EP0579923A1 - Dispositif de broyage en particulier pour débris de jardin - Google Patents

Dispositif de broyage en particulier pour débris de jardin Download PDFInfo

- Publication number

- EP0579923A1 EP0579923A1 EP93108159A EP93108159A EP0579923A1 EP 0579923 A1 EP0579923 A1 EP 0579923A1 EP 93108159 A EP93108159 A EP 93108159A EP 93108159 A EP93108159 A EP 93108159A EP 0579923 A1 EP0579923 A1 EP 0579923A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- comminution device

- funnel

- shredding

- cutting

- comminution

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/06—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives

- B02C18/16—Details

- B02C18/22—Feed or discharge means

- B02C18/2225—Feed means

- B02C18/2291—Feed chute arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C13/00—Disintegrating by mills having rotary beater elements ; Hammer mills

- B02C13/26—Details

- B02C13/282—Shape or inner surface of mill-housings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/06—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives

- B02C18/14—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives within horizontal containers

- B02C18/143—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives within horizontal containers with a disc rotor having generally radially extending slots or openings bordered with cutting knives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/06—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives

- B02C18/16—Details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C2201/00—Codes relating to disintegrating devices adapted for specific materials

- B02C2201/06—Codes relating to disintegrating devices adapted for specific materials for garbage, waste or sewage

- B02C2201/066—Codes relating to disintegrating devices adapted for specific materials for garbage, waste or sewage for garden waste

Definitions

- the invention relates to a shredding device, in particular for garden waste, with a housing which is provided with a main hopper for adding material to be shredded and optionally with a side hopper for filling and cutting coarser parts, with hammer-like shredding members and / or knife-like cutting members a drive device for the comminution and / or cutting members and with an outlet channel for the comminuted material.

- Shredding devices of this type are also referred to as shredders, choppers or hammer mills. They are used to shred and / or cut garden waste, e.g. Twigs, branches and other garden waste. Such devices are also very often used for composting plants.

- the present invention has for its object to provide a crushing device of the type mentioned, which is very easy to maintain with a simple and compact structure, in particular when blockages or other malfunctions occur can be removed easily and very quickly.

- the shredding device should be accident-proof and operationally safe.

- this task is characterized by Part of claim 1 mentioned features solved.

- the inventive division of the housing into an upper part and a lower part and the fact that they can be pivoted relative to one another provides easy and quick access to the interior of the device. All that is required for this is that the connecting links provided and required for operation are easily detachable or removable. This can e.g. in a simple manner by means of appropriate screw, bolt or pin connections with quick-release fasteners.

- the shredding device is of known construction, which is why only the parts essential to the invention are described in more detail below.

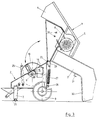

- the shredding device has a housing with an upper part 1 and a lower part 2.

- the upper part 1 is provided in the rear part with a main funnel 3, while in the front part a cover plate 4 forms an outlet channel for the comminuted material.

- a drive motor 5 is arranged on a horizontal section of the upper part 1 on a slide 6 which can be displaced in the horizontal direction (see arrows).

- the lower part 2 is provided with legs 7 in the front area and with wheels 8 in the rear area.

- a horizontal drive shaft 9 with a V-belt pulley 10 is inserted through the lower part 2 and is in drive connection with the drive motor 5 via a V-belt 12 with a V-belt pulley 11.

- a mudguard cover 13 is pushed over the two V-belt pulleys 10 and 11 and the V-belt 12.

- a side funnel 14 is also arranged laterally on the lower part 2 and communicates with the interior of the lower part 2 via an opening 15 in the side wall arranged on this side.

- the side funnel 14 is detachably connected to the lower part 2, for which purpose it can be inserted into side rails from above which are arranged on the side wall of the lower part 2.

- An elongated nose or bar 17 on the upper wall of the side funnel 14 rests on it and is positioned exactly.

- a disk 18 is arranged on the drive shaft 9 in the housing in front of the opening 15 and is provided with knife-like members.

- In a known manner on the drive shaft 9 there are a plurality of transverse bolts 19 distributed over the circumference between the disk 18 and others Disks 20 and 21 arranged.

- Hammer-like comminution members 22 are pivotally arranged on the cross bolts 19 next to one another and at a distance from one another, which are effective during the rotation of the drive shaft 9 due to the centrifugal effect.

- a horizontal pivot axis 23 is mounted in the lower part 2 behind the main funnel 3.

- the upper part 1 is also pivotally connected to the pivot axis 23.

