EP0916613B1 - Tube supplying apparatus for textile machines for making cross-wound bobbins - Google Patents

Tube supplying apparatus for textile machines for making cross-wound bobbins Download PDFInfo

- Publication number

- EP0916613B1 EP0916613B1 EP98118041A EP98118041A EP0916613B1 EP 0916613 B1 EP0916613 B1 EP 0916613B1 EP 98118041 A EP98118041 A EP 98118041A EP 98118041 A EP98118041 A EP 98118041A EP 0916613 B1 EP0916613 B1 EP 0916613B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tube

- sleeve

- feeding device

- control

- track

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H67/00—Replacing or removing cores, receptacles, or completed packages at paying-out, winding, or depositing stations

- B65H67/06—Supplying cores, receptacles, or packages to, or transporting from, winding or depositing stations

- B65H67/068—Supplying or transporting empty cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Definitions

- the invention relates to a sleeve presentation device for Textile machines producing cross-wound bobbins according to the generic term of claim 1.

- a disadvantage of these known devices is, above all, that the package changer positioned at the place of work first wait for the arrival of a requested empty tube got to. The waiting times that occur have a negative effect the overall efficiency of these textile machines.

- the cross-wound bobbin changers of these textile machines have both a handling mechanism for transferring the empty tubes from the tube conveyor belt into the intermediate store and a handling device for receiving and changing the empty tubes deposited in the intermediate stores in the bobbin frame of the relevant winding units.

- a new empty tube is immediately requested by the operating unit at the beginning of the package change process, which transfers the operating unit to the intermediate storage unit of the winding unit before it leaves the winding unit.

- an improved To create sleeve feed means i.e. a Tube feed device, in which the transfer of empty tubes from the central sleeve magazine to the intermediate sleeve stores an alternative way is accomplished.

- the embodiment of the invention has the advantage that the sleeve feed device, which consists essentially of a stationary, horizontal, window-like Recessing path, one along this path slidably mounted, also window-like recesses possessing control band as well as a movable on the train Sleeve transport trolley exists, both the horizontal running web as well as the control band from one ferromagnetic material, preferably steel are, has only a few, relatively robust components. A such training not only leaves a long life Expect establishment, but also leads to a good one Price / performance ratio of the facility.

- the sleeve feed device according to the invention stands out due to their constructive structure also by a high Functionality and good availability.

- the type of control on the sleeve transport trolley arranged sleeve gripping device has proven to be very proven reliable and almost wear-free.

- the web and the control band have a large number of window-like recesses, the dimensions and spacings of which correspond.

- the positions of the recesses arranged in the stationary path result from the winding position division of the textile machine, this winding position division also determining the division of the storage columns of the central sleeve magazine.

- Such an embodiment makes it possible, in a simple and advantageous manner, to create magnetizable or non-magnetizable zones at any time both in the area of the bobbin-specific buffer stores and in the area of the storage columns of the central sleeve magazine, which zones in connection with a corresponding permanent magnet package arrangement arranged on the sleeve transport carriage for a control process of the sleeve gripping device this means of transport can be used. That is, by appropriately positioning the recesses of the control belt slidably mounted along the track, a permanent magnet package arranged on the sleeve transport carriage can be activated if necessary, and the sleeve gripping device of the sleeve transport carriage can thus be actuated reliably and quickly.

- the control belt is, as described in claim 2, connected to a thrust piston gear, which, as usual, has two defined end positions.

- the end positions of the thrust piston transmission each correspond to a first or second control position of the control belt. In connection with the positioning of the control band, no further additional control devices are therefore necessary.

- the control band is preferably positioned in its first control position with respect to the stationary path such that, as stated in claim 3, the window-like recesses of the control band are arranged congruently with the corresponding recesses of the horizontally running path.

- the recesses of the web and the recesses of the control belt are in the middle of the storage columns of the central sleeve magazine or in the middle of the winding station's own intermediate buffers. This means that in the first control position of the control band, these areas are always free of ferromagnetic material, so that there is a non-magnetizable zone.

- the second control position which is described in claim 4, leads to a continuous ferromagnetic zone in the Area of the horizontal path, since the control band in axially shifted this control position relative to the web is that all the recesses of the web through the control band be completely covered.

- a high resolution Sensor device for example an incremental encoder, has, the sleeve transport carriage on the one hand with high Speed the sleeve receiving positions in the range of central sleeve magazine and / or the sleeve delivery positions move to the winding unit's own sleeve buffers and on the other hand, it is always very quick and very precise be positioned.

- Sleeve gripping device of the sleeve transport carriage from two swiveling gripper arms For example, as two-armed gripper arms formed sleeve handling elements are coupled via a spring steel strip in such a way that the Gripper arms in an unloaded spring steel band in one so-called sleeve receiving position.

- the gripper arms are also in the sense of spring elements "Open" applied (claim 9).

- a permanent magnet package is fixed to the spring steel band, which can be used in conjunction with a ferromagnetic counter pole to deflect the spring steel band and thus to close the sleeve gripping device.

- the endeavor of the permanent magnet package is always to a magnetizable opposite pole, for. B. to use the ferromagnetic track or the ferromagnetic control band, exploited.

- the dimensioning of the spring steel strip connected between the gripper arms and its distance from the horizontally running path is advantageously chosen so that a direct application of the permanent magnet package to the ferromagnetic opposite pole is reliably avoided.

- FIG. 1 a front view of a winder generally identified with the reference number 1 is shown schematically.

- Such winding machines 1 usually have a large number of similar winding stations 4 between their machine end frames 2 and 3.

- the spinning bobbins 22 produced on a ring spinning machine (not shown) are rewound to form large-volume cross-wound bobbins 5.

- the finished cross-wound bobbins 5 are pushed out by means of an automatically operating operating device, for example by means of a cross-wound bobbin changer 6, onto a cross-wound bobbin conveyor belt 7 and transported to a bobbin loading device or the like arranged on the machine end (not shown).

- the one arranged above the work stations 4 so as to be movable Cross-coil changer 6 not only ensures that the on the winding units 4 finished packages 5 on the Cross coil conveyor belt 7 are pushed out, but he also automatically changes a sleeve 8 in each Coil frame of the relevant winding unit 4.

- a total of 11 designated central sleeve magazine consists essentially of a central unit 50, with the central magazine Control device 30 and a vertically movable Gripper slide 16 and one on the central unit 50 removable storage unit 51.

- the Storage unit 51 has several, side by side arranged storage columns 12, 13, 14, 15, which in turn a number of one above the other Series of sleeves, so-called loading chutes, for have conical and / or cylindrical empty sleeves 8.

- the central sleeve magazine 11 is above the vertically movable Gripper slide 16, which, as indicated in Fig. 2, in the area each of the storage columns 12-15 defines one controllable sleeve gripper 17, functional with the Sleeve transport device 10 connected.

