EP0899445A2 - Liquid cooled cylinder head for a multi-cylinder internal combustion engine - Google Patents

Liquid cooled cylinder head for a multi-cylinder internal combustion engine Download PDFInfo

- Publication number

- EP0899445A2 EP0899445A2 EP98114792A EP98114792A EP0899445A2 EP 0899445 A2 EP0899445 A2 EP 0899445A2 EP 98114792 A EP98114792 A EP 98114792A EP 98114792 A EP98114792 A EP 98114792A EP 0899445 A2 EP0899445 A2 EP 0899445A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cylinder head

- internal combustion

- combustion engine

- screw

- cylinder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000002485 combustion reaction Methods 0.000 title claims abstract description 20

- 239000007788 liquid Substances 0.000 title 1

- 239000000498 cooling water Substances 0.000 claims abstract description 12

- 238000002347 injection Methods 0.000 claims abstract description 3

- 239000007924 injection Substances 0.000 claims abstract description 3

- 238000005452 bending Methods 0.000 description 6

- 230000036316 preload Effects 0.000 description 3

- 230000008719 thickening Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F1/00—Cylinders; Cylinder heads

- F02F1/24—Cylinder heads

- F02F1/26—Cylinder heads having cooling means

- F02F1/36—Cylinder heads having cooling means for liquid cooling

- F02F1/40—Cylinder heads having cooling means for liquid cooling cylinder heads with means for directing, guiding, or distributing liquid stream

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F1/00—Cylinders; Cylinder heads

- F02F1/24—Cylinder heads

- F02F1/26—Cylinder heads having cooling means

- F02F1/36—Cylinder heads having cooling means for liquid cooling

- F02F1/38—Cylinder heads having cooling means for liquid cooling the cylinder heads being of overhead valve type

Definitions

- the invention relates to a liquid-cooled cylinder head a multi-cylinder internal combustion engine according to the Preamble of claim 1.

- From JP-PS 59 96 341 is a generic liquid-cooled Cylinder head for a multi-cylinder internal combustion engine known.

- the cylinder head has conventional screw pipes for the cylinder head bolts, which are the clamping forces of the cylinder head bolts on the small cross section of the pipe from the ceiling to the bottom plate of the cylinder head.

- Um now the screw clamping forces also in the floor areas between the Distributing screw pipes is between the screw pipes a T-shaped bending beam arranged over a rib is connected to the gas exchange channels and the screw clamping forces should also lead to the intermediate areas.

- the invention has for its object a liquid-cooled Cylinder head of a multi-cylinder internal combustion engine to create with which even in confined spaces as high and even surface pressure as possible of the cylinder head gasket also in the areas between the cylinder head bolts can be achieved.

- An advantage of the invention is the simplification of the Screw whistles, in the adjacent wall sections of the gas exchange channels thickened in the area of the cylinder head bolts are formed and thereby form ribs that are part of the Screw whistles are.

- the screw pipes are not designed as continuous columns. Simplifying the Screw pipes draw a lower weight of the cylinder head after itself.

- Another major advantage is that optimal force distribution of the screw clamping force over the Screw whistles in the cylinder head. Since the screw pipes are not are designed as "conventional pillars", which the Bolting force only on the small cross section of the column Ceiling lead to the bottom of the cylinder head, but afterwards comprise ribs on a columnar portion which a directed distribution of forces in the areas between the Allow cylinder head screws.

- the screw tension of the Cylinder head bolts may appear shortly after being introduced into the conventional columnar section of the screw pipe spread over the adjoining ribs in the cylinder head, whereby the surface pressure on the cylinder head gasket evened out, especially to the advantage of the areas in the middle under the gas exchange channels. This ensures that the surface pressure acting on the cylinder head gasket those arising during operation of the internal combustion engine enormous gas forces due to the even distribution of forces withstands the screw tension better.

- the cylinder head After starting the internal combustion engine, the cylinder head warms up and the crankcase of the internal combustion engine and this also heats up the cooling water very quickly.

- the cylinder head bolts over one Part of their length from a section of the cooling water space completely surrounded, which also makes them very cool quickly brought to the temperature of the surrounding components become. Because the cylinder head bolts are parallel to the cylinder head as well as warm up to the crankcase and thereby also expand, will cause excessive stress on the cylinder head material avoided, which makes it possible on the to forego the conventional screw pipe (column).

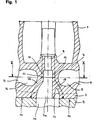

- Fig. 1 is a liquid-cooled cylinder head 1 for one multi-cylinder internal combustion engine, not shown, the left half being a first embodiment and the right half a second embodiment of the invention represents.

