EP0909852A1 - Tamping apparatus - Google Patents

Tamping apparatus Download PDFInfo

- Publication number

- EP0909852A1 EP0909852A1 EP98890251A EP98890251A EP0909852A1 EP 0909852 A1 EP0909852 A1 EP 0909852A1 EP 98890251 A EP98890251 A EP 98890251A EP 98890251 A EP98890251 A EP 98890251A EP 0909852 A1 EP0909852 A1 EP 0909852A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tamping

- drive

- additional

- swivel drive

- pick

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B27/00—Placing, renewing, working, cleaning, or taking-up the ballast, with or without concurrent work on the track; Devices therefor; Packing sleepers

- E01B27/12—Packing sleepers, with or without concurrent work on the track; Compacting track-carrying ballast

- E01B27/13—Packing sleepers, with or without concurrent work on the track

- E01B27/16—Sleeper-tamping machines

Definitions

- the invention relates to a tamping unit for tamping sleepers of a track, which can be provided in pairs to one another by auxiliary drives, pivotable about a side axis on a height adjustable Tool carrier stored tamping tools, which in their lower end area in each case at least one tamping pick intended for immersion in crushed stone is assigned, which runs around a perpendicular to the side axis Swivel axis pivotally mounted on the tamping tool and by a Articulation point with a swivel drive designed as a hydraulic cylinder connected to pivot the tamping pick in the longitudinal direction of the threshold is, the swivel drive articulated via a linkage point on the tamping tool is.

- Another tamping unit is known from US Pat. No. 5,269,226, in which likewise per tamping tool, two tamping axes in the sleepers alongside each other are arranged. During that of the rail to be stuffed Nearby tamping ax rigidly connected to the tamping tool is, the adjacent tamping pimple by a swivel drive from one first pivoted into a second working position. Because both working positions are precisely defined by attacks, a time-consuming is unnecessary Centering process by the operator.

- the object of the present invention is to create a Tamping unit of the generic type, in which the tamping pick is particularly special can be used quickly for different work assignments.

- this object is achieved with a tamping unit at the beginning described type solved in that the swivel drive with an additional drive connected and articulated at one of the two articulation points, while the additional drive is mounted at the other articulation point.

- the invention is suitable Training especially for track areas in which, for example through a section-by-line guard rail or protective rail There are changing stuffing conditions and, if necessary, a complete one Decommissioning a tamping pick is required.

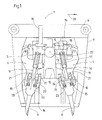

- a in Fig. 1 and 2 visible tamping unit 1 for tamping Thresholds 2 of a track 3 is specially designed for use in switch sections trained and consists of a total of four on normal to one an arrow 29 indicated machine longitudinal direction guide columns 4 sliding units, of which only for the sake of simplicity one is shown.

- the tamping unit 1 has two in the machine longitudinal direction opposite each other and each by an auxiliary drive 5 mutually available, lever-shaped tamping tools 6.

- Each tamping tool 6 is in its lower end region with two tamping picks 7,8 connected, one of which continues from an assembly frame 9 distanced tamping pick 8 around a machine tool in the longitudinal direction Pivot axis 10 is pivotally mounted.

- the stuffing tool 6 is over a side axis that is normal to the machine's longitudinal direction and runs horizontally 11 pivotally mounted on a tool carrier 12. This is with a vibration drive 13 for mounting the auxiliary drives 5 and vibration the tamping pick 7.8 and equipped with guides 14 and one Height adjustable drive 15. Side and swivel axis 11, 10 run in normal direction to each other.

- a hydraulic swivel drive 16 For pivoting the tamping pimple further distanced from the unit frame 9 8 in the longitudinal direction of the threshold is a hydraulic swivel drive 16 intended.

- This has a piston rod 17 with an articulation point 18 and a hydraulic cylinder 19.

- a connecting plate 20 is attached to the end of the hydraulic cylinder 19, on which two hydraulic auxiliary drives 21 are mounted.

- These point each have a piston rod 22 with a pivot point 23 and one the connecting plate 20 attached hydraulic cylinder 24.

