EP0638419A1 - Supporting framework for a rotary web printing press - Google Patents

Supporting framework for a rotary web printing press Download PDFInfo

- Publication number

- EP0638419A1 EP0638419A1 EP94810385A EP94810385A EP0638419A1 EP 0638419 A1 EP0638419 A1 EP 0638419A1 EP 94810385 A EP94810385 A EP 94810385A EP 94810385 A EP94810385 A EP 94810385A EP 0638419 A1 EP0638419 A1 EP 0638419A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- support frame

- unit

- inking

- units

- printing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F31/00—Inking arrangements or devices

- B41F31/30—Arrangements for tripping, lifting, adjusting, or removing inking rollers; Supports, bearings, or forks therefor

- B41F31/302—Devices for tripping inking devices as a whole

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F13/00—Common details of rotary presses or machines

- B41F13/44—Arrangements to accommodate interchangeable cylinders of different sizes to enable machine to print on areas of different sizes

Definitions

- the present invention relates to a support frame for a web-fed rotary machine for receiving at least one printing unit.

- the printing units of a printing tower are stacked one on top of the other, or even the elements of the printing units, namely the cylinder elements and the inking and dampening units, are placed individually next to and on top of one another.

- An example of the first of these two configurations is known from DE 42 19 705 A1.

- the units placed one on top of the other must be designed to be self-supporting and the units placed on them must also be supported. They are therefore to be provided in a correspondingly stable design.

- the structural effort of such a supporting structure is increased by the fact that the cylinder, color and dampening unit elements themselves have a supporting function and are accordingly dimensioned to be larger than their actual task would require.

- the present invention has set itself the task of creating a support frame as a support structure for a web-fed rotary printing press in such a way that the individual printing press elements can be modularly constructed therein with the least possible effort for the required stability and optimal accessibility for the operation and maintenance of the printing press elements.

- the invention is intended to make the printing press cheaper and less expensive to operate.

- a printing unit or a printing tower of a web-fed rotary printing press with at least two printing units arranged one above the other, each having cylinder elements with a plurality of cylinders and inking and dampening units assigned to these cylinder elements

- the cylinder elements and the inking and dampening units are held in a supporting structure, which as a support frame is already stable in itself or at least in a rigid connection with the cylinder elements.

- the effort to be made in the production of a suitable hall floor is reduced when using the supporting structure according to the invention.

- the supporting structure can be set up at the destination regardless of the complex machine parts. After they have been installed, the cylinder elements, inking and dampening units, the folder and other machine parts can be easily and quickly installed in the existing supporting structure.

- the support structure according to the invention in particular the inherently stable support structure, makes it possible to build the printing press largely modularly from comparatively easily replaceable units.

- the modular units no longer build on one another in a load-bearing manner, but they can be supported on the supporting structure, for example by a fixed, adjustable connection, by hanging in, or they can be movably held thereon.

- the invention allows the printing press to be equipped with working platforms for the operating and maintenance personnel with the least possible additional effort.

- the working platforms used in the operation of the printing press can also be integrated into the supporting structure when the machine is being set up, in particular when installing the machine parts in the supporting structure, or can only be added to it.

- the support structure according to the invention enables the accessibility of machine parts to be improved in a particularly simple manner, in that the inking units or parts thereof are designed as modular units which are held on the support structure and / or cylinder elements so as to be movable from their working position relative to the respective cylinder elements.

- the combination of a supporting structure according to the invention with the mentioned movability of inking units, dampening units and possibly other machine parts offers particular advantages, the movability alone brings advantages in terms of space requirements and for the maintenance of the machine.

- inking units par excellence is known from DE-AS 1 169 959.

- a multi-color sheet-fed rotary printing press designed as a series machine is disclosed.

- Their printing unit is formed by two form cylinders or plate cylinders which are assigned to a printing cylinder and are arranged approximately one above the other, and inking units which are in turn assigned to them.

- the two inking units can be moved in a common frame on inclined tracks in the transverse direction to the longitudinal axes of the forme or plate cylinders.

- a unit of printing cylinders which can be moved in the transverse direction to the cylinder longitudinal axes is known from EP 0 315 917 A2.

- the inking unit parts combined to form movable units are arranged on the support structure so as to be movable in the direction of the longitudinal axes of the cylinders.

- the movable units are moved in the direction of the axes of rotation of the cylinders, a reduction in the length of the printing machine measured transversely to the axes of rotation of the rollers can be achieved compared to the known displacement or pivoting mechanisms.

- This advantage is particularly evident in the large rotary printing presses which are designed as in-line presses and which can have 8, 16 or more printing towers arranged one behind the other.

- the cylinder elements and inking units can be arranged closer together, since the maintenance tunnels otherwise necessary for access to the cylinder elements and inking units can be dispensed with.

- the inking units are each in themselves and also in relation to the other inking units and opposite the cylinder elements can be built and arranged to save space.

- the inking and dampening units as well as the printing cylinder elements are optimally accessible.

- machine elements can be replaced almost without interrupting production.

- the versatility of such printing units can also be increased by using different inking units alternatively for different demands on the quality of the printed products and by moving them into their respective working positions.

- inking units for example short inking units with different inking processes for different printing qualities or printing units with different printing methods such as flexographic or gravure printing processes, can be used without any problems or can be interchanged and, if necessary, combined with one another.

- Conventional blanket cylinders can also be exchanged for new blanket cylinders with continuous blankets for the use of a computer to press system.

- a dampening unit which interacts with the inking unit, such as the inking unit in part or in whole, is particularly advantageously integrated in the movable units.

- the extended inking unit or dampening unit easily accessible for maintenance work, but also the correspondingly exposed part of the cylinder element consisting of one or more forme or plate cylinders, blanket cylinder and possibly a central cylinder can be made easily accessible for maintenance work.

- An entire inking unit with an entire dampening unit is particularly preferably combined to form such a movable unit. Both the cylinder elements and the inking and dampening units are freely accessible after they are extended. The changeover times when changing ink and dampening unit types are the shortest and the design effort is the least due to the low fragmentation. In this combination of inking and dampening systems, the largely achieved reductions in the overall height and the total length of the printing press.

- the movable units are each equipped with a separate drive. In principle, however, it would also be possible to couple the movable units into a drive system for the entire printing unit, although an additional auxiliary unit would still be necessary to drive the rollers of the movable unit in the extended state. In addition to its own drive, the movable unit also has a control unit necessary for carrying out maintenance work.

- the supply of the mobile unit i.e. the drive and the control device can be supplied via a trailing cable or via a plug-in connection that has only been established in the extended state.

- FIGS. 1 and 2 printing towers 1, each with two printing units 5 arranged one above the other, of which FIG. 3 shows a further enlarged one, are shown in a lateral cross section and in a front view.

- a web-fed rotary printing press is formed by at least one printing unit 5 or a plurality of printing towers 1 arranged one behind the other, at least one folder 3 and at least one printing material roll stand 4.

- the printing units 5 are each constructed in a modular manner from a cylinder element 6 and four assigned, movable units 10.

- the cylinder element 6 is designed in the form of a satellite printing unit with a central cylinder 7, four blanket cylinders 8 and four form or plate cylinders 9 assigned to the blanket cylinders 8.

- the cylinder element 6 is rigidly attached to four stationary columns 30, which form lateral column pairs 30 for the printing units 5, while the units 10 can be moved in the rails 19 attached to the columns 30 in the direction of the axes of rotation 21 of the cylinders 7, 8, 9.

- the movable units 10 are each formed by an inking unit 11 and a dampening unit 15.

- the ink application rollers 12 and the dampening agent application rollers 16 can be pivoted away from the forme cylinders 9.

- the printing units 5 are each supported on the pairs of columns 30 arranged on their two sides, which together with connecting cross members 50, 150, 151, 152 form the essential part of a supporting structure 2.

- the printing units 5 are in this way framed by the lateral column pairs 30 and in each case an upper and a lower cross member 50.

- Each of the movable units 10 can be individually shifted in a straight line in the direction of the axes of rotation 21 of the cylinders 7, 8 and 9 between a working and a maintenance position.

- the units 10 run with rollers 20 in the running rails 19. In principle, however, other travel mechanisms are also conceivable.

- the two units 10 each arranged above a cylinder element 6 become hanging, and the units 10 each arranged below the cylinder element 6 are supported on the cross members 50 by the columns 30.

- the cylinder elements 6 arranged one above the other are supported on a pair of columns 30 on the right and on the left thereof, for example by corresponding alignment and connecting elements.

- the support structure 2 of the exemplary embodiment is sufficiently inherently rigid to carry both the cylinder elements and the inking and dampening units.

- the cylinder elements 6 can also be exchanged in a modular manner.