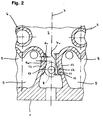

- the cylinder head 1 has a cooling water chamber 2 (see Fig. 2), of which only the inlet 2a is shown in FIG. 1. Of the Cooling water chamber 2 is down from a cylinder head floor 3 and up from one at a distance above the cylinder head floor 3 arranged cylinder head cover 4 limited. In the second embodiment the cylinder head 1 also has one in the inlet 2a arranged, free-standing projection 16 on. In the cooling water chamber 2 there are gas exchange channels 5 and in FIG. 2 shown chambers 6 arranged for spark plugs and / or injection nozzles, the gas exchange channels 5 according to FIG. 2 in the direction a transverse engine axis 7.

- cylinder head clamping screws only indicated in the figures 8 is the cylinder head 1 with the interposition of one here Not shown cylinder head gasket with a crankcase 9 of the internal combustion engine releasably connected.

- the pressing of the Cylinder head 1 to the crankcase 9 and thus the bracing the cylinder head gasket between cylinder head 1 and crankcase 9 takes place when the cylinder head screws 8 are tightened with the necessary screw preload.

- the cylinder head screws 8 extend part of their length free through a section, in this case the inlet 2a, the Cooling water chamber 2 in the cylinder head 1 and through a cooling water chamber section 10 in the crankcase 9.

- the cylinder head bolts 8 are flowed around by the cooling water and quickly on the Brought temperature of the surrounding components 1, 9.

- the cylinder head bolts 8 are by screw pipes described in more detail below 11 of the cylinder head 1 passed, which for Distribution of the bolt clamping forces of the cylinder head bolts 8 serve from the cylinder head cover 4 to the cylinder head base 3.

- Fig. 2 As can be seen from Fig. 2, according to the invention are in both Embodiments of the screw pipes 11 for the cylinder head screws 8 partly through adjacent wall sections 12 in particular, similar gas exchange channels 5, such as Inlet channels formed, the wall portions 12 in Area of the cylinder head screws 8 to form ribs 13 are thickened.

- This configuration according to the invention the screw pipes 11 distributes the screw clamping forces in areas 14 below the gas exchange channels 5 (see Fig. 1).

- Fig. 1 is the introduction of force by the cylinder head screw 8 in the cylinder head 1 and the subsequent distribution of forces over the ribs 13 into the areas 14 below the gas exchange channels 5 marked with dash-dotted arrows 15, the projection 16 in the second embodiment none Has an influence on this distribution of forces because of the lead 16 is not supported from below, but freely in the inlet 2a or the cooling water chamber section 10 protrudes.

- the preload the rib 13 is due to its special shape on the wall sections 12 of the gas exchange channels 5 in the direction of arrow 15 on the Aligned cylinder head gasket, which also in the the cylinder head bolts 8 adjacent areas 14 between the Gas exchange channels 5 a sufficient surface pressure on the Seal is achieved.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Cylinder Crankcases Of Internal Combustion Engines (AREA)

Abstract

Die Erfindung bezieht sich auf einen flüssigkeitsgekühlten Zylinderkopf (1) einer mehrzylindrigen Brennkraftmaschine mit einem Kühlwasserraum (2), in dem in Richtung einer Motorquerachse (7) verlaufende Gaswechselkanäle (5) und mindestens eine Kammer (6) für eine Zündkerze und/oder eine Einspritzdüse angeordnet sind, und mit Schraubenpfeifen (11) zur Verteilung der Schraubenspannkräfte der Zylinderkopfschrauben (8), wobei der Zylinderkopf (1) unter Zwischenschaltung einer Zylinderkopfdichtung mit einem Kurbelgehäuse (9) der Brennkraftmaschine verbindbar ist. Um einen flüssigkeitsgekühlten Zylinderkopf (1) einer mehrzylindrigen Brennkraftmaschine so auszubilden, daß auch bei beengten Platzverhältnissen eine möglichst hohe und gleichmäßige Flächenpressung der Zylinderkopfdichtung auch in den Bereichen zwischen den Zylinderkopfschrauben (8) zu erzielen ist, wird erfindungsgemäß vorgeschlagen, daß benachbarte Wandabschnitte der Gaswechselkanäle (5) im Bereich der Zylinderkopfschrauben (8) zur Bildung von Rippen verdickt ausgeformt sind, die Teil der Schraubenpfeifen (11) sind. <IMAGE>The invention relates to a liquid-cooled cylinder head (1) of a multi-cylinder internal combustion engine with a cooling water chamber (2), in which gas exchange channels (5) extending in the direction of a transverse engine axis (7) and at least one chamber (6) for a spark plug and / or an injection nozzle are arranged, and with screw pipes (11) for distributing the screw clamping forces of the cylinder head screws (8), the cylinder head (1) being connectable to a crankcase (9) of the internal combustion engine with the interposition of a cylinder head gasket. In order to design a liquid-cooled cylinder head (1) of a multi-cylinder internal combustion engine in such a way that the greatest possible and uniform surface pressure of the cylinder head gasket can also be achieved in the areas between the cylinder head bolts (8), even in confined spaces, it is proposed according to the invention that adjacent wall sections of the gas exchange channels ( 5) are thickened in the area of the cylinder head screws (8) to form ribs which are part of the screw pipes (11). <IMAGE>