- the piston side Articulation points 23 of the two additional drives 21 are with articulation points 25 connected, the one on the tamping pick 8, about the pivot axis 10 pivotable pimple holder 26 are attached.

- the piston rod 17 of the swivel drive 16 is connected to articulation points 27 which are attached to the tamping tool 6.

- the two additional drives 21 are related their longitudinal axes parallel to the swivel drive 16 and in relation to a normal to the pivot axis 10 and in the longitudinal direction of the swivel drive 16 extending plane 28 arranged symmetrically.

- Fig. 2 is a first working position of the pivotally mounted in full lines Stopfpickels 8 shown this in the cross machine direction is positioned immediately adjacent to the adjacent tamping pick 7. In this working position, a normal tamping support is tucked under by simultaneously immersing both tamping axes 7,8 in the ballast. The piston rod is in this first working position of the tamping pick 8 17 of the swivel drive 16 and the two piston rods 22 of the Additional drives 21 each in an extended position.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Dry Shavers And Clippers (AREA)

- Road Repair (AREA)

- Vehicle Body Suspensions (AREA)

- Seal Device For Vehicle (AREA)

- Input Circuits Of Receivers And Coupling Of Receivers And Audio Equipment (AREA)

- Road Paving Machines (AREA)

- Soil Working Implements (AREA)

- Forging (AREA)

Abstract

Description

Die Erfindung betrifft ein Stopfaggregat zum Unterstopfen von Schwellen eines Gleises, mit durch Beistellantriebe paarweise zueinander beistellbaren, um eine Beistellachse verschwenkbar auf einem höhenverstellbaren Werkzeugträger gelagerten Stopfwerkzeugen, denen in ihrem unteren Endbereich jeweils wenigstens ein zum Eintauchen in Schotter vorgesehener Stopfpickel zugeordnet ist, der um eine senkrecht zur Beistellachse verlaufende Schwenkachse verschwenkbar am Stopfwerkzeug gelagert und durch eine Anlenkstelle mit einem als Hydraulikzylinder ausgebildeten Schwenkantrieb zum Verschwenken des Stopfpickels in Schwellenlängsrichtung verbunden ist, wobei der Schwenkantrieb über eine Anlenkstelle am Stopfwerkzeug angelenkt ist.The invention relates to a tamping unit for tamping sleepers of a track, which can be provided in pairs to one another by auxiliary drives, pivotable about a side axis on a height adjustable Tool carrier stored tamping tools, which in their lower end area in each case at least one tamping pick intended for immersion in crushed stone is assigned, which runs around a perpendicular to the side axis Swivel axis pivotally mounted on the tamping tool and by a Articulation point with a swivel drive designed as a hydraulic cylinder connected to pivot the tamping pick in the longitudinal direction of the threshold is, the swivel drive articulated via a linkage point on the tamping tool is.

Durch US 4 537 135 ist ein speziell zum Einsatz in Weichenabschnitten ausgebildetes Stopfaggregat bekannt, das jeweils pro Stopfwerkzeug zwei in Schwellenlängsrichtung nebeneinander angeordnete Stopfpickel zum Eintauchen in den Schotter aufweist. Jedem dieser beiden Stopfpickel ist ein eigener Schwenkantrieb zugeordnet, so daß zur Umgehung von verschiedenen Hindernissen in Weichenabschnitten eine optimale Anpassung der Stopfpickel durch seitliches Verschwenken möglich ist. Erforderlichenfalls können beide bzw. auch nur ein Stopfpickel in eine Außerbetriebstellung hochgeschwenkt werden.US Pat. No. 4,537,135 specifically designed for use in switch sections Stuffing unit known, the two per tamping tool Threshold picks arranged side by side for immersion in the gravel. Each of these two tamping axes is unique Swivel drive assigned so that to bypass various Obstacles in switch sections optimal adjustment of the tamping pick is possible by swiveling to the side. If necessary, you can both or just a tamping pick swung up into a non-operating position become.

