EP0740023A1 - Implement arm with double lateral articulation - Google Patents

Implement arm with double lateral articulation Download PDFInfo

- Publication number

- EP0740023A1 EP0740023A1 EP96420140A EP96420140A EP0740023A1 EP 0740023 A1 EP0740023 A1 EP 0740023A1 EP 96420140 A EP96420140 A EP 96420140A EP 96420140 A EP96420140 A EP 96420140A EP 0740023 A1 EP0740023 A1 EP 0740023A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tool

- arrow

- articulation

- arm

- axis

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F3/00—Dredgers; Soil-shifting machines

- E02F3/04—Dredgers; Soil-shifting machines mechanically-driven

- E02F3/28—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets

- E02F3/30—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom

- E02F3/307—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom the boom and the dipper-arm being connected so as to permit relative movement in more than one plane

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F3/00—Dredgers; Soil-shifting machines

- E02F3/04—Dredgers; Soil-shifting machines mechanically-driven

- E02F3/28—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets

- E02F3/30—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom

- E02F3/302—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom with an additional link

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F3/00—Dredgers; Soil-shifting machines

- E02F3/04—Dredgers; Soil-shifting machines mechanically-driven

- E02F3/28—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets

- E02F3/30—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom

- E02F3/301—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom with more than two arms (boom included), e.g. two-part boom with additional dipper-arm

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F3/00—Dredgers; Soil-shifting machines

- E02F3/04—Dredgers; Soil-shifting machines mechanically-driven

- E02F3/28—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets

- E02F3/30—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom

- E02F3/32—Dredgers; Soil-shifting machines mechanically-driven with digging tools mounted on a dipper- or bucket-arm, i.e. there is either one arm or a pair of arms, e.g. dippers, buckets with a dipper-arm pivoted on a cantilever beam, i.e. boom working downwardly and towards the machine, e.g. with backhoes

Definitions

- the present invention relates to an improvement made to public works machines comprising a self-propelled chassis on which is mounted a turret carrying work equipment.

- It relates more particularly to an improvement made to the machines of the type subject of FR-A-2 532 671 and whose work equipment has a structure such that it makes it possible to work either as a loader or excavator by simple change of work tool.

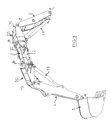

- Figure 1 attached schematically illustrates the general structure of such a machine used as an excavator.

- the work equipment designated by the general reference (1), is composed of four articulated and angularly deployable elements relative to each other, namely an arrow (2), a spout arrow (3), an arm (4) at the end of which is mounted the tool consisting of a bucket (5).

- This equipment is mounted on a turret (6) carried by a conventional vehicle preferably comprising a frame articulated in two parts, the engine being mounted on the rear chassis and the driving position and the work equipment (1) being , meanwhile, mounted side by side on the turret (6) associated with the front chassis.

- the various elements of the equipment are interconnected by an articulation allowing their angular positioning to be modified with respect to each other around horizontal pivot axes, the displacement being obtained by means of jacks.

- the boom (2) is articulated relative to the turret (6) and its position is adjusted by the boom cylinder (7) by means of two arms (8,9).

- the arrow spout (3) is connected to the other end (10) of the arrow (2) and the angular position ⁇ of these two elements (2,3) is adjusted by means of the jack (11) called “jack of arrowhead ".

- the arm (4) is articulated at the end (12) of the arrow spout (3) and the angle ⁇ between these two elements is adjusted by means of a third cylinder (13) called “cylinder of arms ".

- the bucket (5) is mounted at the end (17) of the arm (4) and its position is adjusted by a fourth cylinder (15) called "bucket cylinder".

- control of the various cylinders can be either individual, or possibly carried out in accordance with the teachings of application PCT / FR 95/01286.

- the tool (5) is therefore moved in space on the one hand by modifying the positioning of the various elements forming the work equipment (1) by pivoting about a horizontal axis of the joint. connecting the elements together and to the carrier, and, on the other hand, by rotation of the turret (6) which makes it possible to work as well in the axis of the vehicle, as on both sides of the latter at any angle.

- Such a type of machine is therefore designed to allow work to be carried out while keeping the various elements of the work equipment in line with one another, in the same vertical plane, the axes of articulation being parallel to the ground. and between them.

- a structure poses problems when it is desired to work offset, a possibility which has been obtained to date by mounting the arm jack (13) by means of cardan joints.

- the arm jack (13) poses problems, since this causes the cylinder to rotate and consequently wear out.

- the cylinder forms an angle relative to the element it controls, which results in a decrease in its efficiency.

