EP1136151B1 - Selbstzentrierender Führungsschlitten - Google Patents

Selbstzentrierender Führungsschlitten Download PDFInfo

- Publication number

- EP1136151B1 EP1136151B1 EP00105369A EP00105369A EP1136151B1 EP 1136151 B1 EP1136151 B1 EP 1136151B1 EP 00105369 A EP00105369 A EP 00105369A EP 00105369 A EP00105369 A EP 00105369A EP 1136151 B1 EP1136151 B1 EP 1136151B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cam

- slider

- base

- inverted

- cam slider

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000003754 machining Methods 0.000 claims abstract description 12

- 239000002184 metal Substances 0.000 claims abstract description 11

- 230000000630 rising effect Effects 0.000 description 6

- 230000002787 reinforcement Effects 0.000 description 2

- 230000037237 body shape Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/24—Perforating, i.e. punching holes

- B21D28/32—Perforating, i.e. punching holes in other articles of special shape

Definitions

- the present invention relates to a cam unit for metal mold tools, such as a horizontal cam unit or an inclined cam unit for use in giving a desired bent form to a pressed plate at its selected edge or end to provide a car body shape.

- a conventional horizontal cam unit comprises a cam driver 10 to be fixed to the upper movable mold tool, a cam slider 11 whose inclined slide surface abuts on the inclined cam surface of the cam driver 10, and a cam base 12 supporting the cam slider 11, and fixed to the lower stationary mold tool.

- the rising and lowering of the cam driver will make the cam slider 11 to move a predetermined distance right and left.

- the cam slider 11 has a projection formed on its bottom side.

- the projection slidably fits in the recess of the cam base 12, and the projection has a return spring 13 fixed to its spring pin rod 11a.

- the rising and lowering of the cam driver 10 makes the cam slider 11 having a machining tool fixed to its front end to reciprocate right and left, thereby performing a required machining on a pressed plate article.

- the rising of the cam driver 10 permits the cam slider 11 to return leftward to the original rest position under the influence of the return spring 13.

- the lower part 11a of the cam slider 11 is sandwiched between the opposite upright portions 12a of the cam base 12, and is fastened to the opposite upright portions 12a by applying retainer pieces 14 both to the side projections 11b of the lower part 11a of the cam slider 11 and the top surfaces of the opposite upright portions 12a, thus providing a guide arrangement which permits the cam slider 11 to move smoothly.

- the size "b" from the front to rear side, or width of the cam base 12 is much larger than the width "a" of the cam slider 11, and accordingly the weight of the cam unit increases.

- the sliding surface of the lower part 11a of the cam slider is horizontal, and the counter surface of the cam base 12 is horizontal, too. If uneven wearing is caused on the horizontal surfaces of the confronting parts 11 and 12, the overlying part 11 may be inclined somewhat forward or backward, thus causing the moving parts 10 and 11 to be sticky in motion. Also, if it is desired that the pressing force is increased significantly, the sizes of the cam slider 11 and cam base 12 need to be increased accordingly.

- EP-A-0 983 808 discloses a cam slide driving apparatus including a cam driver having a sliding surface with a V-shaped cross section, a cam slide having a sliding surface of a shape complementary to the sliding surface of the cam driver in such a manner as to be slidably brought into contact with the sliding surface of the cam driver.

- the apparatus further includes a cam slide supporting base for movably supporting the cam slide so that the cam slide can move while being guided by the sliding surface of the cam driver as the sliding surface of the cam slide and the sliding surface of the cam driver are brought into contact with each other.

- the cam slide is disposed with a gap with respect to the cam-slide supporting base such a manner as to be movable in a transverse direction perpendicular to the moving direction of the cam slide.

- US-A-5 904 064 discloses a cam assembly for use in a pressing machine having a lower cam fixed to the base of the pressing machine, a spring-biased sliding cam whose front surface is allotted to fix a machining tool and a cam holder to be fixed to the upper frame of the pressing machine.

- the sliding cam is operatively combined with the lower cam to slide on the inclined surface of the lower cam synchronously with the rising and descending of the upper frame of the pressing machine, whereas the cam holder and the sliding cam is so combined as to leave a predetermined space defined therebetween, thereby permitting the sliding cam to be slidably held in the cam holder.

- the cam assembly further has a spacer to be inserted in the predetermined space and detachable fastening means to fix the sliding mean of the cam holder as if the slider were like with the upper frame of the pressing machine staying at its lower dead end.