- the sleeve transport device 10 consists essentially of a horizontal path 18, one along the path 18 axially displaceable control band 19 and one on the Track 18 movably arranged sleeve transport carriage 20.

- the U-shaped path 18 is made of one ferromagnetic material, for example steel, manufactured and has a plurality of window-like recesses 23.

- the Recesses 23 are each centered on the winding units 4 the winding machine 1 and thus in the center of those arranged there Sleeve buffers 9 and in the middle of the Storage columns 12 - 15 of the central sleeve magazine 11 arranged.

- the control band 19, which is also made of a ferromagnetic Material is made, has similar window-like Recesses 24 on the dimensions of the recesses 23 correspond to track 18.

- the recesses 23, 24 have the same mutual distances. Are preferred the recesses 24 of the control band 19 also from Accident protection reasons, with a grid-like finger protection Mistake.

- the control band 19, which via guide devices 36 is slidably mounted on the track 18 can by a Thrust piston gear 25 between a control position A and a control position B (shown in FIGS. 6 and 7) be moved.

- the connection of the Sleeve transport carriage 20 to the endless traction means 26 thereby via one on the chassis 40 of the sleeve transport carriage 20 arranged connection console 41.

- On the chassis 40 is also a pincer-like sleeve gripping device 21, whose Gripper arms 31, 32 can be pivoted to a limited extent in pivot axes 42 are stored.

- the preferably angled gripper arms 31, 32 are over a Spring steel strip 33 to which a permanent magnet package 35 is attached is connected.

- the gripper arms 31, 32 each spring elements 34 articulated, the gripper arms 31, 32nd act in the sense of "open".

- the winding machine 1 is in an operational state.

- the storage columns 12-15 of the central sleeve magazine 11 are filled with empty sleeves 8.

- the control device 30 is set in accordance with the desired loading program via the input keyboard 43 of the central sleeve magazine 11.

- the sleeve transport carriage 20 then leads first into one 0 position in the area of the electric drive 27 and there by means of a sensor device 29, for example by means of of a high-resolution incremental encoder.

- the gripper carriage 16 moves in the Central unit 50 of the sleeve central magazine 11 the predetermined Sleeve receiving series of the sleeve central magazine 11 (per Storage columns are, for example, eight to ten each Rows of sleeves arranged one above the other).

- One of Sleeve gripper 17 of the gripper carriage 16 takes out of the selected sleeve receiving row an empty tube 8 and passes them to the sleeve gripper device 21 in the meantime above the relevant storage column 12 - 15 des Sleeve central magazine 11 positioned sleeve transport carriage 20th

- the control band 19 is at this time in the Control position A (see Figures 5 and 6), in which the Recesses 23 of the web 18 and the recesses 24 of the Control tape 19 are one above the other. Because of that Sleeve gripping device 21 of the sleeve transport carriage 20 arranged permanent magnet package 35 in the control position A the control band 19 no ferromagnetic counter pole faces, the Permenentmagnetcou35 remains deactivated and the gripper arms 31, 32 by spring elements 34 in the sense "open", remain open. That is, the Sleeve gripping device 21 of the sleeve transport carriage 20 is in the tax position A of the tax band ready for takeover an empty tube 8.

- the control belt 19 in the control position B (see Figure 7) shifted. That means, the control band 19 is axially displaced until the Recesses 23 in the path 18 through the ferromagnetic Control band 19 are completely closed.

- Closing the recesses 23 of the web 18 results in a continuously ferromagnetic, that is to say magnet-activating, zone in the region of the web 18.

- the permanent magnet package 35 of the sleeve transport carriage 20 immediately tries to contact this ferromagnetic opposite pole, so that under the magnetic force of the permanent magnet package 35 the spring steel strip 33 is laid out in the R direction and the gripper arms 31, 32 are pivoted in the S direction.

- the gripper arms 31, 32 pivoting in the direction S fix the empty sleeve 8 between them.

- the tube transport carriage 20 is then immediately conveyed at high speed to the tube buffer 9 of the selected winding unit 4 and positioned there exactly above the tube buffer 9. Subsequently, the control belt 19 is switched back to the control position A, that is, the zone in front of the permanent magnet package 35 of the sleeve transport carriage 20 is made non-magnetizable. The permanent magnet package 35 thereby loses its ferromagnetic opposite pole, so that the gripper arms 31, 32 are pivoted back into a sleeve delivery position under the force of the spring elements 34. The sleeve 8 then falls into the intermediate sleeve store 9 of the winding unit 4 in question.

- the sleeve transport carriage 20 now returns immediately to his Starting position back, that is, it moves to its 0 position in Area of the electric drive 27.

- the newly adjusted Sleeve transport trolley 20 then stands for the next one Sleeve transport process ready.

Landscapes

- Replacing, Conveying, And Pick-Finding For Filamentary Materials (AREA)

- Spinning Or Twisting Of Yarns (AREA)

Description

Die Erfindung betrifft eine Hülsenvorlageeinrichtung für

Kreuzspulen herstellende Textilmaschinen gemäß dem Oberbegriff

des Anspruches 1.The invention relates to a sleeve presentation device for

Textile machines producing cross-wound bobbins according to the generic term

of

Im Zusammenhang mit Kreuzspulen herstellenden Textilmaschinen, beispielsweise Offenend-Spinnmaschinen oder Spulautomaten, sind verschiedene Einrichtungen und Verfahren bekannt, um die zahlreichen Arbeitsstellen dieser Textilmaschinen ausreichend mit Leerhülsen zu versorgen, die diese Textilmaschinen zum Herstellen neuer Auflaufspulen benötigen.In connection with textile machines producing cross-wound bobbins, for example, open-end spinning machines or automatic winding machines various facilities and processes known to the numerous jobs of these textile machines sufficient to supply with empty tubes that these textile machines for Manufacture new take-up spools.

Durch die DE 25 06 417 C2 ist zum Beispiel eine Hülsenvorlageeinrichtung für eine Textilmaschine bekannt, die über eine maschinenlange, kontinuierlich umlaufende Transportkette mit Transporthaken zur Aufnahme von Leerhülsen verfügt. Im Bereich der Arbeitsstellen der Textilmaschine sind schwenkbar gelagerte Zwischenspeicher angeordnet, die in den Transportweg der Transportkette geschwenkt werden können und in dieser Position jeweils eine neue Leerhülse von der Transportkette absteifen, die dann in den Zwischenspeicher fällt.DE 25 06 417 C2, for example, is one Sleeve feed device for a textile machine known over a machine-long, continuously rotating Transport chain with transport hook for receiving empty tubes features. In the area of workplaces of the textile machine are pivoted intermediate storage arranged in the Transport path of the transport chain can be pivoted and in this position a new empty tube from the Stiffen the transport chain, which is then stored in the buffer falls.