- the connection is in the form of a hinge, as a result of which the upper part 1 can be pivoted or folded about the axis of the pivot axis 23.

- the upper part 1 can be folded backwards and away from the lower part 2, namely until the main funnel 3 lies with one of its filling edges on the floor. This ensures a safe and stable position when opened.

- upper part 1 and lower part 2 are connected to one another by one or more bolts 24 which are pushed horizontally through the housing and are correspondingly pushed through bores which are located in the side walls of upper part 1 and lower part 2 which overlap in this area are located.

- the bolts are also the locking bolts for one or more gratings 25 and 26 arranged in front of the outlet duct 4.

- a tension spring 27 is stretched laterally on the back between the upper part 1 and the lower part 2.

- the lower ends of the two tension springs 27 are tensioned in the lower part 2 in a U-rail via bolts 28 inserted through bores in the U-legs. Through several bores lying one above the other, the tension of the tension springs 27 can be changed if necessary by appropriately moving the bolts 28.

- the two tension springs 27 are each articulated to the upper part 1 via a pivot lever 29.

- the purpose of the two tension springs 27 is to ensure that the upper part 1 and lower part 2 are securely folded apart, in particular to prevent the lower part 2 from slipping or folding away. This danger is in fact present when a heavy-duty drive motor 5 possibly together with the Upper part 1 is pivoted. Since the drive motor 5 changes its center of gravity during the pivoting movement, the lower part 2 could suddenly suddenly fold away or slip away without the tension springs 27.

- the carriage 6 with the drive motor located on it is displaced in the horizontal direction in a first step until the V-belt 12 is relaxed so much in a second step that it can be removed, for which purpose the mudguard cover 13 has to be assumed beforehand .

- the side funnel 14 is pushed upward out of its side guide rails 16 and thus detached from the lower part 2 if it is perceived as disturbing. If necessary, it can also remain on the lower part 2.

- a fourth step bolts 24 are pulled out horizontally.

- the securing for the bolts or as a quick release for this can e.g. Serve pins (not shown) that secure the bolts 24 in the operating position and which are then pulled out.

- Fig. 3 which shows the opened state, the bores 30 are visible in a side wall of the upper part 1, through which bolts 24 are inserted in the operating position.

- the upper part 1 can be pivoted about the pivot axis 23, as a result of which access into the interior of the housing, in particular the knife-like cutting members and the hammer-like crushing members and the grating or gratings 25 and 26, is possible.

- the comminuting device After maintenance, cleaning or elimination of the malfunctions that have occurred, the comminuting device can be reassembled in the reverse order.

- the opening 15 is to be covered with a slide for safety reasons.

- a suspension device e.g. Provide in the form of a hook 31 on which, when the side funnel 14 is not used, it can be arranged under a filler neck 32 of the main funnel 3 in a non-disturbing manner. With an edge of the filler neck 32, the upper part 1 also sits securely on the floor in the folded state (see FIG. 3).

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Crushing And Pulverization Processes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4220245 | 1992-06-20 | ||

| DE19924220245 DE4220245A1 (de) | 1992-06-20 | 1992-06-20 | Zerkleinerungsvorrichtung, insbesondere für Gartenabfall |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0579923A1 true EP0579923A1 (fr) | 1994-01-26 |

Family

ID=6461464

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93108159A Withdrawn EP0579923A1 (fr) | 1992-06-20 | 1993-05-19 | Dispositif de broyage en particulier pour débris de jardin |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0579923A1 (fr) |

| CH (1) | CH681342A5 (fr) |

| DE (1) | DE4220245A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106563548A (zh) * | 2016-11-10 | 2017-04-19 | 无锡威格斯电气有限公司 | 一种小型粉碎机 |

| CN107258250A (zh) * | 2017-06-28 | 2017-10-20 | 徐州市沅和牧业有限责任公司 | 一种适应范围广的草料揉丝机 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4409446C2 (de) * | 1994-03-19 | 1996-01-11 | Neudorff W Gmbh Kg | Rotationssymmetrischer Hobelkopf und Zerkleinerungsvorrichtung |

| US6102312A (en) * | 1999-06-17 | 2000-08-15 | Aberle; David H. | Rotary hammer mill |

| DE102015011437A1 (de) | 2015-09-01 | 2017-03-02 | Julius Tielbürger GmbH & Co. KG | Gartenhäcksler mit einem Fahrgestell |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1548895A (fr) * | 1966-12-23 | 1968-12-06 | ||

| US3907216A (en) * | 1973-03-26 | 1975-09-23 | Amerind Mackissic Inc | Disintegration apparatus |

| DE8907251U1 (de) * | 1989-06-14 | 1989-08-03 | Maschinen- und Landmaschinenfabrik Husmann GmbH, 49762 Lathen | Vorrichtung zum Zerkleinern und Entsorgen von organ. Haus- und Gartenabfällen |

| EP0389249A1 (fr) * | 1989-03-21 | 1990-09-26 | Schiller-Pfeiffer, Inc. | Aspirateur-broyeur combiné pour feuilles et déchets de gazon et hache-bois |

