EP1143843B1 - Machine pour traiter les sols - Google Patents

Machine pour traiter les sols Download PDFInfo

- Publication number

- EP1143843B1 EP1143843B1 EP99903660A EP99903660A EP1143843B1 EP 1143843 B1 EP1143843 B1 EP 1143843B1 EP 99903660 A EP99903660 A EP 99903660A EP 99903660 A EP99903660 A EP 99903660A EP 1143843 B1 EP1143843 B1 EP 1143843B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- floor cleaning

- machine according

- cleaning machine

- cleaning unit

- adjustable

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4036—Parts or details of the surface treating tools

- A47L11/4047—Wound-up or endless cleaning belts

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/28—Floor-scrubbing machines, motor-driven

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L11/00—Machines for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L11/40—Parts or details of machines not provided for in groups A47L11/02 - A47L11/38, or not restricted to one of these groups, e.g. handles, arrangements of switches, skirts, buffers, levers

- A47L11/4061—Steering means; Means for avoiding obstacles; Details related to the place where the driver is accommodated

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01H—STREET CLEANING; CLEANING OF PERMANENT WAYS; CLEANING BEACHES; DISPERSING OR PREVENTING FOG IN GENERAL CLEANING STREET OR RAILWAY FURNITURE OR TUNNEL WALLS

- E01H1/00—Removing undesirable matter from roads or like surfaces, with or without moistening of the surface

- E01H1/02—Brushing apparatus, e.g. with auxiliary instruments for mechanically loosening dirt

- E01H1/05—Brushing apparatus, e.g. with auxiliary instruments for mechanically loosening dirt with driven brushes

Definitions

- the present invention relates to a floor cleaning machine with a chassis and at least one position adjustable floor cleaning unit, which is suspended to change the working width about a substantially vertical axis pivotally mounted on the chassis, wherein the at least one variable position floor cleaning unit from its maximum working width corresponding position to reduce the working width is pivotable in both directions about only one vertical axis both forward and backward.

- variable working width is to increase compared to floor cleaning machines with a constant working width, the flexibility in terms of the use of the floor cleaning machine in question by this is equally applicable for processing large areas and narrow areas.

- FR-A-2 297 286 a generic floor cleaning machine with a fixed and two position adjustable floor cleaning units is described.

- the side brushes provided there are each mounted on a four-bar linkage on the chassis so that their position can be varied to change the working width of the floor cleaning machine. Due to the broom suspension, the momentary pivot point moves in each case via two handlebars in the course of the swiveling movement.

- a disadvantage of the known generic floor cleaning machine with variable working width is that that an equivalent floor cleaning in two directions is not possible. In the area of obstacles where the working width is temporarily reduced, moreover, areas remain unprocessed, which are not covered by the position-adjustable floor cleaning unit. Furthermore, the handling of known floor cleaning machines in tillage in "dead ends", which require a reversal of the working direction, difficult, especially when due to obstacles, a change in the working width is required.

- the present invention has for its object to provide a generic floor cleaning machine, which does not have the disadvantages mentioned above and over the prior art has greater flexibility in terms of applications.

- this object is achieved in that in floor cleaning machines of the generic type, the pivot axis of the at least one variable position floor cleaning unit does not change their position on the chassis. While in various known floor cleaning machines, the at least one variable position floor cleaning unit from its maximum working width corresponding position to reduce the working width either forward or backward only, the inventive construction of the floor cleaning machine allows pivoting of at least one variable position floor cleaning unit from their maximum Working width corresponding position out in two directions, especially both forward and backward.

- this effect in particular to the effect that the variable-position floor cleaning unit independently from the current working direction of the floor cleaning machine on an obstacle restricting the working width automatically (based on the floor cleaning machine) can swing backwards or forwards, depending on whether the floor cleaning machine is currently moved in or against the main working direction.

- the suspension according to the invention of the at least one position-adjustable floor cleaning unit permits tillage largely without dead spaces.

