EP0554519A2 - Grounding terminal - Google Patents

Grounding terminal Download PDFInfo

- Publication number

- EP0554519A2 EP0554519A2 EP92118478A EP92118478A EP0554519A2 EP 0554519 A2 EP0554519 A2 EP 0554519A2 EP 92118478 A EP92118478 A EP 92118478A EP 92118478 A EP92118478 A EP 92118478A EP 0554519 A2 EP0554519 A2 EP 0554519A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- conductor terminal

- protective conductor

- contact foot

- terminal according

- spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000004020 conductor Substances 0.000 claims abstract description 26

- 230000001681 protective effect Effects 0.000 claims abstract description 25

- 239000002184 metal Substances 0.000 claims abstract description 13

- 229910052751 metal Inorganic materials 0.000 claims abstract description 13

- 239000007787 solid Substances 0.000 claims abstract description 7

- 239000011810 insulating material Substances 0.000 claims description 3

- 239000000463 material Substances 0.000 claims description 2

- 230000003993 interaction Effects 0.000 abstract 1

- 230000014759 maintenance of location Effects 0.000 abstract 1

- 239000000725 suspension Substances 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 229910000881 Cu alloy Inorganic materials 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/26—Clip-on terminal blocks for side-by-side rail- or strip-mounting

- H01R9/2608—Fastening means for mounting on support rail or strip

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/26—Clip-on terminal blocks for side-by-side rail- or strip-mounting

- H01R9/2691—Clip-on terminal blocks for side-by-side rail- or strip-mounting with ground wire connection to the rail

Definitions

- the invention relates to a protective conductor terminal with a busbar arranged in an insulating material housing, equipped with conductor connections, and with a fastening and contact foot connected to the busbar, which has hook elements and spring means for interacting with the mounting rail legs for mechanical and electrical connection to a mounting rail serving as a protective conductor busbar .

- the contact foot can not only take over the electrical but also the mechanical connection to the mounting rail, specifically for the terminal as a whole, so that the foot region of its insulating housing is kept very simple can, but the contact foot has a complicated and expensive to manufacture. It is a double-leg, complicated sheet metal bent part, in which a spring to be manufactured separately must be installed in the manner of a leaf spring. The reliable hold on the mounting rail to be achieved in particular by the hook elements of the bent sheet metal part is therefore achieved with considerable design effort.

- a separate spring must also be installed in this massive metal part as spring means. If you design the connection between the spring and the solid metal part simply, for example, by a simple tensioning process, it can happen that the spring loses its hold in the metal part when the clamp is moved in the longitudinal direction on the mounting rail.

- the present invention is therefore based on the object to provide a protective conductor terminal of the generic type, the mounting and contact foot is particularly easy to manufacture while ensuring a reliable hold of the mounting rail.

- Such a contact foot is a one-piece solid metal part on which spring means no longer have to be mounted separately.

- the molded hook elements give a reliable hold on the mounting rail, and it has been found that the spring struts formed integrally on the solid metal part, starting from the material usually used here, for example a copper alloy, due to their geometry, for. B. as integrally molded struts can certainly perform the desired function, that is, on the one hand, have the required spring action and, on the other hand, are also sufficiently elastic for easy handling.

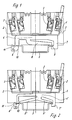

- the protective conductor terminals shown in Figures 1 and 2 have the usual insulating housing 1, in which busbars 2 are inserted, which are equipped with conductor connections 3 of any known type.

- the busbars 2 are electrically and mechanically firmly connected to a fastening and contact foot 4, 4 ', which in turn serves for the electrical connection of the busbar and the mechanical connection of the terminal as a whole with a mounting rail 5, which in such protective conductor terminals serves as a protective conductor busbar.

- the fastening and contact foot 4 has two hook elements 6 and 7, which practically have spring action due to their shape.

- a particularly long strut 8 in one piece. It begins on one side in the vicinity of the hook element 6 and runs from there over a considerable part of the mounting rail width to the other hook element 7.

- the hook element 7 has a bearing slope 9 which is dimensioned so long that space of different lengths and different thicknesses of mounting rails for different mounting rails can be accommodated.

- the strut 8 acts on the top of the support rail leg lying on the bearing slope 9.

- the opposite hook element 6, which serves as a fixed bearing, has a control slope 10, which is followed by a groove-like receptacle 11 for the free end of the other mounting rail leg.

- the fastening and contact foot is first connected in an inclined position to the hook element 7 and the spring strut 8 to the corresponding mounting rail leg.

- the other mounting rail leg runs along the control bevel 10 towards the receptacle 11, with other mounting rail legs correspondingly pushing up on the bevel 9 of the hook element 7.

- the end position is secured by the spring strut 8.

- carrier rail legs of different configurations can thus be used.

- the fastening and contact foot 4 maintains a simple profile and has a particularly long spring strut 8, which is therefore particularly suitable for the intended function.

- FIG. 2 a protective conductor terminal of basically the same construction is shown in FIG. 2, which now has a fastening and contact foot 4 ′, which, starting from approximately the central region, has two shorter spring struts 8 ′ and 8 ′′, each of which stretches from there to one of the mounting rail legs to get lost and with the top of which work together.

