EP0968779B1 - Breitseite einer Brammenkokille - Google Patents

Breitseite einer Brammenkokille Download PDFInfo

- Publication number

- EP0968779B1 EP0968779B1 EP99112238A EP99112238A EP0968779B1 EP 0968779 B1 EP0968779 B1 EP 0968779B1 EP 99112238 A EP99112238 A EP 99112238A EP 99112238 A EP99112238 A EP 99112238A EP 0968779 B1 EP0968779 B1 EP 0968779B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- filler

- grooves

- wide side

- filler members

- side according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000001816 cooling Methods 0.000 claims abstract description 8

- 239000000945 filler Substances 0.000 claims description 47

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 6

- 229910000831 Steel Inorganic materials 0.000 claims description 6

- 229910052802 copper Inorganic materials 0.000 claims description 6

- 239000010949 copper Substances 0.000 claims description 6

- 239000010959 steel Substances 0.000 claims description 6

- 230000015572 biosynthetic process Effects 0.000 claims 1

- 239000000463 material Substances 0.000 claims 1

- 238000005266 casting Methods 0.000 abstract description 20

- 238000013459 approach Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 239000000356 contaminant Substances 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000017525 heat dissipation Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- IHQKEDIOMGYHEB-UHFFFAOYSA-M sodium dimethylarsinate Chemical class [Na+].C[As](C)([O-])=O IHQKEDIOMGYHEB-UHFFFAOYSA-M 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/04—Continuous casting of metals, i.e. casting in indefinite lengths into open-ended moulds

- B22D11/055—Cooling the moulds

Definitions

- the present invention relates to a broad side of a slab mold, with a pouring plate with an inner surface and one of the Inner surface opposite outer surface, with the broadside has an upper and a lower portion, wherein at least the upper part of a middle area and two laterally of the central region has arranged side regions.

- the object of the present invention is a broadside to create a slab mold with little effort the cooling grooves can be formed and in the event of contamination the pouring plate can be minimized so that the pouring plate can be recycled is.

- the object is achieved in that the inner surface of the casting plate has grooves with undercuts to form cooling channels and that the grooves of fillers are positively covered, the are inserted into the undercuts.

- the filler pieces are at least in the The middle section is divided into upper and lower partial filling pieces.

- the broadside is quicker to assemble.

- the lower part filler into a single lower partial filling group can be summarized.

- the upper partial fillings arranged in the side areas to two lateral partial filler groups can be summarized.

- the fillers made of steel consist, while the casting plate is preferably made of copper.

- the filler pieces are preferably fastened in the grooves with screws. You can thread on their sides facing away from the grooves for Have fastening bolts.

- a broad side of a slab mold has one Pouring plate 1 on.

- the casting plate 1 is made of copper and has one Inner surface 2 and an outer surface opposite the inner surface 2 3 on.

- the casting plate 1 is in an upper portion 4 and divided a lower section 5, the upper section 4 - at least in a central region 6 - relative to the lower one Section 5 is kinked.

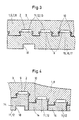

- the inner surface of the casting plate 1 has according to FIGS. 3 and 4 Grooves 9 with undercuts 10.

- fillers 11 are introduced, by means of which the grooves 9 form-fitting are covered.

- the filler pieces 11 are preferably made of Made of steel and fastened in the grooves 9 with screws.

- the Screws are in Figures 3 and 4 by the dashed lines indicated.

- the filler pieces 11 In order not to insert any threads for the screws in the casting plate 1 to have, the filler pieces 11 preferably have threads. The In this case, screws clamp the filler pieces 11 with the Casting plate 1.

- the number of introduced into the inner surface 2 of the casting plate 1 Grooves 9 is dependent on the width of the casting plate 1 and is typically approx. 30 to 50. Of these, approx. 20 to 35 are in the middle range 6 and 3 to 10 each arranged in the side areas 7, 8.

- each groove 9 can have its own filler 11 or two Partial filler pieces 12, 13 can be assigned.

- the partial filling pieces are preferably broadside according to FIG 12, 13 of several grooves combined into partial filling groups.

- the Partial filler groups can either be assembled in advance or be formed in one piece.

- the lower section 5 and the side areas 7, 8 are - each for saw each other - plan.

- the lower partial filling pieces are therefore preferred 13 combined into a single lower partial filling group 15.