Description

Die Erfindung bezieht sich auf einen flüssigkeitsgekühlten Zylinderkopf einer mehrzylindrigen Brennkraftmaschine gemäß dem Oberbegriff des Patentanspruchs 1.The invention relates to a liquid-cooled cylinder head a multi-cylinder internal combustion engine according to the Preamble of claim 1.

Aus der JP-PS 59 96 341 ist ein gattungsgemäßer flüssigkeitsgekühlter Zylinderkopf für eine mehrzylindrige Brennkraftmaschine bekannt. Der Zylinderkopf weist herkömmliche Schraubenpfeifen für die Zylinderkopfschrauben auf, die die Spannkräfte der Zylinderkopfschrauben auf dem kleinen Querschnitt der Pfeife von der Decke bis zur Bodenplatte des Zylinderkopfes führen. Um nun die Schraubenspannkräfte auch in die Bodenbereiche zwischen den Schraubenpfeifen zu verteilen, ist zwischen den Schraubenpfeifen ein T-förmiger Biegebalken angeordnet, der über eine Rippe mit den Gaswechselkanälen verbunden ist und die Schraubenspannkräfte auch in die Zwischenbereiche führen soll.From JP-PS 59 96 341 is a generic liquid-cooled Cylinder head for a multi-cylinder internal combustion engine known. The cylinder head has conventional screw pipes for the cylinder head bolts, which are the clamping forces of the cylinder head bolts on the small cross section of the pipe from the ceiling to the bottom plate of the cylinder head. Um now the screw clamping forces also in the floor areas between the Distributing screw pipes is between the screw pipes a T-shaped bending beam arranged over a rib is connected to the gas exchange channels and the screw clamping forces should also lead to the intermediate areas.

Von Nachteil bei einer derartigen Ausführung zur Verteilung der Schraubenspannkräfte ist allerdings, daß die Kräfteeinleitung über den oben erwähnten Biegeträger zu ungleichmäßig ist, um eine optimale gleichmäßige Kräfteverteilung auch im Bereich zwischen den Schraubenpfeifen zu erreichen, da die Steifigkeit der durchgehenden Schraubenpfeifen über ihre Länge nur eine geringe Krafteinleitung in den Biegeträger zuläßt. Die über den Biegeträger in die Brennraumbegrenzung des Zylinderkopfbodens eingeleitete Vorspannung ist deshalb nur gering und hält einem erhöhten Gasdruck der Brennkraftmaschine nicht stand. Eine gleichmäßige Flächenpressung der zwischen Zylinderkopf und Kurbelgehäuse angeordneten Zylinderkopfdichtung, um so eine optimale Abdichtung zu gewährleisten, ist somit nicht zu erreichen. Ein weiterer Nachteil der Ausführung stellt der enorme Platzbedarf des Biegebalkens dar, wodurch diese Ausführung bei sehr beengten Platzverhältnissen im Zylinderkopf nicht anwendbar ist, insbesondere wenn zur Erzielung einer besseren Kräfteverteilung der Biegebalken stärker ausgelegt werden soll.A disadvantage of such a design for the distribution of However, screw tension is that the introduction of forces is too uneven about the above-mentioned bending beam an optimal, even distribution of forces in the area between the screw pipes because of the rigidity of the continuous screw pipes only a little over their length Allows the introduction of force into the bending beam. The about the Bending beam in the combustion chamber boundary of the cylinder head base The preload introduced is therefore only slight and keeps you increased gas pressure of the internal combustion engine did not stand. A even surface pressure between the cylinder head and crankcase arranged cylinder head gasket, so as an optimal It is therefore not possible to guarantee sealing. Another disadvantage of the design is the enormous space requirement of the bending beam, which makes this version very cramped space in the cylinder head is not applicable is, especially if to achieve a better distribution of forces the bending beam should be designed stronger.

