EP0917829B1 - Procédé d'acheminement d'un flux de tabac, distributeur et machine de fabrication de cigarettes équipée d'un tel distributeur - Google Patents

Procédé d'acheminement d'un flux de tabac, distributeur et machine de fabrication de cigarettes équipée d'un tel distributeur Download PDFInfo

- Publication number

- EP0917829B1 EP0917829B1 EP97810862A EP97810862A EP0917829B1 EP 0917829 B1 EP0917829 B1 EP 0917829B1 EP 97810862 A EP97810862 A EP 97810862A EP 97810862 A EP97810862 A EP 97810862A EP 0917829 B1 EP0917829 B1 EP 0917829B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tobacco

- belt

- stream

- tobacco stream

- transfer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 241000208125 Nicotiana Species 0.000 title claims description 234

- 235000002637 Nicotiana tabacum Nutrition 0.000 title claims description 234

- 238000004519 manufacturing process Methods 0.000 title claims description 23

- 235000019504 cigarettes Nutrition 0.000 title claims description 14

- 238000000034 method Methods 0.000 title claims description 12

- 239000000203 mixture Substances 0.000 claims description 12

- 210000001520 comb Anatomy 0.000 claims description 9

- 238000000926 separation method Methods 0.000 claims description 9

- 238000002156 mixing Methods 0.000 claims description 5

- 238000011084 recovery Methods 0.000 claims description 3

- 230000008030 elimination Effects 0.000 claims description 2

- 238000003379 elimination reaction Methods 0.000 claims description 2

- 230000005484 gravity Effects 0.000 claims description 2

- 238000006073 displacement reaction Methods 0.000 claims 5

- 239000012634 fragment Substances 0.000 claims 4

- 230000001464 adherent effect Effects 0.000 claims 1

- 230000002093 peripheral effect Effects 0.000 claims 1

- 238000013517 stratification Methods 0.000 description 7

- 230000004907 flux Effects 0.000 description 5

- 235000013580 sausages Nutrition 0.000 description 5

- 239000000428 dust Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 230000001419 dependent effect Effects 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000001680 brushing effect Effects 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 235000009508 confectionery Nutrition 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 229940082150 encore Drugs 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 238000003306 harvesting Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000007790 scraping Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/39—Tobacco feeding devices

Definitions

- the present invention relates to the delivery of tobacco in a machine for manufacturing tobacco industry products, including a method of routing a stream of tobacco, a dispenser able to work according to this method and a cigarette manufacturing machine equipped with such distributor.

- a distributor supplies tobacco with the portion of machine in which the tobacco is formed into a rod, by suction along a porous belt, in order to subsequently form a cigarette.

- such a distributor must supply this portion of machine in an absolutely regular way, that is to say that the tobacco in the tobacco flow feeding the manufacturing machine must have a density regular, respectively a distribution of its components, in particular a regular distribution of long and short strands, as well as a flow regular, so that in the tobacco rod generally formed under a porous belt, the longitudinal density of tobacco as well as the distribution of its components to be as regular as possible.

- the distributor Since loose tobacco feeding the distributor consists of a mixture of different components: short and long strands of natural tobacco and / or reconstituted tobacco and / or tobacco homogenized and / or expanded tobacco, tobacco dust, ribs, ribs and stems of large or small section, as well as any possible waste, a other function of such a distributor is to eliminate some of these components, in particular the ribs, the ribs and the stems of large section as well as the waste, knowing that tobacco dust is eliminated by the possible distributor inlet lock as well as through the porous belt on which forms the tobacco rod.

- These devices include means for routing a tobacco flow from an intermediate stock from a distributor to a suction chimney of a machine for manufacturing industry products tobacco.

- the first goal indicated is obtained by a process corresponding to the claim 1, while the other objects as well as variants are obtained by methods described in the claims dependent on the claim 1.

- a dispenser according to the invention has the characteristics mentioned in claim 7; other variants or forms of execution are described in the dependent claims of this claim.

- a cigarette making machine according to the invention comprises the features of claim 23.

