EP0959169A1 - Waschmachine oder Wäschetrockner mit einer einzigen Tür ausgerüsteten Trommel - Google Patents

Waschmachine oder Wäschetrockner mit einer einzigen Tür ausgerüsteten Trommel Download PDFInfo

- Publication number

- EP0959169A1 EP0959169A1 EP99401130A EP99401130A EP0959169A1 EP 0959169 A1 EP0959169 A1 EP 0959169A1 EP 99401130 A EP99401130 A EP 99401130A EP 99401130 A EP99401130 A EP 99401130A EP 0959169 A1 EP0959169 A1 EP 0959169A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- leaf

- drum

- lug

- machine according

- door

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000005406 washing Methods 0.000 title claims description 11

- 230000000903 blocking effect Effects 0.000 claims description 8

- 238000001035 drying Methods 0.000 claims description 4

- 230000000694 effects Effects 0.000 description 7

- 241001417494 Sciaenidae Species 0.000 description 6

- 238000010009 beating Methods 0.000 description 4

- 210000002105 tongue Anatomy 0.000 description 2

- 208000019901 Anxiety disease Diseases 0.000 description 1

- 241000206607 Porphyra umbilicalis Species 0.000 description 1

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000003100 immobilizing effect Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F37/00—Details specific to washing machines covered by groups D06F21/00 - D06F25/00

- D06F37/02—Rotary receptacles, e.g. drums

- D06F37/04—Rotary receptacles, e.g. drums adapted for rotation or oscillation about a horizontal or inclined axis

- D06F37/10—Doors; Securing means therefor

Definitions

- the present invention relates to a washing machine or dryer top-loading laundry, the drum of which is fitted with a a single leaf. It applies equally to washing or drying machines than machines that wash and dry at the same time.

- the user must in fact open at least the door of the carcass of the machine and the drum door, double leaf. This action the opening of the drum is not as harmless as there appears.

- it complicates the task of the accessing user generally on the drum of a machine, being also responsible for laundry.

- the opening of the drum is often quite complicated, and even possibly hurtful, particularly on the fingers and especially the nails.

- Handling a double leaf gate is not in itself easy. It is not elsewhere not at all ergonomic insofar as it forces people to use both hands.

- the object of the invention is to allow the immobilization, in the two-way, from the drum of a washing machine and / or dryer top loading, equipped with a single-leaf gate, simple and economic.

- the subject of the invention is a washing machine and / or dryer, characterized in that its drum being equipped with a gate with a single leaf pivoting by means of a hinge connected to its ferrule , the leaf has at least two widths I 1 , I 2 , the enlarged part of the leaf being on the side of the hinge and the tank comprising at least one lug, so that when the leaf is in the open position, the enlarged part comes in abutment against at least one lug, the enlarged part passing under this lug (33, 34) when the leaf is closed in rotation.

- the main advantages of the invention are that it allows handle the door of a drum effortlessly and simply, requires very few components and increases the safety of closing.

- Figure 1 shows a drum door of a wash and / or dry the laundry according to the prior art, with two leaves.

- the leaves 11, 12 pivot on themselves with hinges 13, 14 connected to the ferrule 15.

- the locking of the two leaves is ensured for example by a latch 16 fixed to one of the leaves, this latch coming to hang on the other beating. Maintaining the grip between the two leaves comes from the force exerted towards the opening by return springs 17, 18 on these doors. As mentioned above, for reasons of closing security, these springs have a large return force.

- a latch 16 is released by a user, the two leaves make a violent movement towards their open position under the effect return springs 17, 18.

- FIG 2 presented by an overall view of a wash and / or dry the laundry 21, the preceding leaves 11, 12 in position opening, the general access door 22 also being in the open state.

- the rotation of the drum 23 is prevented in a direction A by the stop of a beating 11 against the tank 24 or the chassis 25 of the machine, and in the other direction B by the stop of the other leaf 12.