- the device according to the invention is characterized in that at least the tool-carrying arm is connected to the element which precedes it by means of a double articulation allowing on the one hand an angular displacement around a horizontal axis , and, on the other hand, a lateral angular displacement around an axis passing in a plane orthogonal to the horizontal pivot axis, the control of this lateral displacement being obtained by means of a jack mounted laterally with respect to to the support element and which causes the pivoting of the double articulation, the jack controlling the angular movement around a horizontal axis of the tool-carrying arm, for its part, bearing on this articulation in front of the pivoting axis lateral.

- the double articulation according to the invention is at least between the arrow spout and the tool arm, the articulation between the end of the arrow and that of the arrow spout can be simple.

- the two articulations provided at each end of the arrow spout will be produced in accordance with the invention so as to be able to carry out a double offset.

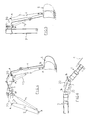

- the machine according to the invention therefore comprises work equipment (1) composed of four angularly articulated elements, deployable with respect to each other, namely a boom (2), a boom spout (3), an arm (4) at the end of which is mounted the tool consisting of a bucket (5) .

- This equipment is mounted on a turret (6) carried by a conventional vehicle.

- the boom (2) is articulated with respect to the turret (6) and its position is adjusted by the boom cylinder (7) by means of two arms (8,9).

- the boom spout (3) is connected to the end (10) of the boom (2) and the angular position ⁇ of these two elements (2,3) is adjusted by means of the boom spout cylinder (11).

- the arm (4) is articulated at the end (12) of the arrow spout (3) and the angle ⁇ between these two elements is adjusted by means of a third jack (13).

- the bucket (5) is mounted at the end (14) of the arm (4) and its position is adjusted by a fourth cylinder (15) called "bucket cylinder".

- At least the arm (4) is connected to the element which precedes it, therefore in the present case to the arrow spout (3) by means of a double articulation designated by the general reference ( 20) and which allows on the one hand, the angular displacement around the horizontal axis A, and, on the other hand, a lateral angular displacement around an axis B passing in a plane orthogonal to the horizontal pivot axis AT.

- the work equipment is preferably designed as illustrated in Figures 3 to 6 so that the connection between the end (10) of the arrow (2) and the end of the arrow spout (3) is made in a similar manner.

- the control of the lateral displacement is obtained by means of a jack (22) mounted laterally with respect to the jib spout (3) and which acts on the double articulation.

- the jacks (11,13) controlling the angular displacements around the horizontal axes A take, for their part, support on the double articulation (20) in front of the lateral pivot axis B, which allows an action in line even during a work in offset.

- the solution according to the invention has very many advantages among which we can cite in particular, when the machine allows to carry out a double offset, to have an additional angular position for the tool (6) making it possible to bypass obstacles.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Operation Control Of Excavators (AREA)

- Forklifts And Lifting Vehicles (AREA)

- Jib Cranes (AREA)

- Shovels (AREA)

Abstract

Description

La présente invention a trait à un perfectionnement apporté aux engins de travaux publics comportant un châssis automoteur sur lequel est monté une tourelle portant un équipement de travail.The present invention relates to an improvement made to public works machines comprising a self-propelled chassis on which is mounted a turret carrying work equipment.

Elle a trait plus particulièrement à un perfectionnement apporté aux engins du type faisant l'objet du FR-A-2 532 671 et dont l'équipement de travail a une structure telle qu'il permet de travailler indifféremment en tant que chargeur ou excavateur par simple changement de l'outil de travail.It relates more particularly to an improvement made to the machines of the type subject of FR-A-2 532 671 and whose work equipment has a structure such that it makes it possible to work either as a loader or excavator by simple change of work tool.

Dans la suite de la description, l'invention sera décrite pour un tel type d'engin, mais il est évident que cela n'est pas limitatif et qu'elle pourrait être appliquée à tout engin dont l'outil de travail est monté à l'extrémité d'un bras articulé.In the following description, the invention will be described for such a type of machine, but it is obvious that this is not limiting and that it could be applied to any machine whose working tool is mounted at the end of an articulated arm.

La figure 1 annexée illustre de manière schématique la structure générale d'un tel engin utilisé en tant qu'excavateur.Figure 1 attached schematically illustrates the general structure of such a machine used as an excavator.

En se reportant à cette figure 1, l'équipement de travail, désigné par la référence générale (1), est composé de quatre éléments articulés et angulairement déployables les uns par rapport aux autres, à savoir une flèche (2), un bec de flèche (3), un bras (4) à l'extrémité duquel est monté l'outil constitué par un godet (5).Referring to this figure 1, the work equipment, designated by the general reference (1), is composed of four articulated and angularly deployable elements relative to each other, namely an arrow (2), a spout arrow (3), an arm (4) at the end of which is mounted the tool consisting of a bucket (5).