- the cylinder elements 6 can also be integrated into the supporting structure 2 in a stabilizing and load-bearing manner with a sufficiently stable design and a correspondingly firm bond with the columns 30. Corresponding compromises could be made in this case in the load-bearing capacity of the columns 30 and the cross beams 50, 150, 151, 152.

- Figure 4 in which equivalent components are provided with the same reference numerals, shows two printing units 5 on the left in a conventionally constructed printing tower 1 and, on the right, in comparison, the printing units of the printing tower 1 of Figure 1, which, in addition to the inherently rigid support structure, also has the further feature of the movable color - And dampening unit 10, so that the maximum space saving is achieved.

- the space requirement for a maintenance tunnel 60 which is necessary in the conventional printing tower 1 and which must remain free in the case of non-movable inking and dampening units 11, 15 in order to be able to carry out maintenance and repair work can be clearly seen.

- the color and dampening unit 10 can be completely omitted in the pressure tower 1 maintenance tunnel shown in FIG.

- the printing units 5 can be made flatter and narrower.

- the reduction in the pressure tower height in the exemplary embodiment is approximately 15% compared to the corresponding conventional pressure tower 1 on the left half of FIG. 4.

- the number of operating levels and the intermediate platforms are also significantly reduced in the supporting structure according to the invention.

- the support structure 2 is further developed by further columns 32, which are each arranged next to a pair of columns 30 in the longitudinal direction of the cylinders 7, 8, 9.

- the arrangement of the columns 32 is approximately mirror-symmetrical to that of the columns 30 to which they are connected by means of elongated cross members.

- the two left-hand columns 32 which only need to partially support the dead weight of the supporting structure 2, the units 10 moved out of the working position, the maintenance personnel and the equipment necessary for maintenance and repair, can be made weaker than the columns 30.

- the columns carry 32 another work crane 23 to support the work.

- a unit 10 which is in the disengaged state, ie in the maintenance position, is indicated in dashed lines.

- the parts of the inking and dampening unit 11 and 15 combined to form unit 10 are supplied with energy and possibly with data for a separate drive and possibly a control unit for the rollers of the movable unit 10 via a fixed plug connection 21.

- the lifting crane 23 can be used for a lower lifting load than is more conventional for the printing units Printing presses would be necessary, which in turn entails cost advantages.

- FIG. 5 shows the pressure tower 1 from FIG. 1 in a top view, in which the column pairs 30 can be seen laterally from the two units 10 arranged next to one another and movable in the direction of the arrows A. Furthermore, a working platform 35 which is movable in the direction of arrow B transversely to the extension direction of the units 10 is indicated. Such work platforms 35 are again shown more clearly in FIG. 6 together with several units 10 moved out into the maintenance position. The work platforms 35 can each be guided under and / or over the extended units 10 of the printing units 5 along further various cross members. It is also possible to move the work platforms freely if other floors are provided on the various supports.

- the advantages of the invention come into play particularly when the printing press is arranged in a row by a plurality of printing units 5 or printing towers 1, each with a plurality of printing units 5 arranged one above the other, each with a plurality of inking and / or dampening units 11 and 15 is formed.

- the greatest cost savings and the largest space savings in terms of press length and height are expected.

- the movability of the inking and dampening units according to the invention moreover, no space is required, which would not also occur with permanently installed inking and dampening units, since their rollers and / or cylinders would also have to be pulled out of the printing machine when changing in the direction of their axes of rotation.

- the known printing presses with otherwise movable inking and dampening units always require additional space, which would not arise with a fixed arrangement.

- the concept of working platforms that can be moved under the extended fab and dampening units also contributes to saving space without requiring concessions on accessibility.

- Each inking unit and dampening unit in its maintenance position is freely accessible from three sides per printing unit.

- the support structure according to the invention enables this high degree of modularity, including the movability of the inking and dampening unit, which benefits the simple installation of the printing press and the need to change machine parts later on.

- FIG. 6 shows a front view of the printing tower of FIG. 5, in which a unit 10 of a lower and an upper printing unit is extended in the maintenance position in the direction of the axis of rotation 21 of the cylinders 7, 8, 9. It can also be seen that a work platform 35 for a lower and an upper printing unit 5 can be moved in the direction of arrow B transversely to the extension direction of the units 10. In doing so, the units 10 with the work platforms are driven under or over. It can also be seen that no additional intermediate platforms corresponding to the conventional design according to FIG. 4 are necessary for operating the units 10.

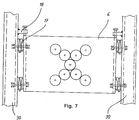

- FIG. 7 shows a detail from the front view of FIG. 3, in which a cylinder element 6 is detachably attached to the columns 30 by means of spherical alignment and connecting elements 17.

- the cylinder elements 6 are aligned in the vertical direction between the columns 30 and in the horizontal direction between the various cross members (50, 150, 151, 152) by means of the alignment and connecting elements 17, 18.

- the units 10 are aligned by aligning the running rails 19, as shown in FIG. 3, which are fastened with the same alignment and connecting elements 17, 18, not shown, as the cylinder elements 6.

- Figure 8 shows a further embodiment of the support structure according to the invention.

- a web-fed rotary printing press shown in a front view consists of at least one printing unit 5, a folder 3 and a printing-material roll stand 4 Folder also divided into different cylinder elements, not shown, which are designed so that they can be aligned with the cylinder elements 6 and detachably attached to the columns 30.

- the substrate roll stands 4 are attached to the columns 30 in the same way.

- the support frame according to the invention which is supported on the machine foundation, the costly customary machine table substructure can be dispensed with as a substantial cost saving.

- the folder and roll stand elements can also be moved in the direction of the axis of rotation 21 between a work and maintenance position.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rotary Presses (AREA)

- Rolls And Other Rotary Bodies (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft ein Traggestell für eine Rollenrotationsmaschine für die Aufnahme mindestens eines Druckwerkes.The present invention relates to a support frame for a web-fed rotary machine for receiving at least one printing unit.

Bei bekannten Druckmaschinenkonfigurationen sind die Druckeinheiten eines Druckturms übereinandergestapelt oder gar die Elemente der Druckeinheiten, nämlich die Zylinderelemente und die Farb- und Feuchtwerke, jeweils einzeln neben- und aufeinandergesetzt. Ein Beispiel für die erste dieser beiden Konfigurationen ist aus der DE 42 19 705 A1 bekannt. In beiden Fällen müssen die aufeinandergesetzten Baueinheiten jeweils in sich tragend ausgebildet sein und die daraufgesetzten Baueinheiten mittragen. Sie sind daher in entsprechend stabiler Ausführung vorzusehen. Der konstruktive Aufwand solch einer Tragkonstruktion wird noch dadurch erhöht, daß die Zylinder-, Farb- und Feuchtwerkelemente selbst eine tragende Funktion einnehmen und dementsprechend stärker zu dimensionieren sind als es ihre eigentliche Aufgabe erfordern würde.In known printing press configurations, the printing units of a printing tower are stacked one on top of the other, or even the elements of the printing units, namely the cylinder elements and the inking and dampening units, are placed individually next to and on top of one another. An example of the first of these two configurations is known from DE 42 19 705 A1. In both cases, the units placed one on top of the other must be designed to be self-supporting and the units placed on them must also be supported. They are therefore to be provided in a correspondingly stable design. The structural effort of such a supporting structure is increased by the fact that the cylinder, color and dampening unit elements themselves have a supporting function and are accordingly dimensioned to be larger than their actual task would require.

Die vorliegende Erfindung hat es sich zur Aufgabe gemacht, ein Traggestell als eine Tragkonstruktion für eine Rollenrotationsdruckmaschine so zu schaffen, daß darin die einzelnen Druckmaschinenelemente modular aufgebaut werden können bei möglichst geringem Aufwand für die erforderliche Stabilität und optimaler Zugänglichkeit für die Bedienung und Wartung der Druckmaschinenelemente. Die Druckmaschine soll durch die Erfindung preiswerter und im Betrieb kostengünstiger werden.The present invention has set itself the task of creating a support frame as a support structure for a web-fed rotary printing press in such a way that the individual printing press elements can be modularly constructed therein with the least possible effort for the required stability and optimal accessibility for the operation and maintenance of the printing press elements. The invention is intended to make the printing press cheaper and less expensive to operate.

Diese Aufgabe wird durch den Gegenstand des Anspruchs 1 gelöst.This object is solved by the subject matter of

Die Unteransprüche sind auf vorteilhafte, nicht glatt selbstverständliche Ausführungen des Gegenstands von Anspruch 1 gerichtet.The subclaims are directed to advantageous, not smoothly self-evident embodiments of the subject matter of

Bei einer Druckeinheit bzw. einem Druckturm einer Rollenrotationsdruckmaschine mit zumindest zwei übereinander angeordneten Druckeinheiten, die jeweils Zylinderelemente mit mehreren Zylindern und diesen Zylinderelmenten zugeordnete Farb- und Feuchtwerke aufweisen, werden nach der Erfindung die Zylinderelemente und die Farb- und Feuchtwerke in einer Tragkonstruktion gehalten, die als Traggestell bereits in sich selbst oder aber zumindest in steifer Verbindung mit den Zylinderelementen tragend stabil ist.In a printing unit or a printing tower of a web-fed rotary printing press with at least two printing units arranged one above the other, each having cylinder elements with a plurality of cylinders and inking and dampening units assigned to these cylinder elements, according to the invention the cylinder elements and the inking and dampening units are held in a supporting structure, which as a support frame is already stable in itself or at least in a rigid connection with the cylinder elements.

