EP0668418B1 - Echafaudage - Google Patents

Echafaudage Download PDFInfo

- Publication number

- EP0668418B1 EP0668418B1 EP95100037A EP95100037A EP0668418B1 EP 0668418 B1 EP0668418 B1 EP 0668418B1 EP 95100037 A EP95100037 A EP 95100037A EP 95100037 A EP95100037 A EP 95100037A EP 0668418 B1 EP0668418 B1 EP 0668418B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- staging

- support

- folded

- floor

- stage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009408 flooring Methods 0.000 claims 4

- 238000000926 separation method Methods 0.000 claims 2

- 238000000465 moulding Methods 0.000 claims 1

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000009415 formwork Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G1/00—Scaffolds primarily resting on the ground

- E04G1/34—Scaffold constructions able to be folded in prismatic or flat parts or able to be turned down

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G17/00—Connecting or other auxiliary members for forms, falsework structures, or shutterings

- E04G17/002—Workplatforms, railings; Arrangements for pouring concrete, attached to the form

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G5/00—Component parts or accessories for scaffolds

- E04G5/06—Consoles; Brackets

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G5/00—Component parts or accessories for scaffolds

- E04G5/06—Consoles; Brackets

- E04G5/061—Consoles; Brackets specially adapted for attachment to scaffolds

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G5/00—Component parts or accessories for scaffolds

- E04G5/06—Consoles; Brackets

- E04G5/062—Consoles; Brackets specially adapted for attachment to building walls

Definitions

- the invention relates to a work platform for a scaffold, in particular for a scaffold in concrete formwork with supports that can be folded up onto the underside of the floor covering of the stage.

- the supports supporting the stage floor are supported on the latter by hanging them in devices arranged on the building wall. It is known, for example FR-A-2 676 771, to fold the supports for stacking onto the underside of the stage floor covering. In known stages, however, a sufficiently flat lower surface of the folded stage is only obtained when the supports are so short that they do not overlap when folded up on the stage floor. However, this cannot always be achieved with a reasonable length of the stage section, especially not if a preferably removable sub-stage is provided below the main stage on the scaffold supports. Also the safety regulations for such work platforms often do not allow the length of the supports to be limited to the size which is approximately half the length of the platform, so that the supports can be folded under the platform without overlapping.

- the invention has for its object to provide a working platform that has a folded flat surface when folded, but the supports have a length that ensures the safety of the working platform in any case.

- the pivot axis of at least one support is movable at right angles to the floor surface of the stage.

- the pivot axis of the support can be moved into a position in which, when the supports overlap when the stage is folded, each support lies in such a way that its lower surface runs parallel to the stage floor.

- the folded stage has a flat lower surface, so that many of these stages can be stacked one above the other for storage or transport without the load capacity of the stage or its safety being reduced in the working state.

- the guides in which the pivot axis is movably guided, can, for example, allow the support to be removed from the stage covering, for example if these guides are a closable slot which is open at the bottom.

- the distance of the pivot axis of the support from the stage floor can only be changed by the amount that an overlying support assumes in the position folded toward the underside of the floor covering.

- the pivot axis of a support is held to be displaceable at right angles to the floor surface of the stage by the thickness of a support.

- This displacement of the pivot axis of a support can, as already mentioned, take place in that the part which forms the axis of rotation of the support is guided in a slot which is formed by at least one fitting.

- the device for the axis of rotation of a support which is carried out at right angles to the floor covering, is realized in that the axis of rotation is rotatably mounted at the free end of a pivotally mounted lever.

- a flat lower surface of a collapsed work platform that runs parallel to the stage floor is not only useful when stacking, but also when transporting, for example when the collapsed platform is to be transported with a forklift so that the folded supports are on the fork of the forklift.

- the stage has a foot with which an upper stage is supported on the next lower stage when stacking several superimposed, folded stages.

- a foot with which an upper stage is supported on the next lower stage when stacking several superimposed, folded stages.

- Such feet can be attached to the underside of the floor covering, but can also be formed by a fitting, for example, which limits the slot for the displacement of the axis of rotation of the support.

- the feet can be so long in embodiments of the invention that between two superimposed, folded stages, a space remains in which to transport the stage Fork of a forklift can be retracted.

- a carrier can be arranged on the sides of the work platform, at least on its narrow side, the width of which projects below the lower surface of the stage floor by the amount that two folded supports take up.

