EP0634612B1 - Cleaning method for cooking vapours, cooking oven, condenser for the vapours and granulate as condenser material - Google Patents

Cleaning method for cooking vapours, cooking oven, condenser for the vapours and granulate as condenser material Download PDFInfo

- Publication number

- EP0634612B1 EP0634612B1 EP93111346A EP93111346A EP0634612B1 EP 0634612 B1 EP0634612 B1 EP 0634612B1 EP 93111346 A EP93111346 A EP 93111346A EP 93111346 A EP93111346 A EP 93111346A EP 0634612 B1 EP0634612 B1 EP 0634612B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bed

- exhaust air

- granular material

- baking oven

- baking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/20—Removing cooking fumes

- F24C15/2007—Removing cooking fumes from oven cavities

Definitions

- the present invention relates to a method according to the The preamble of claim 1, an oven according to that of Claim 8, a vapor condenser according to that of claim 17 and a use of granules after that of claim 21.

- EP-0 275 127 describes a vapor condenser arrangement on one Oven known. Several condenser containers are provided, which are cooled, together with a condensate collector.

- This method or this oven causes a smoke or Grease cleaning of the exhaust air and is extremely simple.

- the present invention aims at a method and a To create an oven of the latter type, by means of which a Vapor filtering, i.e. Odor, water vapor, etc. cleaning is made.

- a Vapor filtering i.e. Odor, water vapor, etc. cleaning is made.

- the exhaust air was on the door handle of the oven opening omitted or through an outlet slot immediately above the handle mentioned.

- the disadvantage is the fact that the exhaust air, which has cooled only slightly, with relative high temperature of up to 135 ° C, for example is there, where an operator on the device Takes access.

- the bed at least as part of a heat store to train. This ensures that due to the heat absorption the heat storage the exhaust air when it is in the environment emerges, has cooled down.

- the exhaust air is distributed over a large area after the bed mentioned let out in the environment. This happens for example, in an oven with an overlying one Hob in that the exhaust air downstream of the bed extremely simple way by structurally provided anyway Cracks and crevices of the aggregate above are omitted is distributed or by specially provided Openings.

- the exhaust air driven through an expanded clay granulate bed is, according to the wording of claim 6, the exhaust air driven through an expanded clay granulate bed. It has been there demonstrated that periods of time during which no vapors contaminated Exhaust air is produced and there is still heating, i.e. during preheating or cooling phases, in particular when using expanded clay, such extensive regeneration of the granules occurs that practically no change the degree of contamination of the granules over the progressive Operating time can be determined. It follows the notable advantage that, if at all, the intended bed can only be replaced very rarely got to.

- the exhaust air grease filtering before bed e.g. using a metal particle board filter.

- FIG. 15 Another preferred embodiment of the bed on the inventive Oven is characterized by the wording of Claim 15 from.

- Claim 15 By providing those kept at a distance Sheathing the bed designed as a granulate cartridge also along the outer surface of the granule cartridge optimally long flow paths and heat exchanger paths for the Exhaust air and thus an optimal heat transfer to the Bed.

- the jacket mentioned is preferably made of Made of metal, with which the latter also absorbs heat and Cooling of the exhaust air contributes.

- a vapor condenser according to the invention which in particular for use to implement the inventive Process or on the oven according to the invention is suitable further according to the wording of claim 17, with preferred embodiments according to claims 18 to 20.

- Claim 21 specifies an inventive use of granules, thereby, according to claim 22, such in particular for expanded clay.

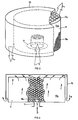

- an exhaust port 3 installed, which over a grease filter 5, for example made of metal pressboard, with a cavity 7 communicates above the oven 1.

- a granulate body 9 forms the active part of the vapor condenser and is with a correspondingly shaped recess 11 on the in plugged into the cavity 7 protruding part of the nozzle 3.

- the lateral parts of the jacket 15 are not up to the Drawn lower edge of the granulate body 9, but define with its lower edge, with respect to an insulating cover plate 17 the oven, outlet openings or an outlet slot 19 for the exhaust air downstream of the granule body 9.

- the formation of the granulate body 9 and the casing 15, which are shown schematically in FIG. 1 and which together form the easily replaceable vapor condenser, are cylindrical. Due to the prevailing with respect to ambient pressure in the oven 1 excess pressure p 1, thermally induced, and optionally due to the action of a circulating air blower, is, in the preferred embodiment, passive, ie without providing an exhaust fan, the exhaust air L through grease filter 5, nozzle 3 and the granulate body 9, then guided along its surface to the openings 19, where the exhaust air cleaned on the fat filter and especially on the vapor condenser 9 and cooled on the latter enters the cavity 7.

- the exhaust air distributed over a large area, leaves the cavity 7 in the environment. This is done either by providing specifically for it provided, distributed outlet openings or as shown schematically, by structural means already provided Slits and chinks, for example on one over the cavity 7 arranged hob 21.

- the granulate body 9 is formed by a porous, absorbent, hydrophilic granules with a large relative surface, preferably with granule diameters of 3 to 5 mm.

- the Air flow paths from nozzle mouth 11 to the surface of the Granules are on the order of a few 10cm, for example 30cm.