Zum allgemeinen technischen Hintergrund wird noch auf die DE 38 36 117 C1 verwiesen.For the general technical background, reference is made to DE 38 36 117 C1 referenced.

Der Erfindung liegt die Aufgabe zugrunde, einen flüssigkeitsgekühlten Zylinderkopf einer mehrzylindrigen Brennkraftmaschine zu schaffen, mit dem auch bei beengten Platzverhältnissen eine möglichst hohe und gleichmäßige Flächenpressung der Zylinderkopfdichtung auch in den Bereichen zwischen den Zylinderkopfschrauben zu erzielen ist.The invention has for its object a liquid-cooled Cylinder head of a multi-cylinder internal combustion engine to create with which even in confined spaces as high and even surface pressure as possible of the cylinder head gasket also in the areas between the cylinder head bolts can be achieved.

Diese Aufgabe wird erfindungsgemäß durch die im Kennzeichen des Patentanspruchs 1 gegebenen Merkmale gelöst.This object is achieved by the in the characteristic of Features given claim 1 solved.

Ein Vorteil der Erfindung besteht in der Vereinfachung der Schraubenpfeifen, bei der benachbarte Wandabschnitte der Gaswechselkanäle im Bereich der Zylinderkopfschrauben verdickt ausgeformt sind und dadurch Rippen ausbilden, die Teil der Schraubenpfeifen sind. Die Schraubenpfeifen sind dadurch nicht als durchgehende Säulen ausgebildet. Die Vereinfachung der Schraubenpfeifen zieht ein geringeres Gewicht des Zylinderkopfes nach sich. Ein weiterer wesentlicher Vorteil liegt in der optimalen Kräfteverteilung der Schraubenspannkraft über die Schraubenpfeifen im Zylinderkopf. Da die Schraubenpfeifen nicht als "konventionelle Säulen" ausgebildet sind, welche die Schraubenkraft nur auf dem kleinen Säulenquerschnitt von der Decke bis zum Boden des Zylinderkopfes führen, sondern im Anschluß an einen säulenartigen Abschnitt Rippen umfassen, die eine gerichtete Kräfteverteilung in die Bereiche zwischen den Zylinderkopfschrauben ermöglichen. Die Schraubenspannkraft der Zylinderkopfschrauben kann sich kurz nach der Einleitung in den konventionellen säulenartigen Abschnitt der Schraubenpfeife über die daran anschließenden Rippen in den Zylinderkopf verteilen, wodurch sich die Flächenpressung auf die Zylinderkopfdichtung vergleichmäßigt, insbesondere zum Vorteil der Bereiche in der Mitte unter den Gaswechselkanälen. Damit ist sichergestellt, daß die auf die Zylinderkopfdichtung wirkende Flächenpressung den im Betrieb der Brennkraftmaschine entstehenden enormen Gaskräften aufgrund der gleichmäßigen Kräfteverteilung der Schraubenspannkräfte besser standhält.An advantage of the invention is the simplification of the Screw whistles, in the adjacent wall sections of the gas exchange channels thickened in the area of the cylinder head bolts are formed and thereby form ribs that are part of the Screw whistles are. The screw pipes are not designed as continuous columns. Simplifying the Screw pipes draw a lower weight of the cylinder head after itself. Another major advantage is that optimal force distribution of the screw clamping force over the Screw whistles in the cylinder head. Since the screw pipes are not are designed as "conventional pillars", which the Bolting force only on the small cross section of the column Ceiling lead to the bottom of the cylinder head, but afterwards comprise ribs on a columnar portion which a directed distribution of forces in the areas between the Allow cylinder head screws. The screw tension of the Cylinder head bolts may appear shortly after being introduced into the conventional columnar section of the screw pipe spread over the adjoining ribs in the cylinder head, whereby the surface pressure on the cylinder head gasket evened out, especially to the advantage of the areas in the middle under the gas exchange channels. This ensures that the surface pressure acting on the cylinder head gasket those arising during operation of the internal combustion engine enormous gas forces due to the even distribution of forces withstands the screw tension better.

