection device 2 and the thread guide 18th guided.

- the thread guide 18 is moved into a position outside by the drive 19 of the winding area.

- the drive 4 becomes the Deflection device 2 activated via the control device 8.

- the Deflection thread guide 3 pivoted out of its rest position and arrives with it Leading edge 5 in the thread path of the thread 1.

- the thread 1 is through the Leading edge 5 of the guide thread guide 3 carried and deflected.

- the thread 1 slides on the leading edge 5 of the guide thread guide 3 to the system, so that the Thread 1 is guided in a deflection position.

- the incoming thread 1 is through the thread guide 18 and the deflection device 2 outside the winding area guided.

- the thread 1 continues to run from the deflection device 2 into the Suction device 37 and is continuously discharged.

- the new sleeve 13 is now brought into contact with the drive roller 29.

- the Sleeve driven to a predetermined spindle speed by the drive roller 29.

- the thread guide 18 is in a catching position guided. This catch position of the thread guide 18 is selected such that the thread 1 runs obliquely over the end edge of the clamping plate 27 facing the sleeve.

- the thread becomes by a between the deflection device 2 and the clamping plate 27 arranged cutting device 45 cut.

- the Thread guide 18 deflected by the drive 19 from the catch position to a Place the thread reserve winding on the core.

- the thread guide 18 moved towards the middle of the sleeve.

- the thread 1 is passed to the traversing thread guide 6. This could also be the case an auxiliary device designed as a ramp can be used.

- the winding up now begins with a new coil journey.

- the thread guide will be back in the rest position moves.

- FIG. 3 and 4 is a further embodiment of an inventive Device shown as in a rewinder in a texturing machine can be used.

- the thread 1 becomes Bobbin change, for catching and for winding by the traversing thread guide 6 led. Since the structure of the winding device is essentially only through the traversing device to the winding device shown in FIG. 1 differs, the components with the same function have identical reference numerals receive. In this respect, the description of FIGS. 1 and Fig. 2 referred.

- the traversing device 22 is constructed as a so-called belt traverse.

- a traversing thread guide 6 is attached to an endless belt 33.

- the Belt 33 is parallel to the sleeve 13 between two deflection rollers 34.1 and 34.2 guided.

- In the belt plane there is a drive roller partially wrapped around the belt 35 arranged parallel to the deflection rollers 34.1 and 34.2.

- the drive roller 35 is attached to a drive shaft 44 of an electric motor 36.

- the electric motor 36 drives the drive roller 35 in an oscillating manner, so that the traversing thread guide 6 in the area between the guide rollers 34.1 and 34.2 is moved back and forth.

- the electric motor can be controlled via the control device 8.

- the Control device 8 is connected to deflection device 2.

- the deflection device 2 is in this embodiment by an im Deflecting thread guide 3 guided essentially parallel to the driving roller educated.

- the deflecting thread guide 3 is connected to the drive 4.

- the Drive 4 could for example be designed as a cylinder piston unit.

- the Deflection thread guide 3 has a guide edge 5, which is the thread running plane of a thread 1 entering the suction device 37.

- the winding device is different Operating situations shown.

- Fig. 3 the winder is at the end of one Spool trip shown.

- the Traversing thread guide 6 positioned in a transfer plane.

- the traversing thread guide 6 remains on the transfer plane a binding wrap 23 is produced.

- the coil holder 26 with the Coil 24 pivoted out of the operating position.

- Transfer device 42 in action by a gripper arm 43 with its free end in the thread path between the full bobbin 24 and the traversing thread guide 21 intervenes.

- the gripper arm 43 is from a rest position to a transfer position pivoted. Here he takes the thread 1 and leads the thread in the Transfer position to the suction device 37.

- the thread is then cut and taken over by the suction connection 39.

- the loose thread end is placed on the bobbin in the area of the binding reel.

- the Deflector 2 is during this phase with the Deflection thread guide 3 in the rest position. Now the coil 24 can by a Empty sleeve to be replaced. After the coil 24 is replaced by a sleeve the creation process begins.

- the continuously fed thread is from the suction device 37 and the Traversing thread guide 6 out.

- the thread end is in a suction opening of the Suction port 39 sucked.

- the drive 4 of the deflection device 2 by the Control device 8 activated.

- the guide thread guide 3 is from the rest position moved out.

- the leading edge 5 detects the thread 1.

- the thread 1 becomes by the guide thread guide 3 resting on the leading edge 5 in a Deflection position moved.

- the traversing thread guide 6 is also in the direction of the clamping plate 27 out of the winding area.

- the sleeve 13 in Bring peripheral contact with the drive roller 29.

- the sleeve 13 is by on Circumferential drive roller 29 to a predetermined by the drive roller Spindle speed driven.

- the control device 8 of the electric motor 36 is controlled by the control device 8 of the electric motor 36 such that the Electric motor brings the traversing thread guide 6 into the catching position.

- the thread 1 now crosses the catch plane of the catch device 14, so that it is caught by the catch groove 21 is caught.

- the thread 1 is caught with the catch groove 21 and with a the catcher or the clamping plate 27 integrated knife cut.

- Such clamping plate is known for example from EP 0 403 949. in this respect reference is made to the publication mentioned.

- the movement of the Traversing thread guide 6 are supported by the deflecting thread guide 3. It is also possible that the traversing thread guide 6 in its position outside the Spooling area remains and for catching the thread 1 by the catching device 21 the thread 1 is moved into a catching position by the deflecting thread guide 3.

- the movements of the traversing thread guide 6 and the deflecting thread guide 3 are coordinated by control device 8.

- the traversing thread guide 6 After catching, the traversing thread guide 6 becomes from the catching position Led winding area.

- the formation of the Thread reserve winding could in this case be caused by one that remains in one position Traversing thread guide 6 take place. Then the thread reserve winding has one Number of parallel windings.

- the traversing thread guide 6 can also at a speed determined by the electric motor 36 Be wound area, so that adjacent turns in the Thread reserve winding are generated. As soon as the thread guide the winding area reached, the winding trip begins.

- the traversing thread guide 6 is then inside of the winding area is oscillatingly driven by the traversing device 22.

- the increasing coil diameter of the coil 24 is indicated by a Pivotal movement of the coil holder 26 allows.

- the coil holder 26 has for this purpose, force transducers, on the one hand, one required to drive the coil Generate contact pressure between the coil 24 and the drive roller 29 and on the other hand allow a pivoting movement of the bobbin holder 26.

Landscapes

- Replacing, Conveying, And Pick-Finding For Filamentary Materials (AREA)

- Winding Filamentary Materials (AREA)

- Treatment Of Fiber Materials (AREA)

- Spinning Or Twisting Of Yarns (AREA)

Abstract

Description

Die Erfindung betrifft eine Vorrichtung zum Führen und Schneiden eines

kontinuierlich zulaufenden Fadens beim Spulenwechsel in einer

Aufwickeleinrichtung gemäß dem Oberbegriff des Anspruchs 1 sowie ein

Verfahren zum Führen und Schneiden eines kontinuierlich zulaufenden Fadens

gemäß dem Oberbegriff des Anspruchs 11.The invention relates to a device for guiding and cutting a

continuously tapering thread when changing bobbins in one

Winding device according to the preamble of

Die Vorrichtung und das Verfahren sind aus der EP 0 311 827 bekannt.The device and the method are known from EP 0 311 827.

