EP0634507B2 - System zur Produktionssteigerung von Spinnereimaschinen - Google Patents

System zur Produktionssteigerung von Spinnereimaschinen Download PDFInfo

- Publication number

- EP0634507B2 EP0634507B2 EP94110331A EP94110331A EP0634507B2 EP 0634507 B2 EP0634507 B2 EP 0634507B2 EP 94110331 A EP94110331 A EP 94110331A EP 94110331 A EP94110331 A EP 94110331A EP 0634507 B2 EP0634507 B2 EP 0634507B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- parameters

- control

- measurable

- fuzzy

- variables

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009987 spinning Methods 0.000 title claims abstract description 14

- 238000004519 manufacturing process Methods 0.000 title claims description 11

- 230000001105 regulatory effect Effects 0.000 claims description 8

- 238000004422 calculation algorithm Methods 0.000 claims description 4

- 230000007613 environmental effect Effects 0.000 claims description 3

- 230000008447 perception Effects 0.000 claims description 2

- 238000007378 ring spinning Methods 0.000 description 7

- 238000000034 method Methods 0.000 description 5

- 230000008569 process Effects 0.000 description 5

- 230000003044 adaptive effect Effects 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 4

- 230000008859 change Effects 0.000 description 4

- 230000006870 function Effects 0.000 description 4

- 230000005684 electric field Effects 0.000 description 3

- 230000014509 gene expression Effects 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 238000004364 calculation method Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- VOXZDWNPVJITMN-ZBRFXRBCSA-N 17β-estradiol Chemical compound OC1=CC=C2[C@H]3CC[C@](C)([C@H](CC4)O)[C@@H]4[C@@H]3CCC2=C1 VOXZDWNPVJITMN-ZBRFXRBCSA-N 0.000 description 1

- 241001136792 Alle Species 0.000 description 1

- 241000282412 Homo Species 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000011217 control strategy Methods 0.000 description 1

- 238000013479 data entry Methods 0.000 description 1

- 238000009795 derivation Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 230000007363 regulatory process Effects 0.000 description 1

- 210000002023 somite Anatomy 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01H—SPINNING OR TWISTING

- D01H13/00—Other common constructional features, details or accessories

- D01H13/32—Counting, measuring, recording or registering devices

Definitions

- the present invention relates to a system for Production increase of spinning machines, with sensors for Measurement of parameters that influence production, and with a controller that is connected to the sensors Control stage, one with the manipulated variables Control for the spinning machine and between control stage and control has a fuzzy controller for derivation of controlled variables from these parameters and for the formation of Control variables for the spinning machine from the obtained Control variables, taking those parameters that are unique mathematical relationship with the respective controlled variable exhibit through conventional algorithms in the regulation are involved and an input station is provided by the other in the scheme, especially not or only with difficulty measurable parameters can be entered, and those parameters that have no clear mathematical connection with the have the respective controlled variable by means of a fuzzy logic of the Fuzzy controllers are included in the control.

- the invention is now intended to be a system for increasing the production of Specify spinning machines where it is still possible further, also subjectively felt by humans Influences on production, for the extraction of Record controlled variables.

- FC Fuzzy controller

- fuzzy logic is not a model of the process to be controlled and that the parameters are not just a single defined value, but several fuzzy ones Show quantities called fuzzy sets.

- the system according to the invention thus has two major advantages: On the one hand, not all parameters have to be mathematical defined function of the control variables are present, and on the other hand All parameters do not necessarily have to be with one sensor be measurable. Both advantages lead to the system parameters perceived by the operating personnel are also entered can be, and that means again Pages 1, 2 and 2a add a significant expansion to the range of usable Parameter.

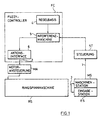

- FIG. 1 shows a block diagram representation of a control system for a ring spinning machine RS, the control system preferably on the known data system USTER RINGDATA (USTER - registered trademark der Zellweger Uster AG) and from this also uses known components.

- This known components are in particular a so-called Machine station MS to which the various Sensors connected for parameters to be recorded are a machine input station ES for data entry, like changing articles, or specifying dates, like Creep spindle report, and a motor control MA the ring spinning machine RS.

- the sensors mentioned are, for example, a provided on each machine side and on the ring bench walking sensor, an underwind sensor and a production sensor.

- the production sensor detects the revolutions of the discharge cylinder on Drafting system and provides basic information about production quantities and delivery speeds, frequency and duration of long downtimes and the like.

- With the underwind sensor the underwind position the ring bench to record the number and duration of the Cops registered.

- the hiking sensor is once per machine side and will be on the Ring bench led along. It detects contactlessly the rotation of the ring traveler and provides information about thread breaks at each spinning position and the mean time to correct them and the mean time Speed of the ring traveler and thus via the spinning positions at too low speed.

- the machine station MS is on via a line 1 one with the USTER RINGDATA data system also as Central unit designated control stage ST connected, in which, among other things, the line 1 of the Machine station MS received information about processes the measurable parameters into control variables become.

- the configuration of the control system described so far is from USTER News Bulletin No. 27 from August 1979 "The detection of thread breaks in der Ringspinnerei ".

- the motor control MA receives on one line 2 a manipulated variable for adjusting the drive of the Ring spinning machine RS based on the in the control stage ST obtained standard sizes.

- Essential to the in Fig. 1 shown control system is now the circumstance that the control stage ST is not just information about the measurable parameters, but also information about non-measurable parameters, and that too the latter parameters when obtaining the control variables be taken into account.

- the control stage ST receives the information about the measurable parameters of those connected to the machine station Sensors and the information about non-measurable Parameters from that with the machine station MS over a line 3 connected input station ES.

- the traditional control technology be it state controllers, P controller (controller with proportional component, with a setting parameter), PI controller (controller with Proportional and integral part, i.e. with two setting parameters), PID controller (controller with proportional, integral and differential component, i.e. with three setting parameters) or the like assumes that the relationships of the process to be regulated and are writable and depicted in a model can be.

- This modeling also includes Disturbances such as temperature drift, where it is also known to include the disturbance variables in the scheme to integrate that they are not on the regulatory process have a negative impact. But here, too, a math Relationship between disturbance variable and controlled variable available. If this is not the case, then the Regulations, apart from coincidences, fail.

- the ring spinning machine significantly determining speed of the spindles not only of the ones mentioned Sensors monitored and measured parameters dependent, but also on influencing factors such as climate, dust, airflow or subjective and individual parameters of the operating personnel, such as its workload.

- influencing factors such as climate, dust, airflow or subjective and individual parameters of the operating personnel, such as its workload.

- the first criterion is technical Select measurability of the influencing variables or parameters, then you can convert the parameters into technically measurable and divide it into technically non-measurable ones. Taking as a criterion the possibility of producing a mathematical Relationship between parameters and controlled variables, then you can change the parameters in those with and in those without a mathematical context divide with the relevant control variable.

- the control system shown in Figure 1 should now enable all four classes of parameters mentioned in to include the regulation. This is done by a Synthesis of conventional adaptive control and Fuzzy logic reached.

- fuzzy logic the meantime extensive literature on this subject for example on the book “Fuzzy Set Theory and its Applications "by H.-J. Zimmermann, Kluwer Academic Publishers, 1991.

- fuzzy sets were Introduced 25 years ago to be inaccurate and incomplete Data records that often occur in the real world (Pictures, subjective descriptions) mathematically to describe.

- the classic control logic only the two sharp values yes or no, Has 0 or 1

- the fuzzy logic knows a membership function, to describe the affiliation of an object to a certain amount within in the range 0 to 1 can take any value.

- control system is designed that defines further parameters that are not yet known be technically measurable or not technically measurable.

- control system entered what relationship between parameter and controlled variable is expected.

- Every class is for Example of a trapezoidal fuzzy set with the tendency to thunderstorms GN on the abscissa and with the weighting G on the ordinate. Typical of these sets is that they overlap of the individual states exist in which clear values of the tendency to thunder Several states can be assigned on the x-axis can.

- a fuzzy controller FC arranged in the control system shown in Fig. 1 is between the control ST and the motor control MA a fuzzy controller FC arranged.

- This consists of a rule base 4 and an interference machine 5 for the premises and from an action interface 6 for the Conclusions. Strictly speaking, the as User interface acting input station ES component of the fuzzy controller FC.