- the machine for manufacturing tobacco industry products 1 shown in Figure 1 includes in particular a tobacco supply part 2, a distribution part or distributor 3, a part for making the tobacco rod 4 and a drive and control part 5.

- the tobacco supply part 2 is essentially intended for transport tobacco 6 from a general stock (not shown) to a distributor 30 input stock 3.

- This tobacco supply part 2 can be made up of any type of known device, i.e. a device continuous strip, batch or other.

- the tobacco supply part 2 consists of a tangential lock such that described for example in one or other of the patents EP-B-0,501,910 or EP-B-0655402.

- such a tangential lock 2 is consisting of a suction part 20 pneumatically sucking a flow of tobacco through line 21 and separating the air used to transport the flow of tobacco, the air loaded with part of the tobacco dust being expelled by the line 22, while the other components mentioned above tobacco stream, passing through lock 23 are sequentially discharged in entry inventory 30.

- Two detectors, preferably cells optics 24 and 25 control the running of tangential lock 2 so that the input stock 30 is properly supplied, without jamming in this place.

- the distributor 3 comprises a continuous strip with combs 31, extending over most of the width of the machine, responsible for taking the tobacco from intermediate stock 30 to bring it onto a continuous conveyor belt transfer 32.

- a first means of equalization for example a first band continuous equalization 33, arranged close to the top of the comb strip 31 is responsible for carrying out a first equalization of the flow of carried tobacco by the band 31, respectively to eliminate any excess thickness of the flux tobacco there.

- a deflector 34 then directs the flow of tobacco according to a first direction determined on the transfer belt 32.

- a detection 35 controls the quantity of tobacco arriving on the transfer belt 32 and controls the speed of the belt 31, respectively of the transfer belt 32, in order to maintain a determined minimum tobacco flow on the transfer mat 32.

- a second means of equalization for example a second band continuous equalization 36, responsible for compacting slightly and equalizing the tobacco flow is placed near the end of the tobacco flow path on the transfer mat 32.

- a means of disentangling preferably a spike roller 37, is arranged slightly downstream of the transfer belt 32 in order to untangle, mix and expand the tobacco flow before it flows essentially descends by gravitation in a transfer pipeline 38.

- tobacco 6 After being introduced into intermediate stock 30, tobacco 6 has tendency to separate in such a way that the bottom portion of the stock 30 is occupied mainly by short strands of tobacco 60 while the upper portion of stock 30 mainly includes long strands of tobacco 61. Ribs, ribs, stems and debris 62 brought with the tobacco flow are mostly found in the upper portion comprising the long strands tobacco 61.

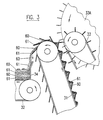

- the comb strip 31 removes tobacco from stock 30 from the bottom of it filling the spaces between two consecutive combs. Saw the distribution between short strands 60 and long strands 61 in the stock 30 which comes to be mentioned and by the corner arrangement of each comb relative to the strip 31, as seen in FIG. 2, the portion of this space between the two branches of the corner fills in the portion stock 30, essentially short strands 60, with a relatively high tobacco strand density, while the portion of this space immediately behind the previous comb fills in the upper portion of the stock 30, essentially long strands 61.

- FIG. 3 shows in particular the first means of equalization, constituted according to a first embodiment of a continuous strip 33, comprising flexible blades fixed perpendicular and transversely on the external surface of said strip and flowing in the direction indicated by the arrow, responsible for harvesting excess tobacco strands on the edges of combs and place them in the less filled upper portions of the spaces between combs or return them to stock 30.

- the blades flexible strips 33 therefore have a height such that their ends meet the ends of the combs of the comb strip 31, bend when from this encounter and push the excess tobacco strands towards the comb next.

- the strip with blades 33 is arranged slightly at a bevel relative to the comb strip 31, the point of the bevel being directed towards the top of the comb strip 31, so that each comb of the strip 31 meets at least one flexible blade of strip 33 over their portion common journey.

- flexible blades can be arranged transversely at a certain angle on the continuous strip 33, or be replaced by flexible pins or more generally by all element capable of brushing or scraping the upper edges of the combs of the comb strip 31.

- the figure shows in broken lines a shape where the continuous strip 33 is replaced by a roller 33A comprising flexible blades as before or as according to one or the other of the variants described.