- EP-A-0 484 588 discloses a die including a slide cam and a cam member, respectively, comprising a slide cam base on the top of which a polyhedral guide portion is formed wherein the slide cam holds and supports the polyhedral guide portion of the slide cam base and slides along the polyhedral guide portion. Machining tools such as a punch and a trimming edge are mounted onto the slide cam. Further, an elastic body is interposed between the slide cam base and the slide cam for urging the slide cam. The die further includes a driving cam in contact with the slide cam for driving the same.

- One object of the present invention is to provide a cam unit which is free of such defects as described above.

- a cam unit to be mounted to a stationary metal mold tool and a movable metal mold tool for use in effecting a required machining on a pressed article comprising a cam driver to be fixed to the movable metal mold, a cam slider to be driven by the cam driver and a cam base to be fixed to the stationary mold tool for supporting slidably the cam slider, is improved according to the present invention in that it further comprises self-centering means on the sliding surfaces of the cam slider and cam base.

- the self-centering means may comprise an inverted "V"-shaped section formed on the cam base with the ridge of the inverted “V”-shaped section extending along the center longitudinal line of the cam base, running parallel to the sliding direction in which the cam slider moves, and an inverted “V”-shaped sliding surface formed on the bottom of the cam slider, which inverted “V"-shaped sliding surface rides closely on the inverted "V”-shaped section of the cam base.

- the cam slider may have the same or substantially same width as the cam base, the width being measured in the direction perpendicular to the sliding direction in which the cam slider moves.

- the cam slider can be repeatedly moved on the cam base without causing such an uneven wearing as would be experienced in the horizontal-to-horizontal sliding surfaces in the conventional cam unit structure, thus assuring the stable work all the time.

- the cam slider can have the same width as the cam base, permitting the machining tool attaching surface of the cam slider to be increased significantly in comparison with the conventional cam unit structure, in which the cam slider is sandwiched between the opposite projections standing upright from the cam base. Also, the size and weight of the cam unit can be reduced substantially in comparison with the conventional cam unit.

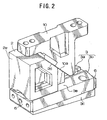

- a cam unit 1 comprises a cam driver 10 to be mounted to an upper movable mold tool, a cam slider 2 and a cam base 3 to be mounted to a lower stationary metal mold tool.

- the cam driver 10 has an inclined cam surface 10a.

- the cam slider 2 has an inclined surface, and is combined with the cam driver 10 with their inclined surfaces laid on each other, thereby permitting the cam slider 2 to move left or right as a counter action to the rising or lowering of the cam driver 10.

- the cam base 3 supports the cam slider 2 slidably.

- the cam base 3 has an inverted "V”-shaped upper surface with its ridge extending along the center longitudinal line of the cam base, running parallel to the sliding direction in which the cam slider 2 moves.

- the cam slider 2 has an inverted “V”-shaped bottom. The inverted “V”-shaped sliding bottom surface of the cam slider 2 rides closely on the inverted "V"-shaped top section of the cam base 3.

- cam slider 2 has oblique bottom surface halves 2a and 2b sloping up from its opposite longitudinal edges into its longitudinal center line, thus forming a roof-like sliding surface on its bottom side.

- the inclined cam surface 2d of the cam slider 2 is slidably laid on the inclined cam surface 10a of the cam driver 10.

- the cam slider 2 has tow forcedly returning followers 4 bolted to its opposite sides for jerking the cam slider 2 toward its original position subsequent to the cam action.

- the cam base 3 comprises a base body 3c to be bolted to the lower stationary mold tool, and two guide blocks 3a and 3b parallel-arranged, leaving a longitudinal space therebetween, running in the sliding direction (see Fig.3).

- the guide blocks 3a and 3b has two reinforcement plates 6 bolted to their opposite ends.

- a spring pin rod 8 for a return spring appears on the reinforcement plate 6.

- each guide block 3a or 3b has an inclined top surface 3d or 3e, which slopes up from its outer longitudinal edge toward the top center line.

- the so formed roof-like shape is exactly same as the roof-like shape defined by the oblique bottom surface halves 2a and 2b of the cam slider 2.

- the self-centering means is provided.

- the parallel arrangement of two confronting guide blocks 3a and 3b with a given longitudinal space left therebetween makes it possible to reduce substantially the size of the cam base 3 in comparison with the overlying cam slider 2, accordingly permitting the saving of the material and weight of the cam base 3.

- the size from the front side to rear side, or width of the cam base 3 perpendicular to the direction in which the cam slider 2 slidably moves is substantially equal to that of the overlying cam slider 2.

- substantially equal is that the minimum difference therebetween is 10 millimeters or below.