Dadurch wird ein Aufeinandersetzen der Druckeinheiten oder gar der einzelnen Zylinderelemente und der Farb- und Feuchtwerke vermieden. Diese Baueinheiten brauchen in sich nicht mehr eigenstabil zu sein. Insbesondere müssen die Zylinderelemente und Farb- und Feuchtwerke selbst keine tragenden Funktionen in der Struktur der Druckmaschine übernehmen und können deshalb leichter und kostengünstiger als bei herkömmlicher Konstruktionsweise gebaut werden. Während in der herkömmlichen Bauweise die tragenden Teile selbst paßgenau gefertigt sein müssen, damit die Zylinder und Walzen in die Tragkonstruktion eingebunden werden und eine tragende Funktion übernehmen können, bedarf es bei der erfindungsgemäßen Tragkonstruktion keiner paßgenauen Bearbeitung. Tragende Konstruktionsteile können deshalb besonders kostensparend aus Stahlbeton oder ähnlich preiswerten Baustoffen hergestellt sein. Der bei der Herstellung eines geeigneten Hallenbodens zu treibende Aufwand wird bei Verwendung der erfindungsgemäßen Tragkonstruktion verringert. Ferner kann die Tragkonstruktion bereits unabhängig von den komplexen Maschinenteilen am Bestimmungsort aufgestellt werden. Nach deren Aufstellung lassen sich die Zylinderelemente, Farb- und Feuchtwerke, der Falzapparat und sonstige Maschinenteile leicht und sehr rasch in die bereits vorhandene Tragkonstruktion einbauen. Durch die erfindungsgemäße Tragkonstruktion, insbesondere die eigenstabile Tragkonstruktion, wird es möglich, die Druckmaschine weitestgehend modular aus vergleichsweise einfach austauschbaren Einheiten aufzubauen. Die modularen Einheiten bauen nicht mehr tragend aufeinander auf, sondern sie können an der Tragkonstruktion abgestützt werden, beispielsweise durch eine feste einstellbare Verbindung, durch Einhängen, oder sie können bewegbar daran gehalten sein. Schließlich erlaubt es die Erfindung, die Druckmaschine bei geringst möglichem zusätzlichen Aufwand mit Arbeitsbühnen für das Bedien- und Wartungspersonal auszustatten. Die im Betrieb der Druckmaschine benutzten Arbeitsbühnen können auch bereits bei der Aufstellung der Maschine, insbesondere beim Einbau der Maschinenteile in die Tragkonstruktion in die Tragkonstruktion eingebunden oder lediglich dazu gestellt werden.This avoids stacking the printing units or even the individual cylinder elements and the inking and dampening units. These units no longer need to be inherently stable. In particular, the cylinder elements and inking and dampening units themselves do not have to take on any supporting functions in the structure of the printing press and can therefore be built more easily and more cost-effectively than with a conventional design. While in the conventional design the load-bearing parts are manufactured to fit must be so that the cylinders and rollers are integrated into the supporting structure and can take on a supporting function, no precise machining is required in the supporting structure according to the invention. Structural parts can therefore be made of reinforced concrete or similar inexpensive building materials in a particularly cost-effective manner. The effort to be made in the production of a suitable hall floor is reduced when using the supporting structure according to the invention. Furthermore, the supporting structure can be set up at the destination regardless of the complex machine parts. After they have been installed, the cylinder elements, inking and dampening units, the folder and other machine parts can be easily and quickly installed in the existing supporting structure. The support structure according to the invention, in particular the inherently stable support structure, makes it possible to build the printing press largely modularly from comparatively easily replaceable units. The modular units no longer build on one another in a load-bearing manner, but they can be supported on the supporting structure, for example by a fixed, adjustable connection, by hanging in, or they can be movably held thereon. Finally, the invention allows the printing press to be equipped with working platforms for the operating and maintenance personnel with the least possible additional effort. The working platforms used in the operation of the printing press can also be integrated into the supporting structure when the machine is being set up, in particular when installing the machine parts in the supporting structure, or can only be added to it.

Die erfindungsgemäße Tragkonstruktion ermöglicht auf besonders einfache Weise eine Verbesserung der Zugänglichkeit von Maschinenteilen, indem die Farbwerke oder Teile davon als modulare Einheiten ausgebildet sind, die aus ihrer Arbeitsposition gegenüber den jeweiligen Zylinderelementen bewegbar an der Tragkonstruktion und/oder Zylinderelementen gehalten sind. Obwohl die Kombination einer erfindungsgemäßen Tragkonstruktion mit der angesprochenen Verfahrbarkeit von Farbwerken, Feuchtwerken und gegebenenfalls weiteren Maschinenteilen besondere Vorteile bietet, bringt auch die Verfahrbarkeit alleine bereits Vorteile hinsichtlich des Platzbedarfs und für die Wartung der Maschine.The support structure according to the invention enables the accessibility of machine parts to be improved in a particularly simple manner, in that the inking units or parts thereof are designed as modular units which are held on the support structure and / or cylinder elements so as to be movable from their working position relative to the respective cylinder elements. Although the combination of a supporting structure according to the invention with the mentioned movability of inking units, dampening units and possibly other machine parts offers particular advantages, the movability alone brings advantages in terms of space requirements and for the maintenance of the machine.

Die Verfahrbarkeit von Farbwerken schlechthin ist aus der DE-AS 1 169 959 bekannt. Dort ist eine als Reihenmaschine ausgebildete Mehrfarben-Bogenrotationsdruckmaschine offenbart. Deren Druckeinheit wird durch zwei, einem Druckzylinder zugeordnete, etwa übereinander angeordnete Form- bzw. Plattenzylinder und diesen wiederum zugeordneten Farbwerken gebildet. Die beiden Farbwerke sind in einem gemeinsamen Rahmen auf Schrägbahnen in Querrichtung zu den Längsachsen der Form- bzw. Plattenzylindern verfahrbar.The movability of inking units par excellence is known from DE-AS 1 169 959. There, a multi-color sheet-fed rotary printing press designed as a series machine is disclosed. Their printing unit is formed by two form cylinders or plate cylinders which are assigned to a printing cylinder and are arranged approximately one above the other, and inking units which are in turn assigned to them. The two inking units can be moved in a common frame on inclined tracks in the transverse direction to the longitudinal axes of the forme or plate cylinders.

Eine in Querrichtung zu den Zylinderlängsachsen verfahrbare Einheit von Druckzylindern ist aus der EP 0 315 917 A2 bekannt.A unit of printing cylinders which can be moved in the transverse direction to the cylinder longitudinal axes is known from EP 0 315 917 A2.

Erfindungsgemäß werden demgegenüber die zu bewegbaren Einheiten zusammengefaßten Farbwerksteile in Richtung der Zylinderlängsachsen verfahrbar an der Tragkonstruktion angeordnet.According to the invention, on the other hand, the inking unit parts combined to form movable units are arranged on the support structure so as to be movable in the direction of the longitudinal axes of the cylinders.