- FIG. 2 is another preferred one Construction of the formed from granulate body 9 and casing 15 Vapor condenser shown here, essentially is cubic.

- the oven was set at niche temperatures, i.e. Temperatures outside the oven wall, measured, which was about 56 ° C.

- the temperature at the service door of such inventive Oven pipes have been reduced to a maximum of 70 ° C, compared to temperatures of approx. 135 ° C when the uncooled exhaust air on or near the door handle.

- FIG. 3 schematically shows a vapor condenser according to the invention, for example in a cylindrical design, as used in the arrangement according to FIG. 1.

- the granulate body 9 with granules 9a has the plug-in recess 11 described above for the connection.

- a protruding plug socket can be installed instead of a recess 11.

- the granulate body 9 is surrounded by the jacket 15, which is preferably made of metal.

- the exhaust air L penetrates through the connection at 11 into the granulate body 9, is distributed in the body, and finally exits at its free surface, as shown schematically at L 1 .

- Bottom and side surfaces of the granulate body 9 are preferably covered with a further casing 15a, optionally also made of metal, in order to force the exhaust air L to penetrate to the body surface 9b opposite the connection 11 and only to flow out there.

- the exhaust air flows, as shown in L 2 , to the outlet openings or the outlet slot 19 according to FIGS. 1 and 2.

- the circulation of the exhaust air is also shown in FIG Fig. 4 clearly visible.

- Um in the preferred embodiment without exhaust fan, ensure the air flow through the grease filter and vapor condenser, the control door of the Baking oven designed so that in the closed state only negligible air flow from the door joints into the Environment is possible.

- the vapor condenser according to the invention can not only be used Ovens are used, but also in the exhaust air duct over hobs. Depending on what is available Space can, according to FIGS. 1 and 2, the shape of the vapor condenser 9, 15 can be varied as desired.

Abstract

Description

Die vorliegende Erfindung betrifft ein Verfahren nach dem

Oberbegriff von Anspruch 1, ein Backrohr nach demjenigen von

Anspruch 8, einen Wrasenkondensator nach demjenigen von Anspruch

17 sowie eine Verwendung von Granulat nach demjenigen

von Anspruch 21.The present invention relates to a method according to the

The preamble of claim 1, an oven according to that of

Claim 8, a vapor condenser according to that of

Es ist bekannt, dass Wrasen in Koch- oder Backabluft sich ausserordentlich nachteilig in der Umgebung von Koch- oder Backgeräten auswirken, beispielsweise an den Wänden von Küchenräumen kondensieren oder sich als Festpartikel ablagern, und auch zu unangenehmer Geruchsbildung führen.It is known that vapors in cooking or baking air are exceptional disadvantageous in the vicinity of cooking or baking equipment impact, for example on the walls of kitchen rooms condense or deposit as solid particles, and also lead to unpleasant odors.

Trotzdem wurde bis heute die Abluft von Koch- oder Backgeräten bezüglich Wrasen in nur unzulässigem Masse behandelt:Even so, the exhaust air from cooking or baking equipment has remained treated with regard to vapors to an inadmissible extent:

Es ist beispielsweise bekannt, die Abluft aus Backrohren in die Umgebung auszulassen, meist ohne Fettfilter. Dadurch wird ausser Fett keine Wrasenfilterung vorgenommen, d.h. Geruchsstoffe, Wasserdampf etc. werden nicht zurückgehalten.It is known, for example, that the exhaust air from ovens comes in omitting the environment, mostly without a grease filter. This will Apart from fat, no vapor filtering was carried out, i.e. Odorants, Water vapor etc. are not retained.

Aus der EP-0 275 127 ist eine Wrasenkondensoranordnung an einem Backofen bekannt. Es sind mehrere Kondensorbehälter vorgesehen, welche gekühlt werden, nebst einem Kondensat-Sammelbehälter.EP-0 275 127 describes a vapor condenser arrangement on one Oven known. Several condenser containers are provided, which are cooled, together with a condensate collector.

Aus der DE-OS-33 46 019 ist es bekannt, an einem Mikrowellen-Backofen eine Wrasenöffnung mit Nachverbrenner, z.B. porösem Keramikstein, vorzusehen, um, während dem Mikrowellenbetrieb, Wrasen möglichst vollständig aus dem Garraum zu entfernen. From DE-OS-33 46 019 it is known to use a microwave oven a vapor opening with an afterburner, e.g. porous Ceramic stone, to be provided to, during microwave operation, Remove vapors as completely as possible from the cooking space.

Aus der US-A-3 446 941 ist nun ein Verfahren bzw. ein Backrohr bekannt, bei dem Abluft durch ein Bett eines porösen Materials getrieben wird. Als poröses Material werden lose Partikel eingesetzt oder Partikel, welche beispielsweise zusammengesintert sind. Als Material wird ein Metall vorgeschlagen.From US-A-3 446 941 is now a method or an oven known in the exhaust air through a bed of a porous material is driven. Loose particles are used as the porous material or particles which are sintered together, for example are. A metal is proposed as the material.

Dieses Verfahren bzw. dieses Backrohr bewirkt eine Rauch- oder Fettreinigung der Abluft und ist äusserst einfach.This method or this oven causes a smoke or Grease cleaning of the exhaust air and is extremely simple.

Die vorliegende Erfindung bezweckt, ein Verfahren bzw. ein Backrohr letztgenannter Art zu schaffen, mittels welchem eine Wrasenfilterung, d.h. Geruchsstoff-, Wasserdampf- etc. Reinigung vorgenommen wird. Dies wird am Verfahren eingangs genannter Art dadurch erreicht, dass die Abluft durch ein Bett eines saugfähigen hydrophilen Granulates getrieben wird.The present invention aims at a method and a To create an oven of the latter type, by means of which a Vapor filtering, i.e. Odor, water vapor, etc. cleaning is made. This is mentioned in the procedure at the beginning Art achieved in that the exhaust air through a bed of a absorbent hydrophilic granules is driven.

Bei der erwähnten, bislang unzulänglichen Behandlung der genannten Abluft gab es auch unterschiedliche Luftführungstechniken:In the aforementioned, inadequate treatment of the aforementioned There were also different airflow techniques for exhaust air:

In vielen Fallen wurde die Abluft am Türgriff der Backrohr-Bedienungsöffnung ausgelassen oder durch einen Auslassschlitz unmittelbar oberhalb des erwähnten Griffes. Nachteilig ist dabei, dass die nur unwesentlich abgekühlte Abluft mit relativ hoher Temperatur von beispielsweise bis zu 135°C ausgelassen wird, und zwar dort, wo eine Bedienungsperson auf das Gerät Zugriff nimmt.In many cases, the exhaust air was on the door handle of the oven opening omitted or through an outlet slot immediately above the handle mentioned. The disadvantage is the fact that the exhaust air, which has cooled only slightly, with relative high temperature of up to 135 ° C, for example is there, where an operator on the device Takes access.

In einer bevorzugten Ausführungsvariante des erwähnten Verfahrens wird deshalb, nach dem Wortlaut von Anspruch 2, vorgeschlagen, das Bett mindestens als Teil eines Wärmespeichers auszubilden. Dadurch wird erreicht, dass aufgrund der Wärmeaufnahme des Wärmespeichers die Abluft, wenn sie in die Umgebung austritt, heruntergekühlt ist.In a preferred embodiment variant of the mentioned method it is therefore proposed, according to the wording of claim 2, the bed at least as part of a heat store to train. This ensures that due to the heat absorption the heat storage the exhaust air when it is in the environment emerges, has cooled down.

Unter dem gleichen Aspekt wird, dem Wortlaut von Anspruch 3

folgend, auch vorgeschlagen, die Abluft grossräumig verteilt

nach dem erwähnten Bett in die Umgebung auszulassen. Dies erfolgt

beispielsweise bei einem Backrohr mit darüber angeordnetem

Kochfeld dadurch, dass die Abluft stromab des Bettes in

höchst einfacher Art und Weise durch baulich ohnehin vorgesehene

Ritzen und Spalten des darüber liegenden Aggregates ausgelassen

wird oder aber durch eigens dafür vorgesehene verteilte

Oeffnungen.In the same aspect, the wording of

Im weiteren ist das erwähnte Vorgehen mit Blick auf die Gebläse-Abluftförderung aus energetischen Betrachtungen nachteilig. Um diesen Nachteil ebenfalls zu beheben, wird in einer bevorzugten Ausführungsform des erfindungsgemässen Verfahrens nach Anspruch 4 vorgeschlagen, dass die Abluft passiv ohne Abluftgebläse druckdifferenzgetrieben durchs Bett gefördert wird.Furthermore, the procedure mentioned is with regard to the fan exhaust air conveyance disadvantageous from an energetic point of view. In order to remedy this disadvantage as well, one is preferred Embodiment of the method according to the invention Claim 4 proposed that the exhaust air passively without exhaust fan differential pressure driven through the bed.

Durch Ausnützung des Bettes mindestens als Teil eines Wärmespeichers,

bevorzugterweise in Kombination mit der passiven

Abluftförderung, werden sowohl thermisch wie auch elektrisch

namhafte Energieeinsparungen erzielt. Mit Blick auf den Wärmespeicher

gilt dies insbesondere dann, wenn er, nach dem

Wortlaut von Anspruch 5, in einem ohnehin beheizten Bereich

angeordnet ist.By using the bed at least as part of a heat store,

preferably in combination with the passive

Exhaust air conveyance, both thermally and electrically

significant energy savings achieved. With a view of the heat accumulator

This applies in particular if, after the

Wording of

In einer bevorzugten Ausführungsvariante des erwähnten Verfahrens wird, dem Wortlaut von Anspruch 6 folgend, die Abluft durch ein Blähtongranulat-Bett getrieben. Es hat sich dabei gezeigt, dass Zeitspannen, während welchen keine wrasenkontaminierte Abluft anfällt und trotzdem eine Beheizung erfolgt, d.h. während Vorheizphasen oder Auskühlphasen, insbesondere bei der Verwendung von Blähton, eine derart weitgehende Regeneration des Granulates erfolgt, dass praktisch keine Aenderung des Kontaminationsgrades des Granulates über die fortschreitende Einsatzzeit festgestellt werden kann. Daraus ergibt sich der namhafte Vorteil, dass, wenn überhaupt, das vorgesehene Bett nur äusserst selten ausgewechselt werden muss.In a preferred embodiment variant of the mentioned method is, according to the wording of claim 6, the exhaust air driven through an expanded clay granulate bed. It has been there demonstrated that periods of time during which no vapors contaminated Exhaust air is produced and there is still heating, i.e. during preheating or cooling phases, in particular when using expanded clay, such extensive regeneration of the granules occurs that practically no change the degree of contamination of the granules over the progressive Operating time can be determined. It follows the notable advantage that, if at all, the intended bed can only be replaced very rarely got to.

Dabei muss auf den Unterschied hingewiesen werden, ob nämlich Wrasen, wie Feuchtigkeit mit Rückständen, in relativ kurzen Zeiten, praktisch als Wrasenstoss, in die Umgebung entlassen wird, was durch das vorgesehene Bett verhindert wird, oder ob während der erwähnten Regeneration äusserst langsam die erwähnte Wrasenabgabe erfolgt. In letzterem Fall ist sowohl die Geruchsbildung wie auch eine Ablagerungskontamination an Raumwänden, möglicherweise auch aufgrund inhärenter Raumluftströmung, kaum manifest.The difference must be pointed out, namely whether Vapors, like moisture with residues, in relatively short Times released, practically as a vaping of steam, into the environment becomes what is prevented by the intended bed or whether during the regeneration mentioned, the mentioned very slowly Vapors are released. In the latter case, both Odor formation as well as contamination of deposits on room walls, possibly also due to inherent indoor air flow, hardly manifest.

Im weiteren wird, dem Wortlaut von Anspruch 7 folgend, in einer bevorzugten Ausführungsvariante vorgeschlagen, die Abluft vor dem Bett einer Fettfilterung zu unterziehen, z.B. mittels eines Metall-Pressspanfilters. Furthermore, following the wording of claim 7, in proposed a preferred embodiment, the exhaust air grease filtering before bed, e.g. using a metal particle board filter.

zur Lösung der erfindungsgemäss gestellten Aufgabe an einem

Backrohr zeichnet sich letzteres nach dem Wortlaut des kennzeichnenden

Teils von Anspruch 8 aus. Die jeweils durch die

bevorzugten Ausführungsformen des Backrohres nach einem oder

mehreren der Ansprüche 9 bis 14 erzielten Vorteile wurden bereits

im zusammenhang mit dem erfindungsgemässen Verfahren

erörtert.to achieve the object according to the invention on one

The oven is characterized by the wording of the label

Part of claim 8. Each by the

preferred embodiments of the oven according to one or

several of the

Eine weitere bevorzugte Ausführungsvariante des Bettes am erfindungsgemässen

Backrohr zeichnet sich nach dem Wortlaut von

Anspruch 15 aus. Durch Vorsehen der auf Abstand gehaltenen

Ummantelung des als Granulatpatrone ausgebildeten Bettes ergeben

sich auch entlang der Aussenfläche der Granulatpatrone

optimal lange Strömungspfade und Wärmetauscherpfade für die

Abluft und damit eine optimale Wärmeabgabe vorerst an das

Bett. Dabei wird bevorzugterweise der erwähnte Mantel aus

Metall gefertigt, womit auch letzterer Wärme aufnimmt und zur

Abkühlung der Abluft beiträgt.Another preferred embodiment of the bed on the inventive

Oven is characterized by the wording of

Um, falls nötig, und je nach eingesetztem Granulat, das Bett leicht auswechseln zu können, wird, dem Wortlaut von Anspruch 16 folgend, vorgeschlagen, mindestens das Bett als einheitlichen Wrasenkondensator-Bauteil auswechselbar auszubilden.To the bed, if necessary, and depending on the granules used easy to change, the wording of claim 16 following, suggested at least the bed as a unitary Form vapor condenser component interchangeably.

Ein erfindungsgemässer Wrasenkondensator, der sich insbesondere

für den Einsatz zur Realisation des erfindungsgemässen

Verfahrens bzw. am erfindungsgemässen Backrohr eignet, zeichnet

sich weiter nach dem Wortlaut von Anspruch 17 aus, mit

bevorzugten Ausführungsvarianten nach den Ansprüchen 18 bis

20. Anspruch 21 spezifiziert eine erfindungsgemässe Verwendung

von Granulat, dabei, nach Anspruch 22, eine solche insbesondere

für Blähton.A vapor condenser according to the invention, which in particular

for use to implement the inventive

Process or on the oven according to the invention is suitable

further according to the wording of

Die Erfindung wird anschliessend beispielsweise anhand von Figuren erläutert.The invention is then described, for example, with reference to Figures explained.

Es zeigen:

- Fig. 1

- schematisch, an einem erfindungsgemässen Backrohr, beispielsweise mit darüber aufgebautem Kochfeld, eine erste bevorzugte Ausführungsvariante eines erfindungsgemässen Wrasenkondensators;

- Fig. 2

- an einer Darstellung analog zu derjenigen von Fig. 1, eine weitere bevorzugte Ausführungsvariante eines erfindungsgemässen Wrasenkondensators, an einem erfindungsgemäss ausgestatteten Backrohr vorgesehen;

- Fig. 3

- schematisch, einen erfindungsgemässen Wrasenkondensator in der schematisch in Fig. 1 dargestellten Ausführungsform;

- Fig. 4

- schematisch, eine teilgeschnittene Darstellung des Kondensators nach Fig. 3 mit erfindungsgemäss eingesetztem Granulat zur weiteren Erläuterung seiner Funktionsweise.

- Fig. 1

- schematically, on an oven according to the invention, for example with a hob built above it, a first preferred embodiment of a vapor condenser according to the invention;

- Fig. 2

- on a representation analogous to that of FIG. 1, a further preferred embodiment of a vapor condenser according to the invention is provided on an oven equipped according to the invention;

- Fig. 3

- schematically, a vapor condenser according to the invention in the embodiment shown schematically in Fig. 1;

- Fig. 4

- schematically, a partially sectioned representation of the capacitor of FIG. 3 with granules used according to the invention to further explain its operation.

An der Oberseite eines Backrohres 1 ist, im wesentlichen zentral,

ein Abluftstutzen 3 eingebaut, welcher über ein Fettfilter

5, beispielsweise aus Metallpressspan, mit einem Hohlraum

7 oberhalb des Backrohres 1 kommuniziert. Ein Granulatkörper

9 bildet den aktiven Teil des Wrasenkondensators und

ist mit einer entsprechend geformten Einnehmung 11 auf den in

den Hohlraum 7 einragenden Teil des Stutzens 3 aufgesteckt.

Beispielsweise mit einer Zentralstütze 13 abgestützt, umgibt

ein vorzugsweise aus Metall gefertigter äusserer Mantel 15 die

dem Hohlraum 7 zugewandte Oberfläche des Granulatkörpers 9.

Die seitlichen Partien des Mantels 15 sind nicht bis auf die

Unterkante des Granulatkörpers 9 gezogen, sondern definieren,

mit ihrer Unterkante, bezüglich einer Isolierabdeckplatte 17

des Backrohres, Austrittsöffnungen bzw. einen Austrittsschlitz

19 für die Abluft stromab des Granulatkörpers 9.At the top of an oven 1 is, essentially central,

an

Die in Fig. 1 schematisch dargestellte Ausbildung von Granulatkörper

9 und Ummantelung 15, welche beiden Teile gemeinsam

den leicht auswechselbaren Wrasenkondensator bilden, sind zylindrisch

aufgebaut. Aufgrund des mit Bezug auf Umgebungsdruck

im Backrohr 1 herrschenden Ueberdruckes p1, thermisch bedingt,

und gegebenenfalls aufgrund der Wirkung eines Umluftgebläses,

wird, in der bevorzugten Ausführungsvariante, passiv, d.h.

ohne Vorsehen eines Abluftgebläses, die Abluft L durch Fettfilter

5, Stutzen 3 und den Granulatkörper 9, dann entlang

seiner Oberfläche zu den Oeffnungen 19 geführt, wo die an

Fettfilter und vor allem am Wrasenkondensator 9 gereinigte und

an letzterem abgekühlte Abluft in den Hohlraum 7 eintritt.The formation of the

In bevorzugter Ausführungsform, wie gestrichelt dargestellt,

verlässt die Abluft, grossräumig verteilt, den Hohlraum 7 in

die Umgebung. Dies wird entweder durch Vorsehen eigens dafür

vorgesehener, verteilter Austrittsöffnungen realisiert oder,

wie schematisch dargestellt, durch baulich ohnehin vorgesehene

Schlitze und Ritzen, beispielsweise an einem über dem Hohlraum

7 angeordneten Kochfeld 21.In a preferred embodiment, as shown in dashed lines,

The exhaust air, distributed over a large area, leaves the cavity 7 in

the environment. This is done either by providing specifically for it

provided, distributed outlet openings or

as shown schematically, by structural means already provided

Slits and chinks, for example on one over the cavity

7 arranged

Aufgrund der Wärmespeicherwirkung von Granulatkörper 9 und

Ummantelung 15 wird die Abluft am Wrasenkondensator nicht nur

gereinigt, sondern auch nachhaltig gekühlt. Dabei wird der

Kondensator, wie dargestellt, beispielsweise im Bereiche des

Kochfeldes 21 angeordnet, also in einem Bereich, der ohnehin

beheizt wird, womit die Wärmeverluste verringert werden bzw.

die Abluftwärme genutzt wird. Due to the heat storage effect of

Der Granulatkörper 9 ist gebildet durch ein poröses, saugfähiges,

hydrophiles Granulat mit grosser relativer Oberfläche,

bevorzugterweise mit Granulatdurchmessern von 3 bis 5mm. Die

Luftfliesswege von Stutzenmündung 11 bis zur Oberfläche des

Granulatkörpers sind in der Grössenordnung von einigen 10cm,

beispielsweise 30cm.The

Ausgehend von Fig. 1, ist in Fig. 2 eine weitere bevorzugte

Bauweise des aus Granulatkörper 9 und Ummantelung 15 gebildeten

Wrasenkondensators dargestellt, der hier im wesentlichen

kubusförmig ausgebildet ist.Starting from FIG. 1, FIG. 2 is another preferred one

Construction of the formed from

Mit der anhand der Fig. 1 und 2 dargestellten Technik an einem Backrohr wurden Nischentemperaturen, d.h. Temperaturen ausserhalb der Backrohrwandung, gemessen, die ca. 56°C betrugen. Auch die Temperatur an der Bedienungstüre derartiger erfindungsgemässer Backrohre wurde bis auf höchstens 70°C reduziert, verglichen mit Temperaturen von ca. 135°C bei Auslass der ungekühlten Abluft am Türgriff oder in dessen Nähe.With the technique shown in FIGS. 1 and 2 on one The oven was set at niche temperatures, i.e. Temperatures outside the oven wall, measured, which was about 56 ° C. The temperature at the service door of such inventive Oven pipes have been reduced to a maximum of 70 ° C, compared to temperatures of approx. 135 ° C when the uncooled exhaust air on or near the door handle.

Verglichen mit einem Backrohr mit Abluftgebläse, welches Raumluft

ansaugt und diese durch einen Hohlraum analog zu Hohlraum

7 bis zum Frontbereich fordert, unter Injektor-Effekt-ähnlicher

Mitnahme von Abluft aus dem Backraum, durch einen analog

zum Stutzen 3 vorgesehenen Stutzen, ohne Wrasenkondensator,

ergab das erfindungsgemässe Vorsehen des Wrasenkondensators

und Ausschalten des Umluftgebläses eine namhafte Energieeinsparung

im Bereich von 100W.Compared to an oven with an exhaust fan, which room air

sucked in and this through a cavity analogous to cavity

7 to the front area calls, under injector-like effect

Take-off of exhaust air from the baking chamber, through an analog

for

In Fig. 3 ist ein erfindungsgemässer Wrasenkondensator, beispielsweise

in zylindrischer Bauform, wie in der Anordnung

gemäss Fig. 1 eingesetzt, schematisch dargestellt. Der Granulatkörper

9 mit Granülen 9a weist die vorbeschriebene Steckeinnehmung

11 für den Anschluss auf. Selbstverständlich kann

anstelle einer Einnehmung 11 ein vorragender Steckstutzen

eingebaut sein. Der Granulatkörper 9 ist vom bevorzugterweise

aus Metall gefertigten Mantel 15 umgeben. Die Abluft L dringt

durch den Anschluss bei 11 in den Granulatkörper 9 ein, verteilt

sich im Körper, tritt schliesslich an seiner freien

Oberfläche, wie bei L1 schematisch dargestellt, aus. Dabei

werden Unter- und Seitenflächen des Granulatkörpers 9, vorzugsweise

mit einer weiteren Ummantelung 15a, gegebenenfalls

auch aus Metall, umhüllt, um zu erzwingen, dass die Abluft L

bis zu der dem Anschluss 11 gegenüberliegenden Körperfläche 9b

dringt und erst dort ausströmt.FIG. 3 schematically shows a vapor condenser according to the invention, for example in a cylindrical design, as used in the arrangement according to FIG. 1. The

Im Hohlraum zwischen Mantel 15 und Oberfläche des Granulatkörpers

9 bzw. Mantels 15a strömt die Abluft, wie bei L2 dargestellt,

zu den Austrittsöffnungen bzw. dem Austrittsschlitz 19

gemäss Fig. 1 bzw. 2. Die Zirkulation der Abluft ist auch aus

der Darstellung von Fig. 4 klar ersichtlich.In the cavity between the

Wie erwähnt, wird bevorzugterweise heute als Wrasenkondensatorgranulat Blähton eingesetzt. Dabei hat sich erwiesen, dass die erwartete Notwendigkeit, das Granulat in relativ kurzen Zeitabständen zu regenerieren, entfällt. Die nicht verschmutzte Abluft generierenden Heizphasen des Backrohres, nämlich z.B. Vorwärmphasen vor Einschieben eines Kochgutes bzw. Auskühlphasen nach Herausnahme des Kochgutes, genügen vollständig, um das Granulat zu regenerieren. Damit muss der Wrasenkondensator, wenn überhaupt, nur selten während der Lebenszeit eines Backrohres ersetzt werden.As mentioned, is preferably used today as vapor condenser granules Expanded clay used. It has been shown that the expected need to get the granules in relatively short There is no need to regenerate intervals. The not polluted Exhaust air-generating heating phases of the oven, namely e.g. Preheating phases before inserting a food or cooling phases after removing the food, are completely sufficient, to regenerate the granules. So the vapor condenser, rarely, if ever, during life of an oven.

Um, in der bevorzugten Ausführungsvariante ohne Abluftgebläse, die Luftströmung durch Fettfilter und Wrasenkondensator sicherzustellen, wird bevorzugterweise die Bedienungstür des Backrohres so ausgebildet, dass in geschlossenem Zustand eine nur vernachlässigbare Luftströmung aus den Türfugen in die Umgebung möglich ist.Um, in the preferred embodiment without exhaust fan, ensure the air flow through the grease filter and vapor condenser, the control door of the Baking oven designed so that in the closed state only negligible air flow from the door joints into the Environment is possible.

Der erfindungsgemässe Wrasenkondensator kann nicht nur an

Backrohren eingesetzt werden, sondern beispielsweise auch in

der Abluftführung über Kochfeldern. Je nach zur Verfügung stehendem

Platz kann, gemäss den Fig. 1 und 2, die Form des Wrasenkondensators

9, 15 beliebig variiert werden.The vapor condenser according to the invention can not only be used

Ovens are used, but also in

the exhaust air duct over hobs. Depending on what is available

Space can, according to FIGS. 1 and 2, the shape of the

Claims (22)

- Cleaning method for exhaust cooking or baking air, wherein the exhaust air is forced through a bed (9) of a porous material, characterised in that the exhaust air is forced through a bed of an absorbent, hydrophilic granular material (9a).

- Method according to claim 1, characterised in that the bed is used at least as part of a heat accumulator (9, 15).

- Method according to either claim 1 or claim 2, characterised in that the exhaust air, after passing through the bed, is let out into the surroundings distributed over a large area.

- Method according to any one of claims 1 to 3, characterised in that the exhaust air is conveyed through the bed (9) in a passive manner, without an exhaust air fan, forced by a pressure difference (p1).

- Method according to claim 2, characterised in that the heat accumulator is arranged in a region which is heated in any case.

- Method according to any one of claims 1 to 5, characterised in that the exhaust air is forced through a bed having an expanded clay granular material.

- Method according to any one of claims 1 to 6, characterised in that, upstream of the bed, grease filtering (5) is carried out, for example by means of a metal pressboard filter.

- Baking oven, wherein a bed (9) of a porous material is provided in a ventilation path for exhaust air between the baking space (1) and the surroundings, characterised in that the bed contains an absorbent, hydrophilic granular material (9a).

- Baking oven according to claim 8, characterised in that the bed (9) is at least part of a heat accumulator (9, 15) which is preferably arranged in a region (7) that is to be heated in any case, such as in the region of a hob (21) arranged above the baking oven.

- Baking oven according to either claim 8 or claim 9, characterised in that distributed exhaust air outlets opening out into the surroundings are provided downstream of the bed and, when a hob (21) is arranged above the baking oven, they are preferably constituted by slots and slits which are provided on the hob in any case.

- Baking oven according to any one of claims 8 to 10, characterised in that no exhaust air fan is provided and the exhaust air is conveyed by means of a pressure difference (p1, pn) between the baking space and the surroundings.

- Baking oven according to any one of claims 8 to 11, characterised in that a grease filter (5), for example of metal pressboard, is arranged upstream of the bed.

- Baking oven according to any one of claims 8 to 12, characterised in that the granular material is at least mainly expanded clay.

- Baking oven according to any one of claims 8 to 13, characterised in that an exhaust air outlet opening (3), which preferably opens out into the baking space (1) by way of a grease filter (5), is preferably provided on the upper side of the baking space, preferably substantially centrally, and in that the outlet opening (3) opens out into the bed (9) which is arranged in a cavity (7) communicating with the surroundings.

- Baking oven according to any one of claims 8 to 14, characterised in that the bed (9) is a granular material cartridge which is surrounded, with spacing, by a jacket (15), preferably of metal, which jacket at least co-defines at least one opening into the surroundings, and/or part of the outer face of the granular material cartridge is substantially airtight (15a).

- Baking oven according to any one of claims 8 to 15, characterised in that at least the bed (9) is in the form of an exchangeable vapour condenser cartridge.

- Vapour condenser, characterised in that it comprises a granular material body (9) of porous, absorbent, hydrophilic granular material (9a).

- Vapour condenser according to claim 17, characterised in that a jacket, preferably a metal jacket, is provided with spacing from the granular material body (9) and/or a portion of the outer face of the granular material body is substantially airtight (15a).

- Vapour condenser according to either claim 17 or claim 18, characterised in that it is cylindrical and a connection branch or a connection sleeve (11) is provided centrally on the granular material body (9) for the attachment of the vapour condenser.

- Vapour condenser according to either claim 17 or claim 18, characterised in that it is substantially in cube form and, in the region of one cube edge, a connection branch or a connection sleeve (11) is provided on the granular material body (9).

- Use of porous, absorbent, hydrophilic granular material for the vapour filtering of exhaust cooking or baking air.