Bei Bedarf entnimmt ein die Arbeitsstellen bedienender Kreuzspulenwechsler die Leerhülse aus dem Zwischenspeicher und wechselt sie in die Spulenrahmen der betreffenden Spulstelle ein. Anschließend wird der Zwischenspeicher wieder in seiner Leerhülsenaufnahmestellung im Bereich des Transportweges der Transportkette positioniert und dort erneut mit einer Leerhülse gefüllt. If necessary, a person taking care of the workplaces Cross coil changer the empty tube from the buffer and it changes into the bobbin frame of the winding unit concerned on. Then the clipboard is back in its Empty sleeve receiving position in the area of the transport route of the Transport chain positioned and there again with an empty sleeve filled.

Die vorbeschriebene Einrichtung hat sich, insbesonders bei Mehrpartienbelegung der Textilmaschinen, als nicht geeignet erwiesen und konnte sich daher in der Praxis nicht durchsetzen.The facility described above has, especially at Multi-lot allocation of the textile machines, as not suitable proven and could therefore not prevail in practice.

Durch die EP 0 262 726 A2 und die DE 195 29 566 A1 sind Einrichtungen Stand der Technik, bei denen die Arbeitsstellen einer Kreuzspulen herstellenden Textilmaschine über ein maschinenlanges Hülsentransportband mit einem maschinenendseitig angeordneten, zentralen Hülsenmagazin verbunden sind. Im Falle eines Kreuzspulenwechsels positioniert sich ein Bedienaggregat an der betreffenden Spulstelle und wechselt die fertiggestellte Kreuzspule gegen eine vorher angeforderte und über das Hülsentransportband angelieferte Leerhülse aus. Die verfahrbaren Bedienaggregate dieser Textilmaschinen weisen dabei Handhabungseinrichtungen auf, mit denen sie die Leerhülse von der Transportbahn aufnehmen und in den Spulenrahmen der Spulstelle einlegen können.Through EP 0 262 726 A2 and DE 195 29 566 A1 State of the art facilities at which the jobs a textile machine producing cross-wound bobbins machine-long sleeve conveyor belt with one central sleeve magazine arranged on the machine end are connected. Positioned in the event of a package change a control unit at the winding unit concerned and the completed bobbin is replaced by a previously requested and delivered via the sleeve conveyor belt Empty sleeve. The movable control units of this Textile machines have handling devices with which they pick up the empty tube from the transport track and in can insert the bobbin frame of the winding unit.

Nachteilig bei diesen bekannten Einrichtungen ist vor allem, daß der an der Arbeitsstelle positionierte Kreuzspulenwechsler zunächst die Ankunft einer angeforderten Leerhülse abwarten muß. Die dabei auftretenden Wartezeiten wirken sich negativ auf den Gesamtwirkungsgrad dieser Textilmaschinen aus.A disadvantage of these known devices is, above all, that the package changer positioned at the place of work first wait for the arrival of a requested empty tube got to. The waiting times that occur have a negative effect the overall efficiency of these textile machines.

Um diese Wartezeiten zu vermeiden, ist in der Vergangenheit bereits vorgeschlagen worden, im Bereich der Arbeitsstellen Zwischenspeicher vorzusehen, die über das Hülsentransportband mit Leerhülsen versorgt werden. Aus diesen Zwischenspeichern kann der Kreuzspulenwechsler dann jederzeit eine Leerhülse entnehmen und sofort in den Spulenrahmen einwechseln.To avoid these waiting times is in the past already been proposed in the field of jobs To provide temporary storage over the sleeve conveyor belt be supplied with empty tubes. From these caches the package changer can then always have an empty tube remove and replace immediately in the coil frame.

In der DE 195 12 891 A1 oder der DE 195 21 372 A1 sind ebenfalls Einrichtungen beschrieben, bei denen die Textilmaschinen über ein maschinenendseitig angeordnetes, zentrales Hülsenmagazin verfügen. Das Hülsenmagazin ist dabei, wie bekannt, über ein maschinenlanges Hülsentransportband mit den arbeitsstelleneigenen Zwischenspeichern verbunden.In DE 195 12 891 A1 or DE 195 21 372 A1 also described facilities where the Textile machines via a machine end central sleeve magazine. The sleeve magazine is about as is known, with a machine-long sleeve conveyor belt connected to the job-specific temporary storage.

Die Kreuzspulenwechsler dieser Textilmaschinen weisen sowohl

einen Handhabungsmechanismus zum Überführen der Leerhülsen vom

Hülsentransportband in die Zwischenspeicher als auch eine

Handhabungseinrichtung zum Aufnehmen und Einwechseln der in den

Zwischenspeichern deponierten Leerhülsen in den Spulenrahmen

der betreffenden Spulstellen auf.

Bei diesen bekannten Einrichtungen wird zu Beginn des

Kreuzspulenwechselvorganges durch das Bedienaggregat sofort

eine neue Leerhülse angefordert, die das Bedienaggregat, bevor

es die Spulstelle wieder verläßt, in den Zwischenspeicher der

Spulstelle überführt.The cross-wound bobbin changers of these textile machines have both a handling mechanism for transferring the empty tubes from the tube conveyor belt into the intermediate store and a handling device for receiving and changing the empty tubes deposited in the intermediate stores in the bobbin frame of the relevant winding units.

In these known devices, a new empty tube is immediately requested by the operating unit at the beginning of the package change process, which transfers the operating unit to the intermediate storage unit of the winding unit before it leaves the winding unit.

Ausgehend vom vorgenannten Stand der Technik liegt der Erfindung die Aufgabe zugrunde, eine verbesserte Hülsenvorlageeinrichtung zu schaffen, d.h. eine Hülsenvorlageeinrichtung, bei der die Übergabe von Leerhülsen vom Hülsenzentralmagazin zu den Hülsenzwischenspeichern auf eine alternative Weise bewerkstelligt wird.Based on the aforementioned prior art, the Invention based on the object, an improved To create sleeve feed means, i.e. a Tube feed device, in which the transfer of empty tubes from the central sleeve magazine to the intermediate sleeve stores an alternative way is accomplished.

Diese Aufgabe wird erfindungsgemäß durch eine Einrichtung

gelöst, wie sie im Anspruch 1 beschrieben ist.This object is achieved by a device

solved, as described in

Vorteilhafte Ausgestaltungen der Erfindung sind Gegenstand der Unteransprüche.Advantageous embodiments of the invention are the subject of Dependent claims.