In Textilmaschinen wird beispielsweise ein gekräuselter Faden kontinuierlich zu einer Spule gewickelt. Nachdem die Spule fertiggewickelt ist, erfolgt ein Spulenwechsel. Hierzu ist es erforderlich, daß der Faden zunächst durchtrennt wird, so daß die volle Spule mit losem Fadenende gegen eine neue Leerhülse gewechselt werden kann. Das Fadenende des kontinuierlich zulaufenden Fadens wird während des Wechsels mittels einer pneumatischen Absaugeinrichtung aufgenommen und abgeführt. Nachdem der Spulenwechsel erfolgt ist, wird der Faden mittels einer Fangeinrichtung gefangen und auf der neuen Hülse angewickelt.In textile machines, for example, a crimped thread is continuously closed a coil wound. After the bobbin has finished winding, a Bobbin change. For this it is necessary that the thread is cut first is so that the full bobbin with loose thread end against a new empty tube can be changed. The thread end of the continuously running thread during the change by means of a pneumatic suction device recorded and discharged. After the bobbin change, the Thread caught by a catcher and on the new tube initially wound.

Bei der aus der EP 0 311 827 bekannten Vorrichtung und bei dem bekannten Verfahren wird der Faden mittels eines beweglichen Fadenführers nach der Fertigstellung der Spule außerhalb des Spulbereiches zu einer seitlich neben dem Spulbereich angeordneten Absaugeinrichtung geführt. Nachdem der Spulenwechsel erfolgt ist und die neue Hülse bereit ist zum Fangen, wird der Fadenführer wieder in den Spulbereich verschwenkt. Zur Übergabe bzw. zum Fangen wird der Faden mittels einer Übergabeeinrichtung zwischen der Absaugeinrichtung und dem Fadenführer ausgelenkt und der Fangeinrichtung zum Fangen angeboten. In the device known from EP 0 311 827 and in the known The thread is moved by means of a movable thread guide according to the Completion of the bobbin outside of the bobbin area to a side next to the Exhaust device arranged winding area. After the The bobbin has been changed and the new tube is ready to be caught Thread guide pivoted back into the winding area. For handover or The thread is caught by means of a transfer device between the Suction device and the thread guide deflected and the catching device for Catch offered.

Die bekannte Vorrichtung und das bekannte Verfahren besitzen den Nachteil, daß am Ende der Spulreise das lose Fadenende auf der fertiggestellten Spule undefiniert anliegt, was insbesondere bei der Weiterverarbeitung das Auffinden des losen Fadenendes erschwert.The known device and the known method have the disadvantage that at the end of the bobbin trip, the loose thread end on the finished bobbin is undefined, which is particularly important for further processing when it is found of the loose thread end difficult.

Des weiteren führt die Auslenkung des Fadens durch die Übergabeeinrichtung zum Fangen des Fadens zu erheblichen Umschlingungen, die im Verhältnis zu der Aufwickelspannung zu größeren Zugkraftschwankungen im Faden führen. Derartige Zugkraftschwankungen können bei vorgeschalteten Förderelementen zu einer Wicklerbildung führen.Furthermore, the deflection of the thread leads through the transfer device to catch the thread to significant wraps that are in relation to the winding tension lead to greater fluctuations in tensile force in the thread. Such fluctuations in tensile force can occur with upstream conveying elements lead to a winder formation.

Die FR 22 47 906 beschribt eine Vorrichtung zum Schneiden eines Fadens, bei

der ein Fadenführer hinter einer angetriebenen Walze angeordnet ist.

Es ist Aufgabe der Erfindung, eine Vorrichtung und ein Verfahren der eingangs genannten Art derart zu schaffen, daß während des Spulenwechsel beim Führen und Fangen des Fadens und beim Anwickeln des Fadens eine möglichst schonende Fadenführung gewährleistet wird.It is an object of the invention, an apparatus and a method of the beginning to create the type mentioned in such a way that during the change of bobbin when guiding and catching the thread and when winding the thread one if possible gentle thread guidance is guaranteed.

Ein weiteres Ziel der Erfindung ist es, nach dem Schneiden des Fadens zu gewährleisten, daß das lose Fadenende am Abbindewulst der Vollspule anliegt und daß der laufende Faden ohne wesentliche Verschlappung an eine neue Hülse angelegt wird.Another object of the invention is to cut after the thread Ensure that the loose end of the thread lies against the binding bead of the full bobbin and that the running thread on a new sleeve without substantial slack is created.

Diese Aufgabe wird erfindungsgemäß durch eine Vorrichtung mit den Merkmalen

gemäß Anspruch 1 sowie durch ein Verfahren mit den Merkmalen gemäß

Anspruch 11 gelöst.This object is achieved by a device with the features

according to

Die Erfindung zeichnet sich dadurch aus, daß der Fadenführer und die Absaugeinrichtung beim Beginn des Spulenwechsels innerhalb des Spulbereiches angeordnet sind. Der Spulbereich ist hierbei der Bereich auf der Hülse, der von dem changierten Faden überdeckt wird. Damit kann der Faden mit relativ geringer Auslenkung geschnitten und von der Fadenabsaugung übernommem werden, so daß während der Wechselphase keine wesentlichen Fadenzugkraftschwankungen auftreten. Die Absaugeinrichtung ist hierbei vorzugsweise ortsfest angeordnet. Bei einer im wesentlichen parallel zur Spule beweglich ausgeführten Absaugeinrichtung besteht die Möglichkeit, das lose Fadenende mit dem Abbindewulst an einer beliebigen Position innerhalb des Spulbereiches zu plazieren. Durch die zwischen der Absaugeinrichtung und dem Fadenführer vorgesehene Umlenkeinrichtung ist eine hohe Flexibilität in der Gestaltung der Fangeinrichtung gegeben. Zudem verhindert die Umlenkeinrichtung, daß der zur Absaugeinrichtung laufende Faden nicht zwischen den Oberflächen einer neuen Hülse und der Treibwalze geklemmt wird. Der Faden wird ohne zu verschlappen von der Vollspule zu einer neuen Hülse übergeben. Ein weiterer Vorteil der Erfindung liegt darin, daß zum Fangen der Faden zu beiden Seiten der Fangeinrichtung geführt ist und somit eine sehr hohe Fangsicherheit erreicht wird.The invention is characterized in that the thread guide and Suction device at the beginning of the bobbin change within the bobbin area are arranged. The winding area is the area on the tube that of the covered thread is covered. This allows the thread to be relatively low Deflection cut and taken over by the thread suction, so that there are no significant thread tension fluctuations during the change phase occur. The suction device is preferably arranged stationary. at one designed to be movable essentially parallel to the coil Suction device there is the possibility of the loose thread end with the The setting bead is closed at any position within the winding area place. By between the suction device and the thread guide The intended deflection device is highly flexible in the design of the Giving device given. In addition, the deflection device prevents the Suction device running thread not between the surfaces of a new one Sleeve and the drive roller is clamped. The thread becomes tangle-free transferred from the full spool to a new tube. Another advantage of Invention is that for catching the thread on both sides of the Catch device is guided and thus a very high level of safety is achieved.