- FIG. 1 shown control system in the definition of the input variables and their relationship to the controlled variable between clearly describable and not mathematical distinguishable relationships.

- the relationships are clearly describable relationships and the climate.

- the Systen limits for the speeds entered within of which the regulation may move (minimum below maximum upper speed).

- the entered speed change i.e. lowering or increasing the speed, used per control step and per acquisition size.

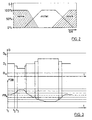

- Fig. 3 shows a graphical representation of the control the speed of a ring spinning machine based on the number of broken threads.

- Speed D in revolutions per minute

- FDB thread break rate

- the permissible maximum upper speed Do the permissible minimum lower speed Du

- the target thread break level FBs as well as symmetrical to them, each around 5% spaced limits for deviations from the Thread breakage rate shown.

- the ring spinning machine runs at a time D 1 at a speed D 1 , the thread break rate being just above the desired thread break level FB s .

- the thread break rate exceeds the limit FB s + 5%, whereupon the speed is reduced by the set amount.

- the speed D is reduced again by the set amount at this time , and so on.

- climate air temperature, air humidity

- the control is carried out analogously to the thread breaks. If the target temperature is exceeded or fallen below or the target humidity becomes the speed step by step within the permissible speed interval changed.

- the speed is regulated based on the entered Rules a to e, the calculation of the Initial variables preferably by means of center of gravity (CoA-Center of Area) or formation of the maximum value average (MoM - Mean of Maximum).

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Textile Engineering (AREA)

- Feedback Control In General (AREA)

- Spinning Or Twisting Of Yarns (AREA)

- Preliminary Treatment Of Fibers (AREA)

- Spinning Methods And Devices For Manufacturing Artificial Fibers (AREA)

- Incineration Of Waste (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH02108/93A CH687994A5 (de) | 1993-07-14 | 1993-07-14 | Vorrichtung zur Produktionssteigerung von Spinnereimaschinen. |

| CH210893 | 1993-07-14 | ||

| CH2108/93 | 1993-07-14 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0634507A1 EP0634507A1 (de) | 1995-01-18 |

| EP0634507B1 EP0634507B1 (de) | 1997-10-15 |

| EP0634507B2 true EP0634507B2 (de) | 2001-10-04 |

Family

ID=4226063

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94110331A Expired - Lifetime EP0634507B2 (de) | 1993-07-14 | 1994-07-04 | System zur Produktionssteigerung von Spinnereimaschinen |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US5511371A (enExample) |

| EP (1) | EP0634507B2 (enExample) |

| JP (1) | JP3536263B2 (enExample) |

| CN (1) | CN1048048C (enExample) |

| AT (1) | ATE159304T1 (enExample) |

| BR (1) | BR9402697A (enExample) |

| CH (1) | CH687994A5 (enExample) |

| DE (1) | DE59404316D1 (enExample) |

| ES (1) | ES2108340T3 (enExample) |

| MY (1) | MY130104A (enExample) |

| TW (1) | TW277080B (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19537694A1 (de) * | 1995-10-10 | 1997-04-17 | Schenck Ag Carl | Verfahren zur Überwachung einer Maschine oder Anlage |

| CH691687A5 (de) * | 1995-12-20 | 2001-09-14 | Schlafhorst & Co W | Verfahren zum Ueberprüfen des Fadenprofils beim Anspinnen in einer Offenend-Spinnmaschine. |

| US6047275A (en) * | 1997-10-14 | 2000-04-04 | Allen-Bradley Company, Llc | Fuzzy logic winder analyzer |

| US20070044627A1 (en) * | 2005-08-26 | 2007-03-01 | Clem Todd L | Speed and stroke control method and apparatus for a product table of a food slicer |

| US20070044621A1 (en) * | 2005-08-26 | 2007-03-01 | Rote Scott J | Top mounted operator interface for a food slicer |

| DE102017112080A1 (de) * | 2016-06-15 | 2017-12-21 | Rieter Ingolstadt Gmbh | Verfahren zum Optimieren der Produktion einer Rotorspinnmaschine |

| US11459676B2 (en) * | 2018-05-28 | 2022-10-04 | Uster Technologies Ag | Automatic ring spinning system and method for automatically operating same |