- the at least one position adjustable floor cleaning unit is biased by means of a spring device in their maximum working width corresponding position and against the force of the spring device in both directions from this position deflected out.

- Yet another preferred embodiment of the invention is characterized in that the at least one variable position floor cleaning unit is suspended linearly displaceable on the chassis in addition to their pivotability. Particularly preferably, the linear displacement of the at least one position-adjustable floor cleaning unit takes place transversely to the working direction.

- the position-adjustable floor cleaning unit again reduces the dead space in the tillage around obstacles, especially in a particularly complex design of the surface to be processed.

- the position-adjustable floor cleaning unit can be used in narrow niches and the like by being moved out of the chassis laterally there and then retracted again.

- variable position floor cleaning unit can also be used for frontal tillage, especially in "dead ends”.

- variable position floor cleaning unit for example, hydraulic or pneumatic type.

- automatic control is possible in such a way that in the front area of the floor cleaning machine an approximate or Tastschalter is provided, which acts on the control of the drive unit for the at least one variable position floor cleaning unit, in such a way that upon actuation of the proximity or pushbutton, especially when the floor cleaning machine against the front wall of a "dead end" drives, the position adjustable floor cleaning units be retracted to reduce the working width.

- the position-adjustable sweeping unit of the floor cleaning machine according to the invention comprises a circulating endless sweeping belt

- the direction of rotation of the endless sweeping belt can be reversed according to a further preferred development of the invention.

- Such a reversibility of the direction of rotation of the endless belt turns out to be particularly advantageous in connection with the equivalence of the floor cleaning in and against the main working direction made possible by the invention.

- the ground can be cleaned particularly effectively around obstacles.

- a particularly preferred development of the invention in this context is characterized in that the direction of rotation of the endless belt reverses automatically in a reversal of the working direction.

- a further advantageous development of the invention relates to floor cleaning machines, in which a position-adjustable sweeping unit is provided in the form of a roller brush.

- the bristle lining may extend helically around a central roll body in the form of a helix. This results in a corresponding direction of rotation of the roller brush an inwardly directed conveying movement of the sweeping. This favors a constant cleaning effect even with - within certain limits - forward or backward swiveled roller brush.

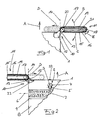

- the sweeper includes in known as such a chassis 1, which is supported by wheels on the ground. Of those wheels, the wheel 2 arranged centrally in the front region is shown, which comprises a roller 5 mounted in a steering roller carrier 4 pivotably mounted about a vertical axis 3. In the chassis 1 a about a horizontal axis 6 rotatably driven sweeping roller 7 is rotatably mounted. With reference to the main working direction (arrow A), behind the main sweeping roller 7 is a dirt-collecting container 8 provided, in which rubbish from the main sweeping roller 7 is conveyed by the provided between this and the dirt collector 8 opening 9.

- the structure of the sweeper corresponds to the prior art, so that is dispensed with a more detailed explanation.

- a carrier 10 for a position-adjustable sweep unit 11 is provided at the front right corner of the chassis 1.

- This support 10 consists of two articulated sections, namely a rigidly connected to the chassis 1 inner portion 12 and an outer portion 13, the latter pivotable about a horizontal, parallel to the main working direction A axis 14 pivotally connected to the inner portion 12 of the support 10 is connected.

- the position-adjustable sweeping unit 11 is mounted on the outer portion 13 of the carrier 10, so that can be varied as a result of the above-described articulated articulation, the inclination of the sweeping unit 11, for example for cleaning ramps.

- the position-adjustable sweeping unit 11 comprises an endless sweeping band 15 in the form of a link chain, the individual chain links having a bristle trim 16.

- the link chain 15 is guided around two guide wheels 17 and 18, which in turn are rotatably mounted in a Kehrbandango 19.

- the Kehrbandzi 19 is pivotally mounted on the outer portion 13 of the carrier 10 about the axis 20, in such a way that a pivoting of the Kehrbandologis 19 about the axis 20 around both the front (arrow B) as well as backwards (arrow C) possible is.

