EP0555792B1 - Procédé et dispositif de fabrication d'engrais à partir des marcs de raisins - Google Patents

Procédé et dispositif de fabrication d'engrais à partir des marcs de raisins Download PDFInfo

- Publication number

- EP0555792B1 EP0555792B1 EP19930101900 EP93101900A EP0555792B1 EP 0555792 B1 EP0555792 B1 EP 0555792B1 EP 19930101900 EP19930101900 EP 19930101900 EP 93101900 A EP93101900 A EP 93101900A EP 0555792 B1 EP0555792 B1 EP 0555792B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rape

- screw

- conveyance

- rotting

- subjected

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05F—ORGANIC FERTILISERS NOT COVERED BY SUBCLASSES C05B, C05C, e.g. FERTILISERS FROM WASTE OR REFUSE

- C05F5/00—Fertilisers from distillery wastes, molasses, vinasses, sugar plant or similar wastes or residues, e.g. from waste originating from industrial processing of raw material of agricultural origin or derived products thereof

- C05F5/002—Solid waste from mechanical processing of material, e.g. seed coats, olive pits, almond shells, fruit residue, rice hulls

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A40/00—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production

- Y02A40/10—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production in agriculture

- Y02A40/20—Fertilizers of biological origin, e.g. guano or fertilizers made from animal corpses

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/141—Feedstock

- Y02P20/145—Feedstock the feedstock being materials of biological origin

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/40—Bio-organic fraction processing; Production of fertilisers from the organic fraction of waste or refuse

Definitions

- the invention relates to a method according to the preamble of claim 1 and a device according to the preamble of claim 9.

- the grape marc is subjected to aerobic rotting and thereby in intervals of one or more weeks are mixed with fresh or temporarily stored grape pomace under anaerobic conditions in order to intensify the microbial rotting. In between can be moistened.

- the mass obtained in this way is dried in order to be able to separate the kernels later, for example by sieving, before they are ground and subjected to post-rotting and, if necessary, mixed again.

- wooden containers with metal bars or grids or expanded metal are used for ventilation and liquid return. If grape pomace is rotted microbially and only rearranged, mixed and stored, ie largely left to itself and the natural transformation, this takes a lot of time and space. A quick and profitable recovery of the grape pomace can hardly be realized.

- the grape marc is subjected to aerobic rotting before the mass is crushed.

- the cores are separated out after the rotting and drying and crushed for themselves.

- the invention has for its object to provide a method of the type mentioned and a device suitable for performing the method, which enable accelerated and thus profitable processing in large quantities of grape pomace to a fertilizer or a fertilizer and raw material for oil production.

- the stated object is achieved with a method according to claim 1 and with the device according to claim 9.

- the knowledge is taken into account that coarse constituents and especially the seeds in the grape pomace cannot be converted within a portable period of time by aerobic and anaerobic rotting, but remain largely unaffected even after years of rotting with shifting, mixing, watering and aerating.

- the grape pomace is deliberately mechanically processed, i.e.

- the screw conveyor achieves conditioning, homogenization and loosening which accelerates the conversion and which is extremely beneficial to the quality of the end product.

- the device according to the invention uses a screw conveyor line, in which the screw conveyor in its conveying channel takes over the work to be carried out with considerable time and effort in the rotting of the grape marc, with very good efficiency and in one pass, considerably more than before.

- the screw conveyor in its conveying channel takes over the work to be carried out with considerable time and effort in the rotting of the grape marc, with very good efficiency and in one pass, considerably more than before.

- the shear gaps along the screw conveyor line not only are the coarse combs crushed, but the baked-in cores are detached and at least partially damaged on their hard surfaces.

- there is extensive homogenization of the mass from which further high-quality fertilizers unexpectedly develop in further rotting processes.

- the physical processing of the grape pomace along the screw conveyor section enables the following core separation, fraction separation and drying steps to be effective, i.e. with a view to the rapid production of the fertilizer. With the device, practically unlimited quantities of grape pomace can be processed relatively quickly and with reasonable effort to produce high-quality products.

- the grape pomace starting material which has been rotted in about a year, is subjected to screw conveying in an intermediate stage and is processed, largely broken down into its individual parts and effectively homogenized.