Cet équipement est monté sur une tourelle (6) portée par un véhicule conventionnel comprenant, de préférence, un châssis articulé en deux parties, le moteur étant monté sur le châssis arrière et le poste de conduite et l'équipement de travail (1) étant, quant à eux, montés côte à côte sur la tourelle (6) associée au châssis avant.This equipment is mounted on a turret (6) carried by a conventional vehicle preferably comprising a frame articulated in two parts, the engine being mounted on the rear chassis and the driving position and the work equipment (1) being , meanwhile, mounted side by side on the turret (6) associated with the front chassis.

Les différents éléments de l'équipement sont reliés entre eux par une articulation permettant de modifier leur positionnement angulaire les uns par rapport aux autres autour d'axes de pivotement horizontaux, le déplacement étant obtenu par l'intermédiaire de vérins.The various elements of the equipment are interconnected by an articulation allowing their angular positioning to be modified with respect to each other around horizontal pivot axes, the displacement being obtained by means of jacks.

Dans le mode de réalisation illustré à la figure 1, la flèche (2) est articulée par rapport à la tourelle (6) et sa position est réglée par le vérin de flèche (7) au moyen de deux bras (8,9). Le bec de flèche (3) est relié à l'autre extrémité (10) de la flèche (2) et la position angulaire α de ces deux éléments (2,3) est réglée au moyen du vérin (11) dit "vérin de bec de flèche". Le bras (4) est quant à lui articulé à l'extrémité (12) du bec de flèche (3) et l'angle β entre ces deux élements est réglé par l'intermédiaire d'un troisième vérin (13) dit "vérin de bras". Enfin, le godet (5) est monté à l'extrémité (17) du bras (4) et sa position est réglée par un quatrième vérin (15) dit "vérin de godet".In the embodiment illustrated in Figure 1, the boom (2) is articulated relative to the turret (6) and its position is adjusted by the boom cylinder (7) by means of two arms (8,9). The arrow spout (3) is connected to the other end (10) of the arrow (2) and the angular position α of these two elements (2,3) is adjusted by means of the jack (11) called "jack of arrowhead ". The arm (4) is articulated at the end (12) of the arrow spout (3) and the angle β between these two elements is adjusted by means of a third cylinder (13) called "cylinder of arms ". Finally, the bucket (5) is mounted at the end (17) of the arm (4) and its position is adjusted by a fourth cylinder (15) called "bucket cylinder".

Dans un tel système, la commande des différents vérins peut être soit individuelle, soit éventuellement réalisée conformément aux enseignements de la demande PCT/FR 95/01286.In such a system, the control of the various cylinders can be either individual, or possibly carried out in accordance with the teachings of application PCT / FR 95/01286.

Dans de tels engins, l'outil (5) est donc déplacé dans l'espace d'une part en modifiant le positionnement des différents éléments formant l'équipement de travail (1) par pivotement autour d'un axe horizontal de l'articulation reliant les éléments entre eux et à l'engin porteur, et, d'autre part, par rotation de la tourelle (6) qui permet de travailler aussi bien dans l'axe du véhicule, que de part et d'autre de ce dernier en formant un angle quelconque.In such vehicles, the tool (5) is therefore moved in space on the one hand by modifying the positioning of the various elements forming the work equipment (1) by pivoting about a horizontal axis of the joint. connecting the elements together and to the carrier, and, on the other hand, by rotation of the turret (6) which makes it possible to work as well in the axis of the vehicle, as on both sides of the latter at any angle.

Un tel type d'engin est donc conçu pour permettre d'effectuer des travaux en maintenant les différents éléments de l'équipement de travail dans le prolongement les uns des autres, dans un même plan vertical, les axes d'articulation étant parallèles au sol et entre eux. En revanche, une telle structure pose des problèmes lorsque l'on souhaite travailler en déport, possibilité qui est obtenue à ce jour en montant le vérin de bras (13) au moyen de cardans. Une telle solution pose cependant des problèmes, car cela entraîne un mouvement de rotation du vérin et par suite une usure de celui-ci. De plus, lors du travail en déport, le vérin forme un angle par rapport à l'élément qu'il commande, ce qui entraîne une diminution de son efficacité.Such a type of machine is therefore designed to allow work to be carried out while keeping the various elements of the work equipment in line with one another, in the same vertical plane, the axes of articulation being parallel to the ground. and between them. On the other hand, such a structure poses problems when it is desired to work offset, a possibility which has been obtained to date by mounting the arm jack (13) by means of cardan joints. However, such a solution poses problems, since this causes the cylinder to rotate and consequently wear out. In addition, when working offset, the cylinder forms an angle relative to the element it controls, which results in a decrease in its efficiency.

