EP0846528B1 - Percussive tool with fluid-pressure drive and a protection device - Google Patents

Percussive tool with fluid-pressure drive and a protection device Download PDFInfo

- Publication number

- EP0846528B1 EP0846528B1 EP97111722A EP97111722A EP0846528B1 EP 0846528 B1 EP0846528 B1 EP 0846528B1 EP 97111722 A EP97111722 A EP 97111722A EP 97111722 A EP97111722 A EP 97111722A EP 0846528 B1 EP0846528 B1 EP 0846528B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- impact device

- tool

- transverse

- percussive tool

- housing part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D17/00—Details of, or accessories for, portable power-driven percussive tools

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T279/00—Chucks or sockets

- Y10T279/17—Socket type

- Y10T279/17042—Lost motion

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T279/00—Chucks or sockets

- Y10T279/17—Socket type

- Y10T279/17042—Lost motion

- Y10T279/17094—Sleeve type retainer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T279/00—Chucks or sockets

- Y10T279/17—Socket type

- Y10T279/17042—Lost motion

- Y10T279/17094—Sleeve type retainer

- Y10T279/17102—Sleeve in socket

Definitions

- the invention relates to a fluid-powered hammer mechanism with a protective device and a housing part connected to the striking mechanism, which at least the striking mechanism shields against the outside environment and in which one of the Percussion driven impact tool protrudes.

- the housing part instructs its passage opening for the striking tool on an outer seal the striking tool transverse to its longitudinal axis at most with a small distance encloses and is designed to be movable in this transverse direction.

- Impact mechanisms driven by a fluid pressure medium are mainly used for material destruction. It falls in addition to the material broken into coarse pieces, also rock dust Grain fractions up to the size of a few millimeters. Because this rock dust in most cases a high proportion of wear-promoting materials (e.g. quartz) has its penetration into the tool guide increased wear and possibly premature failure of the affected Components result.

- wear-promoting materials e.g. quartz

- the invention has for its object a fluid-powered To create striking mechanism with a protective device, especially in rough construction site use expected stresses.

- a fluid-powered To create striking mechanism with a protective device especially in rough construction site use expected stresses.

- functional reliability due to reduced wear in the area of the tool guide of the striking mechanism increased as well as the repair and maintenance effort be reduced.

- the basic idea of the invention is then the striking mechanism Seen in the opposite direction to the striking direction of the striking tool - in the area in front of the tool guide with an external seal in the form of a movable mounted cross slide, against the direction of impact an elastically supporting inner seal connected downstream of the impact tool is.

- the cross slide also acts as a mechanical shield is and serves as a scraper, the inner seal downstream of this Prevent fine impurities from entering the tool guide area.

- the percussion mechanism itself can be of any design as far as it is in a tool guide back and forth movable impact tool, which is driven by the striking mechanism.

- the protective device in question is characterized in that that the outer seal as a transverse slide mounted in a transverse guide is formed as a unit for transverse movements of the striking tool by this is moved; that the outer seal against the direction of impact of the Impact tool an inner seal is connected to the impact tool rests elastically outside of its tool guide, and that the External and internal seals can be replaced (on the component that carries them) are attached.

- the cross slide can - according to the requirements placed on it - consist of different materials, in particular metal or plastic.

- Essential in the context mentioned here is such a configuration of the cross slide, which ensures that it is sufficiently movable as a unit in the transverse direction, ie is displaced by any transverse movements of the striking tool with respect to the transverse guide receiving it.

- the cross slide is disc-shaped (claim 2); he should be like this be designed so that it is sufficient in the longitudinal direction of the striking tool Has rigidity.

- the cross slide can be advantageously designed in that it has a passage opening has, the wall facing the striking tool convex is arched (claim 3).

- cross slide should be designed in such a way that it is in rigid unit forms (claim 4).

- the cross slide can be operated simultaneously also consist of several materials; in particular, it can be configured in this way be that the wall of the passage opening for the striking tool of otherwise rigid cross slide at least partially made of elastic Material consists (claim 5); rubber-like materials in particular come as materials Materials or plastic.

- the cross slide preferably faces the one facing the striking tool Side on an elastic insert, which the wall of the passage opening at least forms (claim 6).

- the elastic insert can advantageously also be dimensioned and designed such that that it rests on the striking tool and thus an additional seal forms.

- the cross slide forms a replacement component with the transverse guide supporting it, which is releasably attached to the housing part (claim 8).

- the inner seal is preferably designed such that it has at least one on the striking tool sealing lip (claim 9).

- At least one sealing lip of the inner seal should face in the direction of impact be arranged obliquely (claim 10).

- the inner seal can be attached to any components of the overall device.

- a particularly simple embodiment is characterized in that the inner seal is attached to an extension of the tool guide, the extension in the area of the inner seal enclosing the striking tool at a distance which is greater than the greatest possible transverse offset of the striking tool (claim 12).

- the housing part already mentioned, which at least the cross slide can be part of the percussion mechanism itself.

- the subject of the invention can also be used in configurations come in which the housing part is part of a supporting the striking mechanism Outer housing is (claim 13).

- the housing part forms the front end of the outer housing.

- the inner seal with respect to the tool guide is preferably arranged such that the distance of the sealing lip from the front edge of the tool guide (ie from the end section of the tool guide facing the outer seal) is greater than the maximum stroke of the striking tool (claim 14). In this way it is ensured that the contact area of the sealing lip does not coincide with the guide area of the impact tool. In the area of the front edge of the tool guide, the striking tool is subject to a particularly high load, which can result in damage to the outer surface of the striking tool.

- the design of the inner seal in question prevents the sealing lip of the inner seal from coming into contact with the possibly attacked outer surface of the striking tool and thereby possibly being damaged prematurely or failing prematurely.

- the inner seal should be regarding the outer seal should be arranged so that after removing the Cross slide or the replacement component comprising this (cf. claim 8) is accessible from the outside and can be dismantled if necessary.

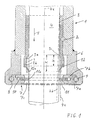

- FIG. 1 shows whose lower part 1, in which a tool guide 3 is immovable via a bolt 2 is held.

- a striking tool in the form of a chisel is supported in this 4 with the longitudinal axis 4a movable in the longitudinal direction.