- the rotation of the drum becomes free in one of the directions A, B. There is no therefore more immobilized.

- the use of an additional device to ensure blocking the drum is therefore necessary.

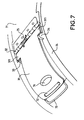

- FIG. 3 shows in a partial top view, schematically, an example of machine according to the invention for immobilizing a drum equipped with a gate with a single leaf.

- the machine drum has a single leaf 31 pivoting by means of a hinge 32 connected to its ferrule.

- the leaf 31 has a length L and at least two widths I 1 , I 2 , the largest width I 1 being on the side of the hinge 32.

- the tank of the machine comprises at least one lug 33, 34 presented in side view according to F in FIG. 4. When the leaf is in the closed position, as illustrated in this FIG. 4, the whole enlarged part 311 passes below this lug, located on the top of the tank 24.

- this lug 33, 34 is placed so that when the leaf is folded into the open position, its zone 311 of greater width I 1 comes into abutment against the lug, as illustrated in FIG. 5. so, the drum remains blocked. Indeed, its rotation in direction B, towards the front of the machine, opposite the hinge 32 of the leaf 31, is prevented by the stop of the enlarged part 311 of the leaf on the lug 33, 34.

- the height h , along the length L, of the enlarged part 311 of the leaf is preferably limited to the height necessary to abut against the lugs 33, 34, that is to say for example of the order of a few centimeters. However, it can be more important.

- the opening perimeter of the tank must at least include inside its total perimeter of the leaf to allow the opening of the latter, and in particular the passage of its enlarged part 311.

- the drum is for example blocked so classic, as in the case of a double leaf opening, by the stop of the leaf 31, in the open state, against the tank 24 as illustrated in FIG. 6.

- This figure 6 also shows how the pins 33, 34 allow the blocking drum in direction B.

- the enlarged part 311 abuts against the lugs 33, 34.

- a single lug 33, 34 can be necessary to hold the drum. In other words, it is not necessary to provide the leaf stop on two pins, only one can possibly suffice.

- FIG. 7 shows, in a perspective and partial view, a example of a particular embodiment of the leaf in association with the or the locking pins 33, 34.

- the leaf 21 pivots using a hinge 32 fixed to the ferrule 71 of the drum.

- the leaf lock is made using a latch 72 which fits into a piece of blocking 73 linked to the ferrule 71.

- the opening is carried out using a handle 74 which releases the latch 72 from the part 73.

- a return spring 75 drives and keeps the leaf 31 in the open position. As it was indicated previously, the return force of this spring does not require to be important. It therefore does not provide unpleasant effects to users.

- the enlarged part 311 of the leaf 31 is for example constituted two tabs. These are located at the base of the leaf, in look of the hinge 32.

- the opening of the drum being for example kept rectangular, these tabs cover the shell. In others terms, there is no opening of the drum opposite these tabs.

- the tongues 311 cooperate with the lugs, of which only one 34 is represented.

- the lug 34 which is for example molded with the tank 24, is of rounded shape to facilitate tilting of the flap tabs on this lug when closing the leaf.

- the opening of the tank 24 is widened to level of the tabs 311 of the leaf to allow the opening of the latter.

- FIG. 7 shows in particular that the drum door can be handled easily and effortlessly, thanks to particular to a handle and a spring of weak return force. Furthermore the closing is easily ensured by means of a latch. This realization also shows that few components are necessary. Finally, closing security is ensured by blocking the latch closure directly on the drum shell so that the reliability of the closure is increased.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Main Body Construction Of Washing Machines And Laundry Dryers (AREA)

- Detail Structures Of Washing Machines And Dryers (AREA)