Da die verfahrbaren Einheiten in Richtung der Rotationsachsen der Zylinder verfahren werden, kann gegenüber den bekannten Verschiebe- oder Schwenkmechanismen eine Verringerung der quer zu den Rotationsachsen der Walzen gemessenen Länge der Druckmaschine erzielt werden. Dieser Vorteil kommt besonders bei den großen, als Reihenmaschinen ausgebildeten Rotationsdruckmaschinen, die 8, 16 oder mehr hintereinander angeordnete Drucktürme aufweisen können, zum Tragen. Gegenüber den herkömmlichen Drucktürmen, die keine verfahrbaren Einheiten besitzen, können die Zylinderelemente und Farbwerke dichter zueinander angeordnet werden, da auf die sonst für den Zugang zu den Zylinderelementen und Farbwerken notwendigen Wartungstunnel verzichtet werden kann. In der Arbeitsposition der Zylinder und der Farbwerkswalzen braucht daher nicht mehr auf die Zugänglichkeit geachtet zu werden, so daß die Farbwerke jeweils in sich und auch gegenüber den anderen Farbwerken sowie gegenüber den Zylinderelementen raumsparender gebaut und angeordnet werden können. In der ausgefahrenen Position sind sowohl die Farb- und Feuchtwerke wie auch die Druckzylinderelemente optimal zugänglich. Desweiteren kann das Auswechseln von Maschinenelementen im Falle einer größeren Wartung oder Reparatur fast ohne Produktionsunterbrechung vorgenommen werden. Es kann auch die Einsatzflexibilität solcher Druckeinheiten erhöht werden, indem für unterschiedliche Ansprüche an die Qualität der Druckprodukte unterschiedliche Farbwerke alternativ eingesetzt und in ihre jeweilige Arbeitsposition gefahren werden können. In der gleichen Druckmaschine können somit problemlos unterschiedliche Farbwerke, z.B. Kurzfarbwerke mit verschiedenen Einfärbverfahren für unterschiedliche Druckqualitäten oder Druckwerke mit unterschiedlichen Druckverfahren wie z.B. Flexo- oder Tiefdruckverfahren eingesetzt oder je nach Bedarf untereinander ausgetauscht und gegebenenfalls miteinander kombiniert werden.Since the movable units are moved in the direction of the axes of rotation of the cylinders, a reduction in the length of the printing machine measured transversely to the axes of rotation of the rollers can be achieved compared to the known displacement or pivoting mechanisms. This advantage is particularly evident in the large rotary printing presses which are designed as in-line presses and which can have 8, 16 or more printing towers arranged one behind the other. Compared to the conventional printing towers, which have no movable units, the cylinder elements and inking units can be arranged closer together, since the maintenance tunnels otherwise necessary for access to the cylinder elements and inking units can be dispensed with. In the working position of the cylinders and the inking unit rollers, it is therefore no longer necessary to pay attention to the accessibility, so that the inking units are each in themselves and also in relation to the other inking units and opposite the cylinder elements can be built and arranged to save space. In the extended position, the inking and dampening units as well as the printing cylinder elements are optimally accessible. Furthermore, in the event of major maintenance or repairs, machine elements can be replaced almost without interrupting production. The versatility of such printing units can also be increased by using different inking units alternatively for different demands on the quality of the printed products and by moving them into their respective working positions. In the same printing press, different inking units, for example short inking units with different inking processes for different printing qualities or printing units with different printing methods such as flexographic or gravure printing processes, can be used without any problems or can be interchanged and, if necessary, combined with one another.

Auch lassen sich herkömmliche Gummituchzylinder gegen neue Gummituchzylinder mit Endlosgummitüchern für den Einsatz eines Computer to Press-Systems nachträglich austauschen.Conventional blanket cylinders can also be exchanged for new blanket cylinders with continuous blankets for the use of a computer to press system.

Besonders vorteilhaft ist in den verfahrbaren Einheiten jeweils ein mit dem Farbwerk zusammenwirkendes Feuchtwerk wie das Farbwerk zum Teil oder im Ganzen integriert. Somit ist nicht nur das jeweils ausgefahrene Farbwerk bzw. Feuchtwerk für Wartungsarbeiten leicht zugänglich, sondern es kann auch der entsprechend freigelegte Teil des aus einem oder mehreren Form- bzw. Plattenzylindern, Gummituchzylinder und ggfs. einem Zentralzylinder bestehenden Zylinderelements für Wartungsarbeiten leicht zugänglich gemacht werden. Besonders bevorzugt wird je ein ganzes Farbwerk mit einem ganzen Feuchtwerk zu solch einer verfahrbaren Einheit zusammengefaßt. Sowohl die Zylinderelemente als auch die Farb- und Feuchtwerke sind nach deren Ausfahren frei zugänglich. Die Umrüstzeiten beim Wechsel von Farb- und Feuchtwerkstypen sind am kürzesten und der konstruktive Aufwand ist wegen der geringen Zersplitterung am geringsten. Bei dieser Zusammenfassung von Farb- und Feuchtwerken werden auch die weitestgehenden Reduzierungen hinsichtlich der Gesamthöhe und der Gesamtlänge der Druckmaschine erzielt.A dampening unit which interacts with the inking unit, such as the inking unit in part or in whole, is particularly advantageously integrated in the movable units. Thus, not only is the extended inking unit or dampening unit easily accessible for maintenance work, but also the correspondingly exposed part of the cylinder element consisting of one or more forme or plate cylinders, blanket cylinder and possibly a central cylinder can be made easily accessible for maintenance work. An entire inking unit with an entire dampening unit is particularly preferably combined to form such a movable unit. Both the cylinder elements and the inking and dampening units are freely accessible after they are extended. The changeover times when changing ink and dampening unit types are the shortest and the design effort is the least due to the low fragmentation. In this combination of inking and dampening systems, the largely achieved reductions in the overall height and the total length of the printing press.

Vorteilhafterweise besteht zwischen den Zylinderelementen und den verschiebbaren Einheiten außer der Halterung an der Tragkonstruktion keine mechanische Verbindung. Die verfahrbaren Einheiten sind jeweils mit einem separaten Antrieb ausgerüstet. Grundsätzlich wäre jedoch auch ein Einkuppeln der verfahrbaren Einheiten in ein Antriebssystem für die gesamte Druckeinheit möglich, wobei jedoch nach wie vor ein zusätzliches Hilfsaggregat für den Antrieb der Walzen der verfahrbaren Einheit im ausgefahrenen Zustand notwendig wäre. Neben dem eigenen Antrieb weist die verfahrbare Einheit auch eine für die Durchführung von Wartungsarbeiten notwendige Steuereinheit auf.There is advantageously no mechanical connection between the cylinder elements and the displaceable units except for the holder on the supporting structure. The movable units are each equipped with a separate drive. In principle, however, it would also be possible to couple the movable units into a drive system for the entire printing unit, although an additional auxiliary unit would still be necessary to drive the rollers of the movable unit in the extended state. In addition to its own drive, the movable unit also has a control unit necessary for carrying out maintenance work.

Die Versorgung der verfahrbaren Einheit, d.h. die Versorgung des Antriebs und der Steuereinrichtung, kann über ein Schleppkabel oder über eine erst im ausgefahrenen Zustand hergestellte Steckverbindung erfolgen.The supply of the mobile unit, i.e. the drive and the control device can be supplied via a trailing cable or via a plug-in connection that has only been established in the extended state.

Nachstehend wird eine bevorzugte Ausführungsform der Erfindung anhand von Zeichnungen erläutert, wobei weitere Merkmale der Erfindung offenbart werden. Es zeigen

Figur 1- die Vorderansicht einer Rollenrotationsdruckmaschine;

Figur 2- eine Seitenansicht eines Druckturms der Rollenrotationsdruckmaschine von

Figur 1 mit zwei übereinander angeordneten Druckeinheiten; Figur 3- eine Druckeinheit des in

Figur 1 dargestellten Druckturms; Figur 4- einen Druckturm nach

Figur 1 im Vergleich zu einem herkömmlichen Druckturm; Figur 5- eine Draufsicht auf einen Druckturm nach

Figur 1; Figur 6- in Wartungsposition ausgefahrene Farb- und Feuchtwerke in Vorderansicht;

Figur 7- Ausricht- und Verbindungselemente zwischen einem Zylinderelement und der Tragkonstruktion; und

- Figur 8

- eine Vorderansicht des Aufbaus einer weiteren Ausführungsform einer Tragkonstruktion.

- Figure 1

- the front view of a web-fed rotary printing press;

- Figure 2

- a side view of a printing tower of the web-fed rotary printing press from FIG. 1 with two printing units arranged one above the other;

- Figure 3

- a printing unit of the printing tower shown in Figure 1;

- Figure 4

- a pressure tower according to Figure 1 in comparison to a conventional pressure tower;

- Figure 5

- a plan view of a printing tower according to Figure 1;

- Figure 6

- Front view of inking and dampening units extended in maintenance position;

- Figure 7

- Alignment and connecting elements between a cylinder element and the supporting structure; and

- Figure 8

- a front view of the structure of a further embodiment of a support structure.