Die erfindungsgemäße Ausführungsform hat dabei den Vorteil, daß die Hülsenvorlageeinrichtung, die im wesentlichen aus einer stationären, horizontal verlaufenden, fensterartige Ausnehmungen aufweisenden Bahn, einem entlang dieser Bahn verschiebbar gelagerten, ebenfalls fensterartige Ausnehmungen besitzenden Steuerband sowie einem an der Bahn verfahrbaren Hülsentransportwagen besteht, wobei sowohl die horizontal verlaufende Bahn als auch das Steuerband aus einem ferromagnetischen Werkstoff, vorzugsweise Stahl, gefertigt sind, nur wenige, relativ robuste Bauteile aufweist. Eine solche Ausbildung läßt nicht nur eine hohe Lebensdauer der Einrichtung erwarten, sondern führt auch zu einem guten Preis-/Leistungsverhältnis der Einrichtung.The embodiment of the invention has the advantage that the sleeve feed device, which consists essentially of a stationary, horizontal, window-like Recessing path, one along this path slidably mounted, also window-like recesses possessing control band as well as a movable on the train Sleeve transport trolley exists, both the horizontal running web as well as the control band from one ferromagnetic material, preferably steel are, has only a few, relatively robust components. A such training not only leaves a long life Expect establishment, but also leads to a good one Price / performance ratio of the facility.

Die erfindungsgemäße Hülsenvorlageeinrichtung zeichnet sich aufgrund ihres konstruktiven Aufbaues außerdem durch eine hohe Funktionalität und eine gute Verfügbarkeit aus. Insbesondere die Art der Ansteuerung der am Hülsentransportwagen angeordneten Hülsengreifeinrichtung hat sich als sehr zuverlässig und nahezu verschleißfrei erwiesen.The sleeve feed device according to the invention stands out due to their constructive structure also by a high Functionality and good availability. In particular the type of control on the sleeve transport trolley arranged sleeve gripping device has proven to be very proven reliable and almost wear-free.

Ein weiterer Vorteil der Einrichtung ist darin zu sehen, daß jederzeit und nahezu problemlos auch eine Nachrüstung bereits ausgelieferter Textilmaschinen mit der erfindungsgemäßen Hülsenvorlageeinrichtung möglich ist.Another advantage of the facility is that Retrofitting at any time and almost without any problems delivered textile machines with the invention Sleeve feed device is possible.

Die Bahn und das Steuerband weisen dabei, wie vorstehend

bereits angedeutet, eine Vielzahl von fensterartigen

Ausnehmungen auf, deren Abmeßungen und Abstände jeweils

übereinstimmen. Die Positionen der in der stationären Bahn

angeordneten Ausnehmungen ergeben sich dabei aus der

Spulstellenteilung der Textilmaschine, wobei diese

Spulstellenteilung auch die Teilung der Speicherkolumnen des

Hülsenzentralmagazins bestimmt.

Eine solche Ausführungsform ermöglicht es auf einfache und

vorteilhafte Weise, sowohl im Bereich der spulstelleneigenen

Zwischenspeicher als auch im Bereich der Speicherkolumnen des

zentralen Hülsenmagazins jederzeit magnetisierbare oder

nichtmagnetisierbare Zonen zu schaffen, die in Verbindung mit

einer entsprechenden, am Hülsentransportwagen angeordneten

Permanentmagnetpaketanordnung für einen Steuerungsvorgang der

Hülsengreifeinrichtung dieses Transportmittels benutzt werden

können. Das heißt, durch entsprechende Positionierung der

Ausnehmungen des entlang der Bahn verschiebbar gelagerten

Steuerbandes kann im Bedarfsfall ein am Hülsentransportwagen

angeordnetes Permanentmagnetpaket aktiviert und damit die

Hülsengreifeinrichtung des Hülsentransportwagens zuverlässig

und schnell betätigt werden.As already indicated above, the web and the control band have a large number of window-like recesses, the dimensions and spacings of which correspond. The positions of the recesses arranged in the stationary path result from the winding position division of the textile machine, this winding position division also determining the division of the storage columns of the central sleeve magazine.

Such an embodiment makes it possible, in a simple and advantageous manner, to create magnetizable or non-magnetizable zones at any time both in the area of the bobbin-specific buffer stores and in the area of the storage columns of the central sleeve magazine, which zones in connection with a corresponding permanent magnet package arrangement arranged on the sleeve transport carriage for a control process of the sleeve gripping device this means of transport can be used. That is, by appropriately positioning the recesses of the control belt slidably mounted along the track, a permanent magnet package arranged on the sleeve transport carriage can be activated if necessary, and the sleeve gripping device of the sleeve transport carriage can thus be actuated reliably and quickly.

Das Steuerband ist dabei, wie im Anspruch 2 beschrieben, an ein

Schubkolbengetriebe angeschlossen, das, wie üblich, zwei

definierte Endstellungen aufweist. Die Endstellungen des

Schubkolbengetriebes entsprechen dabei jeweils einer ersten

beziehungsweise zweiten Steuerstellung des Steuerbandes.

Im Zusammenhang mit der Positionierung des Steuerbandes sind

daher keine weiteren zusätzlichen Steuereinrichtungen mehr

nötig.The control belt is, as described in

In connection with the positioning of the control band, no further additional control devices are therefore necessary.

Vorzugsweise ist das Steuerband in seiner ersten Steuerstellung

bezüglich der stationären Bahn derart positioniert, daß, wie im

Anspruch 3 dargelegt, die fensterartigen Ausnehmungen des

Steuerbandes deckungsgleich mit den entsprechenden Ausnehmungen

der horizontal verlaufenden Bahn angeordnet sind.

Die Ausnehmungen der Bahn und die Ausnehmungen des Steuerbandes

stehen dabei mittig zu den Speicherkolumnen des

Hülsenzentralmagazins bzw. mittig zu den spulstelleneigenen

Hülsenzwischenspeichern. Das heißt, in der ersten

Steuerstellung des Steuerbandes sind diese Bereiche stets frei

von ferromagnetischem Werkstoff, so daß dort eine

nichtmagnetisierbare Zone gegeben ist. The control band is preferably positioned in its first control position with respect to the stationary path such that, as stated in

The recesses of the web and the recesses of the control belt are in the middle of the storage columns of the central sleeve magazine or in the middle of the winding station's own intermediate buffers. This means that in the first control position of the control band, these areas are always free of ferromagnetic material, so that there is a non-magnetizable zone.