| JP7052683B2 (ja) * | 2018-11-13 | 2022-04-12 | 株式会社豊田自動織機 | 紡機のスピンドル制御方法およびスピンドル制御装置 |

| EP3828325A1 (de) * | 2019-11-29 | 2021-06-02 | Saurer Intelligent Technology AG | Spinnstelle und luftspinnmaschine umfassend eine solche spinnstelle und verfahren zur erfassung einer einen soll-wert unterschreitenden fadenfestigkeit |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4974296A (en) † | 1990-02-23 | 1990-12-04 | Platt Saco Lowell Corporation, Inc. | Apparatus for correcting irregularities in a textile strand |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE153709C (enExample) * | ||||

| CH683536A5 (de) * | 1990-06-15 | 1994-03-31 | Rieter Ag Maschf | Ringspinn- oder Zwirnmaschine. |

| JP3075811B2 (ja) * | 1991-11-12 | 2000-08-14 | 津田駒工業株式会社 | ジェットルームの緯入れ制御装置 |

| EP0548023A1 (de) * | 1991-12-17 | 1993-06-23 | Maschinenfabrik Rieter Ag | Durchfluszsteuerung einer Putzereilinie |

| DE4202352A1 (de) | 1992-01-29 | 1993-08-05 | Rieter Ingolstadt Spinnerei | Verfahren und vorrichtung zur regulierung eines streckwerkes |

-

1993

- 1993-07-14 CH CH02108/93A patent/CH687994A5/de not_active IP Right Cessation

-

1994

- 1994-06-01 TW TW083105023A patent/TW277080B/zh active

- 1994-07-01 JP JP18269794A patent/JP3536263B2/ja not_active Expired - Fee Related

- 1994-07-04 ES ES94110331T patent/ES2108340T3/es not_active Expired - Lifetime

- 1994-07-04 EP EP94110331A patent/EP0634507B2/de not_active Expired - Lifetime

- 1994-07-04 DE DE59404316T patent/DE59404316D1/de not_active Expired - Fee Related

- 1994-07-04 AT AT94110331T patent/ATE159304T1/de not_active IP Right Cessation

- 1994-07-08 MY MYPI94001792A patent/MY130104A/en unknown

- 1994-07-13 BR BR9402697A patent/BR9402697A/pt not_active Application Discontinuation

- 1994-07-14 US US08/274,783 patent/US5511371A/en not_active Expired - Fee Related

- 1994-07-14 CN CN94108504A patent/CN1048048C/zh not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4974296A (en) † | 1990-02-23 | 1990-12-04 | Platt Saco Lowell Corporation, Inc. | Apparatus for correcting irregularities in a textile strand |

Non-Patent Citations (2)

| Title |

|---|

| Kontruktion & Elektronik, Vom Labor in die Praxis, 23. und 24. September 1992, Augsburg, Erfolgsbilanz für Fuzzy Logic, Referat Prof. Dr. Steffen F. Bocklisch † |

| Melliand Textilberichte 6/1995, Seite 400-403 † |

Also Published As

| Publication number | Publication date |

|---|---|

| TW277080B (enExample) | 1996-06-01 |

| BR9402697A (pt) | 1995-04-04 |

| JP3536263B2 (ja) | 2004-06-07 |

| CH687994A5 (de) | 1997-04-15 |

| DE59404316D1 (de) | 1997-11-20 |

| CN1117534A (zh) | 1996-02-28 |

| JPH0748739A (ja) | 1995-02-21 |

| ATE159304T1 (de) | 1997-11-15 |

| ES2108340T3 (es) | 1997-12-16 |

| EP0634507A1 (de) | 1995-01-18 |

| US5511371A (en) | 1996-04-30 |

| CN1048048C (zh) | 2000-01-05 |

| MY130104A (en) | 2007-06-29 |

| EP0634507B1 (de) | 1997-10-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0365931B1 (de) | Verfahren und Vorrichtung zum Einstellen einer Luftspinnvorrichtung | |

| EP0634507B2 (de) | System zur Produktionssteigerung von Spinnereimaschinen | |

| DE112016003171T5 (de) | Verfahren zum Überwachen einer Antriebseinheit einer Fahrzeugkarosseriemontagelinie und eine Vorrichtung dafür | |