In den Figuren 1 und 2 sind Drucktürme 1 mit jeweils zwei übereinander angeordneten Druckeinheiten 5, von denen Figur 3 eine einzelne nochmals vergrößert zeigt, im seitlichen Querschnitt und in einer Vorderansicht dargestellt. Eine Rollenrotationsdruckmaschine wird durch mindestens eine Druckeinheit 5 oder mehrere hintereinander angeordnet zusammengestellte Drucktürme 1, mindestens einen Falzapparat 3 und mindestens einen Bedruckstoffrollenständer 4 gebildet.In FIGS. 1 and 2, printing towers 1, each with two

Die Druckeinheiten 5 sind in dem Ausführungsbeispiel nach den Figuren 1 bis 3 jeweils modulartig aus einem Zylinderelement 6 und vier zugeordneten, verfahrbaren Einheiten 10 aufgebaut. Das Zylinderelement 6 ist in Form eines Satellitendruckwerks mit einem Zentralzylinder 7, vier Gummituchzylindern 8 und vier den Gummituchzylindern 8 zugeordneten Form- bzw. Plattenzylindern 9 ausgebildet. Das Zylinderelement 6 ist an vier ortsfesten Säulen 30, die für die Druckeinheiten 5 seitliche Säulenpaare 30 bilden, starr befestigt, während die Einheiten 10 in an den Säulen 30 angebrachten Laufschienen 19 in Richtung der Rotationsachsen 21 der Zylinder 7, 8, 9 verfahrbar sind. Die verfahrbaren Einheiten 10 werden jeweils durch ein Farbwerk 11 und ein Feuchtwerk 15 gebildet. Die Farbauftragswalzen 12 und die Feuchmittelauftragswalzen 16 sind von den Formzylindern 9 abschwenkbar.In the exemplary embodiment according to FIGS. 1 to 3, the

Die Druckeinheiten 5 sind jeweils an den zu deren beiden Seiten angeordneten Säulenpaaren 30 abgestützt, die zusammen mit verbindenden Querträgern 50, 150, 151, 152 den wesentlichen Teil einer Tragkonstruktion 2 bilden. Die Druckeinheiten 5 sind auf diese Weise von den seitlichen Säulenpaaren 30 und jeweils einem oberen und einem unteren Querträger 50 umrahmt. Jede der verfahrbaren Einheiten 10 kann einzeln geradlinig in Richtung der Rotationsachsen 21 der Zylinder 7, 8 und 9 zwischen einer Arbeits- und einer Wartungsposition verschoben werden. Zu diesem Zweck laufen die Einheiten 10 mit Rollen 20 in den Laufschienen 19. Es sind jedoch grundsätzlich auch andere Verfahrmechanismen denkbar. Die beiden jeweils über einem Zylinderelement 6 angeordneten Einheiten 10 werden hängend, und die jeweils unter dem Zylinderelement 6 angeordneten Einheiten 10 werden aufgestützt über die Querträger 50 von den Säulen 30 getragen.The

Die übereinander angeordneten Zylinderelemente 6 sind an einem rechts und einem links davon stehenden Säulenpaar 30 beispielsweise durch entsprechende Ausricht- und Verbindungselemente abgestützt. Die Tragkonstruktion 2 des Ausführungsbeispiels ist genügend eigensteif, um sowohl die Zylinderelemente als auch die Farb- und Feuchtwerke zu tragen. So können auch die Zylinderelemente 6 grundsätzlich modular wechselbar sein. Die Zylinderelemente 6 können aber auch bei ausreichend stabiler Auslegung und entsprechend festem Verbund mit den Säulen 30 stabilisierend und mittragend in die Tragkonstruktion 2 integriert werden. Entsprechende Abstriche könnten in diesem Fall bei der Tragfähigkeit der Säulen 30 und der Querträger 50, 150, 151, 152 gemacht werden.The

Figur 4, in der äquivalente Bauteile mit gleichen Bezugszeichen versehen sind, zeigt links zwei Druckeinheiten 5 in einem herkömmlich aufgebauten Druckturm 1 und rechts im Vergleich dazu die Druckeinheiten des Druckturms 1 von Figur 1, der neben der eigensteifen Tragkonstruktion auch das weitere Merkmal der verfahrbaren Farb- und Feuchtwerkseinheiten 10 aufweist, so daß die maximale Raumeinsparung erzielt wird. Deutlich erkennbar ist der Raumbedarf für einen bei dem herkömmlichen Druckturm 1 notwendigen Wartungstunnel 60, der bei nicht bewegbaren Farb- und Feuchtwerken 11, 15 freibleiben muß, um Wartungs- und Reparaturarbeiten durchführen zu können. Infolge der in Richtung der Zylinderlängsachsen verfahrbaren Farb- und Feuchtwerkseinheiten 10 können bei dem in Figur 4 rechten Druckturm 1 Wartungstunnel gänzlich entfallen, da nicht nur die ausgefahrenen Farb- und Feuchtwerke frei zugänglich sind, sondern auch die Zylinderelemente 6 nach Bedarf durch das Verfahren einer Farb- und Feuchtwerkseinheit 10 vollkommen freigelegt werden können. Dadurch können die Druckeinheiten 5 flacher und schmaler gebaut werden. Die Reduzierung der Druckturmhöhe beträgt in dem Ausführungsbeispiel gegenüber dem entsprechenden herkömmlichen Druckturm 1 auf der linken Hälfte von Figur 4 etwa 15 %.Figure 4, in which equivalent components are provided with the same reference numerals, shows two

Ebenfalls verringern sich bei der erfindungsgemäßen Tragkonstruktion die Anzahl der Bedienungsebenen und der Zwischenplattformen deutlich.The number of operating levels and the intermediate platforms are also significantly reduced in the supporting structure according to the invention.

Die Tragkonstruktion 2 wird, wie in Fig. 2 zu erkennen ist, durch weitere Säulen 32, die in Längsrichtung der Zylinder 7, 8, 9 jeweils neben einem Säulenpaar 30 angeordnet sind, weitergebildet. Die Anordnung der Säulen 32 ist in etwa spiegelsymmetrisch zu der der Säulen 30, mit denen sie durch verlängerte Querträger verbunden sind. Dabei können die beiden linken Säulen 32, die lediglich anteilig das Eigengewicht der Tragkonstruktion 2, die aus der Arbeitsposition gefahrenen Einheiten 10, das Wartungspersonal und zur Wartung und Reparatur notwendige Gerätschaften aufzunehmen brauchen, schwächer ausgeführt sein als die Säulen 30. Im Ausführungsbeispiel tragen die Säulen 32 noch einen Arbeitskran 23 zur Unterstützung der Arbeiten.The

Im unteren linken Teil von Figur 2 ist eine im ausgerückten Zustand, d.h. in der Wartungsposition befindliche Einheit 10 in gestrichelten Linien angedeutet. In dieser Position werden die zur Einheit 10 zusammengefaßten Teile des Farb- und des Feuchtwerks 11 und 15 über eine ortsfeste Steckverbindung 21 mit Energie und ggfs. mit Daten für einen separaten Antrieb und ggfs. eine Steuereinheit für die Walzen der verfahrbaren Einheit 10 versorgt. Der Hebekran 23 kann wegen des leichteren Gewichts der zu der verfahrbaren Einheit 10 zusammengefaßten Farb- und Feuchtwerke bzw. Zylindereinheit für eine geringere Hebelast als dies für die Druckeinheiten herkömmlicher Druckmaschinen notwendig wäre, ausgelegt sein, was seinerseits Kostenvorteile nach sich zieht.In the lower left part of FIG. 2, a

Figur 5 zeigt den Druckturm 1 von Figur 1 in Draufsicht, in der die Säulenpaare 30 seitlich von den beiden nebeneinander angeordneten, in Richtung der Pfeile A verfahrbaren Einheiten 10 zu erkennen sind. Weiterhin ist eine in Richtung des Pfeiles B quer zur Ausfahrrichtung der Einheiten 10 verfahrbare Arbeitsbühne 35 angedeutet. Solche Arbeitsbühnen 35 sind nochmals deutlicher in Figur 6 zusammen mit mehreren in die Wartungsposition herausgefahrenen Einheiten 10 eingezeichnet. Die Arbeitsbühnen 35 sind jeweils unter und/oder über den ausgefahrenen Einheiten 10 der Druckeinheiten 5 entlang weiterer diverser Querträger geführt verfahrbar. Eine freie Verfahrbarkeit der Arbeitbühnen ist ebenfalls möglich, falls auf den diversen Trägern anderweitig aufliegende Böden vorgesehen werden.FIG. 5 shows the

Wie das beschriebene Ausführungsbeispiel deutlich macht, kommen die Vorteile der Erfindung ganz besonders dann zum Tragen, wenn die Druckmaschine durch eine Reihenanordnung mehrer Druckeinheiten 5 oder Drucktürme 1 mit jeweils mehreren übereinander angeordneten Druckeinheiten 5 mit wiederum jeweils mehreren Farb- und/oder Feuchtwerken 11 und 15 gebildet wird. In diesem Fall sind die größten Kosteneinsparungen und die größten Raumeinsparungen hinsichtlich der Druckmaschinenlänge und -höhe zu erwarten. Bei der erfindungsgemäßen Verfahrbarkeit der Farb- und Feuchtwerke wird überdies kein Raumbedarf erforderlich, der nicht auch bei fest eingebauten Farb- und Feuchtwerken anfallen würde, da auch deren Walzen und/oder Zylinder bei einem Wechsel in Richtung ihrer Rotationsachsen aus der Druckmaschine gezogen werden müßten. Demgegenüber benötigen die bekannten Druckmaschinen mit anderweitig bewegbaren Farb- und Feuchtwerken immer zusätzlichen Platz, der bei fester Anordnung nicht entstehen würde. Zur Raumeinsparung trägt weiter das Konzept der unter den ausgefahrenen Fab- und Feuchtwerken verfahrbaren Arbeitsbühnen bei, ohne Zugeständnisse an die Zugänglichkeit zu erfordern. Im Ausführungsbeispiel mit vier Farb- und Feuchtwerken pro Druckeinheit ist jedes Farb- und Feuchtwerk in seiner Wartungsposition von drei Seiten frei zugänglich. Die erfindungsgemäße Tragkonstruktion ermöglicht diesen hohen Grad an Modularität, einschließlich der Verfahrbarkeit der Farb- und Feuchtwerkseinheiten, was der einfachen Aufstellung der Druckmaschine und später notwendigen Wechseln von Maschinenteilen zugute kommt.As the described exemplary embodiment makes clear, the advantages of the invention come into play particularly when the printing press is arranged in a row by a plurality of