Die besonders vorteilhafte Weiterbildung der Vorrichtung gemäß Anspruch 2

ermöglicht, daß der Faden ohne weitere Hilfsmittel allein durch Bewegung des

Fadenführers in der Fangeinrichtung gefangen wird. Hierzu wird der Faden nur in

Längsrichtung parallel zur Hülse ausgelenkt. Durch eine zusätzliche

gleichgerichtete Bewegung der Umlenkeinrichtung läßt sich zudem die

Auslenkung des Fadens minimieren.The particularly advantageous development of the device according to

Bei der erfindungsgemäßen Aufwickelvorrichtung, bei welcher die Hülse zwischen zwei an einem Spulenhalter angeordneten Spannteller gespannt ist und die Fangeinrichtung an einem der Spannteller ausgebildet ist, läßt sich der Faden auf einfache Weise fangen. Hierzu wird der Faden im schrägen Lauf über die Stirnkante des Spanntellers geführt, so daß der Faden in einen in der Stirnkante des Spanntellers eingebrachten Fangschlitz selbsttätig einfällt. Zudem ist die Anordnung des Fadenführers, der Umlenkeinrichtung und der Fangeinrichtung derart vorteilhaft, daß der Faden und der Spannteller eine gleichgerichtete Bewegung ausführen. Damit tritt keine Verschlappung und damit keine überhöhte Fadenspannungsschwankung beim Fangen auf. In the winding device according to the invention, in which the sleeve is stretched between two clamping plates arranged on a coil holder and the catching device is formed on one of the tensioning plates, the thread can be catch easily. To do this, thread the thread in an oblique course over the Front edge of the tension plate guided so that the thread in one in the front edge of the clamping plate inserted automatically falls. In addition, the Arrangement of the thread guide, the deflection device and the catching device so advantageous that the thread and the tension plate are rectified Carry out movement. So there is no waste and therefore no excessive Thread tension fluctuation when catching.

Da die Umlenkeinrichtung während des Spulenwechsels nur kurzzeitig eine Führung des Fadens übernimmt, ist die Ausbildung der erfindungsgemäßen Vorrichtung gemäß Anspruch 4 besonders vorteilhaft. Hierbei besteht die Umlenkeinrichtung aus einem beweglichen Umlenkfadenführer und einem steuerbaren Antrieb. Der Umlenkfadenführer wird dabei mittels des Antriebes aus einer Ruhestellung außerhalb des Fadenlaufs heraus bewegt. In der Phase, in welcher der Faden auf einfache Weise durch die Übergabeeinrichtung von der Vollspule in die Absaugeinrichtung geführt wird und während des Wickelns vom Abbindewulst sowie zu Beginn des Spulenwechsels ist eine Führung des Fadens nur durch den Fadenführer bzw. nur durch den Fadenführer und die Absaugeinrichtung möglich. Der Umlenkfadenführer bleibt zunächst in seiner Ruhestellung. Es treten keine wesentlichen Auslenkungen des Fadens und damit keine wesentlichen Umschlingungen auf. Erst kurz bevor die neue Hülse in Kontakt mit der Treibwalze gebracht wird, wird der Umlenkfadenführer durch den Antrieb aktiviert, um den Faden zu erfassen und auszulenken. Die Bewegung des Umlenkfadenführers kann vorteilhaft mit der Bewegung des Fadenführers zur Führung des Fadens in einem Fangbereich derart koordiniert werden, daß beispielsweise die Ansteuerung der Antriebe durch eine gemeinsame Steuereinrichtung vorgenommen wird. Damit läßt sich die Fadenführung im weiteren Verlauf des Spulenwechsels besonders schonend ausführen. Es ist jedoch auch möglich, den Umlenkfadenführer unabhängig von dem Fadenführer vor der angetriebenen Hülse in Richtung zum Hülsenrand zu bewegen.Since the deflection device only briefly during the coil change Taking control of the thread is the training of the invention Device according to claim 4 particularly advantageous. Here is the Deflection device from a movable deflection thread guide and one controllable drive. The deflecting thread guide is made by means of the drive moved out of a rest position outside the thread path. In the phase in which the thread in a simple manner by the transfer device from the Full coil is guided into the suction device and during winding from Binding bead and at the beginning of the bobbin change is a guide of the thread only by the thread guide or only by the thread guide and Suction device possible. The guide thread guide remains in its first Rest. There are no significant deflections of the thread and thus no significant wrapping. Just before the new sleeve in Is brought into contact with the drive roller, the guide thread is guided by the Actuator activated to catch and deflect the thread. The movement of the Deflecting thread guide can be advantageous with the movement of the thread guide Guide the thread in a catch area be coordinated such that for example the actuation of the drives by a common one Control device is made. So that the thread guide in carry out the further course of the bobbin change particularly gently. However, it is also possible to guide the deflecting thread guide independently of the thread guide to move the driven sleeve towards the sleeve edge.

Bei einer besonders vorteilhaften Ausgestaltung der erfindungsgemäßen

Vorrichtung nach Anspruch 5 wird der Umlenkfadenführer zwischen der

Ruhestellung und einer Umlenkstellung bewegt. Der Umlenkfadenführer

durchläuft dabei eine zum Fadenlauf querliegende Bewegungsbahn, so daß der

Umlenkfadenführer mit einer die Fadenlaufebene durchdringenden Führungskante

den Faden sicher ergreifen und auslenken kann. Der Vorteil dieser Ausbildung

liegt darin, daß der Faden aus definierter Position heraus der Fangeinrichtung zum

Fangen angeboten werden kann. Eine überlagerte Relativbewegung zwischen

Fangeinrichtung und Umlenkfadenführer ist in diesem Fall nicht gegeben.In a particularly advantageous embodiment of the invention

Apparatus according to

Bei einer besonders vorteilhaften Weiterbildung der Vorrichtung gemäß Anspruch

6 sind der Fadenführer und die Absaugeinrichtung in einer Übergabeebene

angeordnet, so daß das lose Fadenende an der Vollspule sicher auf dem

Abbindewickel abgelegt werden kann. Des weiteren kann durch einfache

Schwenkbewegung der Übergabeeinrichtung der Faden in die Schneideinrichtung

der Absaugeinrichtung hineingeführt werden. Hierbei ist nur eine Auslenkung in

der Übergabeebene erforderlich. Der Greifarm der Übergabeeinrichtung erfaßt

den Faden dabei im Fadenlauf zwischen der bereits abgehobenen Spule und dem

Fadenführer. Diese Ausbildung besitzt des weiteren den Vorteil, daß beim

Abheben der Spule von der Treibwalze der Faden durch die Übergaheeinrichtung

sicher in dem Fadenführer geführt bleibt. Die Übergabeebene ist hierbei

vorzugsweise als Normalebene der Spule ausgebildet und enthält den

Abbindewickel der Spule.In a particularly advantageous development of the device according to

Die Ausführung der Vorrichtung gemäß Anspruch 7 gewährleistet, daß der Faden vor Eintritt in die Schneideinrichtung bereits von dem pneumatischen Absauganschluß erfaßt wird. Das Fadenende des zulaufenden Fadens wird somit sicher nach dem Durchtrennen in der Schneideinrichtung aufgenommen und abgeführt. Die Schneideinrichtung weist hierzu vorzugsweise eine Messerklinge auf, die mit dem Greifarm der Übergabeeinrichtung derart zusammenwirkt, daß der Faden sauber und schnell durch die Messerklinge geschnitten wird.The execution of the device according to claim 7 ensures that the thread before entering the cutting device from the pneumatic Suction port is detected. The thread end of the incoming thread is thus safely taken after cutting in the cutter and dissipated. For this purpose, the cutting device preferably has a knife blade on that cooperates with the gripper arm of the transfer device such that the thread is cut cleanly and quickly by the knife blade.