Il a été proposé depuis fort longtemps de réaliser un tel déport latéral de l'outil de travail sur les engins de travaux publics. Ainsi, l'une des solutions proposées qui ressort du FR-A-2 587 384, consiste à déplacer latéralement l'ensemble de l'équipement en le montant sur une console supportée de façon articulée par le bâti de la pelle et qui, par l'intermédiaire de deux bras de parallélogrammes placés côte à côte et latéralement, permet, au moyen d'une commande (vérin), de réaliser un déport de l'outil jusqu'au voisinage de la limite latérale de la pelle ou du prolongement de cette limite.It has been proposed for a long time to carry out such a lateral offset of the work tool on public works machines. Thus, one of the solutions proposed which emerges from FR-A-2 587 384, consists in moving the whole of the equipment laterally by mounting it on a console supported in an articulated manner by the frame of the shovel and which, by by means of two parallelogram arms placed side by side and laterally, allows, by means of a control (jack), to offset the tool to the vicinity of the lateral limit of the shovel or the extension of this limit.

Une telle solution, séduisante a priori, n'est cependant pas transposable aux engins polyvalents du type précité, car le système de relevage de la flèche ne permet pas la liaison mécanique avec le châssis.Such a solution, attractive a priori, is however not transposable to multipurpose machines of the aforementioned type, because the boom lifting system does not allow mechanical connection with the chassis.

Or on a trouvé, et c'est ce qui fait l'objet de la présente invention, une solution simple et efficace qui permet de résoudre l'ensemble des problèmes précités.However, we have found, and this is what is the subject of the present invention, a simple and effective solution which makes it possible to solve all of the aforementioned problems.

D'une manière générale, l'invention concerne un engin de travaux publics comportant :

- un équipement de travail composé d'au moins trois éléments articulés entre eux autour d'axes horizontaux et angulairement déployables les uns par rapport aux autres, le premier étant articulé par rapport au châssis du véhicule porteur, le dernier étant constitué par un outil;

- des vérins permettant de commander le déplacement angulaire desdits éléments les uns par rapport aux autres afin d'assurer le positionnement de l'outil en tous points compris à l'intérieur d'un contour d'un espace de travail déterminé.

- a work equipment composed of at least three elements hinged together around horizontal axes and angularly deployable with respect to each other, the first being articulated with respect to the chassis of the carrier vehicle, the last being constituted by a tool;

- jacks for controlling the angular displacement of said elements with respect to each other in order to ensure the positioning of the tool at all points included within a contour of a determined working space.

L'engin selon l'invention se caractérise ce que au moins le bras porte-outil est relié à l'élément qui le précède par l'intermédiaire d'une double articulation permettant d'une part un déplacement angulaire autour d'un axe horizontal, et, d'autre part, un déplacement angulaire latéral autour d'un axe passant dans un plan orthogonal à l'axe de pivotement horizontal, la commande de ce déplacement latéral étant obtenu par l'intermédiaire d'un vérin monté latéralement par rapport à l'élément support et qui provoque le pivotement de la double articulation, le vérin commandant le déplacement angulaire autour d'un axe horizontal du bras porte-outil prenant, quant à lui, appui sur cette articulation en avant de l'axe de pivotement latéral.The device according to the invention is characterized in that at least the tool-carrying arm is connected to the element which precedes it by means of a double articulation allowing on the one hand an angular displacement around a horizontal axis , and, on the other hand, a lateral angular displacement around an axis passing in a plane orthogonal to the horizontal pivot axis, the control of this lateral displacement being obtained by means of a jack mounted laterally with respect to to the support element and which causes the pivoting of the double articulation, the jack controlling the angular movement around a horizontal axis of the tool-carrying arm, for its part, bearing on this articulation in front of the pivoting axis lateral.

Grâce à une telle structure, lorsque le bras porte-outils est déporté latéralement, le vérin de commande réglant son positionnement angulaire reste toujours dans la même position et agit en ligne sur l'élément qu'il déplace. En conséquence, il n'y a aucune perte d'efficacité lors d'un travail en déport.Thanks to such a structure, when the tool-carrying arm is offset laterally, the control jack adjusting its angular positioning always remains in the same position and acts in line on the element which it displaces. As a result, there is no loss of efficiency when working offset.