- the Kehrbandzi is biased in its illustrated in the drawing, extending transversely to the working direction A position corresponding to the maximum working width. A deflection of the Kehrisme 11 from this position both forward (arrow B) and to the rear (arrow C) is possible against a provided by that spring means restoring force.

- the Kehrbandzi 19 is provided on its upper side with a linear guide 21.

- This linear guide is a counterpart in connection, which is part of the suspension of the sweeping unit 11 on the carrier 10.

- the sweeping unit 11 in addition to their pivotability can be linearly inward move (arrow D).

- An intermediate position is illustrated with broken lines.

- the drive can be designed in any manner known as such, in particular by means of a separate, arranged on the sweeping band carrier 19 motor, as well as by transmission by means of conventional transmission means of a central drive. That central drive can be in the same way a motor as well as a driven by the movement of the sweeper friction wheel.

- a proximity sensor 22 is arranged on the front side of the chassis 1.

- the latter responds as soon as the sweeper has moved so close to a wall, step, or the like, that the front runner of the sweeping device 11 immediately at the wall or step returns.

- the proximity switch 22 acts in this case on a - not shown - drive unit which moves the sweeping unit 11 linearly inwards (arrow D). In this way, the strip is swept between the front wall of the sweeper and the opposite wall or step.

- the direction of rotation of the sweeping band 15 is variable (double arrow E). In this way, it can be ensured that when sweeping in the main working direction A, the front run of the sweeping band 15 turns inwards and supplies the dirt to the main brush 7; in operation of the sweeper counter to the main direction of return A returns by reversing the direction of rotation of the sweeping band 15 whose rear run inwards and leads the dirt inwards, where it can be absorbed by the main sweep roller 7 when re-crossing the respective strip.

- the sweeping unit 11 promotes the respective dirt between two main sweeping rollers, so that when operating in the main working direction as well as against the dirt from the sweeping unit 11 of the two main sweeping rollers is supplied.

- the suction mouth is arranged in particular in the immediate vicinity of the respective corner of the chassis, and this is outlined at 23.

- the suction device in question would need to be switched on only when operating the sweeper counter to the main working direction; However, it can also - in order to support the sweeping - be constantly turned on, with more suction mouths are provided distributed over the working width.

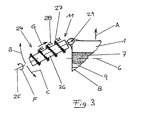

- Fig. 3 illustrates in bottom view the embodiment of the position-adjustable sweeping unit 11 as a roller brush 24 which is rotatable about the axis 25 (arrow F) is driven.

- the roller brush 24 comprises a cylindrical central roller body 26 and a bristle garnish 27, which extends helically around the central roller body 26 in the form of a helix.

- the helical bristle facing 27 exerts an inwardly directed conveying component (arrow G) on the debris 28 located in the working direction A in front of the roller brush 24, so that the debris 28 itself is at - like represented - counter to the working direction A to the rear inclined roller brush 24 a central main brush 7 is supplied.

- roller brush 24 is suspended about the axis 29 pivotally mounted on the chassis 1. It can be pivoted out of its transverse to the direction A standing position both forward (arrow B) as well as to the rear (arrow C) out.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Soil Working Implements (AREA)

- Cleaning In General (AREA)

- Brushes (AREA)

Abstract

Claims (12)

- Machine de nettoyage des sols comportant un châssis (1) et au moins une unité déplaçable de nettoyage des sols (11) qui, pour modifier la largeur de travail, est suspendue de manière pivotable autour d'un axe sensiblement vertical (20, 29) au châssis, l'au moins une unité déplaçable de nettoyage des sols (11) pouvant pivoter, depuis sa position correspondant à la largeur maximale de travail, afin de réduire la largeur de travail, dans deux sens (B, C) autour de simplement un axe vertical (20, 30) aussi bien vers l'avant que vers l'arrière,

caractérisée en ce que

l'axe de pivotement, pendant le pivotement de l'unité déplaçable de nettoyage des sols, ne change pas de position par rapport au châssis. - Machine de nettoyage des sols selon la revendication 1,