Um den laufenden Faden sicher in die Saugöffnung des Absauganschlusses zu

führen, ist dieser gemäß Anspruch 8 vorteilhaft geschlitzt ausgeführt.To securely feed the running thread into the suction opening of the suction connection

lead, this is advantageously designed slotted according to

Bei den zuvor beschriebenen Vorgängen zum Spulenwechsel, zum Fangen und zum Anwickeln des Fadens ist vorausgesetzt, daß der Faden zu Beginn des Spulenwechsels mittels einer Hilfseinrichtung auf einem Changierfadenführer geführt und anschließend von dem Fadenführer übernommen wird. Der Fadenführer ist hierbei vorzugsweise mit einem Antrieb ausgeführt, der den Fadenführer in Längsrichtung parallel zur Hülse bewegt und die Bewegung des Fadenführers richtungsunabhängig mit veränderlicher Geschwindigkeit ausführt. In diesem Fall könnte der Antrieb beispielsweise als Linearantrieb ausgeführt sein.In the previously described processes for changing bobbins, catching and for winding the thread is provided that the thread at the beginning of the Bobbin change by means of an auxiliary device on a traversing thread guide guided and then taken over by the thread guide. The Thread guide is preferably carried out with a drive that the Thread guide moved in the longitudinal direction parallel to the sleeve and the movement of the Thread guide executes at variable speed regardless of direction. In this case, the drive could be designed as a linear drive, for example his.

Bei einer besonders vorteilhaften Weiterbildung der Erfindung ist der Fadenführer als ein Changierfadenführer einer Changiereinrichtung ausgeführt. Hierzu kann der Changierfadenführer den Faden außerhalb und innerhalb des Spulbereichs in Längsrichtung parallel zur Hülse führen. Diese Ausführung besitzt den Vorteil, daß keine zusätzliche Steuereinheit zur Steuerung der Changiereinrichtung erforderlich ist. Alle Vorgänge während des Aufspulens, während des Spulenwechsels und während des Fangens werden über eine Steuereinrichtung der Changiereinrichtung gesteuert.In a particularly advantageous development of the invention, the thread guide executed as a traversing thread guide of a traversing device. This can the traversing thread guide the thread outside and inside the winding area Run lengthways parallel to the sleeve. This version has the advantage that no additional control unit for controlling the traversing device is required. All operations during winding, during Bobbin change and while catching are controlled by a control device Traversing device controlled.

Nachdem der Faden gefangen wurde und auf der Hülse angewickelt ist, erfolgt die eigentliche Spulreise, d.h. das Aufwickeln der Spule. Nachdem die Spule fertiggestellt ist, wird zur Einleitung des Spulenwechsels der Faden von der Absaugeinrichtung übernommen. Hierzu bleibt der den Faden führende Changierfadenführer in einer Übergabeebene stehen. Zunächst wird auf der Vollspule ein Abbindewulst gewickelt, wobei die Vollspule bereits von der Treibwalze abgehoben wird.. Die Übergabeeinrichtung führt sodann den Faden in die Absaugeinrichtung. Nachdem nun der Spulenwechsel erfolgt ist und die Leerhülse in dem Spulenhalter zwischen den Spanntellern gespannt ist, beginnt das Anlegen des Fadens. Bevor die neue Hülse auf die Treibwalze gesetzt wird, führt der Changierfadenführer und die Umlenkeinrichtung den Faden aus dem Kontaktbereich zwischen der Hülse und der Treibwalze. Die Hülse wird auf die Treibwalze aufgesetzt und auf eine für das Anlegen erforderliche Drehzahl beschleunigt. Sobald die Drehzahl erreicht ist, wird der Antrieb des Changierfadenführers aktiviert, und der Changierfadenführer führt den Faden in eine Fangposition, in welcher der Faden schräg über eine Fangebene der Fangeinrichtung läuft, beispielsweise eine Stirnkante des Spanntellers.After the thread has been caught and wound on the tube, the actual winding travel, i.e. winding the spool. After the coil is completed, the thread from the Suction device taken over. For this, the thread leading remains Traversing thread guide stand on a transfer level. First, on the Full coil wound a binding bead, the full coil already from the Driving roller is lifted .. The transfer device then leads the thread in the suction device. Now that the bobbin has been changed and the Empty sleeve in the bobbin holder between the clamping plates begins the threading. Before the new sleeve is placed on the drive roller, the traversing thread guide and the deflection device guides the thread out of the Contact area between the sleeve and the drive roller. The sleeve is on the Driving roller attached and at a speed required for the application accelerated. As soon as the speed is reached, the drive of the Traversing thread guide activated, and the traversing thread guide leads the thread in a catch position in which the thread is inclined over a catch plane of the Catcher runs, for example an end edge of the clamping plate.

Das erfindungsgemäße Verfahren zeichnet sich besonders durch schnelle und präzise Spulenwechsel aus. Insbesondere durch die Führung des Fadens vor und hinter der Fangeinrichtung läßt sich der Faden sehr genau positionieren, so daß der Faden sicher und ohne wesentliche Verschlappung von der Fangeinrichtung gefangen wird.The inventive method is particularly characterized by fast and precise bobbin changes. In particular by guiding the thread in front of and behind the catching device, the thread can be positioned very precisely, so that the thread securely and without substantial slack from the catching device is caught.

Die besonders vorteilhaften Verfahrensvarianten nach Anspruch 12 oder 13 lassen eine große Gestaltungsfreiheit für die Fangeinrichtung zu. Zudem können damit unnötige Fadenumschlingungen vermieden werden.Leave the particularly advantageous method variants according to claim 12 or 13 great freedom of design for the safety gear. You can also use it unnecessary thread wrapping can be avoided.

Die Verwendung der erfindungsgemäße Vorrichtung in einer Falschdralltexturiermaschine ist besonders vorteilhaft, da Falschdralltexturiermaschine über eine Vielzahl von Aufwickelvorrichtungen verfügen, die ohne manuelle Bedienung nach jeder gewickelten Spule einen Spulenwechsel ausführen. Eine mit der erfindungsgemäßen Vorrichtung ausgestattet Falschdralltexturiermaschine besitzt somit die bereits zuvor beschriebenen Vorteile.The use of the device according to the invention in a False twist texturing machine is particularly advantageous because False twist texturing machine via a variety of winding devices have one without manual operation after each wound coil Change the bobbin. One with the device according to the invention The false twist texturing machine already has it described advantages.

Weitere vorteilhafte Weiterbildungen der Erfindung sind in den Unteransprüchen definiert.Further advantageous developments of the invention are in the subclaims Are defined.

Die erfindungsgemäße Vorrichtung sowie das Verfahren sind anhand einiger Ausführungsbeispiele im folgenden unter Hinweis auf die beigefügten Zeichnungen näher beschrieben.The device according to the invention and the method are based on some Embodiments below with reference to the accompanying Drawings described in more detail.

Es stellen dar:

- Fig. 1

- schematisch ein erstes Ausführungsbeispiel einer erfindungsgemäßen Vorrichtung beim Spulenwechsel;

- Fig. 2

- schematisch die Vorrichtung aus Fig. 1 beim Fangen des Fadens;

- Fig. 3

- schematisch ein weiteres Ausführungsbeispiel der erfindungsgemäßen Vorrichtung beim Spulenwechsel;

- Fig. 4

- schematisch die Vorrichtung aus Fig. 3 beim Fangen des Fadens.

- Fig. 1

- schematically a first embodiment of a device according to the invention when changing bobbins;

- Fig. 2

- schematically the device of Figure 1 when catching the thread.

- Fig. 3

- schematically another embodiment of the device according to the invention when changing the bobbin;

- Fig. 4

- schematically the device of Fig. 3 when catching the thread.