- the tobacco flows along the deflector 34, preferably by gravitation, to come deposit on the transfer strip 32.

- the deflector 34 consists here of a sheet metal plate, used to guide the tobacco flow in order to deposit it on the carpet transfer 32 in a first direction.

- Figure 3 we notice that in the tobacco flow, from the moment it leaves the comb strip 31 as well as along the deflector 34, the stratification described above for the comb strip 31 between portions of the tobacco stream comprising a strong proportion of short strands 60, respectively high density strand portions tobacco and high proportion portions of long strands 61, respectively lower density portions of tobacco, is retained, i.e.

- the transfer belt 32 then takes the tobacco flow in a second direction essentially perpendicular, respectively essentially non-parallel, to said first direction in which the tobacco flow is brought onto the carpet transfer.

- the angle between the first and second directions is between 90 ° and 120 °, preferably close to and slightly greater than 90 °.

- the feed speed of the transfer belt 32 i.e. the speed at which the tobacco flow is carried by said carpet, is low enough that the tobacco flow is deposited in a relatively thick layer on the carpet transfer 32.

- this advance speed is chosen to be so that four of the successive portions of the tobacco flow previously mentioned overlap when the tobacco flow arrives on the transfer belt 32.

- Figure 3 shows that in this way, the superimposition of portions with a high rate of short strands 60, respectively strong rate of long strands 61 reproduces along the transfer belt 32, the stratification between portions which was previously essentially transverse to the direction of movement of the tobacco flow essentially becoming parallel to the direction of movement of the tobacco flow on the transfer belt 32.

- the thickness of each portion, respectively of the layer of tobacco on the treadmill is greatly enlarged relative to other dimensions of the system, to better understand this desired effect.

- the speed of movement of the tobacco flow by the transfer belt 32 is chosen so that four successive portions of the tobacco flow arriving on said transfer mat overlap in layers to form the thickness of the tobacco flow on said carpet.

- the speed of the transfer belt 32 can also be chosen to obtain a number of layers other than four. The important thing, in order to get the effect of mixing between desired portions obtained by the mixing means described more low, is that this number is greater than 1. The higher this number, the better will be the mixture between short stranded portions 60 and long stranded portions 61.

- the four-layer embodiment represents an optimum between quality of the mixture obtained and the technical possibilities of the distributor.

- a number of odd layer could also be advantageous, for example 3 or 5, the stratification between layers then being already destroyed on the transfer mat, each layer having an alternating succession of short-stranded portions 60 and portions with long strands 61, the succession of said portions being alternated between two superimposed layers.

- the transfer belt 32 moves the tobacco flow in the direction indicated by the arrow.

- the tobacco flow is unraveled, mixed and expanded by the roller spikes 37.

- the tobacco flow has a certain consistency.

- This consistency is obtained by the second means equalization consisting of the continuous equalization strip 36 whose strand directly in contact with the tobacco flow circulates in the same direction as that latest.

- the strip constituting the transfer belt 32 and that constituting the equalization strip 36 are preferably made of the same material flexible, having a smooth upper surface having a certain adhesion, especially for tobacco.

- the degree of adhesion of the upper surface of the EQ band 36 as well as transfer band 32 can be chosen depending on the composition or mixture of tobacco.

- the equalization band 36 and the transfer mats form a slight bevel, the tip of which is directed towards the spiked roller 37, the cross section of the tobacco flow therefore being gradually tightened at the end of travel on the transfer belt 32, passing through a restricted space corresponding to a passage section minimum determined between the two closest portions of the strip 36 and the transfer mat 32.

- this section of minimum passage can be adjusted, depending on the composition or mixture of tobacco, by varying the distance between the two rollers 32A and 36A.

- the equalization strip 36 is driven at a speed slightly different from that of the transfer belt 32, respectively tobacco flow on the latter.

- the speed difference between the mat transfer 32 and the equalization band 36 can be positive or negative, i.e. the feed rate of the equalization band may be higher or lower than that of the transfer belt 32, this difference in speed which can range between + 10% and -10% depending on the composition or mixture of tobacco. Given this difference in speed and given the mentioned grip of tobacco on the strip 36, the excess thicknesses of the tobacco layer in contact with the strip equalization 36 are slowed down or accelerated and fill the regions thinner.