Durch US 5 269 226 ist ein weiteres Stopfaggregat bekannt, bei dem ebenfalls pro Stopfwerkzeug zwei Stopfpickel in Schwellen längsrichtung nebeneinander angeordnet sind. Während der der Schiene des zu unterstopfenden Gleises nähergelegene Stopfpickel starr mit dem Stopfwerkzeug verbunden ist, kann der benachbarte Stopfpickel durch einen Schwenkantrieb von einer ersten in eine zweite Arbeitsposition verschwenkt werden. Da beide Arbeitspositionen durch Anschläge genau definiert sind, erübrigt sich ein zeitaufwendiger Zentriervorgang durch die Bedienungsperson. Another tamping unit is known from US Pat. No. 5,269,226, in which likewise per tamping tool, two tamping axes in the sleepers alongside each other are arranged. During that of the rail to be stuffed Nearby tamping ax rigidly connected to the tamping tool is, the adjacent tamping pimple by a swivel drive from one first pivoted into a second working position. Because both working positions are precisely defined by attacks, a time-consuming is unnecessary Centering process by the operator.

Die Aufgabe der vorliegenden Erfindung liegt nun in der Schaffung eines Stopfaggregates der gattungsgemäßen Art, bei dem die Stopfpickel besonders rasch für unterschiedliche Arbeitseinsätze verwendbar sind.The object of the present invention is to create a Tamping unit of the generic type, in which the tamping pick is particularly special can be used quickly for different work assignments.

Erfindungsgemäß wird diese Aufgabe mit einem Stopfaggregat der eingangs beschriebenen Art dadurch gelöst, daß der Schwenkantrieb mit einem Zusatzantrieb verbunden und an einer der beiden Anlenkstellen angelenkt ist, während der Zusatzantrieb an der weiteren Anlenkstelle gelagert ist.According to the invention, this object is achieved with a tamping unit at the beginning described type solved in that the swivel drive with an additional drive connected and articulated at one of the two articulation points, while the additional drive is mounted at the other articulation point.

Durch diese spezielle Ausbildung des Schwenkantriebes besteht bei einem Minimum an konstruktivem Mehraufwand die Möglichkeit, den Stopfpickel rasch in verschiedene Arbeitspositionen zu verbringen. Damit erübrigt sich ein für die Bedienungsperson ermüdendes und zeitaufwendiges, wiederholtes Zentrieren des Stopfpickels vor jedem Stopfvorgang. Da die neue Arbeitsposition des Stopfpickels durch die Begrenzung des Kolbenhubes des Schwenk- und/oder Zusatzantriebes genau definiert ist, eignet sich die erfindungsgemäße Ausbildung vor allem für Gleisbereiche, in denen beispielsweise durch eine abschnittsweise vorhandene Leit- oder Schutzschiene wechselnde Stopfverhältnisse vorliegen und gegebenenfalls auch eine komplette Außerbetriebnahme eines Stopfpickels erforderlich ist.Due to this special design of the swivel drive there is one Minimum of additional constructive effort the possibility of the tamping pick to spend quickly in different working positions. So there is no need a repetitive one that is tiring and time-consuming for the operator Center the tamping pick before each tamping process. Because the new working position the tamping pimple by limiting the piston stroke of the Swivel and / or additional drive is precisely defined, the invention is suitable Training especially for track areas in which, for example through a section-by-line guard rail or protective rail There are changing stuffing conditions and, if necessary, a complete one Decommissioning a tamping pick is required.

Vorteilhafte Weiterbildungen der Erfindung ergeben sich aus den Unteransprüchen und der Zeichnung.Advantageous developments of the invention result from the subclaims and the drawing.

Im folgenden wird die Erfindung anhand eines in der Zeichnung dargestellten Ausführungsbeispieles näher beschrieben.In the following the invention with reference to one shown in the drawing Embodiment described in more detail.