- the lower edge of this transverse beam can then form the support of a collapsed platform on the fork of a forklift truck, whereby, if feet are provided in these embodiments, these feet in turn protrude further down by the amount required to be on the floor or to easily insert the fork of a forklift to a next folded stage.

- the displaceability of the pivot axis of a support can be realized by an elongated hole in a fitting attached to the underside of the stage covering.

- the fitting for limiting the slot has a rod which at the same time forms the pivot bearing for a hook which is mounted in the fitting about an axis which is vertical in the working position of the platform. In a swiveled position, this hook serves as a support for the lower of the supports folded up on the stage floor.

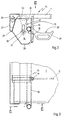

- the foldable stage section has a stage floor 1 which is supported on two supports 2 and 3, which have an approximately triangular shape in the embodiment shown.

- the parallel to the wall plane, with the stage vertical 4 of each support has near its upper end a hook 5 or 5 'and about halfway up a hook 6 or 6' with which they are hung in appropriate loops or shoes can be attached to the wall of the building and through which the load of the stage is transferred to the building wall.

- At the lower end of the vertical rod 4 there is also a device 7 or 7 'for support on the wall.

- an oblique rod 8 or 8 ' extends upwards outward, where it is fastened at 9 or 9' to a cross rod 10 or 24 and beyond the fastening point 9 or 9 'a projection 11 or . 11 '.

- the cross bar 10 with the vertical bar 4 is fastened at 9 or 9' to a cross rod 10 or 24 and beyond the fastening point 9 or 9 'a projection 11 or . 11 '.

- Stiffening rods 12 and 13 are also used to stiffen the support 3, which in the illustrated embodiment also has the shape of a bracket like the support 2.

- Devices are also provided on the stage floor in which a railing, designated as a whole, can be attached.

- the storage of the supports 2 and 3 is described at one end of the stage in connection with the support 2. At the other end of the stage there is a mirror-image arrangement for mounting the support 3.

- the crossbar 10 forms the axis of rotation about which the console 2 can be pivoted toward the underside of the stage floor 1 when the stage is removed.

- a fitting 15 is used, which is shown on a larger scale in FIG. 2 and which is provided at both ends of the crossbar 10, that is to say on the inside of the stage facing the building wall and on the outside of the stage facing away from the building wall.

- the fitting 15 has a plate 16 which extends downward from the edge of the stage floor 1 and at the same time forms a foot 28 for supporting the folded stage.

- the plate 16 has on its inwardly directed edge 17 a support 18 for the cross bar 10.

- a rod 19 is fastened, which together with the edge 17 delimits a slot 20 in which the crossbar 10 can move at right angles to the level of the stage floor 1 and thus change its distance from the lower surface of the stage floor.

- a pivot lock 21 is pivotally mounted around the rod 19 and has a bearing surface 22.

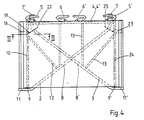

- the cross bar 10 In the working position, ie when it is suspended on the building wall and attached stage, the cross bar 10 is located at the upper end of the slot 20 and in the embodiment shown supports the stage floor 1 directly. However, this can also be done using appropriate intermediate pieces. If the stage is suspended, the weight of the supports moves the crossbar to the lower end of slot 20. The supports 2 and 3 are then folded in.

- the pivot axis 24 of the support 3 is supported, as mentioned, on a fitting which is arranged at the end of the stage floor 1 which faces away from the end of the stage floor which is shown in FIG. 2. If the support 3 is pivoted clockwise about its pivot axis 24 to rest on the stage floor 1, the fuse 21 is first pivoted so far about the axis of the rod 19 that the lower end 7 'of the support 3 can be pivoted past the pivot lock 21 . The swivel lock 21 is then swiveled back into the path of the lower end of the support 3 and this lower end is placed on the bearing surface 22.

- the cross bar 24, which forms the pivot axis of the support 3 is still at the lower end of the slot 20 of the fitting arranged there.

- the support 2 is pivoted counterclockwise around the crossbar 10 to the underside of the stage floor 1 and the lower end of the support 2 is placed on the swivel lock 25, which is arranged on a fitting 23, which is arranged on the opposite end of the fitting 16 of the stage is.

- the support comes to rest on the already pivoted-in support 3 and presses this support upward, so that its crossbar 24 moves into the upper end of the slot there. Since the end 7 of the support 2 on the swivel lock 25 and the crossbar 10 rests at the lower end of the slot 20, the support 2 runs flat and parallel to the stage floor 1.