- the rising and descending of the cam driver 10 will make the machining tool bearing cam slider 2 to move slidably on the cam base 3 without fear of the center deviation of the cam slider 2 which, otherwise, would be caused by the wearing of the sliding surfaces of the counter parts 2 and 3; the inverted "V"-shaped sliding surfaces will not cause any deviation of their center ridges even if a significant wearing is caused between the sliding surfaces of the counter parts 2 and 3.

- the inverted "V"-shaped surfaces of the counter sliding parts 2 and 3 will increase significantly their sliding areas over those of the horizontal surfaces of the counter sliding parts 11 and 12 (Figs.4a and 4b), accordingly increasing the resistance to the pressing force.

- the machining tool bearing area of the cam slider 2 can be increased by setting its dimension from front to rear side to be equal to the width of the cam base 3, thus permitting the fixing of machining tools of increased size.

- a cam unit equipped with self-centering means according to the present invention is guaranteed to be free of any decentering of the cam slider even if a significant wearing is caused between the sliding surfaces of the counter sliding parts.

- the inverted "V"-shaped forms of the counter sliding parts have the effect of increasing the area of the cam unit to which the pressing force is applied, and hence, increasing the resistance to the pressing force applied to the cam unit.

- the size from the front side to rear side or width of the cam base perpendicular to the direction in which the cam slider moves is substantially equal to that of the cam slider. This permits the machining tool bearing area of the cam slider to be increased significantly.

- the parallel arrangement of two confronting guide blocks with a given longitudinal space left therebetween makes it possible to reduce the weight of the whole cam unit to approximately one third of the weight of the conventional cam unit.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mounting, Exchange, And Manufacturing Of Dies (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Investigating Or Analysing Biological Materials (AREA)

- Bag Frames (AREA)

Claims (3)

- Führungsschlitten bzw. Nockeneinheit (1), die zur Verwendung in ein feststehendes Metallformungswerkzeug und ein bewegliches Metallformungswerkzeug einbaubar ist, um eine erforderliche Bearbeitung an einem gepressten Gegenstand zu bewirken, aufweisend ein Nockenantriebsteil (10), das an der beweglichen Metallform zu befestigen ist, einen Nockenschieber (2), der vom Nockenantriebsteil (10) anzutreiben ist und ein Nockenunterteil (3), das am feststehenden Formungswerkzeug zu befestigen ist, um den Nockenschieber (2) verschiebbar zu lagern,

dadurch gekennzeichnet, dass

sie außerdem eine selbstzentrierende Einrichtung (2a, 2b, 3d, 3e) auf den Gleitflächen des Nockenschiebers (2) und des Nockenunterteils (3) aufweist. - Führungsschlitten (1) nach Anspruch 1, wobei die selbstzentrierende Einrichtung (2a, 2b, 3d, 3e) ein umgekehrtes "V"-förmiges Profil, das auf der Oberseite des Nockenunterteils ausgebildet ist, wobei sich der Rand der umgekehrten "V"-Form längs der längsgerichteten Mittellinie des Nockenunterteils (3) erstreckt, die parallel zu der Gleitrichtung verläuft, in der sich der Nockenschieber (2) bewegt, und eine umgekehrte "V"-förmige Gleitfläche aufweist, die an der Unterseite des Nockenschiebers (2) ausgebildet ist, dessen umgekehrte "V"-förmige Gleitfläche

nah auf dem umgekehrten "V"-förmigen Abschnitt des Nockenunterteils (3) fährt. - Führungsschlitten (1) nach Anspruch 1 oder 2, wobei der Nockenschieber (2) die gleiche oder die im Wesentlichen gleiche Breite aufweist wie das Nockenunterteil (3), wobei die Breite in der Richtung rechtwinklig zu der Gleitrichtung gemessen wird, in der sich der Nockenschieber (2) bewegt.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT00105369T ATE271942T1 (de) | 2000-03-17 | 2000-03-17 | Selbstzentrierender führungsschlitten |

| ES00105369T ES2222123T3 (es) | 2000-03-17 | 2000-03-17 | Unidad de leva equipada con medios de auto-centrado. |

| EP00105369A EP1136151B1 (de) | 2000-03-17 | 2000-03-17 | Selbstzentrierender Führungsschlitten |

| DE2000612475 DE60012475T2 (de) | 2000-03-17 | 2000-03-17 | Selbstzentrierender Führungsschlitten |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP00105369A EP1136151B1 (de) | 2000-03-17 | 2000-03-17 | Selbstzentrierender Führungsschlitten |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1136151A1 EP1136151A1 (de) | 2001-09-26 |