- aerobic rotting takes place in a surface layer that reaches approx. 40 cm deep, this surface layer covering the core area of the grape pomace mass and only permitting aerobic rotting that takes place at low temperatures.

- the anaerobic rotting is promoted by expelling the lactic acid and air by rolling and / or pressing, so that an annoying odor after each stops for a short time.

- the homogenized and prepared intermediate material can be processed quickly and easily with a high throughput, eg re-rotting.

- the method step according to claim 3 is particularly favorable because the free-falling mass loosens well and mixes intimately, which is particularly advantageous for subsequent rotting.

- the caked, relatively fresh grape pomace is mechanically conditioned and processed during the screw conveying.

- the cores are detached from the combs and the other components.

- the mass becomes loose and homogeneous, so that fractions can subsequently be easily formed in which the individual components are present separately.

- it is dried to e.g. to achieve a residual moisture content of preferably 15%, which also enables subsequent storage without additional auxiliary measures. Without rotting the resulting product sustainably, it can be used as a soil improvement granulate that loosens the soil, supplies it with nutrients and important mineral and metal substances, and rots into valuable fertilizer in the soil.

- the remaining liquid biomass is mixed with liquid and brought to maturity, so that an effective liquid fertilizer or liquid soil conditioner results without disruptive core components.

- heated water shortens the conversion process, so that a fully developed liquid fertilizer results in only 2 to 4 days. The leached solids are simply filtered out.

- Paper sludge which is normally expensive to dispose of, is used beneficially to form an effective fertilizer with the grape pomace while controlling the pH.

- the paper sludge is mixed with the grape pomace by shearing and wilting during screw conveying to a homogeneous mass which can be fed to further rapid rotting or further process steps.

- the device according to claim 9 takes up little space to process large quantities of grape pomace and possibly also paper sludge in industrial processing.

- the screw conveyor section with its screw conveyor fitted into the conveyor channel at a sufficient distance is primarily assigned the task of mechanically conditioning the grape marc, namely wilting, shearing and intensive mixing during the conveyance.

- the embodiment of claim 10 is also important because the inclined rise of the screw conveyor section creates a favorable counter pressure in the mass, by means of which the components are effectively mixed, homogenized and processed, particularly in the case of wilting and shearing.

- the rise of the screw conveyor screw creates space underneath for filling the product obtained, whereby gravity can be used for this purpose, again aerate and mix.

- the grape pomace is processed intensively because ventilation, further mixing and loosening of the mass takes place between the sections of the screw conveyor section in the free-fall section, which is favorable for further conditioning in the following screw conveyor section.

- the overall height for the screw conveyor line is also reduced. A free fall height of approx. 1 m has proven to be sufficient.

- the measure of claim 12 is particularly important because the swirl track on the one hand helps with the conveyance, but on the other hand intensifies the mechanical processing of the grape marc so that the desired mixing, preparation and homogenization result.

- a core portion is separated out in the free-fall section, by means of a sieve, a blowing device or a flushing device.

- the remaining mass is largely core-free and quickly turns into a usable fertilizer (particle fertilizer or liquid fertilizer).

- the core fraction can also be separated at the end of the screw conveyor.

- either only the core fraction or the entire mass can be comminuted in such a way that, with a relatively short aerobic rotting, a high-quality fertilizer is formed in which there are no longer whole kernels.

- crushing which is done, for example, with a clod crusher or a special mill, larger core components or leaf components or shell components are crushed in such a way that they form important small particles with a large surface area for effective rotting.

- the separation according to claim 16 can be carried out particularly expediently, drying and separation being carried out successively.

- An air dryer, a warm air drum or surface dryer or a continuous dryer is expediently used in order to achieve a high drying performance with a short drying time.

- a larger amount of grape pomace T has been stored in a rent 1 for about 1 year.

- aerobic rotting has taken place in an approximately 40 cm deep surface layer 2.

- the surface layer 2 lies like a shell around a core area 3 of the rent 1.

- the rent 1 was pressed several times with a roller or press 4, so that air and lactic acid were expelled from the core area 3 and unpleasant smells could only occur briefly.