In Fig. 1 und Fig. 2 ist ein erstes Ausführungsbeispiel einer erfindungsgemäßen Vorrichtung innerhalb einer Aufwickelvorrichtung gezeigt, wie sie beispielsweise in einer Texturiermaschine eingesetzt sein kann. Die nachfolgende Beschreibung gilt daher für Fig. 1 und Fig. 2, insoweit nichts anderes gesagt ist.1 and Fig. 2 is a first embodiment of an inventive Device shown within a take-up device, such as, for example can be used in a texturing machine. The following description therefore applies to FIGS. 1 and 2, unless stated otherwise.

Die Aufwickelvorrichtung weist einen schwenkbaren Spulenhalter 26 auf, der an

einer Schwenkachse 40 gelagert ist. Die Schwenkachse 40 ist an einem

Maschinengestell 41 befestigt. An den freien Enden des gabelförmigen

Spulenhalters 26 sind zwei sich gegenüberliegende Spannteller 27 und 28 drehbar

gelagert. Zwischen den Spanntellern 27 und 28 ist eine Hülse 13 zur Aufnahme

einer Spule gespannt. Hierzu weisen die Spannteller 27 und 28 jeweils einen

konischen Zentrieransatz auf, der teilweise in das Hülsenende hineinragt. Damit

ist die Hülse 13 zwischen den Spanntellern 27 und 28 zentriert. An der Oberfläche

der Hülse 13 liegt eine Treibwalze 29 an. Die Treibwalze 29 ist auf einer

Antriebswelle 31 befestigt. Die Antriebswelle 31 ist an einem Ende mit dem

Walzenmotor 30 gekoppelt. Der Walzenmotor 30 treibt die Treibwalze 29 mit im

wesentlichen konstanter Geschwindigkeit an. Über Friktion wird nun die Hülse 13

mittels der Treibwalze 29 zu einer Spuldrehzahl angetrieben, so daß der Faden 1

auf der Hülse 13 zu einer Spule aufgewickelt wird. Hierzu ist vor der Treibwalze

29 im Fadenlauf ein Changierfadenführer 6 angeordnet. Der Changierfadenführer

ist mit einem Changierantrieb gekoppelt, welcher den Changierfadenführer 6

innerhalb des Spulbereiches oszillierend antreibt. Der Changierantrieb kann

beispielsweise durch eine Kehrgewindewelle oder einen Riementrieb gebildet

sein.The winding device has a

Zwischen dem Changierfadenführer 6 und der Hülse 13 ist ein beweglicher

Fadenführer 18 angeordnet. Der Fadenführer 18 ist mit einem Antrieb 19

gekoppelt, welcher den Fadenführer 18 in einer parallelen Ebene zur Hülse 13

derart hin- und herbewegt, daß der Fadenführer 18 sowohl innerhalb des

Spulbereiches als auch außerhalb des Spulbereiches positionierbar ist. Der Antrieb

19 ist mit einer Steuereinrichtung 8 verbunden.Between the traversing

Die Steuereinrichtung 8 dient ebenfalls zur Ansteuerung einer Umlenkeinrichtung

2. Die Umlenkeinrichtung 2 ist auf der zum Fadenführer 18 gegenüberliegenden

Seite der Treibwalze 29 bzw. einer an der Treibwalze anliegenden Hülse 13

angeordnet. Die Umlenkeinrichtung 2 weist einen Antrieb 4 auf, der mit der

Steuereinrichtung 8 verbunden ist. Der Antrieb 4 ist mit einem

Umlenkfadenführer 3 gekoppelt. Der Umlenkfadenführer 3 wird durch eine L-förmige

Stange gebildet. Ein Schenkel des Umlenkfadenführers 3 ist mit dem

Antrieb 4 verbunden, der bei Aktivierung eine Drehbewegung auf den

Umlenkfadenführer 3 ausübt. Der freie Schenkel des Umlenkfadenführers 3 weist

eine Führungskante 5 auf, die durch Drehung des Umlenkfadenführers 3 aus einer

Ruhestellung in eine Betriebsstellung verschwenkbar ist. Dabei durchläuft der

Umlenkfadenführer 3 eine Bewegungsbahn, die den Fadenlauf eines in einer

Absaugeinrichtung 37 einlaufenden Fadens 1 kreuzt. In Fig. 1 ist die

Umlenkeinrichtung 2 mit dem Umlenkfadenführer 3 in der Ruhestellung

dargestellt. In Fig. 2 ist die Umlenkeinrichtung 2 mit dem Umlenkfadenführer 3 in

der Betriebsstellung gezeigt.The

Auf der zur Changierung gegenüberliegenden Seite zur Hülse 13 bzw. zur

Treibwalze 29 ist die Absaugeinrichtung 37 angeordnet. Die Absaugeinrichtung

37 besteht hierbei aus einer Schneideeinrichtung 38 und einem Absauganschluß

39. Der Absauganschluß 39 ist hierbei zwischen der Schneideinrichtung 38 und

der Hülse 13 angeordnet. Der Absauganschluß 39 besitzt eine schlitzförmige

Saugöffnung 46, die fluchtend zu einem Messer 47 der Schneideinrichtung 38

angeordnet ist.On the opposite side to the

Bei der in Fig. 1 gezeigten Situation steht in der Aufwickelvorrichtung ein

Spulenwechsel unmittelbar bevor. Um den Spulenwechsel einzuleiten, wird der

Fadenführer 18 über den Antrieb 19 in dem Spulenbereich in eine Übergabeebene

positioniert. Gleichzeitig wird über eine, hier nicht näher erläuterte

Hilfseinrichtung der Faden 1 aus dem Changierfadenführer 1 geführt und in den

Fadenführer 18 eingelegt. Die Hilfseinrichtung kann hierbei auf einfache Weise

als Rampe ausgeführt sein, die parallel zur Bewegung des Changierfadenführers 6

in den Spulbereich eingeführt wird. Damit könnte der Faden 1 selbsttätig aus dem

Changierfadenführer 6 geführt werden. Die Rampe wäre vorteilhaft mit dem

Fadenführer 18 gekoppelt, so daß der auf die Rampe gleitende Faden selbsttätig in

die Führungsnut des Fadenführers 18 einfällt.In the situation shown in Fig. 1 is in the take-up device

Reel change immediately before. To initiate the bobbin change, the

Während der Fadenführer 18 in der Übergabeebene positioniert ist, wird ein

Abbindewickel 23 wulstartig auf der Spule 24 gewickelt. Um den Spulenwechsel

durchzuführen, wird nun in der Aufwickeleinrichtung der Spulenhalter 26 derart

verschwenkt, daß die Spule 24 sich von der Oberfläche der Treibwalze 29 löst.

Die Spule 24 wird somit nicht mehr aktiv angetrieben. Der Faden 1 wird weiter

als Abbindewulst 23 gewickelt. Nun wird eine seitlich zum Spulenbereich

angeordnete Übergabeeinrichtung 42 aktiviert. Die Übergabeeinrichtung 42

besitzt einen Greifarm 43, der mit einem freien Ende die Übergabeebene

durchdringt. Der Greifarm 43 ist an einer Schwenkachse 25 drehbar gelagert und

wird über einen hier nicht gezeigten Antrieb parallel zur Übergabeebene bewegt.