Es zeigen:

Ein in Fig. 1 und 2 ersichtliches Stopfaggregat 1 zum Unterstopfen von

Schwellen 2 eines Gleises 3 ist speziell für den Einsatz in Weichenabschnitten

ausgebildet und besteht aus insgesamt vier auf normal zu einer durch

einen Pfeil 29 angedeuteten Maschinenlängsrichtung verlaufenden Führungssäulen

4 querverschiebbaren Einheiten, von denen der Einfachheit halber lediglich

eine dargestellt ist. Das Stopfaggregat 1 weist zwei in Maschinenlängsrichtung

einander gegenüberliegende und jeweils durch einen Beistellantrieb

5 zueinander beistellbare, hebelförmige Stopfwerkzeuge 6 auf.

Jedes Stopfwerkzeug 6 ist in seinem unteren Endbereich mit zwei Stopfpickeln

7,8 verbunden, von denen der von einem Aggregatrahmen 9 weiter

distanzierte Stopfpickel 8 um eine in Maschinenlängsrichtung verlaufende

Schwenkachse 10 verschwenkbar gelagert ist. Das Stopfwerkzeug 6 ist um

eine normal zur Maschinenlängsrichtung und horizontal verlaufende Beistellachse

11 verschwenkbar auf einem Werkzeugträger 12 gelagert. Dieser ist

mit einem Vibrationsantrieb 13 zur Lagerung der Beistellantriebe 5 und Vibration

der Stopfpickel 7,8 ausgestattet und über Führungen 14 und einen

Antrieb 15 höhenverstellbar. Beistell- und Schwenkachse 11,10 verlaufen in

normaler Richtung zueinander.A in Fig. 1 and 2

Zur Verschwenkung des vom Aggregatrahmen 9 weiter distanzierten Stopfpickels

8 in Schwellenlängsrichtung ist ein hydraulischer Schwenkantrieb 16

vorgesehen. Dieser weist eine Kolbenstange 17 mit einer Anlenkstelle 18

und einen Hydraulikzylinder 19 auf. Am von der Anlenkstelle 18 weiter entfernten

Ende des Hydraulikzylinders 19 ist eine Verbindungsplatte 20 befestigt,

an der zwei hydraulische Zusatzantriebe 21 gelagert sind. Diese weisen

jeweils eine Kolbenstange 22 mit einer Anlenkstelle 23 sowie einen an

der Verbindungsplatte 20 befestigten Hydraulikzylinder 24 auf. Die kolbenseitigen

Anlenkstellen 23 der beiden Zusatzantriebe 21 sind mit Anlenkstellen

25 verbunden, die auf einer den Stopfpickel 8 lagernden, um die Schwenkachse

10 verschwenkbaren Pickelhalterung 26 befestigt sind. Die Kolbenstange

17 des Schwenkantriebes 16 ist mit Anlenkstellen 27 verbunden, die

am Stopfwerkzeug 6 befestigt sind. Die beiden Zusatzantriebe 21 sind bezüglich

ihrer Längsachsen parallel zum Schwenkantrieb 16 und in bezug auf

eine normal zur Schwenkachse 10 und in Längsrichtung des Schwenkantriebes

16 verlaufende Ebene 28 symmetrisch angeordnet. For pivoting the tamping pimple further distanced from the

In Fig. 2 ist in vollen Linien eine erste Arbeitsposition des verschwenkbar gelagerten

Stopfpickels 8 dargestellt wobei dieser in Maschinenquerrichtung

unmittelbar an den benachbarten Stopfpickel 7 angrenzend positioniert ist.

In dieser Arbeitsposition erfolgt ein Unterstopfen eines normalen Stopfauflagers

durch gleichzeitiges Eintauchen beider Stopfpickel 7,8 in den Schotter.