caractérisée en ce que

au moins une unité déplaçable de nettoyage des sols (11) est suspendue en plus au châssis (1) de manière à pouvoir se déplacer linéairement (D) en plus de sa faculté de pivotement (B, C). - Machine de nettoyage des sols selon la revendication 2,

caractérisée en ce que

le déplacement linéaire (D) de l'au moins une unité déplaçable de nettoyage des sols (11) se fait transversalement par rapport au sens de travail (A). - Machine de nettoyage des sols selon une des revendications 2 ou 3,

caractérisée en ce que,

pour le déplacement linéaire (D) de l'au moins une unité déplaçable de nettoyage des sols (11), il est prévu une unité de propulsion. - Machine de nettoyage des sols selon la revendication 4,

caractérisée en ce que

dans sa zone avant, il est prévu un commutateur à touches qui agit sur la commande de l'unité de propulsion de l'au moins une unité déplaçable de nettoyage des sols. - Machine de nettoyage des sols selon une des revendications 1 à 4,

caractérisée en ce que

l'au moins une unité déplaçable de nettoyage des sols (11) est suspendue au bord avant, par rapport au sens de travail principal (A), du châssis (1). - Machine de nettoyage des sols selon une des revendications 1 à 6,

caractérisée en ce que

l'au moins une unité déplaçable de nettoyage des sols (11) est précontrainte au moyen d'un dispositif à ressort dans sa position correspondant à la largeur maximale de travail. - Machine de nettoyage des sols selon une des revendications 1 à 7,

caractérisée en ce que

l'au moins une unité déplaçable de nettoyage des sols (11), pour pouvoir modifier son inclinaison autour d'un axe horizontal (14), est suspendue de manière pivotable au châssis (1). - Machine de nettoyage des sols selon une des revendications 1 à 8,

caractérisée en ce que

au moins une unité déplaçable de nettoyage des sols (11) comprend une bande d'inversion sans fin rotative (15). - Machine de nettoyage des sols selon la revendication 9,

caractérisée en ce que

le sens de rotation (E) de la bande d'inversion sans fin (15) est inversable. - Machine de nettoyage des sols selon la revendication 10,

le sens de rotation (E) de la bande d'inversion sans fin (15) s'inverse automatiquement en cas d'inversion du sens de travail. - Machine de nettoyage des sols selon la revendication 9,

caractérisée en ce que

l'unité déplaçable de nettoyage des sols (11) comprend une brosse à rouleaux (24) entraînée en rotation (F) dont la garniture de brosse (27) est disposée en forme d'hélice en spirale.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP1999/000355 WO1999035957A1 (fr) | 1999-01-20 | 1999-01-20 | Machine pour traiter les sols |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1143843A1 EP1143843A1 (fr) | 2001-10-17 |

| EP1143843B1 true EP1143843B1 (fr) | 2006-09-20 |

Family

ID=8167192

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99903660A Expired - Lifetime EP1143843B1 (fr) | 1999-01-20 | 1999-01-20 | Machine pour traiter les sols |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP1143843B1 (fr) |

| JP (1) | JP2002514443A (fr) |

| AU (1) | AU2423499A (fr) |

| DE (1) | DE59913864D1 (fr) |

| WO (1) | WO1999035957A1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013042975A2 (fr) * | 2011-09-23 | 2013-03-28 | 엘지전자 주식회사 | Aspirateur automatique |

| CN104825099B (zh) * | 2015-05-28 | 2017-07-25 | 卓永祺 | 一种智能清洁方法及装置 |

| CN108852196A (zh) * | 2018-08-28 | 2018-11-23 | 东莞优乐家智能家电有限公司 | 一种具有除毛发功能的运输带式地刷模块 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3345671A (en) * | 1966-01-11 | 1967-10-10 | Ross D Wilson | Floor scrubbing and polishing machine |