Der Greifarm 43 ist derart dimensioniert, daß das freie Ende des Greifarms 43 den

Faden zwischen dem Fadenführer 18 und der Spule 24 ergreift und den Faden 1 in

der Übergabeebene zu der Absaugeinrichtung 37 führt. Die Absaugeinrichtung 37

liegt hierbei innerhalb der durch das freie Ende des Greifarms 43 beschriebenen

Bewegungsbahn. Damit wird erreicht, daß der Faden 1 in die Schneideinrichtung

38 eintaucht und durch das Messer 47 geschnitten wird. Kurz zuvor bzw.

gleichzeitig gelangt der Faden 1 in die schlitzförmige Saugöffnung 46 des

Absauganschlusses 39. Das Fadenende des zulaufenden Fadens wird somit

unmittelbar nach dem Durchtrennen abgesaugt. Das lose Fadenende der Spule

wird durch die auslaufende Spule 24 auf dem Abbindewickel 23 abgelegt. Die

Übergabeeinrichtung 42 wird nach dem Durchtrennen des Fadens 1 in ihre

Ausgangslage zurückbewegt. Die Umlenkeinrichtung 2 verharrt während dieser

Phase in ihrer Ruhestellung, so daß der Umlenkfadenführer 3 keinen

Fadenkontakt hat.While the

Bei der in Fig. 2 gezeigten Situation ist bereits ein Spulenwechsel erfolgt, und der

kontinuierlich zugeführte Faden wird von der Absaugeinrichtung 37 und dem

Fadenführer 18 geführt. Aufgrund der Übersichtlichkeit wurde in Fig. 2 auf die

Darstellung der Übergabeeinrichtung verzichtet.In the situation shown in FIG. 2, the spool has already been changed, and the

continuously fed thread is from the

Der Faden 1 wird über die Saugöffnung 46 des Absauganschlusses 39

kontinuierlich mittels eines Saugstromes abgeführt. Die Spule 24 wurde durch

eine neue Leerhülse ersetzt, die durch die Treibwalze 29 angetrieben wird. Um

den Faden an die Leerhülse 13 zum Aufwickeln anzulegen, wird der Faden 1 von

der Absaugeinrichtung 37 durch die Umlenkeinrichtung 2 und den Fadenführer 18

geführt. Der Fadenführer 18 wird durch den Antrieb 19 in eine Position außerhalb

des Spulbereichs geführt. Kurz vorher oder gleichzeitig wird der Antrieb 4 der

Umlenkeinrichtung 2 über die Steuereinrichtung 8 aktiviert. Daraufhin wird der

Umlenkfadenführer 3 aus seiner Ruhestellung verschwenkt und gelangt mit seiner

Führungskante 5 in den Fadenlauf des Fadens 1. Der Faden 1 wird durch die

Führungskante 5 des Umlenkfadenführers 3 mitgeführt und ausgelenkt. Nachdem

der Umlenkfadenführer 3 seine Betriebsstellung erreicht hat, gleitet der Faden 1

an der Führungskante 5 des Umlenkfadenführers 3 bis zur Anlage, so daß der

Faden 1 in einer Umlenkposition geführt ist. Der zulaufende Faden 1 wird durch

den Fadenführer 18 und die Umlenkeinrichtung 2 außerhalb des Spulbereichs

geführt. Von der Umlenkeinrichtung 2 läuft der Faden 1 weiterhin in die

Absaugeinrichtung 37 ein und wird kontinuierlich abgeführt.The

Die neue Hülse 13 wird nun in Kontakt mit der Treibwalze 29 gebracht. Durch

den Umfangskontakt zwischen der Treibwalze 29 und der Hülse 13 wird die

Hülse auf eine durch die Treibwalze 29 vorgegebene Spuldrehzahl angetrieben.

Sobald die Spuldrehzahl erreicht ist, wird der Fadenführer 18 in eine Fangposition

geführt. Diese Fangposition des Fadenführers 18 ist derart gewählt, daß der Faden

1 schräg über die zur Hülse gewandte Stirnkante des Spanntellers 27 läuft.

Nachdem die Hülse 13 die Spuldrehzahl erreicht und die Fangnut 21 eine zum

sicheren Fangen erforderliche Position aufweist, wird der Faden 1 nun von der

Fangeinrichtung 14 im Spannteller 27 gefangen.The

Nachdem der Faden 1 von der Fangeinrichtung 14 gefangen ist, wird der Faden

durch eine zwischen der Umlenkeinrichtung 2 und dem Spannteller 27

angeordnete Schneideinrichtung 45 geschnitten. Nach dem Fangen wird der

Fadenführer 18 durch den Antrieb 19 aus der Fangposition ausgelenkt, um eine

Fadenreservewicklung auf der Hülse abzulegen. Hierzu wird der Fadenführer 18

in Richtung Hülsenmitte bewegt. Nachdem die Fadenreservewicklung gelegt ist,

wird der Faden 1 dem Changierfadenführer 6 übergeben. Hierzu könnte ebenfalls

eine als Rampe ausgeführte Hilfseinrichtung eingesetzt werden. Die Aufwicklung

beginnt nun mit einer neuen Spulenreise. Der Umlenkfadenführer wird zurück in

die Ruhestellung bewegt.After the

In Fig. 3 und 4 ist ein weiteres Ausführungsbeispiel einer erfindungsgemäßen

Vorrichtung gezeigt, wie sie bei einer Aufwicklung in einer Texturiermaschine

einsetzbar ist. Bei diesem Ausführungsbeispiel wird der Faden 1 zum

Spulenwechsel, zum Fangen und zum Anwickeln durch den Changierfadenführer

6 geführt. Da der Aufbau der Aufwickelvorrichtung sich im wesentlichen nur

durch die Changiereinrichtung zu der in Fig. 1 gezeigten Aufwickelvorrichtung

unterscheidet, haben die Bauteile gleicher Funktion identische Bezugszeichen

erhalten. Insoweit wird an dieser Stelle auch auf die Beschreibung zu Fig. 1 und

Fig. 2 Bezug genommen.3 and 4 is a further embodiment of an inventive

Device shown as in a rewinder in a texturing machine

can be used. In this embodiment, the

Die Changiereinrichtung 22 ist als sogenannte Riemenchangierung aufgebaut.

Hierbei ist ein Changierfadenführer 6 an einem endlosen Riemen 33 befestigt. Der

Riemen 33 wird zwischen zwei Umlenkrollen 34.1 und 34.2 parallel zur Hülse 13

geführt. In der Riemenebene ist eine vom Riemen teilumschlungene Antriebsrolle

35 parallel zu den Umlenkrollen 34.1 und 34.2 angeordnet. Die Antriebsrolle 35

ist auf einer Antriebswelle 44 eines Elektromotors 36 befestigt. Der Elektromotor

36 treibt die Antriebsrolle 35 oszillierend an, so daß der Changierfadenführer 6 in

dem Bereich zwischen den Umlenkrollen 34.1 und 34.2 hin- und hergeführt wird.

Der Elektromotor ist über die Steuereinrichtung 8 steuerbar. Die

Steuereinrichtung 8 steht in Verbindung mit der Umlenkeinrichtung 2.The traversing

Die Umlenkeinrichtung 2 wird in diesem Ausführungsbeispiel durch einen im

wesentlichen parallel zur Treibwalze linear geführten Umlenkfadenführer 3

gebildet. Hierzu ist der Umlenkfadenführer 3 mit dem Antrieb 4 verbunden. Der

Antrieb 4 könnte beispielsweise als Zylinderkolbeneinheit ausgeführt sein. Der

Umlenkfadenführer 3 weist eine Führungskante 5 auf, die die Fadenlaufebene

eines in die Absaugeinrichtung 37 einlaufenden Fadens 1 durchdringt. Durch

Aktivierung des Antriebes 4 durch die Steuereinrichtung 8 läßt sich der

Umlenkfadenführer 3 mit der Führungskante 5 derart führen, daß ein in die

Absaugeinrichtung 37 einlaufender Faden 1 erfaßt und ausgelenkt wird.The

In den Figuren 3 und 4 ist die Aufwickelvorrichtung in verschiedenen

Betriebssituationen gezeigt. In Fig. 3 ist die Aufwickelvorrichtung am Ende einer