- each side end of the stage there is also a cross member 26 fastened to the narrow side of the stage floor, the leg 27 of which protrudes somewhat further down than the dimension required by the two supports 2 and 3 which are folded over one another.

- the leg 27 therefore extends a little further below the stage floor 1 than the support 18, which is provided at the lower end of the slot.

- this lower edge 29 then rests on the forklift, the fork of which can also rest on the cross tube 10, provided that at this end of the stage the cross bar 10 is in the lower position in the slot 20.

- the fittings 16 and the corresponding devices such as the swivel lock can be arranged at all four corners of the stage floor 1 in embodiments of the invention.

- the folded stage points to everyone Corner one foot

- the two swivel locks on the outer edge have no function, but they can be useful when other than triangular brackets are used as supports, e.g. rectangular frames.

- the fitting 16 can be designed so that the supports are removably attached to it, preferably in a form-fitting manner without the use of screws.

- the invention can be implemented both on entire stages and on individual stage sections.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Ladders (AREA)

Claims (11)

- Plate-forme de travail pour un échafaudage, en particulier pour des coffrages à béton, comprenant des supports rabattables contre la face inférieure du plancher de la plate-forme, caractérisée en ce que l'axe de basculement (10, 24) de l'un au moins de ces supports (2, 3) est mobile perpendiculairement à la surface (1) du plancher de la plate-forme.

- Plate-forme selon la revendication 1, caractérisée en ce que la distance entre l'axe de basculement (10) du support (2) et la face inférieure du plancher de plate-forme peut être modifiée dans la mesure telle qu'un support opposé (13) occupe une position rabattue contre la face inférieure du plancher.

- Plate-forme selon l'une ou l'autre des revendications 1 ou 2, caractérisée en ce qu'il est prévu des ferrures (16) sur la face inférieure du plancher, lesquelles délimitent une fente (20) dans laquelle est guidée en rotation et en translation une pièce (10, 24) qui forme l'axe de rotation des supports (2, 3).

- Plate-forme selon l'une ou l'autre des revendications 1 ou 2, caractérisée en ce que le déplacement de l'axe de rotation des supports pour modifier leur distance depuis la face inférieure du plancher est dérivé d'un mouvement de basculement d'au moins un levier.

- Plate-forme selon l'une quelconque des revendications précédentes, caractérisée en ce que la plate-forme comporte au moins un pied (28) avec lequel une plate-forme supérieure s'appuie sur la plate-forme immédiatement inférieure ou sur un appui, lorsqu'on empile plusieurs plates-formes rabattues les unes sur les autres.

- Plate-forme selon la revendication 5, caractérisée en ce que le pied (28) est prévu sur au moins une ferrure (16) qui retient les supports de la plate-forme.

- Plate-forme selon l'une ou l'autre des revendications 5 et 6, caractérisée en ce que le pied (16, 28) est aussi long qu'il reste entre deux plates-formes superposés et rabattues, au moins au niveau du côté étroit, un intervalle dont la hauteur est quelque peu plus importante que l'épaisseur de la fourche d'un chariot à fourche.

- Plate-forme selon l'une quelconque des revendications précédentes, caractérisée en ce qu'il est prévu à une extrémité de la plate-forme (1) un appui (21, 22) dans lequel on peut poser le support monté sur l'extrémité opposée de la plate-forme, dans la condition rabattue contre le plancher de la plate-forme.

- Plate-forme selon l'une quelconque des revendications précédentes, caractérisée en ce que dans la région du plancher (1) de la plate-forme est prévu un support (26) qui relie longitudinalement ou transversalement les emplacements de montage des supports.

- Plate-forme selon les revendications 5 à 9, caractérisée en ce qu'il est prévu au moins un pied agencé sur le support de liaison (26).

- Plate-forme selon l'une quelconque des revendications précédentes, comportant des côtés étroits, caractérisée en ce qu'il est prévu un support (26) agencé sur ses côtés étroits, dont la largeur au-dessous de la surface inférieure du plancher de plate-forme dépasse plus loin vers le bas de la hauteur occupée par deux supports rabattus l'un sur l'autre, et en ce que la bordure inférieure (29) de ce support transversal (26) forme l'appui d'une plate-forme rabattue sur la fourche d'un chariot à fourche, et en ce que les pieds (16, 28) dépassent si loin vers le bas que la fourche du chariot à fourche trouve de la place dans cet espace intermédiaire entre deux plates-formes rabattues et empilées l'une sur l'autre.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4405289A DE4405289C1 (de) | 1994-02-19 | 1994-02-19 | Arbeitsbühne |