Dans le cas d'un engin du type faisant l'objet du FR-A-2 532 671 et dont l'équipement de travail est composé de quatre éléments articulés entre eux, la double articulation conforme à l'invention se trouve au moins entre le bec de flèche et le bras porte-outil, l'articulation entre l'extrémité de la flèche et celle du bec de flèche pouvant être simple. De préférence, dans un tel engin, les deux articulations prévues à chaque extrémité du bec de flèche seront réalisées conformément à l'invention de manière à pouvoir réaliser un double déport.In the case of a machine of the type which is the subject of FR-A-2 532 671 and whose work equipment is composed of four elements hinged together, the double articulation according to the invention is at least between the arrow spout and the tool arm, the articulation between the end of the arrow and that of the arrow spout can be simple. Preferably, in such a machine, the two articulations provided at each end of the arrow spout will be produced in accordance with the invention so as to be able to carry out a double offset.

L'invention et les avantages qu'elle apporte sera cependant mieux comprise grâce à l'exemple de réalisation qui suit donné à titre indicatif mais non limitatif, et qui est illustré par les schémas annexés dans lesquelles :

- la figure 1 illustre, comme dit précédemment, l'art antérieur constitué par le FR-A-2 532 671 ;

- la figure 2 illustre un chargeur excavateur réalisé conformément à l'invention, vu de côté en élévation, et dont l'équipement de travail est tel qu'il permet de réaliser un simple déport du bras porte-outil ;

- la figure 3 est une vue de détail en perspective éclatée montrant l'adaptation conformément à l'invention d'un outil de travail d'un chargeur excavateur permettant d'obtenir un double déport;

- les figures 4, 5 et 6 sont respectivement des vues en élévation de côté et de dessus d'un équipement de travail réalisé conformément à l'invention en position de double déport.

- Figure 1 illustrates, as said above, the prior art constituted by FR-A-2,532,671;

- FIG. 2 illustrates an excavator loader produced in accordance with the invention, seen from the side in elevation, and the working equipment of which is such that it allows a simple offset of the tool-carrying arm;

- Figure 3 is an exploded perspective detail view showing the adaptation according to the invention of a working tool of an excavator loader for obtaining a double offset;

- Figures 4, 5 and 6 are respectively side and top elevation views of a work equipment produced according to the invention in double offset position.

En se reportant aux schémas annexés, pour lesquels les mêmes références sont utilisées pour désigner des éléments communs avec l'art antérieur illustré à la figure 1, l'engin conforme à l'invention comporte donc un équipement de travail (1) composé de quatre éléments articulés angulairement, déployables les uns par rapport aux autres, à savoir une flèche (2), un bec de flèche (3), un bras (4) à l'extrémité duquel est monté l'outil constitué par un godet (5).Referring to the appended diagrams, for which the same references are used to designate elements common with the prior art illustrated in FIG. 1, the machine according to the invention therefore comprises work equipment (1) composed of four angularly articulated elements, deployable with respect to each other, namely a boom (2), a boom spout (3), an arm (4) at the end of which is mounted the tool consisting of a bucket (5) .

Cet équipement est monté sur une tourelle (6) portée par un véhicule conventionnel.This equipment is mounted on a turret (6) carried by a conventional vehicle.

La flèche (2) est articulée par rapport à la tourelle (6) et sa position est réglée par le vérin de flèche (7) au moyen de deux bras (8,9).The boom (2) is articulated with respect to the turret (6) and its position is adjusted by the boom cylinder (7) by means of two arms (8,9).

Le bec de flèche (3) est relié à l'extrémité (10) de la flèche (2) et la position angulaire α de ces deux éléments (2,3) est réglée au moyen du vérin de bec de flèche (11). Le bras (4) est quant à lui articulé à l'extrémité (12) du bec de flèche (3) et l'angle β entre ces deux élements est réglé par l'intermédiaire d'un troisième vérin (13). Enfin, le godet (5) est monté à l'extrémité (14) du bras (4) et sa position est réglée par un quatrième vérin (15) dit "vérin de godet".The boom spout (3) is connected to the end (10) of the boom (2) and the angular position α of these two elements (2,3) is adjusted by means of the boom spout cylinder (11). The arm (4) is articulated at the end (12) of the arrow spout (3) and the angle β between these two elements is adjusted by means of a third jack (13). Finally, the bucket (5) is mounted at the end (14) of the arm (4) and its position is adjusted by a fourth cylinder (15) called "bucket cylinder".