| EP1136151B1 true EP1136151B1 (de) | 2004-07-28 |

Family

ID=8168089

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00105369A Expired - Lifetime EP1136151B1 (de) | 2000-03-17 | 2000-03-17 | Selbstzentrierender Führungsschlitten |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1136151B1 (de) |

| AT (1) | ATE271942T1 (de) |

| DE (1) | DE60012475T2 (de) |

| ES (1) | ES2222123T3 (de) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE50013358D1 (de) † | 2000-10-13 | 2006-10-05 | Harald Weigelt | Keiltrieb |

| US6990844B1 (en) * | 2004-07-27 | 2006-01-31 | Anchor Lamina America, Inc. | Narrow aerial and die-mount cams |

| DE102005044951B4 (de) * | 2005-09-20 | 2011-09-15 | Fibro Gmbh | Schieberanordnung |

| JP2011140048A (ja) * | 2010-01-08 | 2011-07-21 | Sankyo Oilless Industry Inc | カム装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0484588B1 (de) * | 1990-11-09 | 1995-03-22 | UMIX Co., Ltd. | Gesenk mit Führungsschlitten |

| JPH10235437A (ja) * | 1997-02-25 | 1998-09-08 | Sankyo Oiruresu Kogyo Kk | プレス金型用のカムユニット |

| JP3757635B2 (ja) * | 1998-08-26 | 2006-03-22 | オイレス工業株式会社 | カム装置 |

-

2000

- 2000-03-17 EP EP00105369A patent/EP1136151B1/de not_active Expired - Lifetime

- 2000-03-17 DE DE2000612475 patent/DE60012475T2/de not_active Expired - Lifetime

- 2000-03-17 ES ES00105369T patent/ES2222123T3/es not_active Expired - Lifetime

- 2000-03-17 AT AT00105369T patent/ATE271942T1/de active

Also Published As

| Publication number | Publication date |

|---|---|

| ATE271942T1 (de) | 2004-08-15 |

| DE60012475T2 (de) | 2005-01-13 |

| ES2222123T3 (es) | 2005-02-01 |

| EP1136151A1 (de) | 2001-09-26 |

| DE60012475D1 (de) | 2004-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4510789A (en) | Press brake | |

| EP1136151B1 (de) | Selbstzentrierender Führungsschlitten | |

| KR101772752B1 (ko) | 부스바용 펀칭장치 | |

| JPS6157461A (ja) | シ−ト成形物の直線トリミング装置におけるシ−ト挟着装置 | |

| JPS6312694B2 (de) | ||

| KR20200125984A (ko) | 조정 가능한 안내 장치를 가진 웨지 구동부 | |

| JP3677931B2 (ja) | 搬送機構を備えた部品加工装置 | |

| US3917145A (en) | Stapling machine particularly adapted for use in limited clearance applications | |

| JP3332352B2 (ja) | プレス装置 | |

| JPH10286628A (ja) | ワークサポート装置 | |

| JP3648701B2 (ja) | プレス用パンチリテーナー装置 | |

| RU2152835C2 (ru) | Горизонтальный гидравлический пресс | |

| KR102349432B1 (ko) | 캠 드라이브 좌우 이동식 재질 공용화가 가능한 벤딩 금형 | |

| CN116557391B (zh) | 一种卡扣及冲压设备 | |

| JPH0428650Y2 (de) | ||

| JPS5856028Y2 (ja) | プレス装置 | |

| JP2000135526A (ja) | カムユニット | |

| JP2000301264A (ja) | カムユニット | |

| JP2587210Y2 (ja) | 鋼材加工機 | |

| JPH0529784Y2 (de) | ||

| JP2659660B2 (ja) | 打抜き加工装置 | |

| JP2774374B2 (ja) | ヘッダー機の線材カッター摺動装置 | |

| JP3545024B2 (ja) | 折曲げ加工方法およびその装置 | |

| SU1250360A1 (ru) | Штамп дл обработки листового материала | |

| JPH09220699A (ja) | ダイセット装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20011214 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20030130 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040728 Ref country code: LI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040728 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040728 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040728 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040728 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60012475 Country of ref document: DE Date of ref document: 20040902 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041028 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041028 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041028 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2222123 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050317 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050317 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050317 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050331 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050429 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20110401 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110329 Year of fee payment: 12 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120317 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120317 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120402 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20190325 Year of fee payment: 20 Ref country code: DE Payment date: 20190321 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20190321 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20190418 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 60012475 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 271942 Country of ref document: AT Kind code of ref document: T Effective date: 20200317 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20200318 |