- Drying Of Solid Materials (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9806182 | 1998-05-15 | ||

| FR9806182A FR2778677B1 (fr) | 1998-05-15 | 1998-05-15 | Machine a laver ou secher le linge dont le tambour est equipe d'un portillon a un seul battant |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0959169A1 true EP0959169A1 (de) | 1999-11-24 |

| EP0959169B1 EP0959169B1 (de) | 2003-09-17 |

Family

ID=9526414

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99401130A Expired - Lifetime EP0959169B1 (de) | 1998-05-15 | 1999-05-07 | Waschmachine oder Wäschetrockner mit einer einzigen Tür ausgerüsteten Trommel |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0959169B1 (de) |

| AT (1) | ATE250156T1 (de) |

| DE (1) | DE69911301T2 (de) |

| ES (1) | ES2207135T3 (de) |

| FR (1) | FR2778677B1 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1544343A1 (de) * | 2003-12-19 | 2005-06-22 | Whirlpool Corporation | Von oben beschickbare Waschmaschine mit einer einzigen Tür ausgerüsteten Trommel |

| FR2864114A1 (fr) * | 2003-12-22 | 2005-06-24 | Brandt Ind | Porte de tambour rotatif, notamment pour machine a laver et ou secher le linge |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1926973A1 (de) * | 1969-05-23 | 1970-11-26 | Siemens Elektrogeraete Gmbh | Trommeldeckelverschluss fuer die Beschickungsoeffnung im Mantel einer Waeschetrommel |

| EP0048643A1 (de) * | 1980-09-19 | 1982-03-31 | Thomson-Brandt | Vorrichtung zum zeitweiligen Festhalten einer Waschmaschinentrommel |

| EP0296020A1 (de) * | 1987-06-16 | 1988-12-21 | Ciapem | Trommeltür für eine Wasch- und/oder Trockenmaschine |

-

1998

- 1998-05-15 FR FR9806182A patent/FR2778677B1/fr not_active Expired - Fee Related

-

1999

- 1999-05-07 ES ES99401130T patent/ES2207135T3/es not_active Expired - Lifetime

- 1999-05-07 AT AT99401130T patent/ATE250156T1/de not_active IP Right Cessation

- 1999-05-07 EP EP99401130A patent/EP0959169B1/de not_active Expired - Lifetime

- 1999-05-07 DE DE69911301T patent/DE69911301T2/de not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1926973A1 (de) * | 1969-05-23 | 1970-11-26 | Siemens Elektrogeraete Gmbh | Trommeldeckelverschluss fuer die Beschickungsoeffnung im Mantel einer Waeschetrommel |

| EP0048643A1 (de) * | 1980-09-19 | 1982-03-31 | Thomson-Brandt | Vorrichtung zum zeitweiligen Festhalten einer Waschmaschinentrommel |

| EP0296020A1 (de) * | 1987-06-16 | 1988-12-21 | Ciapem | Trommeltür für eine Wasch- und/oder Trockenmaschine |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1544343A1 (de) * | 2003-12-19 | 2005-06-22 | Whirlpool Corporation | Von oben beschickbare Waschmaschine mit einer einzigen Tür ausgerüsteten Trommel |

| FR2864114A1 (fr) * | 2003-12-22 | 2005-06-24 | Brandt Ind | Porte de tambour rotatif, notamment pour machine a laver et ou secher le linge |

| EP1548170A1 (de) * | 2003-12-22 | 2005-06-29 | Brandt Industries | Trommeltür für Waschmaschine und/oder Trockner |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2207135T3 (es) | 2004-05-16 |

| DE69911301T2 (de) | 2004-07-01 |

| EP0959169B1 (de) | 2003-09-17 |

| FR2778677B1 (fr) | 2000-08-04 |

| ATE250156T1 (de) | 2003-10-15 |

| FR2778677A1 (fr) | 1999-11-19 |

| DE69911301D1 (de) | 2003-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| LU87775A1 (fr) | Assemblage de fermeture avec couvercle articule | |

| FR2705064A1 (fr) | Crochet d'accouplement pour les bras inférieurs d'un dispositif d'attelage trois points d'un tracteur. | |

| EP0959169B1 (de) | Waschmachine oder Wäschetrockner mit einer einzigen Tür ausgerüsteten Trommel | |