- the movement of the chisel 4 in the direction of impact is indicated by an arrow 5.

- the pendulum movements possibly carried out by the chisel 4 are greatly enlarged - schematically illustrated by dashed lines 4b and 4c.

- a housing part 6 is fastened to the striking tool lower part 1 as an extension, which at the end (i.e. in the illustration below) is a removable component 7 receives.

- the housing part 6 is equipped with a recess 8, which is dimensioned slightly lower than the height of the replacement component 7 and their diameter adapted to the diameter of the exchange component 7 is.

- the parts 6 and 7 are detachably fastened to one another via bolts 9.

- the exchange component 7 in turn consists of an end plate 7a and a back plate 7b. These are designed so that on the one hand they are sufficiently large Passage opening 7c for the chisel 4 and on the other hand - transverse to the longitudinal axis 4a - define an annulus 10; in this is an outer seal in the form of a plate-shaped cross slide 11 movably mounted.

- the height of the annular space 10 in the direction of the longitudinal axis 4a is slightly larger dimensioned as the thickness of the cross slide 11, so that this under the influence of Chisel 4 executing transverse movements with respect to the housing part 6 as in itself rigid unit can be moved back and forth.

- the parts 7a and 7b are connected to each other (not shown); accordingly can the exchange component 7 with the freely movably mounted therein Cross slide 11 can be installed and removed as a unit.

- the cross slide 11 is - against the direction of impact (arrow 5) within the housing part 6 an inner seal 12 connected downstream, the sealing lip 12a outside the tool guide 3 rests elastically on the chisel 4 and as the main scraper for impurities which may have penetrated into the housing part 6.

- the inner seal 12 is on an extension 3a of the tool guide releasably attached via a fastening groove 3b; the Extension encloses the chisel 4 in the area of the inner seal a distance s that is greater than the greatest possible transverse offset of the chisel in this area (indicated by lines 4b and 4c).

- the length of the sealing lip 12a is such that the ratio of their length and the greatest possible transverse offset of the chisel 4 has a value greater than 2 in the area of the sealing lip 12a.

- the stripping zone of the inner seal 12 is arranged such that the distance K of Sealing lip 12a from the front edge 3c of the bit guide 3 is larger than the maximum Stroke H of the chisel 4. This ensures that the contact area the sealing lip 12a does not coincide with the guide area of the chisel 4.

- the inner seal takes on 12 with respect to the replacement component 7, a position which, after removal of the Part 7, the inner seal 12 accessible from the front of the component 6 from the outside makes.

- the component 6 receiving the exchange component 7 is part of a Outer housing 13, which surrounds the striking mechanism - supporting it.

- the latter can be displaced in the direction of impact (arrow 5) so far in the direction of the replacement component 7 that its sealing lip 12a is only a short distance from the longitudinal slide 4a in the direction of the longitudinal axis 4a.

- This arrangement has the consequence, among other things, that the area of the inner seal 12 (after removal of part 7 and chisel 4) is particularly easy to see and access.

- FIG. 1 is the annular space (shown in FIG. 1) 10 - which is limited by parts 7a, 7b and 11 - with a ring 14 filled in elastic material.

- the cross slide 11 shows the endeavor with respect to the longitudinal axis 4a of the chisel 4 to assume a predetermined central position.

- the resilient support within the replacement component 7 has the result that undesirable rattling movements - and thus the resulting noise development - be dampened.

- the wall 11a can also have a sealing ring made of elastic material be equipped, which is constantly on the outer surface of the chisel 4 and thus - in addition to the inner seal 12 - forms a further sealing point.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Percussive Tools And Related Accessories (AREA)

Abstract

Description

Die Erfindung betrifft ein fluidbetriebenes Schlagwerk mit einer Schutzvorrichtung und einem mit dem Schlagwerk verbundenen Gehäuseteil, der das Schlagwerk zumindest stirnseitig gegen die Außenumgebung abschirmt und in welchen ein vom Schlagwerk angetriebenes Schlagwerkzeug hineinragt. Das Gehäuseteil weist an seiner Durchtrittsöffnung für das Schlagwerkzeug eine Außendichtung auf, die das Schlagwerkzeug quer zu seiner Längsachse allenfalls mit geringem Abstand umschließt und in dieser Querrichtung beweglich ausgebildet ist.The invention relates to a fluid-powered hammer mechanism with a protective device and a housing part connected to the striking mechanism, which at least the striking mechanism shields against the outside environment and in which one of the Percussion driven impact tool protrudes. The housing part instructs its passage opening for the striking tool on an outer seal the striking tool transverse to its longitudinal axis at most with a small distance encloses and is designed to be movable in this transverse direction.

Mittels eines fluiden Druckmittels angetriebene Schlagwerke, deren Schlagwerkzeuge in den meisten Fällen aus einem ein Einsteckwerkzeug bildenden Meißel bestehen, werden überwiegend zur Materialzertrümmerung eingesetzt. Dabei fällt neben dem in groben Stücken gebrochenen Material auch Gesteinsstaub mit Kornanteilen bis zur Größe von einigen Millimetern an. Da dieser Gesteinsstaub in den meisten Fällen einen hohen Anteil an verschleißfördernden Werkstoffen (beispielsweise Quarz) beinhaltet, hat sein Eindringen in die Werkzeugführung einen erhöhten Verschleiß und möglicherweise den vorzeitigen Ausfall der betroffenen Bauelemente zur Folge.Impact mechanisms driven by a fluid pressure medium, their impact tools in most cases from a chisel forming an insert tool exist, are mainly used for material destruction. It falls in addition to the material broken into coarse pieces, also rock dust Grain fractions up to the size of a few millimeters. Because this rock dust in most cases a high proportion of wear-promoting materials (e.g. quartz) has its penetration into the tool guide increased wear and possibly premature failure of the affected Components result.