Nach dem Starten der Brennkraftmaschine erwärmen sich der Zylinderkopf sowie das Kurbelgehäuse der Brennkraftmaschine und heizen dadurch auch das Kühlwasser sehr schnell mit auf. Vorteilhafterweise sind daher die Zylinderkopfschrauben über einen Teil ihrer Länge von einem Abschnitt des Kühlwasserraumes vollständig umgeben, wodurch sie über das Kühlwasser ebenfalls sehr schnell auf die Temperatur der umgebenden Bauteile gebracht werden. Da sich die Zylinderkopfschrauben parallel zum Zylinderkopf sowie zum Kurbelgehäuse erwärmen und sich dadurch ebenfalls ausdehnen, wird eine übermäßige Beanspruchung des Zylinderkopf-Werkstoffes vermieden, wodurch es möglich wird auf die bisherige konventionelle Schraubenpfeife (Säule) zu verzichten.After starting the internal combustion engine, the cylinder head warms up and the crankcase of the internal combustion engine and this also heats up the cooling water very quickly. Advantageously are therefore the cylinder head bolts over one Part of their length from a section of the cooling water space completely surrounded, which also makes them very cool quickly brought to the temperature of the surrounding components become. Because the cylinder head bolts are parallel to the cylinder head as well as warm up to the crankcase and thereby also expand, will cause excessive stress on the cylinder head material avoided, which makes it possible on the to forego the conventional screw pipe (column).

Weitere Ausgestaltungen und Vorteile der Erfindung gehen aus der Beschreibung hervor.Further configurations and advantages of the invention go out the description.

Ein Ausführungsbeispiel der Erfindung ist im folgenden in zwei Zeichnungen mit weiteren Einzelheiten näher erläutert, und zwar zeigen:

- Fig. 1

- einen Teil eines Längsschnitts durch einen flüssigkeitsgekühlten Zylinderkopf einer mehrzylindrigen Brennkraftmaschine, der mit einem Kurbelgehäuse der Brennkraftmaschine verbunden ist, und

- Fig. 2

- einen Teil eines Schnittes durch den Zylinderkopf der Brennkraftmaschine gemäß Linie II-II aus Fig. 1.

- Fig. 1

- a part of a longitudinal section through a liquid-cooled cylinder head of a multi-cylinder internal combustion engine, which is connected to a crankcase of the internal combustion engine, and

- Fig. 2

- a part of a section through the cylinder head of the internal combustion engine according to line II-II of FIG. 1st

In Fig. 1 ist ein flüssigkeitsgekühlter Zylinderkopf 1 für eine nicht näher dargestellte mehrzylindrige Brennkraftmaschine dargestellt, wobei die linke Hälfte ein erstes Ausführungsbeispiel und die rechte Hälfte ein zweites Ausführungsbeispiel der Erfindung darstellt.In Fig. 1 is a liquid-cooled cylinder head 1 for one multi-cylinder internal combustion engine, not shown, the left half being a first embodiment and the right half a second embodiment of the invention represents.

Der Zylinderkopf 1 weist einen Kühlwasseraum 2 auf (siehe Fig.

2), von dem in Fig. 1 nur der Zulauf 2a dargestellt ist. Der

Kühlwasserraum 2 ist nach unten von einem Zylinderkopfboden 3

und nach oben von einer mit Abstand über dem Zylinderkopfboden

3 angeordneten Zylinderkopfdecke 4 begrenzt. Im zweiten Ausführungsbeispiel

weist der Zylinderkopf 1 zusätzlich einen im Zulauf

2a angeordneten, nach unten freistehenden Vorsprung 16

auf. Im Kühlwasserraum 2 sind Gaswechselkanäle 5 sowie in Fig.

2 gezeigte Kammern 6 für Zündkerzen und/oder Einspritzdüsen angeordnet,

wobei die Gaswechselkanäle 5 gemäß Fig. 2 in Richtung

einer Motorquerachse 7 verlaufen.The cylinder head 1 has a cooling water chamber 2 (see Fig.

2), of which only the inlet 2a is shown in FIG. 1. Of the

Durch in den Figuren nur angedeutete Zylinderkopfspannschrauben

8 ist der Zylinderkopf 1 unter Zwischenschaltung einer hier

nicht dargestellten Zylinderkopfdichtung mit einem Kurbelgehäuse

9 der Brennkraftmaschine lösbar verbunden. Das Anpressen des

Zylinderkopfes 1 an das Kurbelgehäuse 9 und damit das Verspannen

der Zylinderkopfdichtung zwischen Zylinderkopf 1 und Kurbelgehäuse

9 erfolgt beim Anziehen der Zylinderkopfschrauben 8

mit der nötigen Schraubenvorspannung. Über mindestens einen

Teil ihrer Länge erstrecken sich die Zylinderkopfschrauben 8

frei durch einen Abschnitt, in diesem Fall dem Zulauf 2a, des

Kühlwasserraumes 2 im Zylinderkopf 1 und durch einen Kühlwasserraumabschnitt

10 im Kurbelgehäuse 9. Die Zylinderkopfschrauben

8 werden dadurch vom Kühlwasser umströmt und rasch auf die

Temperatur der umgebenden Bauteile 1, 9 gebracht. Die Zylinderkopfschrauben

8 sind durch unten näher beschriebene Schraubenpfeifen

11 des Zylinderkopfes 1 hindurchgeführt, welche zur

Verteilung der Schraubenspannkräfte der Zylinderkopfschrauben 8

von der Zylinderkopfdecke 4 zum Zylinderkopfboden 3 dienen. By means of cylinder head clamping screws only indicated in the figures