Conformément à l'invention, au moins le bras (4) est relié à l'élément qui le précède, donc dans le cas présent au bec de flèche (3) par l'intermédiaire d'une double articulation désignée par la référence générale (20) et qui permet d'une part, le déplacement angulaire autour de l'axe horizontal A, et, d'autre part, un déplacement angulaire latéral autour d'un axe B passant dans un plan orthogonal à l'axe de pivotement horizontal A.According to the invention, at least the arm (4) is connected to the element which precedes it, therefore in the present case to the arrow spout (3) by means of a double articulation designated by the general reference ( 20) and which allows on the one hand, the angular displacement around the horizontal axis A, and, on the other hand, a lateral angular displacement around an axis B passing in a plane orthogonal to the horizontal pivot axis AT.

S'il est possible, comme cela ressort de la figure 2, de n'avoir qu'une seule double articulation (20) entre le bec de flèche (3) et le bras porte-outil (4), l'équipement de travail est de préférence conçu de la manière illustrée aux figures 3 à 6 pour que la liaison entre l'extrémité (10) de la flèche (2) et l'extrémité du bec de flèche (3) soit réalisée d'une manière similaire.If it is possible, as shown in FIG. 2, to have only one double articulation (20) between the boom spout (3) and the tool-carrying arm (4), the work equipment is preferably designed as illustrated in Figures 3 to 6 so that the connection between the end (10) of the arrow (2) and the end of the arrow spout (3) is made in a similar manner.

Conformément à l'invention, la commande du déplacement latéral est obtenue par l'intermédiaire d'un vérin (22) monté latéralement par rapport au bec de flèche (3) et qui agit sur la double articulation. Les vérins (11,13) commandant les déplacements angulaires autour des axes horizontaux A, prennent, quant à eux, appui sur la double articulation (20) en avant de l'axe de pivotement latéral B, ce qui permet une action en ligne même lors d'un travail en déport.According to the invention, the control of the lateral displacement is obtained by means of a jack (22) mounted laterally with respect to the jib spout (3) and which acts on the double articulation. The jacks (11,13) controlling the angular displacements around the horizontal axes A, take, for their part, support on the double articulation (20) in front of the lateral pivot axis B, which allows an action in line even during a work in offset.

Par rapport aux solutions antérieures permettant d'obtenir un déport latéral d'un outil de travail d'un engin de travaux publics, la solution conforme à l'invention présente de très nombreux avantages parmi lesquels on peut citer notamment, lorsque l'engin permet de réaliser un double déport, d'avoir une position angulaire supplémentaire pour l'outil (6) permettant de contourner les obstacles.Compared to previous solutions making it possible to obtain a lateral offset of a working tool of a public works machine, the solution according to the invention has very many advantages among which we can cite in particular, when the machine allows to carry out a double offset, to have an additional angular position for the tool (6) making it possible to bypass obstacles.

Claims (2)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9505184 | 1995-04-25 | ||

| FR9505184A FR2733525B1 (en) | 1995-04-25 | 1995-04-25 | PUBLIC WORKS MACHINE WITH A WORKING TOOL MOUNTED AT THE END OF AN ARTICULATED ARM |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0740023A1 true EP0740023A1 (en) | 1996-10-30 |

Family

ID=9478586

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96420140A Ceased EP0740023A1 (en) | 1995-04-25 | 1996-04-24 | Implement arm with double lateral articulation |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5661917A (en) |

| EP (1) | EP0740023A1 (en) |

| JP (1) | JPH08302725A (en) |

| KR (1) | KR960037990A (en) |

| CN (1) | CN1143139A (en) |

| CA (1) | CA2174789A1 (en) |

| FR (1) | FR2733525B1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1798344A1 (en) * | 2004-09-29 | 2007-06-20 | Hitachi Construction Machinery Co., Ltd. | Working device for construction machine |

| EP2639360A2 (en) | 2008-07-14 | 2013-09-18 | Hudson Bay Holding B.V. | Mobile apparatus |

| DE102014000027A1 (en) | 2014-01-04 | 2014-10-30 | Johannes Burde | Telescopic system for integration in monoblock and adjustable boom for the procedure of the stem and main bearing |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3775687B2 (en) * | 1996-08-15 | 2006-05-17 | 日立建機株式会社 | Operation control device for 3-joint excavator |

| WO2000012826A1 (en) * | 1998-08-31 | 2000-03-09 | Yanmar Diesel Engine Co., Ltd. | Extremely-small-swing working machine |