Zum Schutz der Werkzeugführung gegen das Eindringen von Verschmutzungen ist bereits die Verwendung elastischer Dichtungselemente vorgeschlagen worden, die durch Vorspannung über ihre Kontaktflächen mit dem Schlagwerkzeug das Eindringen auch kleiner bis staubförmiger Verunreinigungen verhindern sollen. Derartige Schutzvorrichtungen werden beim rauhen Baustelleneinsatz jedoch leicht beschädigt und unterliegen darüber hinaus infolge der ständigen Hin- und Herbewegung des Schlagwerkzeugs einem erheblichen Verschleiß.To protect the tool guide against the ingress of dirt the use of elastic sealing elements has already been proposed, the by prestressing the contact surfaces with the striking tool Prevent even small to dusty contaminants from entering. Such protective devices are used in rough construction site use slightly damaged and are also subject to constant back and forth Movement of the striking tool a considerable wear.

Aus der Vorveröffentlichung DE-A1-3440530 ist ein maschinengeführtes Schlagwerkzeug der eingangs erwähnten Gattung bekannt, welches vollständig gekapselt ist und außerhalb seiner Meißelführung ein nach außen abschirmendes, scheibenförmiges Dämmelement aufweist. Das Schlagwerk selbst stützt sich über elastische Dämmelemente innerhalb des umgebenden Gehäuses ab.From the prior publication DE-A1-3440530 is a machine-guided striking tool the genus mentioned above, which is completely encapsulated and outside of its chisel guide is an outward shielding has disc-shaped insulation element. The percussion itself supports itself elastic insulation elements within the surrounding housing.

Der Erfindung liegt die Aufgabe zugrunde, ein fluidbetriebenes Schlagwerk mit einer Schutzvorrichtung zu schaffen, das insbesondere auch den im rauhen Baustelleneinsatz zu erwartenden Beanspruchungen gerecht wird. Insbesondere sollen durch verminderten Verschleiß im Bereich der Werkzeugführung die Funktionssicherheit des Schlagwerks erhöht sowie der Reparatur- und Wartungsaufwand herabgesetzt werden.The invention has for its object a fluid-powered To create striking mechanism with a protective device, especially in rough construction site use expected stresses. In particular, should functional reliability due to reduced wear in the area of the tool guide of the striking mechanism increased as well as the repair and maintenance effort be reduced.

Die Aufgabe wird durch eine Ausgestaltung mit den Merkmalen des Anspruchs 1 gelöst.The object is achieved by an embodiment with the features of claim 1 solved.

Der Grundgedanke der Erfindung besteht danach darin, das Schlagwerk - in Gegenrichtung zur Schlagrichtung des Schlagwerkzeugs gesehen - im Bereich vor der Werkzeugführung gleichzeitig mit einer Außendichtung in Form eines beweglich gelagerten Querschiebers auszustatten, dem entgegen der Schlagrichtung eine sich am Schlagwerkzeug elastisch abstützende Innendichtung nachgeschaltet ist.The basic idea of the invention is then the striking mechanism Seen in the opposite direction to the striking direction of the striking tool - in the area in front of the tool guide with an external seal in the form of a movable mounted cross slide, against the direction of impact an elastically supporting inner seal connected downstream of the impact tool is.

Während der Querschieber gleichzeitig als mechanische Abschirmung wirksam ist und als Vorabstreifer dient, soll die diesem nachgeschaltete Innendichtung das Eindringen feinerer Verunreinigungen in den Bereich der Werkzeugführung verhindern. While the cross slide also acts as a mechanical shield is and serves as a scraper, the inner seal downstream of this Prevent fine impurities from entering the tool guide area.

Das Schlagwerk selbst kann an sich beliebig ausgebildet sein, soweit es ein in einer Werkzeugführung hin und her bewegliches Schlagwerkzeug aufweist, welches mittels des Schlagwerks angetrieben ist.The percussion mechanism itself can be of any design as far as it is in a tool guide back and forth movable impact tool, which is driven by the striking mechanism.

Im einzelnen ist die in Rede stehende Schutzvorrichtung dadurch gekennzeichnet, daß die Außendichtung als in einer Querführung gelagerter Querschieber ausgebildet ist, der als Einheit bei Querbewegungen des Schlagwerkzeugs von diesem mitbewegt wird; daß der Außendichtung entgegen der Schlagrichtung des Schlagwerkzeugs eine Innendichtung nachgeschaltet ist, die an dem Schlagwerkzeug außerhalb von dessen Werkzeugführung elastisch anliegt, und daß die Außen- und die Innendichtung jeweils auswechselbar (an dem sie tragenden Bestandteil) befestigt sind.In particular, the protective device in question is characterized in that that the outer seal as a transverse slide mounted in a transverse guide is formed as a unit for transverse movements of the striking tool by this is moved; that the outer seal against the direction of impact of the Impact tool an inner seal is connected to the impact tool rests elastically outside of its tool guide, and that the External and internal seals can be replaced (on the component that carries them) are attached.

Der Querschieber kann - den an ihn gestellten Anforderungen entsprechend - aus

verschiedenen Werkstoffen, insbesondere Metall oder Kunststoff, bestehen.

Wesentlich in dem hier angesprochenen Zusammenhang ist eine derartige Ausgestaltung

des Querschiebers, die sicherstellt, daß er als Einheit in Querrichtung

ausreichend beweglich ist, d.h. bei etwaigen Querbewegungen des Schlagwerkzeugs

von diesem bezüglich der ihn aufnehmenden Querführung verschoben

wird.

Dies setzt voraus, daß der Querschieber im Bereich seiner Durchtrittsöffnung eine

Ausgestaltung aufweist, welche ein Verkanten des Querschiebers auch bei relativ

dazu schräg gestelltem Schlagwerkzeug ausschließt.The cross slide can - according to the requirements placed on it - consist of different materials, in particular metal or plastic. Essential in the context mentioned here is such a configuration of the cross slide, which ensures that it is sufficiently movable as a unit in the transverse direction, ie is displaced by any transverse movements of the striking tool with respect to the transverse guide receiving it.

This presupposes that the cross slide has a configuration in the area of its passage opening which prevents tilting of the cross slide even when the striking tool is inclined relative to it.

Bei einer besonders einfachen Ausführungsform des Erfindungsgegenstands ist der Querschieber scheibenförmig ausgebildet (Anspruch 2); er sollte dabei derart ausgebildet sein, daß er in Längsrichtung des Schlagwerkzeugs eine ausreichende Steifigkeit aufweist.In a particularly simple embodiment of the subject of the invention the cross slide is disc-shaped (claim 2); he should be like this be designed so that it is sufficient in the longitudinal direction of the striking tool Has rigidity.

Der Querschieber kann dadurch vorteilhaft ausgestaltet sein, daß er eine Durchtrittsöffnung aufweist, deren dem Schlagwerkzeug zugewandte Wandung konvex gewölbt ist (Anspruch 3). The cross slide can be advantageously designed in that it has a passage opening has, the wall facing the striking tool convex is arched (claim 3).

Weiterhin sollte der Querschieber in der Weise ausgebildet sein, daß er eine in sich starre Einheit bildet (Anspruch 4).Furthermore, the cross slide should be designed in such a way that it is in rigid unit forms (claim 4).

Im Rahmen der erfindungsgemäßen Lösung kann der Querschieber gleichzeitig auch aus mehreren Werkstoffen bestehen; insbesondere kann er derart ausgestaltet sein, daß die Wandung der Durchtrittsöffnung für das Schlagwerkzeug des im übrigen in sich starren Querschiebers zumindest teilweise aus elastischem Werkstoff besteht (Anspruch 5); als Werkstoffe kommen insbesondere gummiähnliche Materialien oder Kunststoff in Betracht.In the context of the solution according to the invention, the cross slide can be operated simultaneously also consist of several materials; in particular, it can be configured in this way be that the wall of the passage opening for the striking tool of otherwise rigid cross slide at least partially made of elastic Material consists (claim 5); rubber-like materials in particular come as materials Materials or plastic.

Vorzugsweise weist der Querschieber dabei auf der dem Schlagwerkzeug zugewandten Seite einen elastischen Einsatz auf, welcher die Wandung der Durchtrittsöffnung zumindest mitbildet (Anspruch 6).The cross slide preferably faces the one facing the striking tool Side on an elastic insert, which the wall of the passage opening at least forms (claim 6).

Der elastische Einsatz kann vorteilhaft auch so bemessen und ausgebildet sein, daß er an dem Schlagwerkzeug anliegt und somit eine zusätzliche Abdichtung bildet.The elastic insert can advantageously also be dimensioned and designed such that that it rests on the striking tool and thus an additional seal forms.

Eine unerwünschte zusätzliche Geräuschentwicklung während des Betriebs des Schlagwerks läßt sich gegebenenfalls dadurch in Grenzen halten, daß der Querschieber quer zur Schlagrichtung elastisch abgestützt ist (Anspruch 7). Unter Einwirkung dieser elastischen Abstützung an der Umgebung zeigt der Querschieber das Bestreben, eine vorgegebene Mittellage beizubehalten und sich dementsprechend weitergehend seitlich am Schlagwerkzeug abzustützen.An undesirable additional noise during the operation of the Percussion mechanism can be kept within limits if the cross slide is elastically supported transversely to the direction of impact (claim 7). Under The cross slide shows the effect of this elastic support on the surroundings the endeavor to maintain a predetermined middle position and accordingly continue to be supported laterally on the impact tool.

Bei einer besonders wartungsfreundlichen Ausbildung des Erfindungsgegenstandes bildet der Querschieber mit der ihn abstützenden Querführung ein Austausch-Bauteil, das lösbar an dem Gehäuseteil befestigt ist (Anspruch 8).With a particularly maintenance-friendly training of the subject of the invention the cross slide forms a replacement component with the transverse guide supporting it, which is releasably attached to the housing part (claim 8).

Die Innendichtung ist vorzugsweise derart ausgebildet, daß sie zumindest eine am Schlagwerkzeug anliegende Dichtlippe aufweist (Anspruch 9). The inner seal is preferably designed such that it has at least one on the striking tool sealing lip (claim 9).

Um das Eindringen von Verunreinigungen in den Bereich der Werkzeugführung zu verhindern, sollte zumindest eine Dichtlippe der Innendichtung in Schlagrichtung schräg verlaufend angeordnet sein (Anspruch 10).To prevent contaminants from entering the tool guide area To prevent this, at least one sealing lip of the inner seal should face in the direction of impact be arranged obliquely (claim 10).

Bei der Ausgestaltung der Innendichtung hat es sich als zweckmäßig erwiesen, das Verhältnis aus dem größtmöglichen Querversatz des Schlagwerkzeugs und der Länge jeder Dichtlippe mit mindestens 1 bis 3 zu bemessen (Anspruch 11).When designing the inner seal, it has proven to be useful the ratio of the greatest possible offset of the striking tool and to measure the length of each sealing lip with at least 1 to 3 (claim 11).

Soweit die sonstigen geometrischen und/oder konstruktiven Einzelheiten dies

zulassen, kann die Innendichtung an beliebigen Bestandteilen der Gesamtvorrichtung

befestigt sein.

Eine besonders einfache Ausführungsform ist dadurch gekennzeichnet, daß die

Innendichtung an einer Verlängerung der Werkzeugführung befestigt ist, wobei

die Verlängerung im Bereich der Innendichtung das Schlagwerkzeug mit einem

Abstand umschließt, der größer ist als der größtmögliche Querversatz des

Schlagwerkzeugs (Anspruch 12).As far as the other geometrical and / or structural details allow, the inner seal can be attached to any components of the overall device.

A particularly simple embodiment is characterized in that the inner seal is attached to an extension of the tool guide, the extension in the area of the inner seal enclosing the striking tool at a distance which is greater than the greatest possible transverse offset of the striking tool (claim 12).

Das bereits angesprochene Gehäuseteil, welches zumindest den Querschieber trägt, kann Teil des Schlagwerks selbst sein.The housing part already mentioned, which at least the cross slide can be part of the percussion mechanism itself.

Der Erfindungsgegenstand kann jedoch auch an Ausgestaltungen zur Anwendung kommen, bei denen der Gehäuseteil Bestandteil eines das Schlagwerk abstützenden Außengehäuses ist (Anspruch 13). In diesem Fall bildet das Gehäuseteil den stirnseitigen Abschluß des Außengehäuses.However, the subject of the invention can also be used in configurations come in which the housing part is part of a supporting the striking mechanism Outer housing is (claim 13). In this case, the housing part forms the front end of the outer housing.

Vorzugsweise ist die Innendichtung bezüglich der Werkzeugführung derart angeordnet,

daß der Abstand der Dichtlippe von der Vorderkante der Werkzeugführung

(d.h. von dem der Außendichtung zugewandten Endabschnitt der Werkzeugführung)

größer ist als der maximale Hub des Schlagwerkzeugs (Anspruch 14).

Auf diese Weise ist sichergestellt, daß der Kontaktbereich der Dichtlippe nicht mit

dem Führungsbereich des Schlagwerkzeugs zusammenfällt.

Im Bereich der Vorderkante der Werkzeugführung unterliegt das Schlagwerkzeug

einer besonders hohen Beanspruchung, die Beschädigungen an der Außenfläche

des Schlagwerkzeugs zur Folge haben kann. Durch die in Rede stehende Ausgestaltung

der Innendichtung wird verhindert, daß die Dichtlippe der Innendichtung

mit der etwa angegriffenen Außenfläche des Schlagwerkzeugs in Berührung

kommt und dadurch möglicherweise vorzeitig beschädigt wird bzw. vorzeitig ausfällt.The inner seal with respect to the tool guide is preferably arranged such that the distance of the sealing lip from the front edge of the tool guide (ie from the end section of the tool guide facing the outer seal) is greater than the maximum stroke of the striking tool (claim 14). In this way it is ensured that the contact area of the sealing lip does not coincide with the guide area of the impact tool.

In the area of the front edge of the tool guide, the striking tool is subject to a particularly high load, which can result in damage to the outer surface of the striking tool. The design of the inner seal in question prevents the sealing lip of the inner seal from coming into contact with the possibly attacked outer surface of the striking tool and thereby possibly being damaged prematurely or failing prematurely.

Unter dem Gesichtspunkt der Wartungsfreundlichkeit sollte die Innendichtung bezüglich der Außendichtung derart angeordnet sein, daß sie nach Ausbau des Querschiebers oder des diesen umfassenden Austausch-Bauteils (vgl. Anspruch 8) von außen zugänglich ist und erforderlichenfalls abgebaut werden kann.From the point of view of serviceability, the inner seal should be regarding the outer seal should be arranged so that after removing the Cross slide or the replacement component comprising this (cf. claim 8) is accessible from the outside and can be dismantled if necessary.

Die Erfindung wird nachfolgend anhand in der Zeichnung dargestellter Ausführungsbeispiele im einzelnen erläutert.The invention is described below with reference to exemplary embodiments shown in the drawing explained in detail.

Es zeigen:

- Fig.1

- schematisiert einen Teilschnitt durch das Unterteil eines Schlagwerks mit einem zugehörigen Gehäuseteil, welcher ein Austausch-Bauteil mit einer verschiebbar gelagerten Außendichtung aufnimmt, und

- Fig.2

- schematisiert einen Teilschnitt durch das Unterteil eines Schlagwerks mit einem dieses umschließenden Außengehäuse und einem eine Außendichtung aufnehmenden Gehäuseteil, welcher seinerseits Bestandteil des Außengehäuses ist.

- Fig.1

- schematized a partial section through the lower part of an impact mechanism with an associated housing part, which receives an exchange component with a slidably mounted outer seal, and

- Fig.2

- schematized a partial section through the lower part of a striking mechanism with an outer housing enclosing this and a housing part receiving an outer seal, which in turn is part of the outer housing.

Da die Ausgestaltung des fluidbetriebenen Schlagwerks für die Verwirklichung der

Erfindung im übrigen nicht von Belang ist, zeigt die Darstellung gemäß Fig. 1 lediglich

deren Unterteil 1, in dem über einen Bolzen 2 eine Werkzeugführung 3 unbeweglich

gehalten ist. In dieser stützt sich ein Schlagwerkzeug in Form eines Meißels

4 mit der Längsachse 4a in Längsrichtung beweglich ab. Die Bewegung des Meißels

4 in Schlagrichtung ist durch einen Pfeil 5 angedeutet.Because the design of the fluid-powered hammer mechanism for the realization of the

In addition, the invention according to FIG. 1 is not relevant, the illustration only shows

whose lower part 1, in which a

Die vom Meißel 4 möglicherweise ausgeführten Pendelbewegungen sind - stark vergrößert

- schematisiert durch jeweils gestrichelte Linien 4b und 4c verdeutlicht. The pendulum movements possibly carried out by the

An dem Schlagwerkzeug-Unterteil 1 ist als Verlängerung ein Gehäuseteil 6 befestigt,

welcher stirnseitig (d.h. in der Darstellung unten) lösbar ein Austausch-Bauteil 7

aufnimmt. Zu diesem Zweck ist der Gehäuseteil 6 mit einer Ausnehmung 8 ausgestattet,

die geringfügig tiefer bemessen ist als die Höhe des Austausch-Bauteils 7

und deren Durchmesser an den Durchmesser des Austausch-Bauteils 7 angepaßt

ist. Die Teile 6 und 7 sind über Bolzen 9 lösbar aneinander befestigt.A

Das Austausch-Bauteil 7 besteht seinerseits aus einer Stirnplatte 7a und einer Rükkenplatte

7b. Diese sind so beschaffen, daß sie einerseits eine ausreichend große

Durchtrittsöffnung 7c für den Meißel 4 und andererseits - quer zur Längsachse 4a -

einen Ringraum 10 begrenzen; in diesem ist eine Außendichtung in Form eines

plattenförmigen Querschiebers 11 beweglich gelagert.The

Die Höhe des Ringraums 10 in Richtung der Längsachse 4a ist geringfügig größer

bemessen als die Stärke des Querschiebers 11, so daß dieser unter Einwirkung des

Querbewegungen ausführenden Meißels 4 bezüglich des Gehäuseteils 6 als in sich

starre Einheit hin und her bewegt werden kann.The height of the

Abweichend von der schematischen Darstellung in Fig. 1 ist die Wandung 11a des

Querschiebers 11, welche dessen Durchtrittsöffnung für den Meißel 4 begrenzt, so

ausgebildet, daß auch Querbewegungen des Meißels 4 (angedeutet durch die

Linien 4b und 4c) nicht zum Verkanten der Teile 4 und 11 führen; zu diesem Zweck

ist die Wandung 11a (abweichend von der Darstellung) in Richtung auf den Meißel 4

konvex gewölbt.Deviating from the schematic illustration in FIG. 1, the

Die Teile 7a und 7b sind (in nicht dargestellter Weise) miteinander verbunden; dementsprechend

kann das Austausch-Bauteil 7 mit dem darin frei beweglich gelagerten

Querschieber 11 als Einheit ein- und ausgebaut werden.The

Dem Querschieber 11 ist - entgegen der Schlagrichtung (Pfeil 5) innerhalb des Gehäuseteils

6 eine Innendichtung 12 nachgeschaltet, deren Dichtlippe 12a außerhalb

der Werkzeugführung 3 elastisch an dem Meißel 4 anliegt und als Hauptabstreifer

für in das Gehäuseteil 6 etwa eingedrungene Verunreinigungen dient.The

In dem dargestellten Ausführungsbeispiel ist die Innendichtung 12 an einer Verlängerung

3a der Werkzeugführung über eine Befestigungsnut 3b lösbar befestigt; die

Verlängerung umschließt dabei im Bereich der Innendichtung den Meißel 4 mit

einem Abstand s, der größer ist als der größtmögliche Querversatz des Meißels in

diesem Bereich (angedeutet durch die Linien 4b und 4c).In the illustrated embodiment, the

Um eine einwandfreie Funktion der Innendichtung 12 bei unterschiedlichen Arbeitsbedingungen

sicherzustellen, ist die Länge der Dichtlippe 12a so bemessen, daß

das Verhältnis aus deren Länge und dem größtmöglichen Querversatz des Meißels

4 im Bereich der Dichtlippe 12a einen Wert größer als 2 aufweist.To ensure that the

Die Abstreifzone der Innendichtung 12 ist derart angeordnet, daß der Abstand K der

Dichtlippe 12a von der Vorderkante 3c der Meißelführung 3 größer ist als der maximale

Hub H des Meißels 4. Auf diese Weise ist sichergestellt, daß der Kontaktbereich

der Dichtlippe 12a nicht mit dem Führungsbereich des Meißels 4 zusammenfällt.The stripping zone of the

Wie die Darstellung gemäß Fig. 1 weiterhin erkennen läßt, nimmt die Innendichtung

12 bezüglich des Austausch-Bauteils 7 eine Lage ein, welche nach Ausbau des

Teils 7 die Innendichtung 12 von der Stirnseite des Bauteils 6 her von außen zugänglich

macht.As can also be seen in the illustration according to FIG. 1, the inner seal takes on

12 with respect to the

Abweichend von der zuvor erläuterten Ausführungsform ist bei der Ausgestaltung

gemäß Fig. 2 das das Austausch-Bauteil 7 aufnehmende Bauteil 6 Bestandteil eines

Außengehäuses 13, welches das Schlagwerk - dieses abstützend - umschließt.The embodiment differs from the previously explained

Die in Rede stehende Darstellung zeigt dabei - soweit das Schlagwerk betroffen ist -

wiederum nur das Unterteil 1 des Schlagwerks nebst Werkzeugführung 3, Verlängerung

3a und Innendichtung 12. The illustration in question shows - as far as the striking mechanism is concerned -

again only the lower part 1 of the striking mechanism along with

Letztere kann im Rahmen der Erfindung in Schlagrichtung (Pfeil 5) so weit in Richtung

auf das Austausch-Bauteil 7 verschoben liegen, daß ihre Dichtlippe 12a bezüglich

des Querschiebers 11 lediglich einen geringen Abstand in Richtung der Längsachse

4a aufweist.

Diese Anordnung hat unter anderem zur Folge, daß der Bereich der Innendichtung

12 (nach Ausbau des Teils 7 und des Meißels 4) besonders gut einzusehen und zugänglich

ist.In the context of the invention, the latter can be displaced in the direction of impact (arrow 5) so far in the direction of the

This arrangement has the consequence, among other things, that the area of the inner seal 12 (after removal of

In Abänderung der Ausgestaltung gemäß Fig. 1 ist der (aus Fig. 1 ersichtliche) Ringraum

10 - der von den Teilen 7a, 7b und 11 begrenzt wird - mit einem Ring 14 aus

elastischem Werkstoff ausgefüllt. Unter Einwirkung dieser seitlichen, federnden Abstützung

zeigt der Querschieber 11 das Bestreben, bezüglich der Längsachse 4a

des Meißels 4 eine vorgegebene Mittellage einzunehmen. Die federnde Abstützung

innerhalb des Austausch-Bauteils 7 hat zur Folge, daß unerwünschte Klapperbewegungen

- und damit die sich daraus etwa ergebende Geräuschentwicklung -

gedämpft werden.1 is the annular space (shown in FIG. 1)

10 - which is limited by

Es versteht sich von selbst, daß die durch die Wandung 11a des Querschiebers 11

festgelegte Durchtrittsöffnung für den Meißel 4 - abgesehen von ihrer sonstigen

Ausgestaltung - größenmäßig derart an den Durchmesser des Meißels angepaßt

sein muß, daß zwischen den Teilen 4 und 11 keine Verkantung auftreten kann.It goes without saying that the through the

Die Wandung 11a kann im übrigen mit einem Dichtring aus elastischem Werkstoff

ausgestattet sein, welcher ständig an der Außenfläche des Meißels 4 anliegt und

somit - zusätzlich zur Innendichtung 12 - eine weitere Dichtstelle bildet.The

Claims (14)

- Fluid-operated impact device with a protection device and a housing part (6) connected to the impact device, said housing part screening the impact device against the outside environment at least on the face side and into said housing part a percussive tool (4) driven by the impact device projects, and at its passage for the percussive tool (4) said housing part (6) has an external seal (11), which encloses the percussive tool (4) transversely to its longitudinal axis (4a), possibly at a slight distance, and is constructed to be movable in this transverse direction, characterised in that

the external seal (11) is constructed in the form of a transverse slide disposed in a transverse guide means (7a, 7b), said slide being moved along as a unit by the percussive tool (4) during transverse movements thereof; that an internal seal (12), which abuts elastically against the percussive tool (4) outside its tool guide means (3), is connected after the external seal (11) contrary to the direction of impact (arrow 5) of the percussive tool (4), and that the external and internal seal (11 or 12) are fastened to be respectively replaceable. - Impact device according to Claim 1, characterised in that the transverse slide (11) is disc-shaped.