Figur 6 zeigt den Druckturm von Figur 5 in der Vorderansicht, bei dem jeweils eine Einheit 10 einer unteren und einer oberen Druckeinheit in Richtung der Rotationsachse 21 der Zylinder 7, 8, 9 in Wartungsposition ausgefahren ist. Weiterhin ist erkennbar, daß je eine Arbeitsbühne 35 für eine untere und eine obere Druckeinheit 5 in Richtung des Pfeils B quer zur Ausfahrrichtung der Einheiten 10 verfahren werden kann. Dabei werden die Einheiten 10 mit den Arbeitsbühnen unterfahren bzw. überfahren. Weiter ist ersichtlich, daß für die Bedienung der Einheiten 10 keine zusätzlichen Zwischenplattformen entsprechend der herkömmlichen Bauweise gemäß Figur 4 notwendig sind.FIG. 6 shows a front view of the printing tower of FIG. 5, in which a

Figur 7 zeigt einen Ausschnitt aus der Vorderansicht von Figur 3, bei dem ein Zylinderelement 6 mittels kalottenartigen Ausricht- und Verbindungselementen 17 an den Säulen 30 lösbar befestigt ist. Das Ausrichten der Zylinderelemente 6 erfolgt in vertikaler Richtung zwischen den Säulen 30 und in horizontaler Richtung zwischen den verschiedenen Querträgern (50, 150, 151, 152) mittels den Ausricht- und Verbindungselementen 17, 18.FIG. 7 shows a detail from the front view of FIG. 3, in which a

Das Ausrichten der Einheiten 10 erfolgt mittels dem Ausrichten der Laufschienen 19, gemäß Figur 3, die mit den gleichen Ausricht- und Verbindungselementen 17, 18, nicht dargestellt, befestigt sind wie die Zylinderelemente 6.The

Figur 8 zeigt ein weiteres Ausführungsbeispiel der erfindungsgemäßen Tragkonstruktion. Eine in Vorderansicht dargestellte Rollenrotations-Druckmaschine, besteht mindestens aus einer Druckeinheit 5, einem Falzapparat 3 und einem Bedruckstoffrollenständer 4. Dabei ist der Falzapparat ebenfalls in verschiedene Zylinderelemente, nicht dargestellt, unterteilt, die so ausgebildet sind, daß sie sich entsprechend den Zylinderelementen 6 an den Säulen 30 ausrichten und lösbar befestigen lassen. Die Bedruckstoffrollenständer 4 werden mit der gleichen Art und Weise an den Säulen 30 befestigt. Beim Einsatz des erfindungsgemäßen Traggestells, das auf dem Maschinenfundament abgestützt ist, kann als wesentliche Kosteneinsparung auf den aufwendigen üblichen Maschinentisch-Unterbau verzichtet werden. Die Falzapparat- und Rollenständerelemente können ebenfalls in Richtung der Rotationsachse 21 zwischen einer Arbeits- und Wartungsposition verschoben werden.Figure 8 shows a further embodiment of the support structure according to the invention. A web-fed rotary printing press shown in a front view consists of at least one

Claims (14)

dadurch gekennzeichnet, daß

das Zylinderelement (6) und die Farb- und Feuchtwerke (11, 15) in dem Traggestell (2) gehalten sind, das in sich selbst oder in steifer Verbindung mit dem Zylinderelement (6) tragend stabil ist. 1. Support frame for a web-fed rotary printing press for receiving at least one printing unit (5), which is formed by a cylinder element (6) with a plurality of cylinders (7, 8, 9) and the cylinder element (6) associated with inking and dampening units (11, 15) ,

characterized in that

the cylinder element (6) and the inking and dampening units (11, 15) are held in the support frame (2), which is stable in itself or in a rigid connection with the cylinder element (6).

dadurch gekennzeichnet, daß

die die Druckeinheit (5) bildenden Elemente (6, 11, 15), die den Falzapparat (3) bildenden wesentlichen Teile und die den Bedruckstoffrollenständer (4) bildenden wesentlichen Teile in dem Traggestell (2) gehalten sind, das in sich selbst oder in steifer Verbindung mit den die Druckeinheit (5) bildenden Elementen (6, 11, 15) und/oder die den Falzapparat (3) bildenden Teile und/oder die den Bedruckstoffrollenständer (4) bildenden Teile in steifer Verbindung tragend stabil ist. 13. Support frame for a web-fed rotary printing press for receiving a printing tower, comprising at least one printing unit (5), which is provided by an inking and dampening unit (11) associated with a cylinder element (6) with a plurality of cylinders (7, 8, 9) and the cylinder element (6) , 15), a folder (3), which is formed by rotatably mounted cutting and folding cylinders, and a substrate roll stand (4), which is formed from at least one substrate roll bearing,

characterized in that

the elements (6, 11, 15) forming the printing unit (5), the essential parts forming the folder (3) and the essential parts forming the printing material roll stand (4) are held in the support frame (2), which in itself or in rigid connection with the elements (6, 11, 15) forming the printing unit (5) and / or the parts forming the folder (3) and / or the parts forming the printing material roll stand (4) is stable in a rigid connection.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4327278 | 1993-08-13 | ||

| DE4327278A DE4327278C5 (en) | 1993-08-13 | 1993-08-13 | Supporting frame for a web-fed rotary printing machine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0638419A1 true EP0638419A1 (en) | 1995-02-15 |

| EP0638419B1 EP0638419B1 (en) | 1999-05-06 |

| EP0638419B2 EP0638419B2 (en) | 2005-03-16 |

Family

ID=6495155

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94810385A Expired - Lifetime EP0638419B2 (en) | 1993-08-13 | 1994-06-29 | Supporting framework for a rotary web printing press |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0638419B2 (en) |

| DE (2) | DE4327278C5 (en) |

| ES (1) | ES2133519T3 (en) |

| FI (1) | FI943725A (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0813962A2 (en) * | 1996-06-19 | 1997-12-29 | MAN Roland Druckmaschinen AG | Device for filling cavities on a cylinder, doctor blade device therefore and method for interchanging the liquid |

| DE19833468A1 (en) * | 1998-07-24 | 2000-01-27 | Koenig & Bauer Ag | Printing units arranged at relative distance to each other for offset printing machine has molded cylinders, transfer cylinders and counter printing cylinder |

| WO2000006384A1 (en) * | 1998-07-24 | 2000-02-10 | Koenig & Bauer Aktiengesellschaft | Rotary offset printing machine |

| DE10008217A1 (en) * | 2000-02-23 | 2001-08-30 | Roland Man Druckmasch | Transporter for printer module is composed of traverse-linked beams and connectors ensuring correctly positioned installation-ready printer fluid box and switching cabinet. |

| WO2002007972A1 (en) * | 2000-07-22 | 2002-01-31 | Koenig & Bauer Aktiengesellschaft | Printer of an offset printing machine with separable frame modules |

| US6363848B1 (en) | 1998-07-24 | 2002-04-02 | Koenig & Bauer Aktiengesellschaft | Printing unit with cylinders arranged in the shape of a “V” and “W” |

| US6408746B1 (en) | 1998-07-24 | 2002-06-25 | Koenig & Bauer Aktiengesellschaft | Printing unit |

| WO2004067275A1 (en) * | 2003-01-30 | 2004-08-12 | Koenig & Bauer Aktiengesellschaft | Printing machine, modus operandi of said printing machine and printed products |

| DE10321989A1 (en) * | 2003-01-30 | 2004-08-19 | Koenig & Bauer Ag | Printing press for offset printing has at least one extra printing unit on plane above printing location of upper satellite printing unit |

| DE102004008770A1 (en) * | 2004-02-23 | 2005-09-15 | Koenig & Bauer Ag | Rotary printer has multiple printer stations and at least one folder mounted on a frame with vertical support pillars for horizontal rails, where the printer stations and folder are arranged on the frame |

| EP1598184A3 (en) * | 2003-01-30 | 2005-11-30 | Koenig & Bauer Aktiengesellschaft | Printing press, operational mode of the press and printing product |