- the grape pomace T is then poured into a container 6 in batches. 5 paper sludge P can be added with a conveyor device.

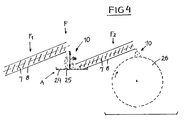

- a screw conveyor section F extends from the container 6 to a free-fall mixing device 10.

- the screw conveyor section F rises and contains an expediently tubular conveyor and processing channel 8, in which a conveyor and processing screw 7 is rotatably arranged.

- the drive of the screw 7 is conventional and not shown.

- the screw turns are designed in such a way that they do not hit the pipe wall directly, but keep some distance.

- the material to be conveyed is pushed upwards by the screw due to the material that is being pushed.

- the wall of the channel 8 slows down the conveying speed, so that the grape marc T is thereby worked up intensively, processed, loosened, mixed and homogenized.

- the screw 7 is fitted into the channel 8 in such a way that effective shear and walk gaps result, in which the kernels K are detached from the grape pomace T and in some cases are already damaged on their hard surfaces.

- the processing of the grape pomace T becomes even more intensive when the channel inner wall 9 is covered with a rising swirl track 42 which approximately corresponds to the screw turn.

- the homogenized and prepared mass is loosened again and mixed intensively.

- a collecting surface 11 is provided, on which the homogenized material is collected.

- a screening device 13 is provided here, with which the core portion can be separated.

- a separating device 12 can also be provided for separating out the cores, for example a blowing device which blows away the lighter components so that the heavier cores K remain. It is also conceivable to have one here Arrange a float that separates the heavier cores and sweeps away the lighter components.

- the entire homogenized mass can be collected on the collecting surface 11, which is then fed to a shredder S. becomes.

- the shredder S can be a clod crusher or a hammer mill. In a shredder S or clod crusher, the larger parts are broken up and the mass is totally homogenized.

- the cores K are also prepared accordingly for rapid subsequent aerobic rotting. The entire material is crushed in a hammer mill, whereby the cores and the larger comb parts are ground into small parts, which enables very rapid subsequent aerobic decomposition. Homogenization is also carried out again.

- the mass obtained in this way is collected in containers B for rotting, with relatively short post-rotting times being sufficient to produce a high-quality fertilizer D.

- the containers B have coarse-mesh grid walls 14 and an inner lining made of jute or perforated cardboard 15.

- relatively fresh grape pomace T is subjected to the screw conveyance through the screw conveying path F according to FIG.

- the individual components are largely separated and processed by mechanical shearing and milling.

- the processed mass is loosened, mixed and homogenized before it is collected on a surface 16 and - as indicated by arrows 17 - dried. Drying takes place with air or in a drum with warm air or in a surface dryer or continuous dryer. The dried mass is then conveyed over sieve trays 18, 19, 20 with different mesh sizes, so that fractions I, II and III are formed which contain coarse particles (fraction I), core parts (fraction II) and fine particles (fraction III). Core fraction II can be separated out and used for oil production. However, it is also conceivable to independently process, grind or grind the core fraction shred and then return to the other two fractions.

- the end product obtained is a soil conditioner that also rots completely in the soil and thus brings in the valuable fertilizer substances.

- a container 21 with water 22 is provided behind the screw conveyor section F and the free-fall mixing device 10 in order to separate out the cores K thanks to their higher specific weight.

- the remaining components floating in the water are filled into containers 23, in which this biomass is mixed with further liquid and converted into a liquid fertilizer DF.

- the cores K can either be used for oil production or processed further for themselves and converted into fertilizer.

- the screw conveyor section F is divided into several sections F 1 and F 2 , between which at least one free-fall mixing device 10 is provided.

- the free fall height is at least 1 m.

- a sieve tray 25 can be provided in a collecting container 24 of the free-fall mixing device 10 in order to largely separate out the cores.

- a separating drum 26, for example a sieve drum is provided, with which the processed mass is divided into fractions.

- drying is carried out beforehand (not shown) in order to bring the dry substance to a residual moisture of approx. 15% and to make it storable. The residual moisture of 40% and more present in the processing of fresh grape pomace in this area of the device would not allow trouble-free storage.

- Paper sludge P can be used for both already deposited and fresh grape pomace T in order to largely neutralize the pH value of the mass.

- the heat generated can be used to heat Greenhouses or stables.

- the CO 2 produced during the rotting process can be used in greenhouses to promote plant growth. However, it is advisable to aerate the mass well during the reddening because the reddening decreases with increasing CO 2 content in the mass. The CO 2 is also expelled in the course of the screw conveyance, in the free-fall mixture and in the layering and filling processes, so that the rotting takes place quickly and effectively and leads to an excellent fertilizer.

- FIG. 5 shows a complete device V for processing grape pomace T (and possibly paper sludge P) which enables industrial production.

- the core of the device is the screw conveyor section F, which consists of two sections F 1 and F 2 which are connected to one another in a staggered manner and which are connected to one another via the free-fall mixing device 10 and which can also have a further free-fall mixing device.

- the free-fall mixing device 10 is formed by a chamber 10a, into which the first section F 1 opens at the top, whereas the second section F 2 opens at the bottom into the chamber 10a. In this way, the overall height is saved and the desirable effect of mixing, loosening and aeration of the grape marc when falling to the receiving side of the second section F 2 is achieved.

- the first section F 1 begins in the bottom area of the container 6, to the side of which a bulk trough 27 with a feed conveyor 28, expediently a screw conveyor, is attached.

- a further pouring trough 29 with a feed conveyor 30, expediently a further screw conveyor can be attached in order to be able to supply larger quantities or to be able to process paper sludge P at the same time.

- the second section F 2 ends on the discharge side in a raised housing 31, in which an upper sieve plate 32 and a lower, inclined sieve plate 33 are arranged below the discharge side of the second section F 2 .

- the lower sieve plate 33 is expediently designed with a mesh size in which only the Detached cores K fall through, while the remaining constituents fall obliquely downward into the housing 34 with the integrated shredder S.

- From the housing 34 extends down a tapered chute 36, at the lower end of which a pendulum mouthpiece 37 is attached, which can be moved back and forth by an unspecified drive in order to move the components falling down quickly into the container B. distribute, which is in the filling station L formed below the chute 36.

- the container B is elongated cuboid and open at the top and has coarse-meshed side walls 14 and an air-permeable wall lining 15 on the inside.

- a collecting funnel 38 for the falling-through cores is provided in the housing 31 and is connected to a bagging station 39. There, a sack 41 can be placed on a platform 40 for filling the separated cores.

- the container B is stackable, so that several such containers can be stacked for rotting. Furthermore, it either has wheels for moving or it is placed on a movable carriage.

- the pouring troughs 27 and 29 are expediently loaded with lorries or with shovel loaders.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Botany (AREA)

- Environmental & Geological Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Fertilizers (AREA)

- Processing Of Solid Wastes (AREA)

Claims (17)

- Procédé de fabrication d'engrais à partir de marc de raisin, dans lequel on soumet le marc de raisin à une fermentation et au moins une fois à un transport par vis, caractérisé par le fait qu'on prépare le marc de raisin mécaniquement par cisaillement et foulage lors d'un transport par vis dirigé obliquement vers le haut et le décompose dans une large mesure en ses différentes parties, c'est-à-dire rafles, pépins, peaux, et le mélange de façon intense.

- Procédé selon la revendication 1, caractérisé par les étapes suivantes :on stocke le marc de raisin pendant environ un an sous la forme d'une meule pour sa fermentation anaérobie,pendant ce stockage, pour favoriser la fermentation anaérobie à l'intérieur de la meule, on chasse au moins une fois l'air et l'acide lactique par cylindrage ou pressage,après la fermentation, on soumet le marc de raisin à un traitement de cisaillement et de foulage au moyen du transport par vis etaprès le transport par vis, on broie le marc de raisin et éventuellement le soumet à une fermentation secondaire aérobie.

- Procédé selon l'une des revendications 1 et 2 ou les deux, caractérisé par le fait qu'après le transport par vis, on soumet le marc de raisin à une chute libre.

- Procédé selon au moins une des revendications 1 à 3, caractérisé par le fait qu'on sépare les pépins détachés lors du transport par vis par criblage, soufflage ou lavage par un courant d'eau et les traite pour la production d'huile.

- Procédé selon la revendication 1, caractérisé par les étapes suivantes :on soumet le marc de raisin à l'état frais au transport par vis et ensuite le divise en trois fractions, à savoir éléments fins, gros éléments et pépins.

- Procédé selon la revendication 5, caractérisé par le fait qu'on sépare la fraction pépins par lavage par un courant d'eau, et qu'on transforme la matière liquide restante des deux autres fractions en engrais liquide dans des récipients avec du liquide supplémentaire.

- Procédé selon au moins une des revendications 1 à 5, caractérisé par le fait qu'on maintient le marc de raisin travaillé mécaniquement à pépins écrasés ou broyés pendant 48 à 84 heures dans de l'eau chauffée à environ 50 à 60 °C et ensuite met l'eau en récipients comme engrais liquide en la faisant passer à travers un filtre.

- Procédé selon les revendications 1 à 7, caractérisé par le fait qu'avant le transport par vis, on ajoute au marc de raisin de la boue de papier et/ou des déchets organiques.

- Dispositif (V) pour la mise en oeuvre du procédé de la revendication 1, dans lequel est prévu pour le marc de raisin (T) au moins un transporteur à vis (F) qui présente une vis transporteuse placée dans un canal de transport, caractérisé par le fait que la vis transporteuse (7) est ajustée dans le canal de transport (8) avec formation d'interstices de cisaillement et de foulage pour le travail mécanique du marc de raison pendant son transport.

- Dispositif selon la revendication 9, caractérisé par le fait que le transporteur à vis (F) monte obliquement dans la direction de transport.

- Dispositif selon l'une des revendications 9 et 10, caractérisé par le fait que le transporteur à vis (F) présente plusieurs tronçons se faisant suite (F1, F2), et qu'entre au moins deux tronçons (F1, F2) est prévu un trajet de chute libre (10).

- Dispositif selon au moins une des revendications 9 à 11, caractérisé par le fait que la paroi intérieure (9) du canal de transport (8) est pourvue d'un piste hélicoïdale (42).

- Dispositif selon la revendication 10, caractérisé par le fait que dans le trajet de chute libre (10) est prévu un dispositif de séparation des pépins (A) comportant un crible (11, 13), un dispositif de soufflage (12) et/ou un dispositif de lavage par courant d'eau (21).

- Dispositif selon au moins une des revendications 9 à 13, caractérisé par le fait qu'à l'extrémité du transporteur à vis (F) est prévu un broyeur (S).

- Dispositif selon la revendication 9, caractérisé par le fait qu'à l'extrémité du transporteur à vis (F) est placé un tambour cribleur (26) ou un dispositif de criblage (18, 19, 20 ; 32, 33) qui permet de former à partir du marc de raisin (T) des fractions (I, II, III), à savoir éléments fins, gros éléments et pépins.

- Dispositif selon la revendication 15, caractérisé par le fait qu'avant le tambour cribleur (26) est prévu un dispositif de séchage (17).

- Dispositif selon au moins une des revendications 9 à 16, caractérisé par le fait que sur un récipient (6) est prévue sur le côté au moins une auge de déversement (27, 29) dans laquelle est monté un transporteur (28, 30) d'alimentation en marc de raison (T) menant au récipient (6), que du fond du récipient (6) part un premier tronçon de transport (F1) qui va à une chambre (10a) formant le trajet de chute libre (10) dans laquelle le premier tronçon de transport (F1) débouche côté sortie en haut et le deuxième tronçon de transport (F2), faisant suite au premier, débouche côté entrée en bas, que le deuxième tronçon de transport (F2) débouche côté sortie dans une boîte située en hauteur (31) dans laquelle des surfaces de criblage (32, 33) sont placées avant le broyeur (s), et qu'au-dessous du broyeur (S) est prévu un poste de remplissage (L) pour le remplissage des récipients collecteurs (B).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4203720A DE4203720C2 (de) | 1992-02-08 | 1992-02-08 | Verfahren und Vorrichtung zum Herstellen eines Düngemittels aus Traubentrester |

| DE4203720 | 1992-02-08 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0555792A1 EP0555792A1 (fr) | 1993-08-18 |

| EP0555792B1 true EP0555792B1 (fr) | 1997-05-07 |

Family

ID=6451272

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19930101900 Expired - Lifetime EP0555792B1 (fr) | 1992-02-08 | 1993-02-08 | Procédé et dispositif de fabrication d'engrais à partir des marcs de raisins |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0555792B1 (fr) |

| AT (1) | ATE152703T1 (fr) |

| DE (2) | DE4203720C2 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2078879B1 (es) * | 1994-05-09 | 1996-07-16 | Construcciones Vento S C Ltda | Procedimiento integral para depuracion de aguas residuales en destilerias. |

| DE4427644A1 (de) * | 1994-08-04 | 1996-02-08 | Hese Gmbh Maschf Ernst | Verfahren und Vorrichtung zur Behandlung von organischen Bio-Reststoffen |

| DE4444745C1 (de) * | 1994-12-15 | 1996-08-22 | Lehmann Maschbau Gmbh | Verfahren zur Herstellung von hochwertigem Pflanzsubstrat |

| US20120040328A1 (en) * | 2009-01-28 | 2012-02-16 | Michael Niederbacher | Fermenter feed system for fermentable biomass of a biogas system and method for operating the feed system |

| EP2792739B1 (fr) * | 2013-04-15 | 2021-03-24 | BTS Biogas Srl/GmbH | Installation de biogaz dotée d'un dispositif d'alimentation en ferments |

| DE102020007220A1 (de) | 2020-11-25 | 2022-05-25 | Asam Betriebs-GmbH | Verfahren zum Herstellen eines Huminsäureextraktes sowie Huminsäureextrakt |

| CN118579449B (zh) * | 2024-08-02 | 2024-10-18 | 连云港龙塔研磨材料有限公司 | 一种用于碳化硅微粉研磨的原料输送装置及其输送方法 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE675866C (de) * | 1934-05-13 | 1939-05-19 | Robert Feix | Verfahren zur Herstellung organischer Duengemittel aus Obstrueckstaenden |

| FR928584A (fr) * | 1946-06-04 | 1947-12-02 | Procédé d'utilisation et de valorisation des sous-produits de la vinification | |

| DE946547C (de) * | 1953-09-22 | 1956-08-02 | Willard L Morrison | Verfahren und Vorrichtung zur Kompostierung von organischen Duengermassen |

| FR1426053A (fr) * | 1959-01-29 | 1966-01-28 | Produit obtenu à partir des marcs de vinification et de distillation-fabrication | |

| US3140920A (en) * | 1961-03-14 | 1964-07-14 | Jr John K Barrow | Apparatus for continuously producing a fertilizer mixture |

| DE1592662A1 (de) * | 1967-12-16 | 1971-01-21 | Rolando Giallombardo | Verfahren zur Herstellung organischer Duengemittel und nach diesem Verfahren hergestelltes organisches Duengemittel |

| AT344210B (de) * | 1976-07-07 | 1978-07-10 | Graefe Gernot | Verfahren zur herstellung von hochwertigem duenger aus obstrueckstaenden durch deren aerobe vergaerung |

| DE2729379C2 (de) * | 1976-07-07 | 1987-03-26 | Gernot Dr.rer.nat. Donnerskirchen Graefe | Verfahren zur Herstellung eines Düngemittels aus Traubentrester |

| AT359530B (de) * | 1979-03-27 | 1980-11-10 | Graefe Gernot | Mittel zur herstellung hochwertigen duengers, verfahren zur herstellung des mittels, anwendung des mittels und erzeugung von duenger unter verwendung des mittels |

| GR67223B (fr) * | 1979-03-27 | 1981-06-25 | Graefe Gernot | |

| AT372067B (de) * | 1980-09-11 | 1983-08-25 | Graefe Gernot | Verfahren zur herstellung von duenger und nuetzlichen nebenprodukten |

| DE3400988A1 (de) * | 1984-01-13 | 1985-07-18 | Rudolf 5160 Düren Ociepka | Verfahren zur herstellung von hochwertigem duenger |

| DE3844737C2 (en) * | 1987-05-19 | 1991-10-02 | Georg 2807 Achim De Neumann | Compost bin |

| DE59103379D1 (de) * | 1990-02-05 | 1994-12-08 | Mfe Marienfelde Gmbh | Holz- und/oder Trestergranulat und dessen Verwendung. |