- the tobacco flow has a stratification between portions or layers of the tobacco flow tobacco with a high proportion of long strands and high proportion portions or layers short strands essentially longitudinal, respectively parallel to the flow of tobacco thanks to the difference between the first direction that the flow of tobacco is brought to the transfer mat 32 and the second direction according to which tobacco flow is carried by said transfer mat 32; thickness tobacco stream has several portions or layers with a high proportion of long strands interspersed with several portions or layers in high proportion short strands thanks to the speed difference between the traveling speed of the tobacco flow on the transfer mat 32 and the speed at which this flow tobacco is brought to said transfer mat.

- the tobacco flow is relatively compact thanks to the tightening between the equalization strip 36 and the transfer mat 32 and thickness, respectively of medium density, constant thanks to the speed difference between the equalization band 36 and the transfer mat 32.

- the tobacco flow passes through a means of untangling, mixing and expansion, preferably a pin roller 37, arranged across and in the plane of the tobacco flow and rotating around a axis perpendicular to the direction of movement of the tobacco flow.

- a means of untangling, mixing and expansion preferably a pin roller 37, arranged across and in the plane of the tobacco flow and rotating around a axis perpendicular to the direction of movement of the tobacco flow.

- the pin roller 37 untangles the tobacco strands and performs a first separation of the ribs, ribs, stems and debris that have circulated in the tobacco stream to date; by the movement of the pins taking place transversely to the flow and transverse to the mentioned stratification between portions or layers of the tobacco flow with a high proportion of long strands 61 and portions with a high proportion short strands 60, a mixture of the portions mentioned is obtained, respectively a destruction of the mentioned stratifications, leading to a regular distribution of the different components of the tobacco flow, respectively a regular distribution of long strands and short strands in the tobacco flow, and by introducing the tobacco flow in the portion upper part of a transfer line 38 having a section of significantly higher tobacco flow than mentioned previously encountered by the same tobacco flow between the strip equalization 36 and the transfer mat 32, a strong expansion of section of the tobacco flow, respectively a sharp decrease in the density of tobacco in said stream.

- the tobacco flow thus regulated then follows, preferably by gravity, the transfer pipe 38.

- the confection part of the tobacco rod visible in Figure 1 is known in the art, generally comprising a suction chamber 40 sucking tobacco through a porous belt 41 along a chimney suction 42 which, in the described embodiment of the dispenser, opens out in a separation chamber 38A disposed in the central portion of the transfer line 38, so that the tobacco is placed in the form of a tube under the porous belt 41.

- This part of making sausage is generally supplemented with means for compressing portions of the sausage, clipping as well as laying the paper tape around the sausage, these various means not being shown here.

- a movable valve 43 is also provided near the portion bottom of the transfer line 38, so that, when stopping the production machine, in particular a stop of the porous belt 41 causing the suction to stop or the suction chimney to clog 42, the tobacco flow still moving in the upper portion of the transfer line is directed to recovery means 44 which will bring the tobacco back to the entry inventory 30.

- Machine 1 is equipped with motorized means, shown schematically in 5, allowing to train the various moving components of the machine.

- Control means shown diagrammatically at 50, known from the technical, provide the different commands necessary for the adjustment drive speeds of the various components, for controlling the movable valve 43 and the tangential lock 2.

- the means control act on these different components so as to keep a constant flow of tobacco in each place of the dispenser. They react to various sensors such as sensors 24, 25 and 35 mentioned.

- a first advantage of such a distributor is therefore a food of the chimney 42, respectively of the tobacco rod under the belt porous 41 by a stream of tobacco of constant density and having a regular distribution of its components, especially short tobacco strands and long, the irregularities having been eliminated in the manner indicated above when the tobacco flow passes through the dispenser.