8 is the cylinder head 1 with the interposition of one here

Not shown cylinder head gasket with a crankcase

9 of the internal combustion engine releasably connected. The pressing of the

Cylinder head 1 to the crankcase 9 and thus the bracing

the cylinder head gasket between cylinder head 1 and crankcase

9 takes place when the cylinder head screws 8 are tightened

with the necessary screw preload. About at least one

The cylinder head screws 8 extend part of their length

free through a section, in this case the inlet 2a, the

Wie aus Fig. 2 ersichtlich ist, sind erfindungsgemäß bei beiden

Ausführungsbeispielen die Schraubenpfeifen 11 für die Zylinderkopfschrauben

8 teilweise durch benachbarte Wandabschnitte 12

insbesondere gleichartiger Gaswechselkanäle 5, wie beispielsweise

Einlaßkanäle, gebildet, wobei die Wandabschnitte 12 im

Bereich der Zylinderkopfschrauben 8 zur Bildung von Rippen 13

verdickt ausgeformt sind. Diese erfindungsgemäße Ausgestaltung

der Schraubenpfeifen 11 bewirkt eine Verteilung der Schraubenspannkräfte

in Bereiche 14 unterhalb der Gaswechselkanäle 5

(siehe Fig. 1).As can be seen from Fig. 2, according to the invention are in both

Embodiments of the screw pipes 11 for the cylinder head screws

8 partly through

In Fig. 1 ist die Krafteinleitung durch die Zylinderkopfschraube

8 in den Zylinderkopf 1 und die anschließende Kräfteverteilung

über die Rippen 13 in die Bereiche 14 unterhalb der Gaswechselkanäle

5 mit strichpunktierten Pfeilen 15 gekennzeichnet,

wobei der Vorsprung 16 im zweiten Ausführungsbeispiel keinerlei

Einfluß auf diese Kräfteverteilung hat, da der Vorsprung

16 nicht von unten gestützt wird, sondern frei in den Zulauf 2a

bzw. den Kühlwasserraumabschnitt 10 ragt. Die Vorspannkraft aus

der Rippe 13 ist durch deren besondere Anformung an die Wandabschnitte

12 der Gaswechselkanäle 5 in Pfeilrichtung 15 auf die

Zylinderkopfdichtung ausgerichtet, wodurch auch in den den Zylinderkopfschrauben

8 benachbarten Bereichen 14 zwischen den

Gaswechselkanälen 5 eine ausreichende Flächenpressung auf die

Dichtung erzielt wird.In Fig. 1 is the introduction of force by the cylinder head screw

8 in the cylinder head 1 and the subsequent distribution of forces

over the

Die Dimensionierung des Mindestquerschnitts ARmin der teilweise

die Schraubenpfeife 11 bildenden Rippe 13 ist näherungsweise

durch die Formel

- ARmin

- = erforderlicher Mindestquerschnitt der Rippe,

- dK

- = Dicke der Gaswechselkanalwand,

- dV

- = Dicke der einen Teil der Rippe bildenden Verdickung,

- bV

- = Breite der Verdickung,

- FS

- = Schraubenkraft der Zylinderkopfschraube und

- σSstreck

- = Streckgrenze der Zylinderkopfschraube.

- A Rmin

- = required minimum cross-section of the rib,

- d K

- = Thickness of the gas exchange duct wall,

- d V

- = Thickness of the thickening forming part of the rib,

- b V

- = Width of the thickening,

- F S

- = Screw force of the cylinder head screw and

- σ stretch

- = Yield point of the cylinder head screw.