| FR2297286A1 (fr) * | 1975-01-07 | 1976-08-06 | Materiel De Voirie | Vehicule de nettoyage pour la voirie |

| FR2653359A1 (fr) * | 1989-10-19 | 1991-04-26 | Protee | Engin pour nettoyer une surface, procede de nettoyage utilisant cet engin, et application de ce procede au nettoyage du sol d'un vehicule de transport en commun. |

| ES2064165T3 (es) * | 1991-02-01 | 1995-01-16 | Kurt Zachhuber | Maquina para la manipulacion del suelo. |

| DE4118708C1 (fr) * | 1991-06-07 | 1992-08-20 | Zachhuber Kurt | |

| DE4425924A1 (de) * | 1994-07-21 | 1996-01-25 | Siemens Ag | Autonome mobile Einheit mit raumsparendem Manipulator und zugehöriges Steuerungsverfahren |

| DE19638425C2 (de) * | 1996-09-19 | 1998-05-07 | Hefter Maschinenbau | Kehrband-Umlenkrollen-Anordnung |

-

1999

- 1999-01-20 DE DE59913864T patent/DE59913864D1/de not_active Expired - Fee Related

- 1999-01-20 AU AU24234/99A patent/AU2423499A/en not_active Abandoned

- 1999-01-20 EP EP99903660A patent/EP1143843B1/fr not_active Expired - Lifetime

- 1999-01-20 WO PCT/EP1999/000355 patent/WO1999035957A1/fr active IP Right Grant

- 1999-01-20 JP JP2000539742A patent/JP2002514443A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002514443A (ja) | 2002-05-21 |

| DE59913864D1 (de) | 2006-11-02 |

| WO1999035957A1 (fr) | 1999-07-22 |

| EP1143843A1 (fr) | 2001-10-17 |

| AU2423499A (en) | 1999-08-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60113886T2 (de) | Gestapelte Werkzeuge zum Überkopfkehren | |

| EP0569430B1 (fr) | Machine de traitement de planchers | |

| EP2721220A1 (fr) | Balayeuse de voirie comprenant un dispositif de réglage de disque de brosse | |

| DE102006037453B4 (de) | Handgeführtes, motorgetriebenes Kehrgerät | |

| DE2460584C3 (de) | Kehrmaschine | |

| EP1241298B1 (fr) | Véhicule, notamment pour le nettoyage des plages | |

| DE19704777C2 (de) | Vorrichtung zum Reinigen von Stall-, Hof- und sonstigen Flächen | |

| DE69114798T2 (de) | Universelle Kehreinheit. | |

| DE69826345T2 (de) | Bürstenwalze für eine Kehrmaschine | |

| EP0482293B1 (fr) | Machine pour travailler le sol et train de roues | |

| EP0670139B1 (fr) | Machine à balayer | |

| EP1143843B1 (fr) | Machine pour traiter les sols | |

| DE4022390C2 (fr) | ||

| DE19715435A1 (de) | Überkopfwerfer-Reinigungsmaschine | |

| EP1612335B1 (fr) | Dispositif de balayage automobile | |

| DE102019214187B3 (de) | Roboter zur Oberflächenpflege | |

| DE9115713U1 (de) | Scheuersaugmaschine | |

| DE69823020T2 (de) | Kehrmaschine | |

| DE3512730A1 (de) | Strassenkehrmaschine | |

| EP3208383B1 (fr) | Balayeuse manuelle | |

| EP1424448A1 (fr) | Balayeuse et procédé de fonctionnement | |

| EP0659054B1 (fr) | Machine de traitement de sols | |

| DE9115578U1 (de) | Scheuersaugmaschine | |

| EP1179314A1 (fr) | Balayeuse avec brosse rotatif cylindrique | |

| DE2312094C3 (de) | Straßenkehrmaschine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20010703 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE GB IT |

|

| 17Q | First examination report despatched |

Effective date: 20031217 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE GB IT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060920 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060920 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 59913864 Country of ref document: DE Date of ref document: 20061102 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070801 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070621 |