In dieser ersten Arbeitsposition des Stopfpickels 8 befinden sich die Kolbenstange

17 des Schwenkantriebes 16 und die beiden Kolbenstangen 22 der

Zusatzantriebe 21 jeweils in einer ausgefahrenen Stellung.In Fig. 2 is a first working position of the pivotally mounted in

Durch Einziehen der beiden Kolbenstangen 22 der beiden Zusatzantriebe 21

kann der verschwenkbar gelagerte Stopfpickel 8 sehr rasch von der ersten

in eine zweite, in strichpunktierten Linien dargestellte Arbeitsposition verschwenkt

werden. Diese Umstellung der Arbeitsposition ist vor allem dann

sehr vorteilhaft, wenn abschnittsweise eine Hilfsschiene oder eine Weichenzunge

vorliegt.By pulling in the two

Schließlich kann durch Einfahren der Kolbenstange 17 des Schwenkantriebes

16 der schwenkbar gelagerte Stopfpickel 8 auch in eine (in strichpunktierten

Linien dargestellte) Außerbetriebstellung hochgeschwenkt werden. Dies

ist vor allem dann zweckmäßig, wenn aus Platzgründen ein Eintauchen beider

Stopfpickel 7,8 nicht möglich ist.Finally, by retracting the

Claims (5)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0174097A ATA174097A (en) | 1997-10-14 | 1997-10-14 | STOP UNIT |

| AT1740/97 | 1997-10-14 | ||

| AT174097 | 1997-10-14 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0909852A1 true EP0909852A1 (en) | 1999-04-21 |

| EP0909852B1 EP0909852B1 (en) | 2002-09-04 |

Family

ID=3519985

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98890251A Expired - Lifetime EP0909852B1 (en) | 1997-10-14 | 1998-08-26 | Tamping apparatus |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US6067910A (en) |

| EP (1) | EP0909852B1 (en) |

| JP (1) | JP3980771B2 (en) |

| CN (1) | CN1102977C (en) |

| AT (2) | ATA174097A (en) |

| AU (1) | AU731270B2 (en) |

| CA (1) | CA2250639C (en) |

| CZ (1) | CZ288290B6 (en) |

| DE (1) | DE59805389D1 (en) |

| DK (1) | DK0909852T3 (en) |

| ES (1) | ES2182262T3 (en) |

| PL (1) | PL191787B1 (en) |

| RU (1) | RU2158796C2 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101481896B (en) * | 2008-01-12 | 2011-12-28 | 襄樊金鹰轨道车辆有限责任公司 | Tamping apparatus for railroad switch |

| CN107849827A (en) * | 2015-08-21 | 2018-03-27 | 普拉塞-陶依尔铁路出口股份有限公司 | Tamping machine |

| WO2019165483A1 (en) * | 2018-03-02 | 2019-09-06 | Hp3 Real Gmbh | Tamping assembly for a track-tamping machine |

| WO2022087643A1 (en) * | 2020-10-28 | 2022-05-05 | Hp3 Real Gmbh | Tamping unit for a track-tamping machine |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6978718B2 (en) * | 2004-03-04 | 2005-12-27 | Seyrlehner Georg J | Tamping device and method of tamping a railroad track's ballast |

| SG11201509170PA (en) | 2013-07-02 | 2016-01-28 | Saudi Basic Ind Corp | Process and installation for the conversion of crude oil to petrochemicals having an improved btx yield |

| ES2875751T3 (en) | 2013-07-02 | 2021-11-11 | Saudi Basic Ind Corp | Process and facility for the conversion of crude oil into petrochemicals that have improved propylene performance |

| USD789994S1 (en) | 2015-08-05 | 2017-06-20 | Nordco Inc. | Tamper tool |

| AU2016204901A1 (en) * | 2015-08-10 | 2017-03-02 | Nordco Inc. | Tamper Tool and Associated Holder |

| JP7130207B2 (en) * | 2018-11-19 | 2022-09-05 | 株式会社交通建設 | Track maintenance device and track maintenance method |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2526882A1 (en) * | 1982-04-05 | 1983-11-18 | Genet Gerard | Double acting hydraulic actuator - has mechanical coupling between series mounted cylinders to double thrust |

| US4537135A (en) | 1983-05-04 | 1985-08-27 | Franz Plasser Bahnbaumaschinen Industriegesellschaft M.B.H. | Tamping unit |

| US5269226A (en) | 1991-10-24 | 1993-12-14 | Franz Plasser Bahnbaumaschinen-Industriegesellschaft M.B.H. | Ballast tamping assembly with mechanical stops on tamping picks for limiting pivotal movement |