- the tobacco strands are never brutalized, respectively never damaged. Indeed, the tobacco strands do not are never projected at high speed against a wall in order to separate them from ribs, ribs, rods and debris as in other known distributors; the separation between tobacco strands and ribs, ribs, stems and debris is made gentle way, by suction of tobacco strands while the ribs, ribs and larger debris, respectively of larger mass, are separated from the flow by gravitation.

- the dispenser according to the invention described does not use no air jet for this purpose, thus allowing the humidity of the tobacco strands not is not affected.

- Yet another advantage of such a mode of separation is a better separation of tobacco strands on one side and ribs, ribs, stems and large section debris on the other side, that is to say that there is less ribs, ribs, stems and debris in the tobacco rod and fewer strands of tobacco in the container for collecting ribs, ribs, stems and sharp debris section than in prior art dispensers.

- Yet another advantage of such a dispenser is that it allows increased production speed of the machine making tobacco industry products. If we admit that at the time of paper, the tobacco rod has a thickness having a value set at 100 according to a given arbitrary scale, we know that in order to take into account the compression of the portions of the flange which should form the ends of the cigarette, the sausage is clipped to a value of around 112 according to the same ladder; no hollow in the undulations of the lower surface of the tube does can therefore have a value less than 112.

- Such a dispenser can easily be incorporated into a machine for manufacturing tobacco industry products, in particular at a cigarette making machine.

- Such a distributor can thus easily be installed in place of a distributor of an old type in a existing manufacturing, and given the best mentioned use of the tobacco flow, we can increase the speed of production of the machine for a flow of determined tobacco.

Landscapes

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

Priority Applications (13)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES97810862T ES2183115T3 (es) | 1997-11-12 | 1997-11-12 | Procedimiento de encaminamiento de tabaco de un flujo de tabaco, distribuidor y maquina de fabricacion de cigarrillos equipada con tal distribuidor. |

| EP97810862A EP0917829B1 (fr) | 1997-11-12 | 1997-11-12 | Procédé d'acheminement d'un flux de tabac, distributeur et machine de fabrication de cigarettes équipée d'un tel distributeur |

| DE69715008T DE69715008T2 (de) | 1997-11-12 | 1997-11-12 | Verfahren zur Abgabe eines Tabakstromes, Verteiler und Zigarettenherstellungsmaschine mit einem solchen Verteiler |

| AU10178/99A AU1017899A (en) | 1997-11-12 | 1998-11-11 | Method for conveying a tobacco flux, feeder and cigarette-making machine equipped with such a feeder |

| RU2000114871/13A RU2206251C2 (ru) | 1997-11-12 | 1998-11-11 | Способ подачи табачного потока, питатель-дозатор и сигаретная машина, оборудованная таким питателем-дозатором |

| BR9814149-0A BR9814149A (pt) | 1997-11-12 | 1998-11-11 | Processo de encaminhamento de um fluxo de tabaco, distribuidor e máquina de fabricação de cigarros equipada com esse distribuidor |

| HU0100701A HUP0100701A3 (en) | 1997-11-12 | 1998-11-11 | Method for conveying a tobacco flux, feeder and cigarette-making machine equipped with such a feeder |

| PL98340409A PL188776B1 (pl) | 1997-11-12 | 1998-11-11 | Sposób dostarczania tytoniu do maszyny wytwarzającej papierosy i dystrybutor do dostarczania tytoniu |

| PCT/CH1998/000481 WO1999023899A1 (fr) | 1997-11-12 | 1998-11-11 | Procede d'acheminement d'un flux de tabac, distributeur et machine de fabrication de cigarettes equipee d'un tel distributeur |

| JP2000520012A JP2001522596A (ja) | 1997-11-12 | 1998-11-11 | タバコ流の搬送方法、供給装置、および、このような供給装置を備えたタバコ製造機 |

| CZ20001420A CZ20001420A3 (cs) | 1997-11-12 | 1998-11-11 | Způsob vedení proudu tabáku a transportní linka stroje na výrobu cigaret |

| US09/189,802 US20010052346A1 (en) | 1997-11-12 | 1998-11-12 | A process of feeding a tobacco stream, a hopper and a machine equipped with a hopper |