| FR2669076A1 (fr) | Ensemble anti-effraction pour ouvrant, notamment pour porte. | |

| EP0219589A1 (de) | Falttür | |

| FR2789108A1 (fr) | Systeme de serrure pour element de fermeture mobile | |

| FR2597914A1 (fr) | Mecanisme de blocage complementaire pour un ensemble de verrouillage a tension | |

| EP1548170B1 (de) | Trommeltür für Waschmaschine und/oder Trockner | |

| FR2657916A1 (fr) | Espagnolette de volets et/ou de croisees comportant un moyen de verrouillage du levier de commande faisant office d'entrebailleur de securite. | |

| EP0014114B1 (de) | Kipptür eines Haushaltsgerätes, welche stets in eine halbgeöffnete Stellung zurückkehrt | |

| FR2746173A1 (fr) | Dispositif de securite pour l'ouverture de la porte d'un appareil de cuisson | |

| EP1001068A1 (de) | Vorrichtung zum Öffnen und Schliessen der Trommel einer von oben beschickbaren Wasch- oder Trockenmaschine | |

| FR2579261A1 (fr) | Loquet pour verrouillage de volet | |

| FR2730249A1 (fr) | Dispositif de verrouillage d'un portillon de tambour dans un lave-linge ou dans un seche-linge | |

| FR2490689A1 (fr) | Dispositif d'immobilisation temporaire d'un tambour de machine a laver le linge | |

| FR2633968A1 (fr) | Dispositif de fixation et de verrouillage automatique pour barres de securite sur des elements de fermetures du type volets, persiennes, portes et similaires | |

| EP3988749B1 (de) | Gelenkvorrichtung für klappladen und mit einer solchen vorrichtung ausgestatteter klappladen | |

| FR2892129A1 (fr) | Dispositif de fermeture de tambour de machine a laver | |

| FR2650334A1 (fr) | Dispositif d'obturation d'une ouverture | |

| CA1298044C (fr) | Pivot pour fenetre basculante ou oscillante de toiture | |

| FR2636663A1 (fr) | Dispositif de securite pour vantaux | |

| FR2484485A3 (fr) | Dispositif de securite pour un couvercle de tambour rotatif d'une machine a laver le linge | |

| FR2760029A1 (fr) | Dispositif d'accrochage a une barre, et bras de manipulation d'outil le comportant | |

| FR2699940A1 (fr) | Dispositif de fermeture de portillon de tambour. | |

| FR2600962A1 (fr) | Dispositif de securite pour poussette pliante ou analogue |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR IT LI |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| AKX | Designation fees paid |

Free format text: DE ES FR IT |

|

| 17P | Request for examination filed |

Effective date: 20000519 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE DK ES FR IT LI |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030917 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 69911301 Country of ref document: DE Date of ref document: 20031023 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031217 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2207135 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: BRANDT INDUSTRIES |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040618 |

|

| BERE | Be: lapsed |

Owner name: *CIAPEM Effective date: 20040531 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20090529 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100507 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: FAGORBRANDT SAS, FR Effective date: 20110826 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: FAGORBRANDT SAS Effective date: 20111021 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 69911301 Country of ref document: DE Representative=s name: PRINZ & PARTNER PATENTANWAELTE RECHTSANWAELTE, DE Effective date: 20120322 Ref country code: DE Ref legal event code: R081 Ref document number: 69911301 Country of ref document: DE Owner name: FAGORBRANDT SAS, FR Free format text: FORMER OWNER: BRANDT INDUSTRIES, RUEIL MALMAISON, FR Effective date: 20120322 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20120622 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131203 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 69911301 Country of ref document: DE Effective date: 20131203 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20150525 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: GROUPE BRANDT Effective date: 20160307 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: GROUPE BRANDT, FR Effective date: 20160420 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: GC Effective date: 20160426 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160508 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180528 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20181128 |