- those are arranged in the side areas 7, 8 upper partial filler 12 to two lateral partial filler groups 16, 17 summarized.

- the upper partial region 4 is only in the central region 6 kinked relative to the lower section 5.

- alternative could therefore fillers 11 in side areas 7, 8 too continuous filler groups can be summarized.

- the lower partial filling group 15 extend over the central region 6.

- the casting plate 1 together with filler pieces 11 must be on a (not shown) Water box to be attached. This is usually done by means of fastening bolts (also not shown).

- the Filling pieces 11 consequently have at their 9 facing away from the grooves Sides of thread 18 for screwing in these fastening bolts.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

- Motor Or Generator Cooling System (AREA)

- Moulds, Cores, Or Mandrels (AREA)

- Casting Support Devices, Ladles, And Melt Control Thereby (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19829606 | 1998-07-02 | ||

| DE19829606A DE19829606A1 (de) | 1998-07-02 | 1998-07-02 | Breitseite einer Brammenkokille |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0968779A1 EP0968779A1 (de) | 2000-01-05 |

| EP0968779B1 true EP0968779B1 (de) | 2002-04-10 |

Family

ID=7872776

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99112238A Expired - Lifetime EP0968779B1 (de) | 1998-07-02 | 1999-06-25 | Breitseite einer Brammenkokille |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6173756B1 (es) |

| EP (1) | EP0968779B1 (es) |

| AT (1) | ATE215856T1 (es) |

| DE (2) | DE19829606A1 (es) |

| ES (1) | ES2175877T3 (es) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008032672A1 (de) | 2008-07-10 | 2010-01-14 | Sms Siemag Aktiengesellschaft | Stranggießkokille |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19842674A1 (de) * | 1998-09-17 | 2000-03-23 | Schloemann Siemag Ag | Kokillenwand einer Stranggießkokille |

| DE19904149A1 (de) * | 1999-02-03 | 2000-08-10 | Sms Demag Ag | Anordnung zum Verbinden einer Kokillenplatte mit einem Wasserkasten |

| DE10148150B4 (de) * | 2001-09-28 | 2014-05-22 | Egon Evertz Kg (Gmbh & Co.) | Flüssigkeitsgekühlte Stranggießkokille |

| US7392970B2 (en) * | 2004-05-25 | 2008-07-01 | Douglas J Bachan | Cooling injection mold |

| DE102005040634A1 (de) | 2005-08-27 | 2007-03-01 | Sms Demag Ag | Kokillenbreitseite einer Trichterkokille |

| ATE552930T1 (de) * | 2007-06-04 | 2012-04-15 | Concast Ag | Kokille zum stranggiessen von vorblöcken, brammen oder knüppeln |

| DE102010047392A1 (de) * | 2010-10-02 | 2012-04-05 | Egon Evertz Kg (Gmbh & Co.) | Stranggießkokille |

| GB2570926A (en) * | 2018-02-12 | 2019-08-14 | Surface Generation Ltd | Mould tool, method of assembling a mould tool and method of manufacture using a mould tool |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3866664A (en) * | 1973-06-01 | 1975-02-18 | United States Steel Corp | Mold for use in continuous-casting of metals |

| SU573924A1 (ru) * | 1975-03-31 | 1986-08-15 | Краматорский Научно-Исследовательский И Проектно-Технологический Институт Машиностроения | Кристаллизатор дл машин непрерывного лить |

| FR2310821A1 (fr) * | 1975-05-16 | 1976-12-10 | Siderurgie Fse Inst Rech | Lingotiere de coulee a parois minces |

| SU561612A1 (ru) * | 1975-12-22 | 1977-06-15 | Краматорский Научно-Исследовательский И Проектно-Технологический Институт Машиностроения | Кристаллизатор дл непрерывного лить |

| AT389251B (de) * | 1987-12-23 | 1989-11-10 | Voest Alpine Ind Anlagen | Kuehlung einer stranggiesskokille |

| US5513691A (en) * | 1994-02-02 | 1996-05-07 | Sms Concast Inc. | Mold for continuous casting and method of making the mold |

| US5467810A (en) * | 1994-04-01 | 1995-11-21 | Acutus Industries | Continuous metal casting mold |

| AU712782B2 (en) * | 1996-05-13 | 1999-11-18 | Km Europa Metal Ag | Liquid-cooled chill mould |