| US7156019B2 (en) | 2001-10-05 | 2007-01-02 | Koenig & Bauer Aktiengesellschaft | Rotary roller printing press |

| WO2007004053A3 (en) * | 2005-07-06 | 2007-04-26 | Pakgoiz Mario Javier | Machine for lithographic printing of tin sheets |

| EP1900522A1 (en) * | 2004-04-05 | 2008-03-19 | Koenig & Bauer Aktiengesellschaft | Printing unit in a web-fed rotaty printing press |

| DE102006042884A1 (en) * | 2006-09-13 | 2008-03-27 | Gallus Druckmaschinen Gmbh | press |

| EP2036723A2 (en) * | 2007-09-14 | 2009-03-18 | manroland AG | Printing unit in a web-fed rotary printing press |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19805898C2 (en) * | 1998-02-13 | 2003-09-18 | Roland Man Druckmasch | Printing unit for a web-fed rotary printing machine |

| DE10035785A1 (en) | 2000-07-22 | 2002-02-07 | Koenig & Bauer Ag | Printing group for offset rotary printing machine; has at least one form cylinder , at least one transfer cylinder and at least one inking system and can be adjusted parallel to cylinder axes |

| DE10223414B4 (en) * | 2002-05-25 | 2013-04-25 | Windmöller & Hölscher Kg | Change station for sleeves of printing presses |

| DE10260574A1 (en) * | 2002-12-21 | 2004-07-01 | Man Roland Druckmaschinen Ag | Modular printing unit |

| BRPI0509605A (en) | 2004-04-05 | 2007-09-18 | Koenig & Bauer Ag | printer unit of a rotary roll printer |

| ATE391015T1 (en) | 2004-04-05 | 2008-04-15 | Koenig & Bauer Ag | DRIVES OF A PRESSURE UNIT |

| DE102004037889B4 (en) | 2004-04-05 | 2006-05-11 | Koenig & Bauer Ag | Device for supporting a cylinder and printing unit with at least three together as a printing unit acting cylinders |

| DK1867478T3 (en) | 2005-04-21 | 2009-05-04 | Koenig & Bauer Ag | Pressure works with at least two cooperating cylinders |

| DE102005035875A1 (en) * | 2005-07-30 | 2007-02-15 | Man Roland Druckmaschinen Ag | Printing unit for printing machine, particularly web-fed rotary printing machine, has printer, which has cylinder module, where cylinder module has form cylinder, transfer cylinder and inking module |

| DE102006030290B3 (en) | 2006-03-03 | 2007-10-18 | Koenig & Bauer Aktiengesellschaft | printing unit |

| DE102006030457A1 (en) | 2006-07-01 | 2008-01-03 | Man Roland Druckmaschinen Ag | Printing unit e.g. for web-fed rotary press, has pair of printing couples, each printing couple has form cylinder and transfer cylinder |

| DE102007025499A1 (en) * | 2007-06-01 | 2008-12-04 | Manroland Ag | Rotary press |

| DE102008025650A1 (en) * | 2008-05-28 | 2009-12-10 | Gallus Stanz- Und Druckmaschinen Gmbh | Printing unit for printing a substrate web in a printing machine |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1169959B (en) * | 1962-04-13 | 1964-05-14 | Koenig & Bauer Schnellpressfab | Multi-color sheet-fed rotary press for letterpress printing |

| FR2420426A1 (en) * | 1978-03-22 | 1979-10-19 | Chambon Machines | Variable format as multicolour printer - has counter rollers mounted in adjustable frame to tangentially contact blanket rollers |

| EP0186862A2 (en) * | 1984-12-20 | 1986-07-09 | J.G. Mailänder GmbH & Co. | Rotary printing press of the satellite type |

| EP0308942A2 (en) * | 1987-09-25 | 1989-03-29 | Miyakoshi Printing Machinery Co., Ltd. | Interchangeable drum unit interchange system in all interchangeable drum type rotary printing machine installation |

| EP0315917A2 (en) * | 1987-11-06 | 1989-05-17 | Miyakoshi Printing Machinery Co., Ltd. | Interchangeable drum unit type rotary printing machine |

| EP0573877A1 (en) * | 1992-06-12 | 1993-12-15 | MAN Roland Druckmaschinen AG | Printing machine, in particular for printing solid and rigid cardboard, with exchangeable printing cylinders |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2460504A (en) * | 1944-10-24 | 1949-02-01 | William C Huebner | Printing apparatus |

| GB1104406A (en) * | 1965-07-30 | 1968-02-28 | Simon Ltd Henry | Improvements in or relating to in-iine machine unit installations |

| US4046070A (en) * | 1974-04-22 | 1977-09-06 | James Halley & Sons Limited | Rotary printing presses |

| SE7504029L (en) * | 1975-04-08 | 1976-10-09 | Wifag Maschf | FOLDING DEVICE WITH SASOM CASSETTE REPLACABLE FOLDING MECHANISM |

| US4384522A (en) * | 1977-12-07 | 1983-05-24 | Paper Converting Machine Company | Apparatus for producing business forms |

| DE2924591A1 (en) * | 1979-06-19 | 1981-01-22 | Maschf Augsburg Nuernberg Ag | BASE FOR A ROLL ROTARY PRINTING MACHINE |

| GB8611722D0 (en) * | 1986-05-14 | 1986-06-25 | Drg Uk Ltd | Processing paper & other webs |

| DE3626287C3 (en) * | 1986-08-02 | 1997-04-03 | Koenig & Bauer Albert Ag | Folder |

| DE9017332U1 (en) * | 1990-12-21 | 1991-03-21 | Baldwin-Gegenheimer GmbH, 8900 Augsburg | Device for the surface application of spreadable media to a carrier material |

| JPH0773908B2 (en) * | 1991-06-21 | 1995-08-09 | 株式会社東京機械製作所 | Rotary printing machine |

-

1993

- 1993-08-13 DE DE4327278A patent/DE4327278C5/en not_active Expired - Fee Related

-

1994

- 1994-06-29 ES ES94810385T patent/ES2133519T3/en not_active Expired - Lifetime

- 1994-06-29 EP EP94810385A patent/EP0638419B2/en not_active Expired - Lifetime

- 1994-06-29 DE DE59408202T patent/DE59408202D1/en not_active Expired - Fee Related

- 1994-08-12 FI FI943725A patent/FI943725A/en not_active IP Right Cessation

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1169959B (en) * | 1962-04-13 | 1964-05-14 | Koenig & Bauer Schnellpressfab | Multi-color sheet-fed rotary press for letterpress printing |

| FR2420426A1 (en) * | 1978-03-22 | 1979-10-19 | Chambon Machines | Variable format as multicolour printer - has counter rollers mounted in adjustable frame to tangentially contact blanket rollers |

| EP0186862A2 (en) * | 1984-12-20 | 1986-07-09 | J.G. Mailänder GmbH & Co. | Rotary printing press of the satellite type |

| EP0308942A2 (en) * | 1987-09-25 | 1989-03-29 | Miyakoshi Printing Machinery Co., Ltd. | Interchangeable drum unit interchange system in all interchangeable drum type rotary printing machine installation |

| EP0315917A2 (en) * | 1987-11-06 | 1989-05-17 | Miyakoshi Printing Machinery Co., Ltd. | Interchangeable drum unit type rotary printing machine |

| EP0573877A1 (en) * | 1992-06-12 | 1993-12-15 | MAN Roland Druckmaschinen AG | Printing machine, in particular for printing solid and rigid cardboard, with exchangeable printing cylinders |