Claims (2)

dadurch gekennzeichnet,

daß benachbarte Wandabschnitte (12) der Gaswechselkanäle (5) im Bereich der Zylinderkopfschrauben (8) zur Bildung von Rippen (13) verdickt ausgeformt sind, die Teil der Schraubenpfeifen (11) sind.Liquid-cooled cylinder head for a multi-cylinder internal combustion engine with a cooling water chamber in which gas exchange channels and at least one chamber for a spark plug and / or an injection nozzle are arranged in the direction of a transverse engine axis, and with screw whistles for distributing the screw clamping forces of the cylinder head screws, the cylinder head being interposed by a cylinder head gasket can be connected to a crankcase of the internal combustion engine,

characterized,

that adjacent wall sections (12) of the gas exchange channels (5) in the area of the cylinder head screws (8) are formed to form ribs (13) which are part of the screw pipes (11).

dadurch gekennzeichnet,

daß die Zylinderkopfschrauben (8) über mindestens einen Teil ihrer Länge von Kühlwasser vollständig umgeben sind.Liquid-cooled cylinder head for a multi-cylinder internal combustion engine according to claim 1,

characterized,

that the cylinder head screws (8) are completely surrounded by cooling water over at least part of their length.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19737492 | 1997-08-28 | ||

| DE19737492A DE19737492C1 (en) | 1997-08-28 | 1997-08-28 | Liquid cooled cylinder head for motor vehicle internal combustion engine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0899445A2 true EP0899445A2 (en) | 1999-03-03 |

| EP0899445A3 EP0899445A3 (en) | 2000-01-12 |

| EP0899445B1 EP0899445B1 (en) | 2003-02-26 |

Family

ID=7840435

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98114792A Expired - Lifetime EP0899445B1 (en) | 1997-08-28 | 1998-08-06 | Liquid cooled cylinder head for a multi-cylinder internal combustion engine |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US6129064A (en) |

| EP (1) | EP0899445B1 (en) |

| DE (1) | DE19737492C1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009041708A1 (en) * | 2009-09-16 | 2011-03-24 | GM Global Technology Operations, Inc., Detroit | Screw pipe for cylinder head of internal combustion engine of vehicle, particularly motor vehicle, has area, where area is formed as truncated cone with base surface, cover surface and lateral area |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20130127546A (en) * | 2011-04-11 | 2013-11-22 | 도요타 지도샤(주) | Cylinder head of internal combustion engine |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5996341A (en) | 1982-11-22 | 1984-06-02 | 株式会社 中井(保)組 | Installation of cylinder in underground |

| DE3836117C1 (en) | 1988-10-22 | 1989-07-27 | Krupp Mak Maschinenbau Gmbh, 2300 Kiel, De | Cylinder head for internal combustion engines |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1220202B (en) * | 1964-05-08 | 1966-06-30 | Daimler Benz Ag | Arrangement of cylinder liners, in particular wet cylinder liners in internal combustion engines |

| DE1301655C2 (en) * | 1965-01-12 | 1970-04-23 | Daimler Benz Ag | Internal combustion engine with fluid-cooled cylinder liners |

| DE2143734B2 (en) * | 1971-09-01 | 1973-10-04 | Daimler-Benz Ag, 7000 Stuttgart | Internal combustion engine with an intermediate pipe inserted into the passage for the cooling water between the cylinder head and the crankcase |

| DE3228922A1 (en) * | 1982-08-03 | 1984-02-09 | M.A.N. Maschinenfabrik Augsburg-Nürnberg AG, 8500 Nürnberg | Connection of preferably dynamically highly-stressed machine parts by means of a plurality of long bolts and a plurality of short bolts |

| JPS5996341U (en) * | 1982-12-20 | 1984-06-29 | マツダ株式会社 | Engine cylinder head structure |

| DE3513126C2 (en) * | 1985-04-12 | 1987-02-12 | Daimler-Benz Ag, 7000 Stuttgart | Liquid-cooled four-valve cylinder head for a multi-cylinder internal combustion engine |

| DE3545333A1 (en) * | 1985-12-20 | 1987-07-02 | Kloeckner Humboldt Deutz Ag | CYLINDER HEAD |

| DE3616629A1 (en) * | 1986-05-16 | 1987-11-19 | Audi Ag | INTERNAL COMBUSTION ENGINE |

| DE3726027A1 (en) * | 1987-08-05 | 1989-02-16 | Alcan Gmbh | HEAT-INPUTED COMPONENT |

| DE3922885A1 (en) * | 1989-07-12 | 1991-01-17 | Man Nutzfahrzeuge Ag | CYLINDER HEAD GASKET FOR PISTON PISTON, IN PARTICULAR COMBUSTION ENGINES |

| DE4223780C2 (en) * | 1992-07-18 | 1996-04-11 | Bayerische Motoren Werke Ag | Screw connection for a cylinder head of an internal combustion engine |

| IT1270244B (en) * | 1993-07-23 | 1997-04-29 | Porsche Ag | SCREW COUPLING OF THE CYLINDER HEAD OF AN INTERNAL COMBUSTION ENGINE |

| US5630389A (en) * | 1995-09-29 | 1997-05-20 | Self; Kevin G. | Cylinder head bolt plug |

| SE9503622L (en) * | 1995-10-13 | 1996-09-23 | Scania Cv Ab | Apparatus for sealing an internal combustion engine's combustion chamber |

| DE19644530C1 (en) * | 1996-10-26 | 1998-02-12 | Daimler Benz Ag | Cylinder head for multi-cylinder IC engine |