-

1998

- 1998-07-02 DE DE19829606A patent/DE19829606A1/de not_active Withdrawn

-

1999

- 1999-06-25 AT AT99112238T patent/ATE215856T1/de not_active IP Right Cessation

- 1999-06-25 ES ES99112238T patent/ES2175877T3/es not_active Expired - Lifetime

- 1999-06-25 EP EP99112238A patent/EP0968779B1/de not_active Expired - Lifetime

- 1999-06-25 DE DE59901169T patent/DE59901169D1/de not_active Expired - Fee Related

- 1999-07-02 US US09/346,829 patent/US6173756B1/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008032672A1 (de) | 2008-07-10 | 2010-01-14 | Sms Siemag Aktiengesellschaft | Stranggießkokille |

| WO2010003695A1 (de) | 2008-07-10 | 2010-01-14 | Sms Siemag Ag | Stranggiesskokille |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19829606A1 (de) | 2000-01-05 |

| EP0968779A1 (de) | 2000-01-05 |

| ATE215856T1 (de) | 2002-04-15 |

| DE59901169D1 (de) | 2002-05-16 |

| ES2175877T3 (es) | 2002-11-16 |

| US6173756B1 (en) | 2001-01-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2014393B1 (de) | Kokille zum Stranggiessen von Vorblöcken, Brammen oder Knüppeln | |

| EP0968779B1 (de) | Breitseite einer Brammenkokille | |

| DE4127333C2 (de) | Stahlstranggießkokille | |

| DE102016124801B3 (de) | Kokillenplatte und Kokille | |

| EP2323785A1 (de) | Stranggiesskokille | |

| DE19920858C2 (de) | Oberbau-Zungenvorrichtung | |

| EP3385462A1 (de) | Thermisch isolierendes bauelement | |

| WO2010015399A1 (de) | Stranggiesskokille für flüssiges metall, insbesondere für flüssigen stahl | |

| EP1332811B1 (de) | Kokillenrohr | |

| DE19835111A1 (de) | Kokillenwand einer Stranggießanlage | |

| EP0965401A1 (de) | Kokillenwand einer Stranggiesskokille | |

| DE68922285T2 (de) | Stranggiesskokille mit direkter Kühlung mit verstellbarem Kühlmitteltreffpunkt. | |

| DE19741131C2 (de) | Stranggießkokille | |

| EP1757385B1 (de) | Kokillenbreitseite einer Trichterkokille | |

| DE69127853T2 (de) | Kokillen-Vorrichtung mit veränderlicher Breite | |

| EP0987073A1 (de) | Kokillenwand einer Stranggiesskokille | |

| DE3943146C2 (de) | Spritz-, Stanz- oder Ziehwerkzeug mit austauschbaren Formwerkzeugen | |

| DE10035737A1 (de) | Stranggießkokille mit den Gießquerschnitt umschließenden Kupferplatten | |

| DE3340520C2 (es) | ||

| EP1025929A1 (de) | Anordnung zum Verbinden einer Kokillenplatte mit einem Wasserkasten | |

| DE19801728C1 (de) | Stranggießkokille | |

| DE3319332C2 (de) | Platte für eine Stranggießkokille | |

| DE102023112607B3 (de) | Kokille | |

| DE3206987C2 (de) | Gießform zum Herstellen von Hohlgußstücken | |

| EP2360004B1 (de) | Kalibrierblende und Kalibriereinsatz für ein Kalibrierwerkzeug |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19990714 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE DE ES FR GB IT LU NL SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SMS DEMAG AG |

|

| AKX | Designation fees paid |

Free format text: AT BE DE ES FR GB IT LU NL SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010803 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE ES FR GB IT LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 215856 Country of ref document: AT Date of ref document: 20020415 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020410 |

|

| REF | Corresponds to: |

Ref document number: 59901169 Country of ref document: DE Date of ref document: 20020516 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20020531 Year of fee payment: 4 Ref country code: AT Payment date: 20020531 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20020603 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20020606 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20020611 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20020612 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20020613 Year of fee payment: 4 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2175877 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030625 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030625 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030625 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030626 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030626 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030630 |

|

| BERE | Be: lapsed |

Owner name: *SMS DEMAG A.G. Effective date: 20030630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040101 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040101 |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20030625 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040227 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20040101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20030626 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050625 |