Cited By (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6095045A (en) * | 1996-06-19 | 2000-08-01 | Man Roland Druckmaschinen Ag | Device for filling depressions in a cylinder; doctor blade device for this purpose and process for changing it |

| EP0813962A3 (en) * | 1996-06-19 | 1998-09-09 | MAN Roland Druckmaschinen AG | Device for filling cavities on a cylinder, doctor blade device therefore and method for interchanging the liquid |

| EP0813962A2 (en) * | 1996-06-19 | 1997-12-29 | MAN Roland Druckmaschinen AG | Device for filling cavities on a cylinder, doctor blade device therefore and method for interchanging the liquid |

| US6408746B1 (en) | 1998-07-24 | 2002-06-25 | Koenig & Bauer Aktiengesellschaft | Printing unit |

| DE19833468A1 (en) * | 1998-07-24 | 2000-01-27 | Koenig & Bauer Ag | Printing units arranged at relative distance to each other for offset printing machine has molded cylinders, transfer cylinders and counter printing cylinder |

| DE19833468C2 (en) * | 1998-07-24 | 2000-05-18 | Koenig & Bauer Ag | Printing units |

| WO2000006384A1 (en) * | 1998-07-24 | 2000-02-10 | Koenig & Bauer Aktiengesellschaft | Rotary offset printing machine |

| WO2000006385A1 (en) * | 1998-07-24 | 2000-02-10 | Koenig & Bauer Aktiengesellschaft | Five-cylinder offset printing units with adjustable spacing |

| US6363848B1 (en) | 1998-07-24 | 2002-04-02 | Koenig & Bauer Aktiengesellschaft | Printing unit with cylinders arranged in the shape of a “V” and “W” |

| US6474232B1 (en) | 1998-07-24 | 2002-11-05 | Koenig & Bauer Aktiengesellschaft | Rotary offset printing machine |

| US6539857B1 (en) | 1998-07-24 | 2003-04-01 | Koenig & Bauer Aktiengesellschaft | Five-cylinder offset printing units with adjustable spacing |

| DE10008217A1 (en) * | 2000-02-23 | 2001-08-30 | Roland Man Druckmasch | Transporter for printer module is composed of traverse-linked beams and connectors ensuring correctly positioned installation-ready printer fluid box and switching cabinet. |

| DE10008217B4 (en) * | 2000-02-23 | 2007-06-14 | Man Roland Druckmaschinen Ag | Transport device for a printing unit module |

| WO2002007972A1 (en) * | 2000-07-22 | 2002-01-31 | Koenig & Bauer Aktiengesellschaft | Printer of an offset printing machine with separable frame modules |

| US6786151B2 (en) | 2000-07-22 | 2004-09-07 | Koenig & Bauer Aktiengesellschaft | Printer of an offset printing machine with separable frame modules |

| EP1524115A2 (en) * | 2000-07-22 | 2005-04-20 | Koenig & Bauer Aktiengesellschaft | Satellite printer of an offset printing machine |

| EP1524115A3 (en) * | 2000-07-22 | 2007-08-29 | Koenig & Bauer Aktiengesellschaft | Satellite printer of an offset printing machine |

| US7448320B2 (en) | 2001-10-05 | 2008-11-11 | Koenig & Bauer Aktiengesellschaft | Printing unit and a rotary roller printing press |

| US7546801B2 (en) | 2001-10-05 | 2009-06-16 | Koenig & Bauer Aktiengesellschaft | Printing unit and a rotary roller printing press |

| US7296516B2 (en) | 2001-10-05 | 2007-11-20 | Koenig & Bauer Aktiengesellschaft | Rotary roller printing press |

| US7159512B2 (en) | 2001-10-05 | 2007-01-09 | Koenig & Bauer Aktiengesellschaft | Printing unit and a rotary roller printing press |

| US7562623B2 (en) | 2001-10-05 | 2009-07-21 | Koenig & Bauer Aktiengesellschaft | Printing unit and a rotary roller printing press |

| US7156019B2 (en) | 2001-10-05 | 2007-01-02 | Koenig & Bauer Aktiengesellschaft | Rotary roller printing press |

| DE10321989A1 (en) * | 2003-01-30 | 2004-08-19 | Koenig & Bauer Ag | Printing press for offset printing has at least one extra printing unit on plane above printing location of upper satellite printing unit |

| GB2404168B (en) * | 2003-01-30 | 2006-09-20 | Koenig & Bauer Ag | Printing machine, modus operandi of said printing machine and printed products |

| EP1598184A3 (en) * | 2003-01-30 | 2005-11-30 | Koenig & Bauer Aktiengesellschaft | Printing press, operational mode of the press and printing product |

| DE10321989B4 (en) * | 2003-01-30 | 2005-10-06 | Koenig & Bauer Ag | press |

| GB2404168A (en) * | 2003-01-30 | 2005-01-26 | Koenig & Bauer Ag | Printing machine, modus operandi of said printing machine and printed products |

| WO2004067275A1 (en) * | 2003-01-30 | 2004-08-12 | Koenig & Bauer Aktiengesellschaft | Printing machine, modus operandi of said printing machine and printed products |

| DE102004008770A1 (en) * | 2004-02-23 | 2005-09-15 | Koenig & Bauer Ag | Rotary printer has multiple printer stations and at least one folder mounted on a frame with vertical support pillars for horizontal rails, where the printer stations and folder are arranged on the frame |

| DE102004008770B4 (en) * | 2004-02-23 | 2007-09-20 | Koenig & Bauer Aktiengesellschaft | Rotary press |

| EP1900522A1 (en) * | 2004-04-05 | 2008-03-19 | Koenig & Bauer Aktiengesellschaft | Printing unit in a web-fed rotaty printing press |

| EP1894719A3 (en) * | 2004-04-05 | 2011-04-13 | Koenig & Bauer Aktiengesellschaft | Printing unit on a web-fed rotary printing press |

| WO2007004053A3 (en) * | 2005-07-06 | 2007-04-26 | Pakgoiz Mario Javier | Machine for lithographic printing of tin sheets |

| DE102006042884A1 (en) * | 2006-09-13 | 2008-03-27 | Gallus Druckmaschinen Gmbh | press |

| US7980176B2 (en) | 2006-09-13 | 2011-07-19 | Heidelberger Druckmaschinen, Ag | Printing machine |

| EP2036723A2 (en) * | 2007-09-14 | 2009-03-18 | manroland AG | Printing unit in a web-fed rotary printing press |

| EP2036723A3 (en) * | 2007-09-14 | 2011-07-27 | manroland AG | Printing unit in a web-fed rotary printing press |

Also Published As

| Publication number | Publication date |

|---|---|

| FI943725A (en) | 1995-02-14 |

| ES2133519T3 (en) | 1999-09-16 |

| DE4327278C5 (en) | 2005-09-22 |

| FI943725A0 (en) | 1994-08-12 |

| DE4327278C2 (en) | 2001-03-22 |

| DE4327278A1 (en) | 1995-02-16 |

| EP0638419B1 (en) | 1999-05-06 |

| EP0638419B2 (en) | 2005-03-16 |

| DE59408202D1 (en) | 1999-06-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0638419B1 (en) | Supporting framework for a rotary web printing press | |

| EP0749369B1 (en) | Printing group for a colour-printing web-fed rotary press | |

| EP0186862B1 (en) | Rotary printing press of the satellite type | |

| DE10008215A1 (en) | Printing unit for a rotary machine with cross slide | |

| EP0745031B1 (en) | Printing group for a colour-printing web-fed rotary press | |

| EP1100681B1 (en) | Five-cylinder offset printing units with adjustable spacing | |

| EP1303401B1 (en) | Printer of an offset printing machine with separable frame modules | |

| DE19805898A1 (en) | Printing unit for a web-fed rotary printing press | |

| DE10261999A1 (en) | Printing machine with footplate to reach the upper inking units | |

| EP1303405B1 (en) | Printing group of an offset rotary printing machine | |

| DE19516653C1 (en) | Rotary printing machine with swiveling rubber cylinders | |

| EP1100680B1 (en) | Rotary offset printing machine | |

| DE19833469C2 (en) | Offset printing machine | |

| EP1102679B1 (en) | Printing unit | |

| EP1578607B1 (en) | Modular printing unit | |

| DE102004011070B4 (en) | Expandable printing unit for web offset presses | |

| EP1365916B1 (en) | Printing unit | |

| DE102006008303B3 (en) | Web-fed rotary press, has pressure cylinders that are divided into sections, which are movable against each other in axial length and are rotatable independent of each other by drive systems | |

| DE102016124332A1 (en) | Rotary press | |

| DE20023116U1 (en) | Printing group for offset rotary printing machine; has at least one form cylinder , at least one transfer cylinder and at least one inking system and can be adjusted parallel to cylinder axes | |

| DE102004019018A1 (en) | Offset sheet-fed printing press has a number of print stations mounted in series on a bridge over a bed of print cylinders |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE CH DE ES FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19950419 |

|

| 17Q | First examination report despatched |

Effective date: 19961029 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE ES FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990506 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990506 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990510 |

|

| REF | Corresponds to: |

Ref document number: 59408202 Country of ref document: DE Date of ref document: 19990610 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2133519 Country of ref document: ES Kind code of ref document: T3 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: KOENIG & BAUER AKTIENGESELLSCHAFT -LIZENZEN-PATENT Effective date: 20000204 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: KOENIG & BAUER AKTIENGESELLSCHAFT -LIZENZEN-PATENT |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| RDAH | Patent revoked |

Free format text: ORIGINAL CODE: EPIDOS REVO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAE | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOS REFNO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| APBY | Invitation to file observations in appeal sent |

Free format text: ORIGINAL CODE: EPIDOSNOBA2O |

|

| APCA | Receipt of observations in appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNOBA4O |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20040617 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20040622 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20040623 Year of fee payment: 11 Ref country code: BE Payment date: 20040623 Year of fee payment: 11 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20050316 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): BE CH DE ES FR GB IT LI NL SE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| NLR2 | Nl: decision of opposition |

Effective date: 20050316 |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |