EP0805035B1 - Anbring- und abnehmbare Verbindungskabelplattform für einen kontinuierlich arbeitenden Tintenstrahldruckkopf - Google Patents

Anbring- und abnehmbare Verbindungskabelplattform für einen kontinuierlich arbeitenden Tintenstrahldruckkopf Download PDFInfo

- Publication number

- EP0805035B1 EP0805035B1 EP19970302689 EP97302689A EP0805035B1 EP 0805035 B1 EP0805035 B1 EP 0805035B1 EP 19970302689 EP19970302689 EP 19970302689 EP 97302689 A EP97302689 A EP 97302689A EP 0805035 B1 EP0805035 B1 EP 0805035B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ink jet

- umbilical

- jet printhead

- printhead

- rigid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007641 inkjet printing Methods 0.000 description 7

- 239000012530 fluid Substances 0.000 description 6

- 238000007639 printing Methods 0.000 description 6

- 238000000429 assembly Methods 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/17—Ink jet characterised by ink handling

- B41J2/175—Ink supply systems ; Circuit parts therefor

Definitions

- the present invention relates to continuous ink jet printing and, more particularly, to an attachable and detachable umbilical cap that facilitates ink, power, air, data and registration for a continuous ink jet printhead and printing system.

- Ink jet printing systems are known in which a printhead defines one or more rows of orifices which receive an electrically conductive recording fluid from a pressurized fluid supply manifold and eject the fluid in rows of parallel streams.

- Printers using such printheads accomplish graphic reproduction by selectively charging and deflecting the drops in each of the streams and depositing at least some of the drops on a print receiving medium, while others of the drops strike a drop catcher device.

- Continuous ink jet printing systems include an umbilical that supplies fluid (ink), air, power, and data to the printhead.

- installation of the umbilical has been a difficult and tedious process, comprised of a complex weldment with precision machined features that contributed little to assembling of the hardware.

- the umbilical has typically had many lines, cables, and connectors.

- the printhead housing cap and spine i.e., ink jet printhead support

- the printhead housing cap and spine i.e., ink jet printhead support

- cables become twisted, connectors get caught on other features, and various elements end up out of position. After component parts from the printing assembly were assembled to the spine, disassembly was almost impossible without damaging the hardware.

- a system for linking an umbilical to a continuous ink jet printhead comprising:

- the rigid printhead housing cap serves as a platform in that it serves as an attachment/detachment point for the umbilical, covers, and structural elements of a continuous ink jet printhead.

- the umbilical is easily attachable/detachable by separating the printhead housing cap from the ink jet printhead support structure, and threading the umbilical into or out of the rigid printhead housing cap.

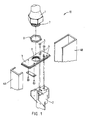

- Fig. 1 is an exploded view of an ink jet printhead structure illustrating alignment between the ink jet printhead support structure and the umbilical, in accordance with the present invention.

- a device in a continuous ink jet printing system that will serve as a rigid link between the umbilical 1 that supplies fluid (ink), air, power, and data to a continuous ink jet printhead (not shown) and the support structure 2 which supports the printhead and receives the fluid, air, power and data.

- the air provided a rigid ink jet printhead housing cap and umbilical platform 3.

- the rigid member 3 is located between the ink jet printhead support structure 2 and the umbilical 1.

- the rigid member 3 operates as a "cap” or lid for the structure 2, and as a platform under the umbilical 1.

- the umbilical 3 has a threaded end portion 7.

- the umbilical is easily attached/detached by separating the rigid member 3 from the support structure 2 and threading the umbilical end portion 7 into or out of receiving means or threaded aperture 9 of the rigid member 3.

- a locking means such as a nut 8 can be placed between the threaded end portion 7 and the rigid member 3 as umbilical 1 is attached to member 3, to lock the umbilical 1 to the rigid member 3.

- the support structure 2 can also be easily attached/detached from the umbilical and rigid member assembly by removing attachment means, such as screws 5. Hence, the umbilical 1 is threaded into the top of rigid member 3, and the support structure 2 is screwed onto the bottom of rigid member 3.

- the umbilical 1 and the rigid platform 3 can be built as a module, thereby eliminating twisting of components.

- the support structure 2 and all of its related hardware can also be built as a module.

- Final assembly then, merely comprises placing both assemblies together via self-locating features, and fastening the modules with attachment means 5.

- Built-in registration features in the rigid plate 3 accurately align the support structure 2. This insures transference of position of everything that mounts on the support structure 2 to the rigid platform 3.

- Covers 4A and 4B then enclose the entire linkage apparatus 10.

- Built-in alignment features also automatically locate and properly position the covers 4A and 4B.

- Fig. 1 The self-locating or built-in features can be seen in Fig. 1 as naturally occurring features of tongue-and-groove, lap joining, and pin-in-hole. These naturally occurring features are the keys that locate all of the separate pieces together, without resorting to complex weldment. With the loose hardware precisely located together from printhead to rigid platform 3, tolerances involving the continuous ink jet printhead are known at remote mount holes 6. Hardware that is modular and self-locating is easier to fabricate, inspect, assemble, and is more cost effective, functional, and reliable.

- the present invention is useful in the field of ink jet printing, and has the advantage of providing an optimum connection between a printing system umbilical and the structure that supports an ink jet printhead.

- the present invention provides the further advantage of providing a platform that serves as an attachment/detachment point for the umbilical, covers, and structural elements of a continuous ink jet printing system.

- the attachable/detachable umbilical platform facilitates ink, power, air, and data transference, and registration of a continuous ink jet printhead and printing system.

Landscapes

- Ink Jet (AREA)

- Particle Formation And Scattering Control In Inkjet Printers (AREA)

- Common Mechanisms (AREA)

Claims (7)

- System zum Verbinden eines Versorgungskabels mit dem Druckkopf eines kontinuierlichen Tintenstrahldruckers, enthaltend:eine Tintenstrahldruckkopf-Haltestruktur (2) zum Halten des Tintenstrahldruckkopfes,eine steife Druckkopfgehäuseabdeckung (3), die zwischen der Tintenstrahldruckkopf-Haltestruktur (2) und dem Versorgungskabel angeordnet ist,Anbring-/Lösemittel zum Anbringen der Tintenstrahldruckkopf-Haltestruktur (2) an bzw. zum Lösen der Tintenstrahldruckkopf-Haltestruktur (2) von der steifen Druckkopfgehäuseabdeckung (3) undein Aufnahmemittel (9), das zu der steifen Druckkopfgehäuseabdeckung (3) gehört, zum Aufnehmen des Versorgungskabels (1), wobei das Versorgungskabel (1) in das Aufnahmemittel (9) der steifen Druckkopfgehäuseabdeckung (3) einschraubbar und herausschraubbar ist.

- System zum Verbinden eines Versorgungskabels mit dem Druckkopf eines kontinuierlichen Tintenstrahldruckers nach Anspruch 1,

bei dem die Anbringmittel zumindest eine Schraube (5) enthalten. - System zum Verbinden eines Versorgungskabels mit dem Druckkopf eines kontinuierlichen Tintenstrahldruckers nach Anspruch 1,

bei dem das Aufnahmemittel eine mit einem Gewinde versehene Öffnung (9) durch die steife Druckkopfgehäuseabdeckung (3) enthält. - System zum Verbinden eines Versorgungskabels mit dem Druckkopf eines kontinuierlichen Tintenstrahldruckers nach Anspruch 1,

weiterhin enthaltend Ersteinbau-Registriermerkmale in der steifen Druckkopfgehäuseabdeckung (3), um mit der Tintenstrahldruckkopf-Haltestruktur (2) genau ausgerichtet zu sein. - System zum Verbinden eines Versorgungskabels mit dem Druckkopf eines kontinuierlichen Tintenstrahldruckers nach Anspruch 1,

weiterhin enthaltend Umschließungsmittel (4A, 4B) zum Umschließen des Verbindungssystems. - System zum Verbinden eines Versorgungskabels mit dem Druckkopf eines kontinuierlichen Tintenstrahldruckers nach Anspruch 5,

weiterhin enthaltend Zweiteinbau-Registriermerkmale, um die Umschließungsmittel (4A, 4B) automatisch zu lokalisieren und genau auszurichten. - System zum Verbinden eines Versorgungskabels mit dem Druckkopf eines kontinuierlichen Tintenstrahldruckers nach Anspruch 1,

weiterhin enthaltend selbstzentrierende Mittel zum korrekten Ausrichten des Versorgungskabels (1) und der steifen Druckkopfgehäuseabdeckung (3) mit der Tintenstrahldruckkopf-Haltestruktur (2).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US64023896A | 1996-04-30 | 1996-04-30 | |

| US640238 | 1996-04-30 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0805035A2 EP0805035A2 (de) | 1997-11-05 |

| EP0805035A3 EP0805035A3 (de) | 1997-11-12 |

| EP0805035B1 true EP0805035B1 (de) | 2001-06-06 |

Family

ID=24567412

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19970302689 Expired - Lifetime EP0805035B1 (de) | 1996-04-30 | 1997-04-21 | Anbring- und abnehmbare Verbindungskabelplattform für einen kontinuierlich arbeitenden Tintenstrahldruckkopf |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0805035B1 (de) |

| JP (1) | JPH1034908A (de) |

| CA (1) | CA2203846A1 (de) |

| DE (1) | DE69705089T2 (de) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2837421B1 (fr) | 2002-03-22 | 2004-07-02 | Imaje Sa | Raccord hydro-electrique pour tete d'imprimante et imprimante equipee |

| GB0802349D0 (en) * | 2008-02-08 | 2008-03-12 | Domino Printing Sciences Plc | Improvements in or relatign to continuous inkjet printers |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2060278B (en) * | 1979-10-05 | 1983-04-13 | Victor Products Ltd | Gland for metal sheathed cable |

| US4593940A (en) * | 1983-04-29 | 1986-06-10 | Wilder Don R | Flange assembly for hydraulic power systems |

| GB8622196D0 (en) * | 1986-09-15 | 1986-10-22 | Domino Printing Sciences Plc | Ink jet marking apparatus |

| US4769658A (en) * | 1986-09-16 | 1988-09-06 | Matsushita Electric Industrial Co., Ltd. | Ink jet recording apparatus with pressure adjustable mechanisms for discharging a constant ink amount |

| DE3730686A1 (de) * | 1987-09-12 | 1989-03-23 | Lapp Kg U I | Kabelverschraubung |

| US4872641A (en) * | 1988-07-22 | 1989-10-10 | Life Support Products, Inc. | Gas pressure regulator mounting yoke |

| DE4002244C1 (de) * | 1990-01-26 | 1991-05-08 | Abs Pumpen Ag, 5204 Lohmar, De | |

| EP0585901B1 (de) * | 1992-09-02 | 1999-12-08 | Canon Kabushiki Kaisha | Farbstrahlgerät mit Rückgewinnungsvorrichtung |

| DE4300521A1 (de) * | 1993-01-12 | 1994-07-14 | Weidmueller Interface | Kabelabdichtungs- und Zugentlastungsvorrichtung für Wanddurchbrüche |

-

1997

- 1997-04-21 EP EP19970302689 patent/EP0805035B1/de not_active Expired - Lifetime

- 1997-04-21 DE DE1997605089 patent/DE69705089T2/de not_active Expired - Lifetime

- 1997-04-28 CA CA 2203846 patent/CA2203846A1/en not_active Abandoned

- 1997-04-30 JP JP11238697A patent/JPH1034908A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| CA2203846A1 (en) | 1997-10-30 |

| EP0805035A3 (de) | 1997-11-12 |

| AU1993497A (en) | 1997-11-06 |

| AU714357B2 (en) | 1999-12-23 |

| DE69705089T2 (de) | 2001-09-20 |

| DE69705089D1 (de) | 2001-07-12 |

| JPH1034908A (ja) | 1998-02-10 |

| EP0805035A2 (de) | 1997-11-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4559543A (en) | Ink jet recording device modular frame | |

| EP0571786B1 (de) | Kontinuierlich arbeitender Tintenstrahldrucker mit Orientierungsvorrichtung für die Bauelemente des Druckkopfes | |

| JPH0626886B2 (ja) | 液体噴射記録装置 | |

| EP0860285A3 (de) | Tintenstrahlaufzeichnungsgerät und Verfahren zur Montage eines Tintenstrahlaufzeichnungskopfes | |

| EP0622240B1 (de) | Modularer Wagenzusammenbau für einen Tintenstrahldrucker | |

| US5969776A (en) | Display device and method of assembly | |

| US4809015A (en) | Continuous ink jet printer having modular print head assembly | |

| EP0031449B1 (de) | Tintenstrahldrucker mit zusammensetzbarem Tintenspritzkopf | |

| JPH06340064A (ja) | 単一相互接続システム | |

| EP0805035B1 (de) | Anbring- und abnehmbare Verbindungskabelplattform für einen kontinuierlich arbeitenden Tintenstrahldruckkopf | |

| AU733378B2 (en) | Continuous ink jet print head with separate electronics and refurbishable components | |

| EP0805031A1 (de) | Mittel zum Positionieren einer Augenlidanordnung an einen kontinuierlich arbeitenden Tintenstrahldruckerkopf | |

| US5825401A (en) | Slide in formatter for image forming devices | |

| US5739830A (en) | Monolithic printheads for ink jet printing apparatus | |

| EP0741040B1 (de) | Tintennebelsammler mit porösem Boden | |

| AU714036B2 (en) | Tool-less printhead mount | |

| JP2002159117A (ja) | 信号及び電力経路供給装置及び方法 | |

| JPH0752377A (ja) | インクジェット記録装置 | |

| US5495277A (en) | Image sensor having a first light receptor substrate and a substrate with electronics mounted against the first substrate | |

| JP4370486B2 (ja) | インクジェットヘッドおよびプリンタ | |

| US20120007922A1 (en) | Liquid ejecting head unit, manufacturing method for a liquid ejecting head unit, and liquid ejecting apparatus | |

| CN222973050U (zh) | 一种小票打印机的装配结构及电子设备 | |

| CN221111642U (zh) | 一种轴承顶出装置 | |

| JPS61125849A (ja) | 液体噴射記録装置 | |

| JP4078925B2 (ja) | インクジェットヘッド |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB |

|

| 17P | Request for examination filed |

Effective date: 19971208 |

|

| 17Q | First examination report despatched |

Effective date: 19990702 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB |

|

| REF | Corresponds to: |

Ref document number: 69705089 Country of ref document: DE Date of ref document: 20010712 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20050314 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050401 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050429 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF THE APPLICANT RENOUNCES Effective date: 20060221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060421 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20060421 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20061230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060502 |