Spulreise gezeigt. Nachdem die Spule 24 zu Ende gewickelt ist, wird der

Changierfadenführer 6 in eine Übergabeebene positioniert. In dieser

Übergabeebene verharrt der Changierfadenführer 6. Auf der Spule 24 wird nun

ein Abbindewickel 23 erzeugt. Gleichzeitig wird der Spulenhalter 26 mit der

Spule 24 aus der Betriebsstellung verschwenkt. Nun tritt eine

Übergabeeinrichtung 42 in Aktion, indem ein Greifarm 43 mit seinem freien Ende

in den Fadenlauf zwischen der Vollspule 24 und dem Changierfadenführer 21

eingreift. Der Greifarm 43 wird aus einer Ruhestellung in eine Übergabestellung

verschwenkt. Hierbei ergreift er den Faden 1 und führt den Faden in der

Übergabestellung zur Absaugeinrichtung 37. In der Schneidvorrichtung 38 wird

der Faden sodann geschnitten und von dem Absauganschluß 39 übernommen. Das

lose Fadenende wird auf der Spule im Bereich der Abbindewickel gelegt. Die

Umlenkeinrichtung 2 befindet sich während dieser Phase mit dem

Umlenkfadenführer 3 in der Ruhestellung. Nun kann die Spule 24 durch eine

Leerhülse ausgetauscht werden. Nachdem die Spule 24 durch eine Hülse ersetzt

wurde, beginnt der Ablauf des Anlegens.In Figures 3 and 4, the winding device is different

Operating situations shown. In Fig. 3 the winder is at the end of one

Spool trip shown. After the

In Fig. 4 ist der Beginn des Anlegevorgangs gezeigt. Der kontinuierlich

zugeführte Faden wird von der Absaugeinrichtung 37 und dem

Changierfadenführer 6 geführt. Hierzu ist das Fadenende in eine Saugöffnung des

Absauganschlusses 39 eingesogen. Bevor die neue Hülse 13 auf die Treibwalze

29 aufgesetzt wird, wird der Antrieb 4 der Umlenkeinrichtung 2 durch die

Steuereinrichtung 8 aktiviert. Der Umlenkfadenführer 3 wird aus der Ruhestellung

herausbewegt. Hierbei erfaßt die Führungskante 5 den Faden 1. Der Faden 1 wird

durch den Umlenkfadenführer 3 an der Führungskante 5 anliegend in eine

Umlenkposition bewegt. Der Changierfadenführer 6 wird ebenfalls in Richtung

des Spanntellers 27 außerhalb des Spulbereichs geführt. Sobald der Faden 1 durch

den Changierfadenführer 6 und den Umlenkfadenführer 3 aus dem Kontaktbereich

zwischen der Hülse 13 und der Treibwalze 29 geführt ist, wird die Hülse 13 in

Umfangskontakt mit der Treibwalze 29 gebracht. Die Hülse 13 wird durch am

Umfang anliegende Treibwalze 29 auf eine durch die Treibwalze vorgegebene

Spuldrehzahl angetrieben. Nachdem die Hülse 13 die Spuldrehzahl erreicht hat,

wird durch die Steuereinrichtung 8 der Elektromotor 36 derart gesteuert, daß der

Elektromotor den Changierfadenführer 6 in die Fangposition bringt. Der Faden 1

kreuzt nun die Fangebene der Fangeinrichtung 14, so daß er von der Fangnut 21

gefangen wird. Der Faden 1 wird mit der Fangnut 21 gefangen und mit einem in

der Fangeinrichtung bzw. dem Spannteller 27 integrierten Messer geschnitten. Ein

derartiger Spannteller ist beispielsweise aus der EP 0 403 949 bekannt. Insoweit

wird auf die genannte Druckschrift Bezug genommen.4 shows the start of the application process. The continuously

fed thread is from the

Um den Faden 1 an die Fangeinrichtung zu führen, kann die Bewegung des

Changierfadenführers 6 durch den Umlenkfadenführer 3 unterstützt werden. Es ist

auch möglich, daß der Changierfadenführer 6 in seiner Stellung außerhalb des

Spulbereiches verharrt und zum Fangen des Fadens 1 durch die Fangeinrichtung

21 der Faden 1 durch den Umlenkfadenführer 3 in eine Fangposition bewegt wird.

Die Bewegungen des Changierfadenführers 6 und des Umlenkfadenführers 3

werden hierbei durch Steuereinrichtung 8 koordiniert.In order to guide the

Nach dem Fangen wird der Changierfadenführer 6 aus der Fangposition zum

Spulbereich geführt. Hierbei wird der Faden 1 auf der Hülse 13 außerhalb des

Spulbereichs zu einer Fadenreservewicklung gewickelt. Die Bildung der

Fadenreservewicklung könnte hierbei durch einen in einer Position verharrenden

Changierfadenführer 6 erfolgen. Dann weist die Fadenreservewicklung eine

Anzahl von Parallelwicklungen auf. Der Changierfadenführer 6 kann aber auch

mit einer durch den Elektromotor 36 bestimmten Geschwindigkeit zum

Spulbereich geführt werden, so daß nebeneinanderliegende Windungen in der

Fadenreservewicklung erzeugt werden. Sobald der Fadenführer den Spulbereich

erreicht, beginnt die Spulreise. Der Changierfadenführer 6 wird sodann innerhalb

des Spulbereichs durch die Changiereinrichtung 22 oszillierend angetrieben. Der

anwachsende Spulendurchmesser der Spule 24 wird durch eine

Schwenkbewegung des Spulenhalters 26 ermöglicht. Der Spulenhalter 26 weist

hierzu Kraftgeber auf, die einerseits einen zum Antrieb der Spule erforderlichen

Anpreßdruck zwischen der Spule 24 und der Treibwalze 29 erzeugen und

andererseits eine Schwenkbewegung des Spulenhalters 26 ermöglichen. After catching, the traversing

- 11

- Fadenthread

- 22

- Umlenkeinrichtungdeflecting

- 33

- UmlenkfadenführerUmlenkfadenführer

- 44

- Antriebdrive

- 55

- Führungskanteleading edge

- 66

- ChangierfadenführerTraversing thread guide

- 88th

- Steuereinrichtungcontrol device

- 1313

- Hülseshell

- 1414

- Fangeinrichtungcatcher

- 1818

- Fadenführerthread guides

- 1919

- Antriebdrive

- 2121

- Fangnutcatching groove

- 2222

- ChangiereinrichtungTraversing device

- 2323

- AbbindewickelAbbindewickel

- 2424

- SpuleKitchen sink

- 2525

- Schwenkachseswivel axis

- 2626

- Spulenhalterspool holder

- 2727

- Spanntellerclamping plate

- 2828

- Spanntellerclamping plate

- 2929

- Treibwalzedrive roll

- 3030

- Walzenmotorroller motor

- 3131

- Antriebswelledrive shaft

- 3333

- Riemenbelt

- 3434

- Umlenkrolleidler pulley

- 3535

- Antriebsrollecapstan

- 3636

- Elektromotorelectric motor

- 3737

- Absaugeinrichtungsuction

- 3838

- Schneidvorrichtungcutter

- 3939

- Absauganschluß suction connection

- 4040

- Schwenkachseswivel axis

- 4141

- Maschinengestellmachine frame

- 4242

- ÜbergabeeinrichtungTransfer device

- 4343

- Greifarmclaw arm

- 4444

- Antriebswelledrive shaft

- 4545

- Schneidvorrichtungcutter

- 4646

- Saugöffnungsuction opening

- 4747

- Messerknife

Claims (14)