- Use according to claim 21, of expanded clay granular material.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP93111346A EP0634612B1 (en) | 1993-07-15 | 1993-07-15 | Cleaning method for cooking vapours, cooking oven, condenser for the vapours and granulate as condenser material |

| DE59309747T DE59309747D1 (en) | 1993-07-15 | 1993-07-15 | Process for cleaning cooking or baking exhaust air, oven, vapor condenser and use of granules as vapor condenser material |

| AT93111346T ATE183818T1 (en) | 1993-07-15 | 1993-07-15 | METHOD FOR CLEANING COOKING OR BAKING AIR, OVEN PIPE, WATER CONDENSER AND USE OF GRANULES AS VAUX CONDENSER MATERIAL |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP93111346A EP0634612B1 (en) | 1993-07-15 | 1993-07-15 | Cleaning method for cooking vapours, cooking oven, condenser for the vapours and granulate as condenser material |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0634612A1 EP0634612A1 (en) | 1995-01-18 |

| EP0634612B1 true EP0634612B1 (en) | 1999-08-25 |

Family

ID=8213078

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93111346A Expired - Lifetime EP0634612B1 (en) | 1993-07-15 | 1993-07-15 | Cleaning method for cooking vapours, cooking oven, condenser for the vapours and granulate as condenser material |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0634612B1 (en) |

| AT (1) | ATE183818T1 (en) |

| DE (1) | DE59309747D1 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE9402193U1 (en) * | 1994-02-10 | 1994-03-31 | Hoba Tech Software Gmbh | Steam condenser |

| DE102006043184B4 (en) | 2005-10-10 | 2019-07-25 | BSH Hausgeräte GmbH | Cooking appliance |

| EP2283729A1 (en) | 2009-08-13 | 2011-02-16 | Electrolux Home Products Corporation N.V. | Processing chamber, device for household and industrial application and sorption cartridge |

| EP4279821A1 (en) * | 2022-05-18 | 2023-11-22 | B/E Aerospace, Inc. | Filter for an aircraft oven |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3446941A (en) * | 1966-09-14 | 1969-05-27 | Whirlpool Co | Oven heating means |

| DE3346019C2 (en) * | 1983-12-20 | 1985-11-07 | Bosch-Siemens Hausgeraete Gmbh, 7000 Stuttgart | oven |

| DE3700567A1 (en) * | 1987-01-10 | 1988-07-21 | Bauknecht Hausgeraete | CONDENSER DEVICE FOR VASES CREATING IN AN OVEN |

-

1993

- 1993-07-15 DE DE59309747T patent/DE59309747D1/en not_active Expired - Fee Related

- 1993-07-15 AT AT93111346T patent/ATE183818T1/en not_active IP Right Cessation

- 1993-07-15 EP EP93111346A patent/EP0634612B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE59309747D1 (en) | 1999-09-30 |

| EP0634612A1 (en) | 1995-01-18 |

| ATE183818T1 (en) | 1999-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69917770T2 (en) | METHOD FOR DRYING A COATED SUBSTRATE | |

| EP2254422B1 (en) | Cooking apparatus having a vapor condensation device | |

| DE2414573B1 (en) | Suspended ceiling for shielding load-bearing ceilings in rooms | |

| DE102016113356A1 (en) | Extractor device for a fryer and cooking appliance in the form of a fryer | |

| WO2019081271A1 (en) | Combination appliance with fume extraction device and cooktop | |

| EP0275127B1 (en) | Condenser for the vapours in an oven | |

| EP0634612B1 (en) | Cleaning method for cooking vapours, cooking oven, condenser for the vapours and granulate as condenser material | |

| DE60201724T2 (en) | Home stove for broiler | |

| DE102005034303B4 (en) | Cooking oven | |

| EP3759397B1 (en) | Table hood and method for cleaning a table hood | |

| DE3219912A1 (en) | DEVICE FOR CONDENSING COOKING STEAMS | |

| DE2653323A1 (en) | ARRANGEMENT TO PREVENT DUST AND STEAM EMISSIONS WHEN MAKING COKE AND USING THIS ARRANGEMENT | |

| DE2919761C2 (en) | Air purifier | |

| DE3027566C2 (en) | Oven with a vapor outlet duct | |

| EP1094278A2 (en) | Fumes evacuation device | |

| EP2677872A1 (en) | Method for removing organic components and the conversion products of said components contained in vapor and for recovering heat from vapor, and device for carrying out said method | |

| DE3643299C1 (en) | Apparatus for dehumidifying the interior exhaust air or exhaust gases and/or for condensing the vapour and waste steam from bakeries or the like | |

| DE2229991C3 (en) | Pressure cooker | |

| DE3914198C2 (en) | Afterburner | |

| DE4321530A1 (en) | Air-conducting apparatus | |

| DE4100859C2 (en) | ||

| CH656942A5 (en) | Baking oven | |

| WO2003052166A1 (en) | Method and device for removing adhesions, especially oily or fatty adhesions that are present on the surface of metal parts | |

| DE2815960A1 (en) | Fluidised bed calcination reactor - with heating element wound round the reactor and gas flowing upwards from ports in the bed of the reactor | |

| DE202017107499U1 (en) | Recirculation hood with a grease filter and a scent capsule |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE DK ES FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19950703 |

|

| 17Q | First examination report despatched |

Effective date: 19970605 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE DK ES FR GB IT LI SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990825 |

|

| REF | Corresponds to: |

Ref document number: 183818 Country of ref document: AT Date of ref document: 19990915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: TROESCH SCHEIDEGGER WERNER AG Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59309747 Country of ref document: DE Date of ref document: 19990930 |

|

| ITF | It: translation for a ep patent filed |

Owner name: PROPRIA S.R.L. |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19991125 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19991125 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000715 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000731 |

|

| 26N | No opposition filed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20000715 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed |

Ref document number: 93111346.8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010928 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000731 |