Die zweite Steuerstellung, die im Anspruch 4 beschrieben ist,

führt hingegen zu einer durchgängig ferromagnetischen Zone im

Bereich der horizontal verlaufenden Bahn, da das Steuerband in

dieser Steuerstellung gegenüber der Bahn derart axial verlagert

ist, daß alle Ausnehmungen der Bahn durch das Steuerband

vollständig abgedeckt werden.The second control position, which is described in

In vorteilhafter Ausbildung ist der an der Bahn verfahrbar

angeordnete Hülsentransportwagen, der eine magnetisch

aktivierbare Hülsengreifeinrichtung aufweist, über ein

Zugmittel, gemäß Anspruch 6 einen Endlos-Zahnriemen, mit einem

reversierbaren Elektro-Antrieb verbunden (Anspruch 5).In an advantageous embodiment, it can be moved on the track

arranged sleeve transport carriage, one of which is magnetic

has activatable sleeve gripping device, via a

Traction means, according to

Da der Endlos-Zahnriemen formschlüssig auf einem Antriebsritzel

des Elektro-Antriebes geführt ist und die Antriebseinrichtung

außerdem, wie im Anspruch 7 dargelegt, eine hoch auflösende

Sensoreinrichtung, beispielsweise einen Inkrementalgeber,

aufweist, kann der Hülsentransportwagen einerseits mit hoher

Geschwindigkeit die Hülsenaufnahmestellungen im Bereich des

zentralen Hülsenmagazins und/oder die Hülsenabgabestellungen an

den spulstelleneigenen Hülsenzwischenspeichern anfahren und

anderseits dort dennoch stets sehr schnell und sehr exakt

positioniert werden.Because the endless toothed belt fits positively on a drive pinion

of the electric drive and the drive device

moreover, as set out in

In bevorzugter Ausbildung (Anspruch 8) besteht die Hülsengreifeinrichtung des Hülsentransportwagens aus zwei schwenkbar gelagerten Greiferarmen. Die beispielsweise als zweiarmige Greiferarme ausgebildeten Hülsenhandhabungselemente sind dabei über ein Federstahlband derart gekoppelt, daß die Greiferarme bei unbelastetem Federstahlband in einer sogenannten Hülsenaufnahmestellung stehen. Die Greiferarme werden dabei außerdem durch Federelemente zusätzlich im Sinne "öffnen" beaufschlagt (Anspruch 9). In a preferred embodiment (claim 8) Sleeve gripping device of the sleeve transport carriage from two swiveling gripper arms. For example, as two-armed gripper arms formed sleeve handling elements are coupled via a spring steel strip in such a way that the Gripper arms in an unloaded spring steel band in one so-called sleeve receiving position. The gripper arms are also in the sense of spring elements "Open" applied (claim 9).

Wie im Anspruch 10 beschrieben, ist am Federstahlband ein

Permanentmagnetpaket festgelegt, das in Verbindung mit einem

ferromagnetischen Gegenpol zur Auslenkung des Federstahlbandes

und damit zum Schließen der Hülsengreifeinrichtung benutzt

werden kann. Das heißt, durch magnetisch initiiertes seitliches

Auslenken des Federstahlbandes können die Greiferarme

zuverlässig in eine Schließstellung, in der eine zwischen den

Greiferarmen positionierte Leerhülse sicher fixiert ist,

überführt werden. Dabei wird das Bestreben des

Permanentmagnetpakets, sich stets an einen magnetisierbaren

Gegenpol, z. B. die ferromagnetische Bahn oder das ebenfalls

ferromagnetische Steuerband anzulegen, ausgenutzt.

Die Dimensionierung des zwischen die Greiferarme

eingeschalteten Federstahlbandes sowie dessen Abstand zur

horizontal verlaufenden Bahn ist dabei vorteilhafterweise so

gewählt, daß ein direktes Anlegen des Permanentmagnetpaketes an

den ferromagnetischen Gegenpol zuverlässig vermieden wird.As described in

The dimensioning of the spring steel strip connected between the gripper arms and its distance from the horizontally running path is advantageously chosen so that a direct application of the permanent magnet package to the ferromagnetic opposite pole is reliably avoided.

Weitere Einzelheiten der Erfindung sind einem nachfolgend anhand der Zeichnungen erläuterten Ausführungsbeispiel entnehmbar.Further details of the invention are as follows exemplary embodiment explained with reference to the drawings removable.

Es zeigt:

- Fig. 1

- eine Vorderansicht auf eine Kreuzspulen herstellende Textilmaschine, mit einer erfindungsgemäßen Hülsenvorlageeinrichtung,

- Fig. 2

- die Einrichtung gemäß

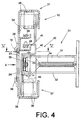

Figur 1, in Draufsicht, - Fig. 3

- eine Seitenansicht einer Arbeitsstelle, der in den

Figuren 1 und 2 dargestellten Textilmaschine, - Fig. 4

- eine Seitenansicht auf eine horizontal verlaufende

Bahn mit einem verschiebbar gelagerten Steuerband

sowie einen Hülsentransportwagen, gemäß

Schnitt IV-IV der

Figur 5, - Fig. 5

- eine Draufsicht auf einen Hülsentransportwagen,

gemäß Schnitt V-V der

Figur 4, - Fig. 6

- die horizontal verlaufende Bahn mit einem in Steuerstellung A positionierten Steuerband, gemäß Blickrichtung X der Fig.4,

- Fig. 7

- die Bahn mit einem in Steuerstellung B positionierten Steuerband, ebenfalls gemäß Blickrichtung X der Fig.4,

- Fig. 1

- 2 shows a front view of a textile machine producing cross-wound bobbins, with a tube feed device according to the invention,

- Fig. 2

- the device according to Figure 1, in plan view,

- Fig. 3

- 2 shows a side view of a work station of the textile machine shown in FIGS. 1 and 2,

- Fig. 4

- 3 shows a side view of a horizontally running web with a displaceably mounted control belt and a sleeve transport carriage, according to section IV-IV of FIG. 5,

- Fig. 5

- 3 shows a plan view of a sleeve transport wagon, according to section VV of FIG. 4,

- Fig. 6

- the horizontally running web with a control belt positioned in control position A, in the viewing direction X of FIG. 4,

- Fig. 7

- the web with a control belt positioned in control position B, likewise in the viewing direction X of FIG. 4,

In Fig. 1 ist in Vorderansicht schematisch eine insgesamt mit

der Bezugszahl 1 gekennzeichnete Spulmaschine dargestellt.

Derartige Spulmaschinen 1 weisen üblicherweise zwischen ihren

Maschinenendgestellen 2 und 3 eine Vielzahl gleichartiger

Spulstellen 4 auf. Auf diesen Spulstellen 4 werden, wie bekannt

und daher nicht näher erläutert, die auf einer (nicht

dargestellten) Ringspinnmaschine produzierten Spinnkopse 22 zu

großvolumigen Kreuzspulen 5 umgespult.

Die fertiggestellten Kreuzspulen 5 werden mittels einer

selbsttätig arbeitenden Bedienvorrichtung, zum Beispiel mittels

eines Kreuzspulenwechslers 6, auf ein

Kreuzspulentransportband 7 ausgeschoben und zu einer

maschinenendseitig angeordneten (nicht dargestellten)

Spulenverladeeinrichtung oder dergleichen transportiert.In Fig. 1 a front view of a winder generally identified with the

The finished

Der oberhalb der Arbeitsstellen 4 verfahrbar angeordnete

Kreuzspulenwechsler 6 sorgt dabei nicht nur dafür, daß die auf

den Spulstellen 4 fertiggestellten Kreuzspulen 5 auf das

Kreuzspulentransportband 7 ausgeschoben werden, sondern er

wechselt auch jeweils selbsttätig eine Hülse 8 in den

Spulenrahmen der betreffenden Spulstelle 4 ein. Die

entsprechende Hülse 8 entnimmt er dabei einem

spulstelleneigenen Hülsenzwischenspeicher 9, der über eine

maschinenlange Transporteinrichtung 10 mit einem

maschinenendseitig angeordneten Hülsenzentralmagazin 11 der

Spulmaschine 1 verbunden ist.The one arranged above the

Das in den Figuren 1 und 2 angedeutete, insgesamt mit 11

bezeichnete Hülsenzentralmagazin besteht im wesentlichen aus

einer Zentraleinheit 50, mit der zentralmagazineigenen

Steuereinrichtung 30 und einem vertikal verfahrbaren

Greiferschlitten 16 sowie einer an der Zentraleinheit 50

auswechselbar festgelegten Speichereinheit 51. Die

Speichereinheit 51 weist dabei mehrere, nebeneinander

angeordnete Speicherkolumnen 12, 13, 14, 15 auf, die ihrerseits

jeweils eine Anzahl übereinander angeordneter

Hülsenaufnahmereihen, sogenannte Beschickungsschächte, für

konische und/oder zylindrische Leerhülsen 8 aufweisen.The indicated in Figures 1 and 2, a total of 11

designated central sleeve magazine consists essentially of

a

Das Hülsenzentralmagazin 11 ist über den vertikal verfahrbaren

Greiferschlitten 16, der, wie in Fig. 2 angedeutet, im Bereich

der Speicherkolumnen 12 - 15 jeweils einen definiert

ansteuerbaren Hülsengreifer 17 aufweist, funktional mit der

Hülsentransporteinrichtung 10 verbunden.The

Die Hülsentransporteinrichtung 10 besteht im wesentlichen aus

einer horizontal verlaufenden Bahn 18, einem entlang der Bahn

18 axial verschiebbaren Steuerband 19 sowie einem an der

Bahn 18 verfahrbar angeordneten Hülsentransportwagen 20.The

Die U-förmig ausgebildete Bahn 18 ist aus einem

ferromagnetischen Werkstoff, zum Beispiel Stahl, gefertigt und

weist eine Vielzahl fensterartiger Ausnehmungen 23 auf. Die

Ausnehmungen 23 sind dabei jeweils mittig zu den Spulstellen 4

der Spulmaschine 1 und damit mittig zu den dort angeordneten

Hülsenzwischenspeichern 9 sowie mittig zu den

Speicherkolumnen 12 - 15 des Hülsenzentralmagazins 11

angeordnet.The

Das Steuerband 19, das ebenfalls aus einem ferromagnetischen

Material gefertigt ist, weist ähnliche fensterartige

Ausnehmungen 24 auf, die in ihren Abmeßungen den Ausnehmungen

23 der Bahn 18 entsprechen. Die Ausnehmungen 23, 24 besitzen

dabei die gleichen gegenseitigen Abstände. Vorzugsweise sind

die Ausnehmungen 24 des Steuerbandes 19 außerdem, aus

Unfallschutzgründen, mit einem gitterartigen Fingerschutz

versehen. Das Steuerband 19, das über Führungseinrichtungen 36

an der Bahn 18 verschiebbar gelagert ist, kann durch ein

Schubkolbengetriebe 25 zwischen einer Steuerstellung A und

einer Steuerstellung B (in den Figuren 6 und 7 dargestellt)

verschoben werden.The

Der Hülsentransportwagen 20, der ein Fahrwerk 37, dessen

Räder 38 sich am Innenprofil 39 der Horizontalbahn 18

abstützen, aufweist, ist über ein Zugmittel 26, vorzugsweise

einen Endlos-Zahnriemen, an einen reversierbaren

Elektro-Antrieb 27 angeschlossen. Die Anbindung des

Hülsentransportwagens 20 an das Endlos-Zugmittel 26 erfolgt

dabei über eine am Fahrgestell 40 des Hülsentransportwagens 20

angeordnete Anschlußkonsole 41. Am Fahrwerk 40 ist außerdem

eine zangenartige Hülsengreifeinrichtung 21 festgelegt, deren

Greiferarme 31, 32 in Schwenkachsen 42 begrenzt schwenkbar

gelagert sind.The

Die vorzugsweise abgewinkelten Greiferarme 31, 32 sind über ein

Federstahlband 33, an dem ein Permanentmagnetpaket 35 befestigt

ist, verbunden. Außerdem sind an den Greiferarmen 31, 32

jeweils Federelemente 34 angelenkt, die die Greiferarme 31, 32

im Sinne "öffnen" beaufschlagen.The preferably angled

Die Spulmaschine 1 befindet sich in einem betriebsbereitem

Zustand.

Die Speicherkolumnen 12 - 15 des Hülsenzentralmagazins 11 sind

mit Leerhülsen 8 gefüllt.

Über die Eingabetastatur 43 des Hülsenzentralmagazins 11 wird

die Steuereinrichtung 30 entsprechend dem gewünschten

Beschickungsprogramm eingestellt.The winding

The storage columns 12-15 of the

The

Der Hülsentransportwagen 20 führt daraufhin zunächst in eine

0-Stellung im Bereich des Elektroantriebes 27 und wird dort

mittels einer Sensoreinrichtung 29, beispielsweise mittels

eines hoch auflösenden Inkrementalgebers, einjustiert.

Gleichzeitig fährt der Greiferschlitten 16 in der

Zentraleinheit 50 des Hülsenzentralmagazins 11 die vorbestimmte

Hülsenaufnahmereihe des Hülsenzentralmagazins 11 an (pro

Speicherkolumne sind beispielsweise jeweils acht bis zehn

Hülsenaufnahmereihen übereinander angeordnet). Einer der

Hülsengreifer 17 des Greiferschlittens 16 nimmt aus der

ausgewählten Hülsenaufnahmereihe eine Leerhülse 8 und übergibt

sie an die Hülsengreifereinrichtung 21 des inzwischen oberhalb

der betreffenden Speicherkolumne 12 - 15 des

Hülsenzentralmagazins 11 positionierten Hülsentransportwagens

20.The

Das Steuerband 19 steht zu diesem Zeitpunkt in der

Steuerstellung A (siehe Figuren 5 und 6), in der die

Ausnehmungen 23 der Bahn 18 und die Ausnehmungen 24 des

Steuerbandes 19 übereinanderstehen. Da dem an der

Hülsengreifeinrichtung 21 des Hülsentransportwagens 20

angeordneten Permanentmagnetpaket 35 in der Steuerstellung A

des Steuerbandes 19 kein ferromagnetischer Gegenpol

gegenübersteht, bleibt das Permenentmagnetpaket 35 deaktiviert

und die Greiferarme 31, 32, die durch Federelemente 34 im Sinne

"öffnen" beaufschlagt werden, bleiben geöffnet. Das heißt, die

Hülsengreifeinrichtung 21 des Hülsentransportwagens 20 ist in

der Steuerstellung A des Steuerbandes bereit zur Übernahme

einer Leerhülse 8.The

Sobald der betreffende Hülsengreifer 17 des

Greiferschlittens 16 die aus einer Hülsenaufnahmereihe einer

der Speicherkolumnen 12 - 15 abgeholte Hülse 8 zwischen den

Greiferarmen 31, 32 der Hülsengreifeinrichtung 21 des

Transportwagens 20 positioniert hat, wird das Steuerband 19 in

die Steuerstellung B (siehe Figur 7) verlagert. Das bedeutet,

das Steuerbandes 19 wird so weit axial verschoben bis die

Ausnehmungen 23 in der Bahn 18 durch das ferromagnetische

Steuerband 19 vollständig geschlossen sind.As soon as the

Durch das Schließen der Ausnehmungen 23 der Bahn 18 ergibt sich

im Bereich der Bahn 18 eine durchgehend ferromagnetische, das

heißt, magnetaktivierende Zone.

Das Permanentmagnetpaket 35 des Hülsentransportwagens 20

versucht sofort sich an diesen ferromagnetischer Gegenpol

anzulegen, so daß unter der Magnetkraft des

Permanentmagnetpaketes 35 das Federstahlband 33 in Richtung R

ausgelegt wird und die Greiferarme 31, 32 in Richtung S

verschwenkt werden. Die in Richtung S einschwenkenden

Greiferarme 31, 32 fixieren dabei die Leerhülse 8 zwischen

sich.Closing the

The

Ders Hülsentransportwagen 20 wird anschließend sofort mit hoher

Geschwindigkeit zum Hülsenzwischenspeicher 9 der ausgewählten

Spulstelle 4 befördert und dort exakt oberhalb des

Hülsenzwischenspeichers 9 positioniert. Im Anschluß daran wird

das Steuerband 19 in die Steuerstellung A zurückgeschaltet, das

heißt, die Zone vor dem Permanentmagnetpaket 35 des

Hülsentransportwagens 20 wird nichtmagnetisierbar gemacht.

Das Permanetmagnetpaket 35 verliert dadurch seinen

ferromagnetischen Gegenpol, so daß die Greiferarme 31, 32 unter

der Kraft der Federelemente 34 in eine Hülsenabgabestellung

zurückgeschwenkt werden. Die Hülse 8 fällt daraufhin in den

Hülsenzwischenspeicher 9 der betreffenden Spulstelle 4.The

The

Der Hülsentransportwagen 20 kehrt jetzt unmittelbar in seine

Ausgangslage zurück, das heißt, er fährt in seine 0-Position im

Bereich des Elektro-Antriebes 27. Der neu justierte

Hülsentransportwagen 20 steht anschließend für den nächsten

Hülsentransportvorgang bereit.The

Claims (10)

- Tube feeding device for textile machines producing cross-wound bobbins, comprising a central tube magazine (11) arranged on the machine end-side, workstation-specific intermediate tube stores (9) and a conveying device (10) for distributing the empty tubes (8) to the workstation-specific intermediate tube stores (9), the conveying device (10) having a horizontally extending track (18) the length of the machine, characterised in thata control strip (19) is displaceably mounted along the track (18),the track (18) and the control strip (19) are each equipped with a plurality of corresponding, window-like recesses (23, 24),guided on the track (18) is a tube conveying carriage (20) which can be displaced between a central tube magazine (11) and the intermediate tube stores (9) and has a magnetically activatable tube gripper device (21),the tube gripper device (21) of the tube conveying carriage (20) can be controlled in a defined manner by adjusting the control strip (19) andboth the horizontally extending track (18) and the control strip (19) are produced from a ferromagnetic material.

- Tube feeding device according to claim 1, characterised in that the control strip (19) can be displaced in a defined manner between a first (A) or a second (B) control position by a thrust piston drive (25).

- Tube feeding device according to any one of the preceding claims, characterised in that in the first control position (A) of the control strip (19) the recesses (24) thereof are positioned congruently with the corresponding recesses (23) of the stationary track (18).

- Tube feeding device according to any one of the preceding claims, characterised in that in a second control position (B) of the control strip (19) all the recesses (23) of the stationary track (18) are covered.

- Tube feeding device according to any one of the preceding claims, characterised in that the tube conveying carriage (20) is connected to a reversible electric drive (27) via a traction means (26).

- Tube feeding device according to claim 5, characterised in that an endless toothed belt guided with interlocking fit via a corresponding drive pinion (28) of the electric drive (27) is used as the traction means (26).

- Tube feeding device according to any one of the preceding claims, characterised in that a high-resolution sensor device (29) is provided allowing monitoring of the respective position of the tube conveying carriage (20).

- Tube feeding device according to any one of the preceding claims, characterised in that the tube gripper device (21) has two pivotally mounted gripper arms (31, 32) coupled by a spring steel strip (33).

- Tube feeding device according to any one of the preceding claims, characterised in that a permanent magnet package (35) is fixed to the spring steel strip (33).

- Tube feeding device according to any one of the preceding claims, characterised in that spring elements (34) loading the gripper arms (31, 32) in the "open" direction are arranged on the gripper arms (31, 32).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19750836 | 1997-11-17 | ||

| DE19750836A DE19750836A1 (en) | 1997-11-17 | 1997-11-17 | Sleeve feed device for textile machines producing cross-wound bobbins |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0916613A2 EP0916613A2 (en) | 1999-05-19 |

| EP0916613A3 EP0916613A3 (en) | 2000-09-13 |

| EP0916613B1 true EP0916613B1 (en) | 2003-05-21 |

Family

ID=7848949

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98118041A Expired - Lifetime EP0916613B1 (en) | 1997-11-17 | 1998-09-23 | Tube supplying apparatus for textile machines for making cross-wound bobbins |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6012671A (en) |

| EP (1) | EP0916613B1 (en) |

| JP (1) | JPH11209002A (en) |

| DE (2) | DE19750836A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CZ302884B6 (en) * | 2007-03-22 | 2012-01-04 | Rieter Cz S.R.O. | Yarn distribution device on textile machines |

| CZ303337B6 (en) * | 2011-08-25 | 2012-08-01 | VÚTS, a.s. | Device for distributing yarn wound onto a bobbin |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10050693A1 (en) * | 2000-10-13 | 2002-04-18 | Schlafhorst & Co W | Sleeve feeder for a work station of a textile machine producing cross-wound bobbins |

| CN101153647B (en) * | 2007-10-19 | 2010-04-21 | 周建平 | Magnetic power head transmission device of rewinder |

| EP2362241A1 (en) | 2010-02-25 | 2011-08-31 | Leica Geosystems AG | Electromagnetic proximity detection Method and Unit |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE262726C (en) * | ||||

| DE2427016C2 (en) * | 1974-06-04 | 1983-11-10 | Barmag Barmer Maschinenfabrik Ag, 5630 Remscheid | Automatic bobbin changing device |

| DE2506417C2 (en) * | 1975-02-15 | 1986-09-11 | W. Schlafhorst & Co, 4050 Mönchengladbach | Method and device for feeding an empty bobbin tube from a continuous conveyor to a winding station of a textile machine |

| JPS58216871A (en) * | 1982-05-21 | 1983-12-16 | Murata Mach Ltd | Paper pipe supply system |

| GB2140553B (en) * | 1983-05-24 | 1988-03-23 | Rieter Ag Maschf | Automat location system |

| IT1202589B (en) * | 1987-02-27 | 1989-02-09 | Savio Spa | DEVICE AND PROCEDURE FOR THE AUTROMATIC REMOVAL OF THE SPOOLS IN A WINDING MACHINE |

| DE3719091A1 (en) * | 1987-06-06 | 1988-12-22 | Mayer Fa Karl | WINDING MACHINE WITH SEVERAL REELS |

| EP0450661B1 (en) * | 1988-09-24 | 1995-05-17 | Maschinenfabrik Rieter Ag | Spinning machine |

| MY107925A (en) * | 1990-08-31 | 1996-06-29 | Teijin Seiki Co Ltd | An automatic bobbin changing apparatus of a winding machine. |

| DE4217575A1 (en) * | 1991-05-28 | 1992-12-03 | Murata Machinery Ltd | COIL REPLACEMENT METHOD AND PAPPULULE FEEDING DEVICE FOR AN AUTOMATIC WINDING MACHINE |

| DE4418339A1 (en) * | 1994-05-26 | 1995-11-30 | Schlafhorst & Co W | Crossed=spool textile machine |

| JP3203961B2 (en) * | 1994-06-13 | 2001-09-04 | 村田機械株式会社 | Tube supply device for winder winding |

| CZ283034B6 (en) * | 1994-08-24 | 1997-12-17 | Maschinenfabrik Rieter Ag | Process and apparatus for supplying winding devices of textile machine with empty tubes |

| DE19512891A1 (en) * | 1995-04-06 | 1996-10-10 | Schlafhorst & Co W | Multi-station textile cone winder promptly supplying tubes by belt from central magazine |

-

1997

- 1997-11-17 DE DE19750836A patent/DE19750836A1/en not_active Withdrawn

-

1998

- 1998-09-23 EP EP98118041A patent/EP0916613B1/en not_active Expired - Lifetime

- 1998-09-23 DE DE59808429T patent/DE59808429D1/en not_active Expired - Fee Related

- 1998-10-16 US US09/173,765 patent/US6012671A/en not_active Expired - Fee Related

- 1998-11-13 JP JP10323705A patent/JPH11209002A/en active Pending

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CZ302884B6 (en) * | 2007-03-22 | 2012-01-04 | Rieter Cz S.R.O. | Yarn distribution device on textile machines |

| CZ303337B6 (en) * | 2011-08-25 | 2012-08-01 | VÚTS, a.s. | Device for distributing yarn wound onto a bobbin |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59808429D1 (en) | 2003-06-26 |

| EP0916613A2 (en) | 1999-05-19 |

| US6012671A (en) | 2000-01-11 |

| JPH11209002A (en) | 1999-08-03 |

| DE19750836A1 (en) | 1999-05-20 |

| EP0916613A3 (en) | 2000-09-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3431790C2 (en) | ||

| EP0274626B1 (en) | Apparatus for transporting bobbins to or from multiple spinning machines or twisting machines | |

| EP0916614B1 (en) | Tube magazine for a textile machine producing crosswound bobbins | |

| DE102007036696A1 (en) | Rotatable coupling consists of coupling body with ceiling hook and suspension hook for holding light | |

| DE4338552A1 (en) | Transport system for economic, flexible handling of yarn spools | |

| DE4418339A1 (en) | Crossed=spool textile machine | |

| DE3536869C2 (en) | ||

| DE3742220C2 (en) | Method and device for removing pre-wound packages | |

| EP0916613B1 (en) | Tube supplying apparatus for textile machines for making cross-wound bobbins | |

| DE3440598A1 (en) | Spinning machine with a multiplicity of spinning units arranged alongside one another | |

| DE3435951A1 (en) | TEXTILE MACHINE FOR MAKING CROSS COILS | |

| DE10050693A1 (en) | Sleeve feeder for a work station of a textile machine producing cross-wound bobbins | |

| DE19524946B4 (en) | Cheese making textile machine | |

| EP0379600B1 (en) | Double-sided textile machine with a plurality of winding units for producing cross-wound bobbins, in particular a two-for-one twister | |

| DE3606612A1 (en) | METHOD AND DEVICE FOR THE AUTONOMOUS REPLACEMENT OF OUTLET PRE-YARN SPOOLS ON A SPINNING MACHINE | |

| DE19631987A1 (en) | Bobbin transport system | |

| EP0503016B1 (en) | Device for the automatic handling of bobbin cases and completely wound bobbins in spinning machines | |

| DE3843554C2 (en) | Automatic winder with bobbin conveyor belt | |

| EP0841278B1 (en) | Bobbin changing- and transport arrangement | |

| DE102013018985A1 (en) | Method for carrying out a cross-bobbin change at a workstation of a textile machine producing cross-wound bobbins as well as textile machines producing cross-wound bobbins. | |

| CH632722A5 (en) | DOUBLE-SIDED TEXTILE MACHINE WITH CROSS-COIL WINDING DEVICES. | |

| CH691490A5 (en) | Transport and Umsetzanlage between at least one roving frame and a downstream storage or processing area. | |

| EP0534184B1 (en) | Transporting system for transporting individual carriers | |

| DE202005015261U1 (en) | Feeding device for feed bobbins | |

| DE102015008378A1 (en) | Device for picking up and removing wound coils |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE FR IT LI |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20010313 |

|

| AKX | Designation fees paid |

Free format text: CH DE FR IT LI |

|

| 17Q | First examination report despatched |

Effective date: 20020828 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RTI1 | Title (correction) |

Free format text: TUBE SUPPLYING APPARATUS FOR TEXTILE MACHINES FOR MAKING CROSS-WOUND BOBBINS |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): CH DE FR IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030521 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59808429 Country of ref document: DE Date of ref document: 20030626 Kind code of ref document: P |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20030925 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20031002 Year of fee payment: 6 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: SAURER GMBH & CO. KG |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040224 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050401 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050923 |