| BG104429A BG64111B1 (bg) | 1997-11-12 | 2000-05-12 | Метод за транспортиране на поток тютюн, разпределително устройство и машина за производство на цигари, снабдена с разпределителното устройство |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP97810862A EP0917829B1 (fr) | 1997-11-12 | 1997-11-12 | Procédé d'acheminement d'un flux de tabac, distributeur et machine de fabrication de cigarettes équipée d'un tel distributeur |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0917829A1 EP0917829A1 (fr) | 1999-05-26 |

| EP0917829B1 true EP0917829B1 (fr) | 2002-08-28 |

Family

ID=8230465

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97810862A Expired - Lifetime EP0917829B1 (fr) | 1997-11-12 | 1997-11-12 | Procédé d'acheminement d'un flux de tabac, distributeur et machine de fabrication de cigarettes équipée d'un tel distributeur |

Country Status (13)

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102754903A (zh) * | 2012-07-30 | 2012-10-31 | 昆明船舶设备集团有限公司 | 在贮柜内进行物料灵活和均匀掺配的方法 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0988802A1 (fr) | 1998-09-22 | 2000-03-29 | Fabriques De Tabac Reunies S.A. | Procédé de débourrage d'une machine de fabrication de produits de l'industrie du tabac et machine de fabrication fonctionnant selon ce procédé |

| DE69810792T2 (de) | 1998-12-30 | 2003-11-06 | Philip Morris Products S.A., Neuchatel | Verfahren zum Verteilen von Tabakkomponenten und Verteiler für eine Rauchartikelherstellungsmaschine |

| DE102004008116A1 (de) * | 2004-02-18 | 2005-09-15 | Hauni Primary Gmbh | Verfahren und Vorrichtung zum Zuführen von Schnitttabak in eine Verteilereinheit |

| DE102007062341B3 (de) * | 2007-12-22 | 2009-07-30 | Metso Lindemann Gmbh | Aufstromsichter |

| PL216367B1 (pl) | 2009-05-14 | 2014-03-31 | Int Tobacco Machinery Poland | Sposób i urządzenie do dystrybucji krajanki tytoniowej do zasilania maszyn produkujących papierosy |

| WO2012130823A1 (en) | 2011-03-30 | 2012-10-04 | Basf Se | Suspension concentrates |

| WO2012146598A1 (en) | 2011-04-28 | 2012-11-01 | Basf Se | Process for the preparation of 2-substituted 4-amino-2,4-dihydro-[1,2,4]triazole-3-thiones |

| WO2012146535A1 (en) | 2011-04-28 | 2012-11-01 | Basf Se | Process for the preparation of 2-substituted 2,4-dihydro-[1,2,4]triazole-3-thiones |

| DE102012109906A1 (de) * | 2012-10-17 | 2014-10-30 | Hauni Maschinenbau Ag | Verteilervorrichtung und Verfahren zum Beschicken einer Strangmaschine der Tabak verarbeitenden Industrie mit einem aus Fasermaterial bestehenden Produktstrom |

| DE102012109903A1 (de) * | 2012-10-17 | 2014-10-30 | Hauni Maschinenbau Ag | Verteilervorrichtung und Verfahren zum Beschicken einer Strangmaschine der Tabak verarbeitenden Industrie mit einem aus Fasermaterial bestehenden Produktstrom |

| DE102014210719B3 (de) * | 2014-06-05 | 2015-08-20 | Hauni Maschinenbau Ag | Maschinenanordnung der Tabak verarbeitenden Industrie |

| DE102016116465A1 (de) * | 2016-09-02 | 2018-03-08 | Hauni Maschinenbau Gmbh | Schusstrenneinrichtung für eine Einrichtung zur Herstellung von Produkten der Tabak verarbeitenden Industrie und Verfahren zur Steuerung einer Schusstrenneinrichtung |

| CN109225882A (zh) * | 2018-11-01 | 2019-01-18 | 四川三联新材料有限公司 | 一种卷烟供丝装置以及卷烟设备 |

| US11865747B2 (en) * | 2020-12-11 | 2024-01-09 | Ivan Arbouzov | Light plastic densifier |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB383142A (en) * | 1932-03-08 | 1932-11-10 | Muller J C & Co | Process and apparatus for introducing short tobacco into the continuous tobacco rod of a cigarette making machine |