- Impact device according to at least one of the preceding claims, characterised in that

the transverse slide (11) has a passage, the wall (11a) of which facing the percussive tool (4) is arched in a convex shape. - Impact device according to at least one of the preceding claims, characterised in that

the transverse slide (11) is constructed in the form of an inherently rigid unit. - Impact device according to at least one of Claims 1 to 3, characterised in that

the wall (11a) of the passage of the otherwise inherently rigid transverse slide (11) for the percussive tool (4) is made at least partially of elastic material. - Impact device according to Claim 5, characterised in that on the side facing the percussive tool (4), the transverse slide (11) has an elastic insert which at least also forms the wall (11a) of the passage.

- Impact device according to at least one of the preceding claims, characterised in that

the transverse slide (11) is elastically supported transversely to the direction of impact (arrow 5). - Impact device according to at least one of the preceding claims, characterised in that

with the transverse guide means (7a, 7b) supporting it, the transverse slide (11) forms a replaceable structural part (7), which is detachably fastened to the housing part (6). - Impact device according to at least one of the preceding claims, characterised in that

the internal seal (12) has at least one sealing lip (12a) abutting against the percussive tool (4). - Impact device according to Claim 9, characterised in that at least one sealing lip (12a) of the internal seal (12) is arranged to run on an incline in the direction of impact (arrow 5).

- Impact device according to at least one of Claims 9 and 10, characterised in that

the ratio of the length of each sealing lip (12a) to the largest possible transverse displacement of the percussive tool (4) amounts to at least 1 to 3. - Impact device according to at least one of the preceding claims, characterised in that

the internal seal (12) is fastened to an extension (3a) of the tool guide means (3) and in the region of the internal seal (12) the extension (3a) encloses the percussive tool (4) at a distance (s) which is greater than the largest possible transverse displacement of the percussive tool (4). - Impact device according to at least one of the preceding claims, characterised in that

the housing part (6) is a component of the external housing (13) in which the impact device is supported. - Impact device according to at least one of Claims 9 to 13, characterised in that

the distance (K) of the sealing lip (12a) from the front edge (3c) of the tool guide means (3) is greater than the maximum stroke (H) of the percussive tool (4).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19628815 | 1996-07-17 | ||

| DE19628815A DE19628815C2 (en) | 1996-07-17 | 1996-07-17 | Protective device for preventing the ingress of contaminants on a fluid-powered hammer mechanism |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0846528A1 EP0846528A1 (en) | 1998-06-10 |

| EP0846528B1 true EP0846528B1 (en) | 2002-04-03 |

Family

ID=7800073

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97111722A Expired - Lifetime EP0846528B1 (en) | 1996-07-17 | 1997-07-10 | Percussive tool with fluid-pressure drive and a protection device |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5873579A (en) |

| EP (1) | EP0846528B1 (en) |

| JP (1) | JP4037938B2 (en) |

| AT (1) | ATE215427T1 (en) |

| DE (1) | DE19628815C2 (en) |

| ES (1) | ES2171786T3 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19851444B4 (en) * | 1998-11-09 | 2008-05-15 | Atlas Copco Construction Tools Gmbh | Removal device for the outer, serving as a tool support guide bush in the housing of a striking mechanism |

| DE10012916A1 (en) * | 2000-03-16 | 2001-09-20 | Krupp Berco Bautechnik Gmbh | Protective device for preventing the ingress of contaminants on a fluid-powered hammer mechanism |

| US6510904B1 (en) * | 2000-05-26 | 2003-01-28 | Nippon Pneumatic Mfg. Co., Ltd. | Protected tool bushing for an impact hammer |

| DE10061810A1 (en) * | 2000-12-12 | 2002-06-13 | Hilti Ag | Striking hand tool with rotating guide tube |

| US6761723B2 (en) * | 2002-01-14 | 2004-07-13 | Dynamic Spine, Inc. | Apparatus and method for performing spinal surgery |

| DE10202648A1 (en) * | 2002-01-23 | 2003-07-31 | Atlas Copco Constr Tools Ab | Bracket for the inner seal on a fluid-powered hammer mechanism |

| DE10257483A1 (en) * | 2002-12-10 | 2004-07-01 | Hilti Ag | Tool receiver for liquid-flushed striking tools has at least one flushing line running along interior surface of pot |

| EP1651150B1 (en) * | 2003-08-07 | 2021-03-24 | Dynamic Spine, Inc. | Intervertebral prosthetic device and associated devices and methods for implanting the intervertebral prosthetic device |

| SE528035C2 (en) * | 2004-03-12 | 2006-08-15 | Atlas Copco Constr Tools Ab | Hydraulic breaker with lubricated tool sleeve |

| US8360167B2 (en) * | 2010-08-11 | 2013-01-29 | Caterpillar Inc. | Composite seal for a hydraulic hammer |

| US9102045B2 (en) * | 2011-09-29 | 2015-08-11 | Caterpillar Inc. | System and method for easy removal of hydraulic hammer bushing |

| KR101592447B1 (en) * | 2014-06-11 | 2016-02-11 | 대모 엔지니어링 주식회사 | Oil pressure breaker equipped lower sealing unit |

| US10065301B2 (en) * | 2015-02-05 | 2018-09-04 | Caterpillar Inc. | Lower buffer and bushing protector |

| EP3446835A1 (en) | 2017-08-21 | 2019-02-27 | Sandvik Mining and Construction Oy | Seal and method of sealing a tool of a breaking hammer |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2764138A (en) * | 1953-03-02 | 1956-09-25 | Atlas Copco Ab | Percussion tools having a reciprocable hammer piston actuated by combustion gases |

| DE1678280A1 (en) * | 1967-10-18 | 1972-05-18 | Mutzhas Maximilian F | Safety ski binding |

| DE3125454A1 (en) * | 1981-06-29 | 1983-01-20 | Hilti AG, 9494 Schaan | DRILLING HAMMER FOR DRILLING AND IMPACT DRILLING |

| DE3440530A1 (en) * | 1983-11-02 | 1985-05-09 | Heinrich 1000 Berlin Henze | Hydraulic breaking-up hammer |