-

1992

- 1992-02-08 DE DE4203720A patent/DE4203720C2/de not_active Expired - Fee Related

-

1993

- 1993-02-08 DE DE59306356T patent/DE59306356D1/de not_active Expired - Fee Related

- 1993-02-08 AT AT93101900T patent/ATE152703T1/de not_active IP Right Cessation

- 1993-02-08 EP EP19930101900 patent/EP0555792B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| ATE152703T1 (de) | 1997-05-15 |

| DE59306356D1 (de) | 1997-06-12 |

| EP0555792A1 (fr) | 1993-08-18 |

| DE4203720C2 (de) | 1994-10-20 |

| DE4203720A1 (de) | 1993-08-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0082815B2 (fr) | Procédé pour séparer au moins une fraction des ordures municipales et dispositif pour la mise en oeuvre du procédé | |

| DE2616725A1 (de) | Verfahren und einrichtung zum herstellen von briketts | |

| EP0555792B1 (fr) | Procédé et dispositif de fabrication d'engrais à partir des marcs de raisins | |

| DE3802499C2 (fr) | ||

| DE3802011A1 (de) | Verfahren und hilfsvorrichtung zur aufbereitung organischer abfaelle | |

| EP0773914B1 (fr) | Procede et dispositif de traitement de residus organiques biologiques | |

| CH632227A5 (en) | Plant for composting a mixture of sewage sludge and waste material containing household rubbish | |

| DE102011114232A1 (de) | Verfahren und Anlage zur Verwertung von Biomasse | |

| DE2415068A1 (de) | Verfahren zur kompostierung von muell und anderen abfaellen | |

| EP1226883A1 (fr) | Procédé de tri d'un mélange de déchets | |

| DE4312923A1 (de) | Verfahren zur Aufbereitung von als Bio-Wertstoffe anfallenden, aus pflanzlichen Stoffen bestehenden Abfallprodukten und von aus pflanzlichen Stoffen hergestellten Produkten, insbesondere Nahrungsmittelabfällen, zu wiederverwertbaren Stoffen | |

| CH635304A5 (de) | Verfahren zur aufbereitung und hygienisierung von muell-klaerschlammgemischen mittels kompostierung. | |

| DE3912474C2 (fr) | ||

| DE3736889A1 (de) | Verfahren zum aufbereiten von organischen abfaellen durch verrottung | |

| EP3535231A1 (fr) | Procédé et dispositif de valorisation d'excréments d'animaux | |

| DE3531605A1 (de) | Reaktor zur behandlung organischer massen und verfahren zur erzielung mehrerer zwischen- und endprodukte aus diesen massen | |

| DE60119677T2 (de) | Verfahren und Vorrichtung zur Behandlung von festen Siedlungsabfällen | |

| DE3634476C2 (fr) | ||

| DE102004052726B3 (de) | Verfahren zur Herstellung eines organischen N/P/K-Düngers | |

| EP1094048B1 (fr) | Procédé et appareil pour le traitement de matières à composter | |

| EP0152524B1 (fr) | Procédé de compostage de détritus organiques | |

| EP0613870A1 (fr) | Procédé de recupération des matières végétales contenant de l'eau | |

| AT240886B (de) | Verfahren und Vorrichtung zum Aufbereiten von Müll für Düngemittel | |

| EP0581992A1 (fr) | Procédé de transformation des matériaux organiques structurés et non structurés en humus | |

| DE1137451B (de) | Verfahren zum Kompostieren von Muell zu Duengemitteln |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE ES FR IT LI |

|

| 17P | Request for examination filed |

Effective date: 19930719 |

|

| 17Q | First examination report despatched |

Effective date: 19950526 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19970507 Ref country code: FR Effective date: 19970507 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19970507 |

|

| REF | Corresponds to: |

Ref document number: 152703 Country of ref document: AT Date of ref document: 19970515 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59306356 Country of ref document: DE Date of ref document: 19970612 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980228 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20040423 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050901 |