| US3138163A (en) * | 1961-07-03 | 1964-06-23 | American Mach & Foundry | Cigarette making machine |

| DE2729730C2 (de) * | 1976-09-24 | 1986-11-13 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Verteiler einer Strangmaschine zum Herstellen von Rauchartikeln |

| DE2758358A1 (de) * | 1977-12-27 | 1979-07-05 | Hauni Werke Koerber & Co Kg | Vorrichtung zur regelung des tabakniveaus in einem stauschacht |

| US4373538A (en) * | 1981-02-17 | 1983-02-15 | Hauni-Werke Korber & Co. Kg. | Method and apparatus for forming a stream from several types of tobacco |

| DE8331379U1 (de) * | 1983-11-02 | 1985-04-11 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Vorrichtung zum bilden einer homogenen schicht aus fasern von tabak |

| IT1171992B (it) * | 1983-12-20 | 1987-06-10 | Gd Spa | Metodo e macchina per il confezionamento di sigarette con controllo della distribuzione del tabacco corto |

| GB8802976D0 (en) * | 1988-02-10 | 1988-03-09 | Molins Plc | Cigarette making machine |

| DE69201739T2 (de) | 1991-02-25 | 1995-11-23 | Tabac Fab Reunies Sa | Tangentialer Abscheider. |

| DE69307898T2 (de) | 1993-11-30 | 1997-07-24 | Tabac Fab Reunies Sa | Tangentialer Abscheider |

| IT1278227B1 (it) * | 1995-05-29 | 1997-11-17 | Gd Spa | Unita' di alimentazione per una macchina confezionatrice di sigarette |

-

1997

- 1997-11-12 ES ES97810862T patent/ES2183115T3/es not_active Expired - Lifetime

- 1997-11-12 DE DE69715008T patent/DE69715008T2/de not_active Expired - Fee Related

- 1997-11-12 EP EP97810862A patent/EP0917829B1/fr not_active Expired - Lifetime

-

1998

- 1998-11-11 PL PL98340409A patent/PL188776B1/pl not_active IP Right Cessation

- 1998-11-11 RU RU2000114871/13A patent/RU2206251C2/ru not_active IP Right Cessation

- 1998-11-11 JP JP2000520012A patent/JP2001522596A/ja active Pending

- 1998-11-11 CZ CZ20001420A patent/CZ20001420A3/cs unknown

- 1998-11-11 AU AU10178/99A patent/AU1017899A/en not_active Abandoned

- 1998-11-11 BR BR9814149-0A patent/BR9814149A/pt not_active Application Discontinuation

- 1998-11-11 HU HU0100701A patent/HUP0100701A3/hu unknown

- 1998-11-11 WO PCT/CH1998/000481 patent/WO1999023899A1/fr not_active Application Discontinuation

- 1998-11-12 US US09/189,802 patent/US20010052346A1/en not_active Abandoned

-

2000

- 2000-05-12 BG BG104429A patent/BG64111B1/bg unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102754903A (zh) * | 2012-07-30 | 2012-10-31 | 昆明船舶设备集团有限公司 | 在贮柜内进行物料灵活和均匀掺配的方法 |

| CN102754903B (zh) * | 2012-07-30 | 2014-08-20 | 昆明船舶设备集团有限公司 | 在贮柜内进行物料灵活和均匀掺配的方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| BG104429A (en) | 2000-12-29 |

| CZ20001420A3 (cs) | 2001-11-14 |

| DE69715008T2 (de) | 2003-04-30 |

| DE69715008D1 (de) | 2002-10-02 |

| AU1017899A (en) | 1999-05-31 |

| US20010052346A1 (en) | 2001-12-20 |

| JP2001522596A (ja) | 2001-11-20 |

| HUP0100701A2 (hu) | 2001-07-30 |

| EP0917829A1 (fr) | 1999-05-26 |

| PL340409A1 (en) | 2001-01-29 |

| RU2206251C2 (ru) | 2003-06-20 |

| BG64111B1 (bg) | 2004-01-30 |

| ES2183115T3 (es) | 2003-03-16 |

| PL188776B1 (pl) | 2005-04-29 |

| BR9814149A (pt) | 2000-10-03 |

| HUP0100701A3 (en) | 2003-01-28 |

| WO1999023899A1 (fr) | 1999-05-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0917829B1 (fr) | Procédé d'acheminement d'un flux de tabac, distributeur et machine de fabrication de cigarettes équipée d'un tel distributeur | |