-

1997

- 1997-10-14 AT AT0174097A patent/ATA174097A/en not_active Application Discontinuation

-

1998

- 1998-08-26 EP EP98890251A patent/EP0909852B1/en not_active Expired - Lifetime

- 1998-08-26 DK DK98890251T patent/DK0909852T3/en active

- 1998-08-26 DE DE59805389T patent/DE59805389D1/en not_active Expired - Lifetime

- 1998-08-26 AT AT98890251T patent/ATE223537T1/en active

- 1998-08-26 ES ES98890251T patent/ES2182262T3/en not_active Expired - Lifetime

- 1998-09-14 US US09/152,832 patent/US6067910A/en not_active Expired - Lifetime

- 1998-09-15 CZ CZ19982942A patent/CZ288290B6/en not_active IP Right Cessation

- 1998-10-08 PL PL329087A patent/PL191787B1/en not_active IP Right Cessation

- 1998-10-13 AU AU88436/98A patent/AU731270B2/en not_active Ceased

- 1998-10-13 CN CN98120948A patent/CN1102977C/en not_active Expired - Fee Related

- 1998-10-13 JP JP29078498A patent/JP3980771B2/en not_active Expired - Fee Related

- 1998-10-14 RU RU98118737/28A patent/RU2158796C2/en not_active IP Right Cessation

- 1998-10-14 CA CA002250639A patent/CA2250639C/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2526882A1 (en) * | 1982-04-05 | 1983-11-18 | Genet Gerard | Double acting hydraulic actuator - has mechanical coupling between series mounted cylinders to double thrust |

| US4537135A (en) | 1983-05-04 | 1985-08-27 | Franz Plasser Bahnbaumaschinen Industriegesellschaft M.B.H. | Tamping unit |

| US5269226A (en) | 1991-10-24 | 1993-12-14 | Franz Plasser Bahnbaumaschinen-Industriegesellschaft M.B.H. | Ballast tamping assembly with mechanical stops on tamping picks for limiting pivotal movement |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101481896B (en) * | 2008-01-12 | 2011-12-28 | 襄樊金鹰轨道车辆有限责任公司 | Tamping apparatus for railroad switch |

| CN107849827A (en) * | 2015-08-21 | 2018-03-27 | 普拉塞-陶依尔铁路出口股份有限公司 | Tamping machine |

| CN107849827B (en) * | 2015-08-21 | 2019-12-13 | 普拉塞-陶依尔铁路出口股份有限公司 | Tamping apparatus |

| WO2019165483A1 (en) * | 2018-03-02 | 2019-09-06 | Hp3 Real Gmbh | Tamping assembly for a track-tamping machine |

| AT521008A1 (en) * | 2018-03-02 | 2019-09-15 | Hp3 Real Gmbh | Tamping unit for a tamping machine |

| AT521008B1 (en) * | 2018-03-02 | 2020-02-15 | Hp3 Real Gmbh | Tamping unit for a track tamping machine |

| US11807995B2 (en) | 2018-03-02 | 2023-11-07 | Hp3 Real Gmbh | Tamping assembly for a track tamping machine |

| WO2022087643A1 (en) * | 2020-10-28 | 2022-05-05 | Hp3 Real Gmbh | Tamping unit for a track-tamping machine |