- Device for guiding and cutting a continuously tapering thread (1) when changing bobbins in a winding device, wherein the thread (1) is wound to a bobbin (24) on a tube (13) being driven by a drive roll (29), with a movable thread guide (18) being movable essentially parallel to the tube (13) by a drive (19), with a suction device (37) being arranged downstream with respect to the thread guide (18), which comprises a pneumatic vacuum connection (39) and a cutting device (38) and with a transfer device (42) interacting with the suction device (37), said transfer device (42) guiding the advancing thread to the transfer to the suction device (37), whereby the thread (1) is guided through the thread guide (18) during changing of the tubes, during catching in a catching device (14) and during winding onto a new tube (13) and whereby the advancing thread is taken up and lead away by the suction device (37) after the cutting and until the catching of the thread, characterized in that a deflection device (2) is installed between the thread guide (18) and the suction device (37) whereby the deflection device (2) and the suction device (37) are arranged within the path of the thread upstream of the driven tube (13) and that the thread is guidable by the deflection device (2) and the thread guide (18) outside of the contact area between the new tube (13) and the drive roller (29) after the take over by the suction device (37).

- Device according to claim 1, characterized in that the thread guide (18) and the deflection device (2) are arranged for the catching with respect to each other such that the catching device (14) is positioned between the thread guide and the deflection device (2) with respect to the path of the thread.

- Device according to claim 2, characterized in that the tube (13) is claimed between two clamping plates (27, 28) being arranged at a package holder (26), wherein the catching device (14) is arranged at one of the clamping plates (27).

- Device according to one of claims 1 to 3, characterized in that the deflection device (2) has a movable deflecting thread guide (3) and a controllable drive (4), wherein the deflecting thread guide (3) is movable out of an idle position outside the floor of the thread by the drive (4).

- Device according to claim 4, characterized in that the deflecting thread guide (3) is movable between the idle position and a deflecting position, wherein the deflection thread guide (3) is guidable on a moving path being transverse to the path of the sucked off thread (1) between the idle position and the deflection position, wherein the deflecting thread guide (3) comprises a guiding edge (5), which engages and deflects the thread (1) during the movement of the deflecting thread guide (3).

- Device according to one of claims 1 to 5, characterized in that for the cutting, the thread guide (18) and the suction device (37) are arranged in a transfer plane, wherein the transfer device (42) is a gripping arm (43) being movable parallel to the transfer plane, said gripping arm (43) being pivotable with its free end into the floor of the thread between the thread guide (48) and the package (24) being taken off the drive roll (29), wherein the suction device (37) is arranged within the moving radius of the free end of the gripping arm (43).

- Device according to claim 6, characterized in that the vacuum connection (39) and the cutting device (38) of the suction device (37) are arranged one behind another within the transfer plane.

- Device according to claim 7, characterized in that the vacuum connection (39) comprises a suction opening (46) being slotted within the direction of the path of the thread, said suction opening (46) being arranged in alignment with a cutting plate (47) of the cutting device (38).

- Device according to one of the claims 1 to 8, characterized in that the thread guide is a traversing thread guide (6) of a traversing device (22), said traversing thread guide (6) guiding the thread (1) outside and inside of the winding range in longitudinal direction parallel to the tube (13), wherein the traversing thread guide (6) is drivable by a drive (36) allowing the variation of its speed independently of the direction.

- Device according to claim 9, characterized in that the traversing thread guide (6) is movable to a transfer position within the winding range after the winding of the thread to a package (full package), wherein the tube (13) with the full package is pivotable from a working position by a pivotable package holder (26) and that the transfer device (42) is movable such that the thread (1) is engagable between the full package (24) and the traversing thread guide (6) and said thread (1) is guidable to the suction device for cutting and transferring.

- Method for guiding and cutting of a continuously advancing thread (1) during a change of package in a winding device, said winding device winding the thread (1) on a tube (13) being driven by a drive roll (29) to a package, wherein the thread (1) is guided substantially parallel with respect to the axis of the package by a movable thread guide (18) for a change of packages, for catching in a catching device (14) and for the winding on a new tube, wherein for the cutting the thread is guided to a suction device (37) by a transfer device (42), wherein the advancing thread is taken up and deflected by a suction device (37) after the cutting and until the catching of the thread (1), characterized in that after the winding of the thread to a package (full package) the thread guide (18) is moved in a transfer plane within the winding range to form a laced winding, wherein the tube (13) with the full package is moved away from the drive roll (29), wherein the thread (1) is engaged by the transfer device (42) being movable parallel to the transfer plane, between the thread guide (18) and the full package and is supplied to the suction device (37) being arranged in the transfer plane for the cutting and the transfer, wherein after transfer of the thread (1) by the suction device (37), the thread (1) is engaged within the portion between the suction device (37) and the thread guide (18) by a deflection device (2) and deflected in such a way that the advancing thread (1) is guided out of the contact region between the new tube (13) and the drive roll (29).

- Method according to claim 11, characterized in that for the catching of the thread (1), the tread guide (18) is guided with the thread into an engagement position outside the winding range in such a way that the thread (1) with the portion between the deflection device (2) and the thread guide (18) is intersecting a catching plane of the catching device (14).

- Method according to claim 11, characterized in that for the catching of the thread, the deflection device (2) is guided with the thread (1) in a catching position such that the thread (1) is intersecting with the portion inbetween the deflection device (2) and the thread guide (18) a catching plane of the catching device (14).

- A thread false twist texturing machine with at least one winding device, wherein a textured thread (1) is wound upon a tube (13) being driven by a drive roll (29) to a package (24) comprising an apparatus for guiding and cutting of the thread (1) during a changing of packages, characterized in that the device comprises features of at least one of claims 1 to 10.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19911264 | 1999-03-13 | ||

| DE19911264 | 1999-03-13 | ||

| PCT/EP2000/002060 WO2000055084A1 (en) | 1999-03-13 | 2000-03-09 | Device and method for guiding and cutting a tapering thread when changing bobbins |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1161397A1 EP1161397A1 (en) | 2001-12-12 |

| EP1161397B1 true EP1161397B1 (en) | 2003-08-20 |

Family

ID=7900882

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00912574A Expired - Lifetime EP1161397B1 (en) | 1999-03-13 | 2000-03-09 | Device and method for guiding and cutting a tapering thread when changing bobbins |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6457668B1 (en) |

| EP (1) | EP1161397B1 (en) |

| JP (1) | JP4709391B2 (en) |

| CN (1) | CN1162315C (en) |

| DE (1) | DE50003358D1 (en) |

| WO (1) | WO2000055084A1 (en) |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7195194B2 (en) * | 2002-07-08 | 2007-03-27 | Superba S.A.S. | Process for automatic removal of packages |

| CA2526394A1 (en) * | 2003-06-06 | 2004-12-23 | Pall Corporation | Fluid treatment element |

| EP1496003B1 (en) * | 2003-07-11 | 2006-03-22 | Schärer Schweiter Mettler AG | Automatic bobbin changer for an automatic winding machine |

| JP4059206B2 (en) * | 2004-02-06 | 2008-03-12 | 村田機械株式会社 | Spinner with bunch winding device |

| US7802749B2 (en) | 2007-01-19 | 2010-09-28 | Automated Creel Systems, Inc. | Creel magazine supply system and method |

| DE102007023490A1 (en) * | 2007-05-19 | 2008-11-20 | Oerlikon Textile Gmbh & Co. Kg | Method and device for operating a winding device of a cross-wound producing textile machine |