| FR2539592A1 (fr) | Procede et dispositif pour la fabrication d'un boudin de tabac qui est constitue par un noyau et une couche annulaire entourant ce dernier | |

| CH647935A5 (fr) | Procede pour la production d'un materiau de remplissage, machine pour sa mise en oeuvre, application du procede et installation pour la production d'un boudin de filtres de cigarettes. | |

| FR2695008A1 (fr) | Procédé et machine pour la fabrication de cigarettes. | |

| FR2974705A1 (fr) | Procede et systeme d’elimination des dechets d’un flux de recolte | |

| EP0447208A2 (en) | Method of and apparatus for reclaiming tobacco from cigarette packages | |

| WO2018189485A1 (fr) | Transfert multilignes de produits | |

| FR2577112A1 (fr) | Machine de fabrication de cigarettes | |

| FR2540353A1 (fr) | Dispositif et procede pour confectionner des produits en forme de batonnets de l'industrie de transformation du tabac | |

| EP1300492B1 (fr) | Procédé et installation pour la production d'un non-tissé condensé, et dispositif de condensation d'un non-tissé | |

| FR2634106A1 (fr) | Machine pour la fabrication de cigarettes | |

| FR2661363A1 (fr) | Dispositif pour deposer une couche de composition d'enduction sur une bande de substrat. | |

| FR2735659A1 (fr) | Perfectionnements apportes aux machines de fabrication de cigarettes | |

| FR2556568A1 (fr) | Procede de fabrication de cigarettes et machine de commande de distribution de tabac a brins courts, notamment avec un pourcentage preregle de tabac a brins courts et de tabac a brins longs | |

| FR2712148A1 (fr) | Perfectionnements apportés aux machines à faire les cigarettes. | |

| FR2528660A1 (fr) | Dispositif sur roues pour ramasser et lier des tiges essentiellement paralleles | |

| FR2484481A1 (fr) | Procede pour transferer un mat d'un poste de formation a un poste de liaison secondaire | |

| FR2519517A1 (fr) | Dispositif pour delivrer du tabac a une pluralite de machines a faire des cigarettes | |

| FR3018790A1 (fr) | Dispositif et procede de convoyage et ordonnancement | |

| FR2473276A1 (fr) | Procede et mecanisme d'alimentation pour hachoirs a tabac | |

| WO2001088246A1 (fr) | Procede de formation et conditionnement de feutres isolants et son dispositif de mise en oeuvre | |

| FR2521177A1 (fr) | Procede et dispositif de traitement d'etoupe, notamment pour la fabrication de boudins de filtres | |

| CH524329A (fr) | Appareil distributeur d'objets allongés de forme sensiblement cylindrique, notamment de bâtonnets de matière filtrante destinés à la confection de bouts filtres pour des articles de tabac | |

| FR2461532A1 (fr) | Appareil de recouvrement d'un materiau filtrant avec un additif fluide | |

| WO2008068415A1 (fr) | Procede et dispositif de fabrication de portions d'un produit alimentaire filaire |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI NL |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991119 |

|

| AKX | Designation fees paid |

Free format text: CH DE ES FR GB IT LI NL |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: PHILIP MORRIS PRODUCTS S.A. |

|

| 17Q | First examination report despatched |

Effective date: 20010511 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: TALLIER, BERNARD Inventor name: VUILLEUMIER, DAVID |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI NL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENTANWAELTE Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 69715008 Country of ref document: DE Date of ref document: 20021002 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20021111 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2183115 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030530 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20061013 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20061016 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20061017 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20061025 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20061108 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20061130 Year of fee payment: 10 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20071112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20080601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080601 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080603 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20061002 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071112 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20071113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071112 |