| DE4405289 | 1994-02-19 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0668418A1 EP0668418A1 (fr) | 1995-08-23 |

| EP0668418B1 true EP0668418B1 (fr) | 1997-04-09 |

Family

ID=6510620

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95100037A Expired - Lifetime EP0668418B1 (fr) | 1994-02-19 | 1995-01-03 | Echafaudage |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0668418B1 (fr) |

| DE (2) | DE4447467C2 (fr) |

| ES (1) | ES2102890T3 (fr) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108797990A (zh) * | 2018-06-15 | 2018-11-13 | 王秀丽 | 一种建筑施工用抹灰辅助装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1837232A (en) * | 1929-10-21 | 1931-12-22 | Joseph Pavelka | Hinge for electric grids |

| CH266847A (de) * | 1949-01-28 | 1950-02-28 | Fehrenbach Joseph | Zusammenlegbarer Bock. |

| FR2676771B1 (fr) * | 1991-05-21 | 1995-08-25 | Al Cant Coffrages | Perfectionnement aux consoles pignons repliables pour echafaudages ou analogues. |

-

1994

- 1994-02-19 DE DE4447467A patent/DE4447467C2/de not_active Expired - Fee Related

-

1995

- 1995-01-03 EP EP95100037A patent/EP0668418B1/fr not_active Expired - Lifetime

- 1995-01-03 DE DE59500165T patent/DE59500165D1/de not_active Expired - Fee Related

- 1995-01-03 ES ES95100037T patent/ES2102890T3/es not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| ES2102890T3 (es) | 1997-08-01 |

| DE4447467C2 (de) | 1997-02-06 |

| EP0668418A1 (fr) | 1995-08-23 |

| DE59500165D1 (de) | 1997-05-15 |

| DE4447467A1 (de) | 1995-08-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1958347C2 (de) | Stapelbares Ladegestell mit schwenkbar gelagerten Eckstützen oder Stirnwänden | |

| DE2237817B2 (fr) | ||

| DE3039079A1 (de) | Zusammenlegbarer frachtgut-traeger | |

| DE4113314A1 (de) | Stapelbares traggestell fuer lager- und transportgut | |

| DE102009050871B4 (de) | Vorrichtung zum Transport von hängenden Kleidungsstücken | |

| EP0668418B1 (fr) | Echafaudage | |

| DE4135677A1 (de) | Ladungstraeger | |

| DE4405289C1 (de) | Arbeitsbühne | |

| DE9421413U1 (de) | Arbeitsbühne | |

| EP0642980B1 (fr) | Palette pour le stockage et le transport d'objets | |

| EP1484278B1 (fr) | Dipositif, grue gerbeuse et magasin à rayonnage pour l'emmagasinage et le transport de palettes | |

| DE3124360A1 (de) | "mit fuessen versehener behaelter, insbesondere stapelbarer behaelter fuer landwirtschaftliche und industrielle zwecke" | |

| DE3728647A1 (de) | Palette mit schutz- und stapelbuegeln | |

| DE9300111U1 (de) | Transportbehälter, insbesondere Wäschetransportwagen | |

| DE1193430B (de) | Aufsteckgestell fuer Paletten mit rechtwinkliger Ladeflaeche | |

| EP0625619A1 (fr) | Plate-forme d'échafaudage | |

| DE1586870C (de) | Zerlegbarer Aufsetzrahmen für Paletten | |

| DE3117012A1 (de) | Schutzkorb fuer krangabeln | |

| DE20113396U1 (de) | Vorrichtung zur Lagerung und zum Transport von Platten | |

| DE20001120U1 (de) | Transportfahrzeug | |

| DE1556719C (de) | Palettenartiges Transportmittel | |

| DE10324358A1 (de) | Glastransportgestell (AZL 2003 CF) mit verstellbaren Anlagen und in sich falt- und stapelbar | |

| DE8431349U1 (de) | Flaschenpalette | |

| DE2152860A1 (de) | Ladepalette mit klappbaren stuetzelementen | |

| DE20009576U1 (de) | Laderaumaufbau für Fahrzeuge |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE ES FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19950810 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19960902 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19970410 |

|

| REF | Corresponds to: |

Ref document number: 59500165 Country of ref document: DE Date of ref document: 19970515 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2102890 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030124 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030127 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20030130 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040105 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050103 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20040105 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090122 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100803 |