| US4694911A (en) * | 1984-07-13 | 1987-09-22 | Kennedy James D | Drilling assembly for percussion drilling of deep wells |

| DE8436752U1 (en) * | 1984-12-15 | 1985-03-21 | Röhm, Günter Horst, 7927 Sontheim | DRILL CHUCK |

| DE3606331A1 (en) * | 1986-02-27 | 1987-09-03 | Bosch Gmbh Robert | Dust-sealing mechanism |

| DE9115805U1 (en) * | 1991-12-20 | 1993-04-15 | Robert Bosch Gmbh, 7000 Stuttgart | Dust cap for drilling rigs |

| SE9201340L (en) * | 1992-04-29 | 1993-10-30 | Berema Atlas Copco Ab | Striking machine |

| US5301761A (en) * | 1993-03-09 | 1994-04-12 | Ingersoll-Rand Company | Pressure reversing valve for a fluid-actuated, percussive drilling apparatus |

| US5562170A (en) * | 1995-08-30 | 1996-10-08 | Ingersoll-Rand Company | Self-lubricating, fluid-actuated, percussive down-the-hole drill |

-

1996

- 1996-07-17 DE DE19628815A patent/DE19628815C2/en not_active Expired - Lifetime

-

1997

- 1997-07-10 AT AT97111722T patent/ATE215427T1/en active

- 1997-07-10 ES ES97111722T patent/ES2171786T3/en not_active Expired - Lifetime

- 1997-07-10 EP EP97111722A patent/EP0846528B1/en not_active Expired - Lifetime

- 1997-07-15 JP JP18941097A patent/JP4037938B2/en not_active Expired - Lifetime

- 1997-07-16 US US08/895,237 patent/US5873579A/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| US5873579A (en) | 1999-02-23 |

| DE19628815A1 (en) | 1998-01-22 |

| EP0846528A1 (en) | 1998-06-10 |

| JPH1058353A (en) | 1998-03-03 |

| ATE215427T1 (en) | 2002-04-15 |

| JP4037938B2 (en) | 2008-01-23 |

| ES2171786T3 (en) | 2002-09-16 |

| DE19628815C2 (en) | 1999-02-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0846528B1 (en) | Percussive tool with fluid-pressure drive and a protection device | |

| DE69327169T2 (en) | DRILL CHUCK | |

| DE102014001921B4 (en) | Milling drum with a, in particular replaceable, material guide device | |

| EP0472982B1 (en) | Hydraulically operated impact drilling device, especially for boltdrilling | |

| DE29811073U1 (en) | Device for screening and / or crushing screen materials | |

| DE2717336A1 (en) | PNEUMATIC HAMMER DRIVE | |

| DE2111234B2 (en) | Chisel or hammer drill | |

| DE3515244A1 (en) | PERFORMANCE TOOL | |

| DE69837186T2 (en) | Arrangement in connection with a hydraulic breaking device | |

| DE2844110A1 (en) | HAND TOOL MACHINE, ESPECIALLY CHISEL HAMMER | |

| DE2810606C2 (en) | Chisel for a breaking tool that works by striking the rock | |

| EP1691954B1 (en) | Percussion hammer and/or drill hammer comprising a handle which can be guided in a linear manner | |

| DE69518161T2 (en) | HYDRAULIC BREAKING HAMMER | |

| EP1136190B1 (en) | Protection element for preventing the passage of contaminants for a percussive tool with fluid-pressure drive | |

| DE69031836T2 (en) | DEMOLITION HAMMER | |

| EP1342539B1 (en) | Support for an inner seal of a fluid-pressure drive | |

| DE3842891A1 (en) | ROTATIONAL DRILLING METHOD AND ROTATIONAL DRILLING DEVICE FOR CARRYING OUT THE METHOD | |

| DE4136584B4 (en) | Drilling and chiseling device with tool holder | |

| DE3630444A1 (en) | Excavating device for material excavation by cutting | |

| DE102004039865B4 (en) | drill | |

| EP3693532B1 (en) | Earth boring device, method of manufacturing a device for boring in earth, method of servicing a device for boring in earth and use of a device for boring in earth | |

| DE9411545U1 (en) | Device for holding a cutting chisel | |

| DE3241483C2 (en) | Impact device | |

| DE2838103A1 (en) | IMPROVED EXHAUST DRILL DRILL | |

| DE4110261A1 (en) | SOUND INSULATION DEVICE ON A HAND-GUIDED, FLUID-DRIVEN IMPACT OR DRILLING TOOL |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH ES FI FR GB IT LI SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KRUPP BERCO BAUTECHNIK GMBH |

|

| 17P | Request for examination filed |

Effective date: 19981210 |

|

| AKX | Designation fees paid |

Free format text: AT CH DE ES FI FR GB IT LI SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT CH DE ES FI FR GB IT LI SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| RTI1 | Title (correction) |

Free format text: PERCUSSIVE TOOL WITH FLUID-PRESSURE DRIVE AND A PROTECTION DEVICE |

|

| 17Q | First examination report despatched |

Effective date: 20010601 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT CH ES FI FR GB IT LI SE |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHAREINA, MARTIN Inventor name: DEIMEL, THOMAS Inventor name: PROKOP, HEINZ-JUERGEN, DR.-ING. Inventor name: FRITZ, KARLHEINZ Inventor name: AHR, THORSTEN |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH ES FI FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 215427 Country of ref document: AT Date of ref document: 20020415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020403 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: TROESCH SCHEIDEGGER WERNER AG |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2171786 Country of ref document: ES Kind code of ref document: T3 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: ATLAS COPCO CONSTRUCTION TOOLS GMBH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: KRUPP BERCO BAUTECHNIK GMBH TRANSFER- ATLAS COPCO CONSTRUCTION TOOLS GMBH |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030106 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20160713 Year of fee payment: 20 Ref country code: CH Payment date: 20160721 Year of fee payment: 20 Ref country code: GB Payment date: 20160721 Year of fee payment: 20 Ref country code: IT Payment date: 20160725 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20160721 Year of fee payment: 20 Ref country code: SE Payment date: 20160720 Year of fee payment: 20 Ref country code: AT Payment date: 20160721 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20160715 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20170709 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 215427 Country of ref document: AT Kind code of ref document: T Effective date: 20170710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170709 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20180508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170711 |