-

1997

- 1997-08-28 DE DE19737492A patent/DE19737492C1/en not_active Expired - Fee Related

-

1998

- 1998-08-06 EP EP98114792A patent/EP0899445B1/en not_active Expired - Lifetime

- 1998-08-28 US US09/143,626 patent/US6129064A/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5996341A (en) | 1982-11-22 | 1984-06-02 | 株式会社 中井(保)組 | Installation of cylinder in underground |

| DE3836117C1 (en) | 1988-10-22 | 1989-07-27 | Krupp Mak Maschinenbau Gmbh, 2300 Kiel, De | Cylinder head for internal combustion engines |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009041708A1 (en) * | 2009-09-16 | 2011-03-24 | GM Global Technology Operations, Inc., Detroit | Screw pipe for cylinder head of internal combustion engine of vehicle, particularly motor vehicle, has area, where area is formed as truncated cone with base surface, cover surface and lateral area |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19737492C1 (en) | 1998-10-29 |

| EP0899445A3 (en) | 2000-01-12 |

| EP0899445B1 (en) | 2003-02-26 |

| US6129064A (en) | 2000-10-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2420051C3 (en) | Liquid-cooled cylinder head for multi-cylinder internal combustion engines | |

| EP0928405B1 (en) | Plate-type heat exchanger, especially oil/coolant cooler in vehicles | |

| DE10258319A1 (en) | Flat gasket, in particular exhaust manifold gasket, as well as such a gasket receiving assembly | |

| DE2429355A1 (en) | COMBUSTION ENGINE | |

| DE2638025B2 (en) | Water-cooled internal combustion engine | |

| AT402325B (en) | CYLINDER HEAD OF A LIQUID-COOLED INTERNAL COMBUSTION ENGINE WITH SERIES OF CYLINDERS | |

| DE2742296A1 (en) | DEVICE FOR CONNECTING A SINGLE-PIECE EXHAUST MANIFOLD TO THE CYLINDER HEADS OF MULTI-CYLINDER, IN-LINE COMBUSTION ENGINES | |

| EP1144836B1 (en) | Combustion chamber cooling structure for a rocket engine | |

| EP0845592B1 (en) | Cooling element and fuel injector with cooling element for an internal combustion engine | |

| EP1769207B1 (en) | Plate heat exchanger | |

| DE19644530C1 (en) | Cylinder head for multi-cylinder IC engine | |

| DE102004062522B4 (en) | Cylinder head with stiffening | |

| EP0899445B1 (en) | Liquid cooled cylinder head for a multi-cylinder internal combustion engine | |

| DE69509411T2 (en) | CYLINDER BLOCK FOR AN INTERNAL COMBUSTION ENGINE | |

| WO2003100237A1 (en) | Cylinder head of an internal combustion engine | |

| EP1972772B1 (en) | Cylinder head for a fluid-cooled combustion engine | |

| DE19600448C1 (en) | Liquid-cooled cylinder head for multicylinder engine | |

| DE19508986C1 (en) | Cylinder head for water=cooled multi=cylinder IC engine | |

| DE19637122C1 (en) | Liquid-cooled cylinder head | |

| DE4344356A1 (en) | Cylinder head for IC engine with secondary air feed | |

| DE9401035U1 (en) | Cooling device for a motor vehicle | |

| DE2952490C2 (en) | Cylinder head for compression-ignited internal combustion engines with pre-combustion chambers | |

| DE19640122C1 (en) | Cylinder head cooling device for multi=cylinder internal combustion engine in V=formation | |

| AT519245B1 (en) | Liquid-cooled internal combustion engine with sleeve element | |

| EP1669582B1 (en) | Integrated injection system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT Kind code of ref document: A2 Designated state(s): FR GB IT |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: DAIMLERCHRYSLER AG |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991209 |

|

| AKX | Designation fees paid |

Free format text: DE FR GB IT |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20020625 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): FR GB IT |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| AK | Designated contracting states |

Designated state(s): FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20030509 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20031127 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20050725 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050812 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060831 Year of fee payment: 9 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20060806 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060806 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070806 |