| US6409457B1 (en) * | 1999-10-15 | 2002-06-25 | George Korycan | Work vehicle |

| DE10321070B3 (en) * | 2003-05-10 | 2004-11-04 | O & K Orenstein & Koppel Gmbh | Divided boom for an excavator has a lower part which is resistant to twisting in its upper end and is inserted from below into an upper part |

| US20080020867A1 (en) * | 2003-08-28 | 2008-01-24 | Callaway Golf Company | Golfer's impact properties during a golf swing |

| AU2004280583A1 (en) * | 2003-10-03 | 2005-04-21 | Michael T. Lumbers | Multi-function work machine |

| US7698838B1 (en) * | 2005-11-09 | 2010-04-20 | Strayhorn David W | Hoe equipped excavator having increased range |

| US9777459B2 (en) | 2012-07-31 | 2017-10-03 | Solar Foundations Usa, Inc | Attachment for a skid steer loader and method of use thereof |

| CN104563176B (en) * | 2015-01-15 | 2017-11-28 | 王学义 | The poking device of loading machine |

| CN108118730A (en) * | 2016-11-29 | 2018-06-05 | 广西大学 | A kind of three mobility linkage mechanical arm of servo-drive for assembling work |

| CN106759564A (en) * | 2016-12-30 | 2017-05-31 | 徐州徐工挖掘机械有限公司 | A kind of excavator tunnel gauche form equipment structure |

| CN108702898A (en) * | 2018-05-30 | 2018-10-26 | 泉州永春佳鼎农业机械有限公司 | A kind of mobile device for agricultural planting ditching |

| DE102019100075B3 (en) * | 2019-01-03 | 2020-03-19 | Mecalac Baumaschinen GmbH | Wheel loader |

| CN111058503A (en) * | 2019-12-13 | 2020-04-24 | 谢志坚 | Hydraulic engineering desilting equipment with shovel function |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2086347A (en) * | 1980-11-04 | 1982-05-12 | Vema Spa | Articulated arm for excavator machines |

| JPS58135232A (en) * | 1982-02-03 | 1983-08-11 | Ishikawajima Harima Heavy Ind Co Ltd | Excavator |

| GB2222998A (en) * | 1988-09-22 | 1990-03-28 | Kubota Ltd | Homing control for backhoe bucket |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3099358A (en) * | 1960-08-01 | 1963-07-30 | Int Harvester Co | Means for shifting the axis of boom means or the like |

| FR1546526A (en) * | 1967-06-21 | 1968-11-22 | Poclain Sa | Improvements to turret handling equipment |

| FR2031763A5 (en) * | 1969-02-06 | 1970-11-20 | Poclain Sa | |

| SE437050B (en) * | 1982-06-04 | 1985-02-04 | Ingemar Eriksson | FOR A LOADER APPLICABLE GRAVAGGGGAT FOR MINOR GRAVING WORK |

| FR2532671A1 (en) * | 1982-09-08 | 1984-03-09 | Pingon Pierre De | Articulated combined loader and excavator jib |

| JPS60169352U (en) * | 1984-04-18 | 1985-11-09 | 株式会社 竹内製作所 | drilling equipment |

| DE3435981A1 (en) * | 1984-10-01 | 1986-04-17 | Macmoter S.P.A., Modigliana | COMPACT EXCAVATOR |

| DE3533427A1 (en) * | 1985-09-19 | 1987-03-26 | Schaeff Karl Gmbh & Co | SIDE OFFSET DEVICE FOR AN EXCAVATOR CONSOLE |

| DE3843753A1 (en) * | 1988-12-24 | 1990-06-28 | Schaeff Karl Gmbh & Co | EXCAVATOR ARM |

| JPH04254625A (en) * | 1990-11-30 | 1992-09-09 | Hitachi Constr Mach Co Ltd | Offset boom type construction machine |

| FR2707956B1 (en) * | 1993-07-01 | 1995-10-06 | Thibault Jacques | Flexible double-closure packaging, especially for the presentation and shipping of objects. |

-

1995

- 1995-04-25 FR FR9505184A patent/FR2733525B1/en not_active Expired - Fee Related

-

1996

- 1996-04-23 CA CA002174789A patent/CA2174789A1/en not_active Abandoned

- 1996-04-24 EP EP96420140A patent/EP0740023A1/en not_active Ceased

- 1996-04-24 CN CN96108977A patent/CN1143139A/en active Pending

- 1996-04-24 JP JP8102938A patent/JPH08302725A/en not_active Withdrawn

- 1996-04-25 US US08/626,430 patent/US5661917A/en not_active Expired - Fee Related