-

1992

- 1992-06-20 DE DE19924220245 patent/DE4220245A1/de not_active Withdrawn

- 1992-08-21 CH CH260592A patent/CH681342A5/de not_active IP Right Cessation

-

1993

- 1993-05-19 EP EP93108159A patent/EP0579923A1/fr not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1548895A (fr) * | 1966-12-23 | 1968-12-06 | ||

| US3907216A (en) * | 1973-03-26 | 1975-09-23 | Amerind Mackissic Inc | Disintegration apparatus |

| EP0389249A1 (fr) * | 1989-03-21 | 1990-09-26 | Schiller-Pfeiffer, Inc. | Aspirateur-broyeur combiné pour feuilles et déchets de gazon et hache-bois |

| DE8907251U1 (de) * | 1989-06-14 | 1989-08-03 | Maschinen- und Landmaschinenfabrik Husmann GmbH, 49762 Lathen | Vorrichtung zum Zerkleinern und Entsorgen von organ. Haus- und Gartenabfällen |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106563548A (zh) * | 2016-11-10 | 2017-04-19 | 无锡威格斯电气有限公司 | 一种小型粉碎机 |

| CN107258250A (zh) * | 2017-06-28 | 2017-10-20 | 徐州市沅和牧业有限责任公司 | 一种适应范围广的草料揉丝机 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE4220245A1 (de) | 1993-12-23 |

| CH681342A5 (fr) | 1993-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3248687B1 (fr) | Desintegrateur a deux arbres comprenant un dispositif de changement rapide | |

| EP2012927A1 (fr) | Dispositif de desintegration | |

| DE3807983C2 (de) | Vorrichtung zum Zerkleinern | |

| EP1442796B1 (fr) | Dispositif de broyage | |

| EP0832554B1 (fr) | Moissonneuse-batteuse | |

| EP0674983A1 (fr) | Dispositif de granulation pour matériau filiforme | |

| EP2065091B1 (fr) | Désintégrateur de matériau | |

| DE4000887A1 (de) | Vorrichtung zum zerkleinern von material aller art, insbesondere brennbarer abfall wie stangenholz und aeste | |

| EP3912727A1 (fr) | Broyeur | |

| DE102010050786B3 (de) | Austragvorrichtung für eine Holzhackmaschine | |

| EP0579923A1 (fr) | Dispositif de broyage en particulier pour débris de jardin | |

| DE4315671C2 (de) | Zerkleinerungsmaschine für Feststoffe mit paarweise umlaufenden Rollenschermessern | |

| WO1998028078A1 (fr) | Hachoir pourvu d'un dispositif de fixation | |

| EP0015877A1 (fr) | Dispositif de broyage d'ordures et procédé de fonctionnement dudit dispositif | |

| EP2708340B1 (fr) | Dispositif de tri pour des copeaux de bois | |

| DE102012006650A1 (de) | Zerkleinerungsvorrichtung | |

| DE10026825C2 (de) | Zerkleinerungsvorrichtung | |

| DE2947510C2 (fr) | ||

| EP4045189A1 (fr) | Appareil de broyage de charge d'alimentation fluide et procédé d'ouverture d'un tel appareil | |

| DE9210423U1 (de) | Zerkleinerungsvorrichtung, insbesondere für Gartenabfall | |

| CH415334A (de) | Zerkleinerungsmaschine für Fleisch oder andere zerkleinerungsfähige Nahrungsmittel und Genussmittel | |

| DE3211137A1 (de) | Zerkleinerungseinrichtung | |

| DE3123484C2 (de) | Zerkleinerungsvorrichtung für faseriges Gut | |

| DE2347354A1 (de) | Vorrichtung zum zerkleinern, streifenschneiden oder muerben von nahrungsmitteln | |

| DE19706425C1 (de) | Zerlegbare Laborschneidmühle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT DE FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19940308 |

|

| 17Q | First examination report despatched |

Effective date: 19950620 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19960103 |