| EP3774267A1 (de) | VERFAHREN ZUR AUTOMATISCHEN PROZESSÜBERWACHUNG UND PROZESSDIAGNOSE EINES STÜCKBASIERTEN PROZESSES (BATCH-FERTIGUNG), INSBESONDERE EINES SPRITZGIEßPROZESSES UND EINE DEN PROZESS DURCHFÜHRENDE MASCHINE ODER EIN DEN PROZESS DURCHFÜHRENDER MASCHINENPARK | |

| EP0685580B1 (de) | Verfahren und Vorrichtung zur Ermittlung von Ursachen für Fehler in Garnen, Vorgarnen und Bändern | |

| DE102016121961A1 (de) | Verfahren zur Steuerung einer Windenergieanlage und zugehörige Windenergieanlage | |

| EP0436204A1 (de) | Verfahren zur Gewinnung eines Fadenlaufsignals | |

| EP0894895B1 (de) | Verfahren und Vorrichtung zur Erkennung und Korrektur einer Faserorientierungs-Querprofil-Veränderung | |

| WO1993018213A1 (de) | Verfahren und vorrichtung zur regelung des verzugs eines streckwerks | |

| DE4131765A1 (de) | Regelparameter-verbesserungsverfahren fuer industrielle anlagen | |

| DE102020107861B4 (de) | System zur Verwaltung von Werkzeugwechselzeiten | |

| DE4402582A1 (de) | Verfahren und Vorrichtung zur Optimierung der Spinngeometrie einer Ringspinnmaschine | |

| DE3717749C2 (enExample) | ||

| EP1405147B1 (de) | Überwachung eines messsignals, insbesondere in der automatisierungstechnik | |

| WO1994012919A1 (de) | Verfahren zur stellgliedidentifizierung bei der querprofil-regelung einer kontinuierlich erzeugten materialbahn | |

| EP0606615B1 (de) | Verfahren und Vorrichtung zur On-line Qualitätsüberwachung im Spinnereivorwerk | |

| EP2354554B1 (de) | Verfahren zum Ermitteln des funktionalen Zusammenhangs von Pumpen | |

| DE3521571C1 (de) | Verfahren und Vorrichtung fuer die Herstellung von Monofilfaeden geringer Dickentoleranz aus thermoplastischem Kunststoff | |

| EP3805884A1 (de) | Verfahren zur bestimmung und/oder klassifizierung eines bahnzustands einer warenbahn, computerprogrammprodukt, vorrichtung zur herstellung und industrielle anlage | |

| DE69104508T2 (de) | Verfahren und Vorrichtung zum Überwachen einer Fadenspannung. | |

| AT526314A2 (de) | Verfahren und vorrichtung zum visualisieren oder beurteilen eines prozesszustandes | |

| WO2020078651A9 (de) | Druckregelung an einem streckwerk | |

| DE19624301B4 (de) | Lernverfahren für ein neuronales Netz | |

| EP3186203A1 (de) | Verfahren zur regelung einer kühlung, herstellungsverfahren und einrichtung zum regeln und steuern sowie herstellungsvorrichtung für glaskörper | |

| EP2483461A1 (de) | Verfahren zur optimierung eines textilen produktionsprozesses |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE DE DK ES FR GB GR IE IT LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19950718 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19961007 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE DK ES FR GB GR IE IT LU NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19971015 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19971015 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19971015 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19971015 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971015 |

|

| REF | Corresponds to: |

Ref document number: 159304 Country of ref document: AT Date of ref document: 19971115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59404316 Country of ref document: DE Date of ref document: 19971120 |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2108340 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19980115 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| EN | Fr: translation not filed | ||

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19971219 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19971015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980605 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D Ref document number: 76971 Country of ref document: IE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 19980703 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980704 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980704 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19980720 Year of fee payment: 5 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980731 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: RIETER INGOLSTADT SPINNEREIMASCHINENBAU AG Effective date: 19980714 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| BERE | Be: lapsed |

Owner name: ZELLWEGER LUWA A.G. Effective date: 19980731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990705 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20000131 |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20011004 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE DE DK ES FR GB GR IE IT LU NL PT SE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20020603 |

|

| EN | Fr: translation not filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20060629 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060731 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070704 |