Also Published As

| Publication number | Publication date |

|---|---|

| US6067910A (en) | 2000-05-30 |

| AU8843698A (en) | 1999-05-06 |

| ES2182262T3 (en) | 2003-03-01 |

| DE59805389D1 (en) | 2002-10-10 |

| CN1102977C (en) | 2003-03-12 |

| RU2158796C2 (en) | 2000-11-10 |

| ATA174097A (en) | 1999-01-15 |

| CZ288290B6 (en) | 2001-05-16 |

| EP0909852B1 (en) | 2002-09-04 |

| AU731270B2 (en) | 2001-03-29 |

| CN1214391A (en) | 1999-04-21 |

| ATE223537T1 (en) | 2002-09-15 |

| CA2250639A1 (en) | 1999-04-14 |

| CZ294298A3 (en) | 1999-05-12 |

| CA2250639C (en) | 2005-11-08 |

| PL191787B1 (en) | 2006-07-31 |

| JPH11200305A (en) | 1999-07-27 |

| DK0909852T3 (en) | 2002-11-11 |

| JP3980771B2 (en) | 2007-09-26 |

| PL329087A1 (en) | 1999-04-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CH641859A5 (en) | MOBILE TRACK MACHINING MACHINE FOR SWITCHES, CROSSINGS AND TRACKED TRACKS. | |

| AT400341B (en) | THRESHOLDING MACHINE | |

| EP0909852B1 (en) | Tamping apparatus | |

| DD292492A5 (en) | RUNNING RUNNING, LEVELING AND DIRECTION MACHINE | |

| EP0539347B1 (en) | Tamping unit | |

| AT400337B (en) | TRACKING MACHINE WITH STAMPING UNITS ADJUSTABLE IN THE TRACK DIRECTION | |

| DE3015283A1 (en) | METHOD AND TRACKABLE MACHINE FOR REMOVING IRREGULARITIES ON THE RAIL HEAD SURFACE OF LAYED TRACKS | |

| EP0572370B1 (en) | Ballast plow | |

| EP0584055A1 (en) | Tamping machine for tamping switches and crossings on a railway track | |

| DE3026883C2 (en) | Mobile track tamping machine | |

| DE2610520A1 (en) | TRACK POT MACHINE, IN PARTICULAR TRACK POT AND LEVELING MACHINE | |

| EP0784121B1 (en) | Tamping device for railway track | |

| CH622302A5 (en) | Track-tamping machine, in particular for tamping down track points, crossings and the like | |

| DE3409848A1 (en) | MOBILE TRACK LEVELING AND LEVELING MACHINE | |

| EP0775779B1 (en) | Tamping assembly | |

| DE3425637C2 (en) | ||

| DE3814732C2 (en) | Track-moving device for clearing or leveling the ballast of a track with cross sleepers | |

| DE3110832A1 (en) | TRACK CONSTRUCTION MACHINE WITH TRACK LOCATION CORRECTION DEVICE | |

| DD293853A5 (en) | RUNNING DRIPPING MACHINE | |

| DE3015289A1 (en) | TRACKABLE PLANING MACHINE WITH PLANING TOOL | |

| DE2651951C2 (en) | Machine for tamping the sleepers of a track | |

| DE2602161A1 (en) | TRACK POT MACHINE | |

| DD141538A5 (en) | Tamping machine | |

| DE3205511C2 (en) | ||

| DE3642809C2 (en) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB IT LI NL SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19990825 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE DK ES FI FR GB IT LI NL SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 20020215 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 223537 Country of ref document: AT Date of ref document: 20020915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020904 |

|

| REF | Corresponds to: |

Ref document number: 59805389 Country of ref document: DE Date of ref document: 20021010 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2182262 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030605 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20110722 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20120629 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20120720 Year of fee payment: 15 Ref country code: SE Payment date: 20120725 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120808 Year of fee payment: 15 Ref country code: IT Payment date: 20120824 Year of fee payment: 15 Ref country code: BE Payment date: 20120725 Year of fee payment: 15 Ref country code: ES Payment date: 20120720 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20121024 Year of fee payment: 15 Ref country code: NL Payment date: 20120727 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20120711 Year of fee payment: 15 |

|

| BERE | Be: lapsed |

Owner name: FRANZ *PLASSER BAHNBAUMASCHINEN- INDUSTRIEG.- M.B. Effective date: 20130831 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20140301 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20130831 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 223537 Country of ref document: AT Kind code of ref document: T Effective date: 20130826 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130826 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130827 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140301 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140301 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130826 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59805389 Country of ref document: DE Effective date: 20140301 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130826 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130831 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130826 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130826 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130902 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20140908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130827 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20160711 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 |