- 1996-04-25 KR KR1019960014087A patent/KR960037990A/en not_active Application Discontinuation

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2086347A (en) * | 1980-11-04 | 1982-05-12 | Vema Spa | Articulated arm for excavator machines |

| JPS58135232A (en) * | 1982-02-03 | 1983-08-11 | Ishikawajima Harima Heavy Ind Co Ltd | Excavator |

| GB2222998A (en) * | 1988-09-22 | 1990-03-28 | Kubota Ltd | Homing control for backhoe bucket |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 7, no. 250 (M - 254)<1395> 8 November 1983 (1983-11-08) * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1798344A1 (en) * | 2004-09-29 | 2007-06-20 | Hitachi Construction Machinery Co., Ltd. | Working device for construction machine |

| EP1798344A4 (en) * | 2004-09-29 | 2011-02-23 | Hitachi Construction Machinery | Working device for construction machine |

| EP2639360A2 (en) | 2008-07-14 | 2013-09-18 | Hudson Bay Holding B.V. | Mobile apparatus |

| DE102014000027A1 (en) | 2014-01-04 | 2014-10-30 | Johannes Burde | Telescopic system for integration in monoblock and adjustable boom for the procedure of the stem and main bearing |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1143139A (en) | 1997-02-19 |

| CA2174789A1 (en) | 1996-10-26 |

| JPH08302725A (en) | 1996-11-19 |

| FR2733525A1 (en) | 1996-10-31 |

| US5661917A (en) | 1997-09-02 |

| KR960037990A (en) | 1996-11-19 |

| FR2733525B1 (en) | 1997-07-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0740023A1 (en) | Implement arm with double lateral articulation | |

| FR2635130A1 (en) | ||

| FR2595107A1 (en) | A COMPLETE PIVOT LIFTING VEHICLE WITH REDUCED RADIUS TO FACILITATE OPERATIONS IN A WEAK SITE | |

| FR2606967A1 (en) | MACHINE FOR FELLING AND TREATING TREES | |

| EP0997062B1 (en) | Agricultural machine | |

| FR2624898A1 (en) | BULLDOZER APPARATUS FOR CONSTRUCTION EQUIPMENT COMPRISING SEVERAL EXCESSIVE FORCE COMPENSATION JETS DURING EARTH, EXCAVATION OR OTHER OPERATIONS | |

| EP0700795B1 (en) | Device for marking, to get identification signs in two dimensions on the surface of an object | |

| US5634523A (en) | Blade device | |

| FR2499535A1 (en) | METHOD AND DEVICE FOR CONTROLLING THE ARROW OF A LIFTING APPARATUS | |

| FR2532671A1 (en) | Articulated combined loader and excavator jib | |

| FR2701627A1 (en) | Device which can be fitted to an automotive vehicle of the tractor type, especially for the upkeep of green spaces, banks and verges | |

| FR3032595A1 (en) | VEGETABLE CUTTING MACHINE AND MOTOR VEHICLE COMPRISING SUCH CUTTING MACHINE | |

| FR2727998A1 (en) | Articulated excavator or similar vehicle with pivoting cabin | |

| FR2506830A1 (en) | Tractor-mounted rotary drill - is mounted so as to rotate about two orthogonal axes to drill several holes within small radius | |

| FR2701047A1 (en) | Universal linking system for attaching an accessory, particularly a bucket or shovel, to the articulated arm of a civil engineering works vehicle | |

| EP1245739B1 (en) | Construction machine | |

| FR2494747A1 (en) | Dredging arm attachment for earthworking machine - comprises ram=actuated telescopic arm pivotally attached to existing jointed arm | |

| FR2750411A1 (en) | Building site crane with lower pivot | |

| EP0750702B1 (en) | Digger-loader | |

| EP1527671B1 (en) | Mower or shredder to be mounted on a self-propelled vehicle of tractor type | |

| FR2569216A1 (en) | Cleaning device, particularly for trenches perpendicular to a road | |

| FR2883698A1 (en) | Tool e.g. auger, coupling device for e.g. quad bike, has rod positioning plate relative to arms for placing plate relative to arms along pivoting course of arms, or for pivoting plate relative to arms for translating plate along course | |

| EP0391808A1 (en) | Telescopic hoisting device for a vehicle, in particular for a loader | |

| FR2629114A1 (en) | Vehicle for earth moving works | |

| EP1136703A1 (en) | Means for rotating an assembly mounted pivotally in relation to a fixed pivot axis |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB IT LI LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19961212 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19990930 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 20000319 |