- the hook elements 6 and 7 are held in their geometry so that they also have spring action again.

- the hook elements 6 and 7 thus again act like suspension struts.

- the overall required and desired spring strut effect can thus be distributed over a total of four spring-acting elements, with which one can achieve a particularly secure suspension on the mounting rail with good handling with respect to the locking on the mounting rail with a corresponding design.

- a fastening and contact foot 4 ′′ is provided, in which the one hook element 7 ′ has an extended spring travel.

- the hook element 7 ' is extended laterally beyond the mounting rail and then bent back again in a C-shape to the corresponding mounting rail leg.

- the hook element 7 ' At its end interacting with this mounting rail leg, the hook element 7 'has a bearing slope 9'.

- due to the longer spring travel of the hook element 7 ' it is particularly possible to ensure tolerance compensation for the different dimensions of the mounting rails.

- only one spring strut 8 ''' is again provided, which, however, can be relatively short in itself with regard to the suspension properties of the arrangement and is shown in FIG Exemplary embodiment extends approximately from the center of this fastening and contact foot 4 ′′ to the C-shaped hook element 7 ′.

Landscapes

- Connections Arranged To Contact A Plurality Of Conductors (AREA)

- Elimination Of Static Electricity (AREA)

- Mounting Components In General For Electric Apparatus (AREA)

- Insulated Conductors (AREA)

Abstract

Description

Die Erfindung betrifft eine Schutzleiterklemme mit einer in einem Isolierstoffgehäuse angeordneten, mit Leiteranschlüssen bestückten Stromschiene und einem mit der Stromschiene verbundenen Befestigungs- und Kontaktfuß, der zur mechanischen und elektrischen Verbindung mit einer als Schutzleiter-Sammelschiene dienenden Tragschiene Hakenelemente und Federmittel zum Zusammenwirken mit den Tragschienenschenkeln aufweist.The invention relates to a protective conductor terminal with a busbar arranged in an insulating material housing, equipped with conductor connections, and with a fastening and contact foot connected to the busbar, which has hook elements and spring means for interacting with the mounting rail legs for mechanical and electrical connection to a mounting rail serving as a protective conductor busbar .

Bei einer bekannten Schutzleiterklemme der gattungsgemäßen Art (EP 0 233 458 A1) kann zwar der Kontaktfuß nicht nur die elektrische, sondern auch die mechanische Verbindung zu der Tragschiene übernehmen, und zwar für die Klemme insgesamt, so daß der Fußbereich ihres Isolierstoffgehäuses sehr einfach gehalten werden kann, doch hat der Kontaktfuß einen komplizierten und in der Herstellung teuren Aufbau. Es handelt sich um ein doppelschenkliges, kompliziertes Blechbiegeteil, in das eine gesondert herzustellende Feder in Art einer Blattfeder einmontiert werden muß. Der insbesondere durch die Hakenelemente des Blechbiegeteiles zu erreichende zuverlässige Halt auf der Tragschiene wird von daher mit einem erheblichen konstruktiven Aufwand erreicht.In a known protective conductor terminal of the generic type (EP 0 233 458 A1), the contact foot can not only take over the electrical but also the mechanical connection to the mounting rail, specifically for the terminal as a whole, so that the foot region of its insulating housing is kept very simple can, but the contact foot has a complicated and expensive to manufacture. It is a double-leg, complicated sheet metal bent part, in which a spring to be manufactured separately must be installed in the manner of a leaf spring. The reliable hold on the mounting rail to be achieved in particular by the hook elements of the bent sheet metal part is therefore achieved with considerable design effort.

Es ist zwar auch schon eine Schutzleiterklemme bekannt geworden (DE-GM 77 12 331), bei der als Verbindungsstück zwischen der Stromschiene der Klemme und der Tragschiene ein massives Metallteil vorgesehen ist, doch wirkt dieses massive Metallteil aufgrund seiner Formgestalt für die mechanische Verbindung mit der Tragschiene nur so unzureichend zusammen, daß für die mechanische Verbindung auch besondere Montagefußgestaltungen am Isolierstoffgehäuse der Klemme erforderlich sind.Although a protective conductor terminal has already become known (DE-GM 77 12 331), in which a solid metal part is provided as a connecting piece between the busbar of the terminal and the mounting rail, this solid metal part acts due to its shape for the mechanical connection with the Support rail only insufficiently together that for the mechanical connection also special mounting base designs on the insulating housing of the terminal are required.

Ferner muß auch in dieses massive Metallteil als Federmittel wieder eine gesonderte Feder einmontiert werden. Gestaltet man die Verbindung zwischen Feder und massivem Metallteil beispielsweise durch einen einfachen Verspannvorgang einfach, kann es bei einem Verschieben der Klemme in Längsrichtung auf der Tragschiene dazu kommen, daß die Feder ihren Halt im Metallteil verliert.Furthermore, a separate spring must also be installed in this massive metal part as spring means. If you design the connection between the spring and the solid metal part simply, for example, by a simple tensioning process, it can happen that the spring loses its hold in the metal part when the clamp is moved in the longitudinal direction on the mounting rail.

Der vorliegenden Erfindung liegt von daher die Aufgabe zugrunde, eine Schutzleiterklemme der gattungsgemäßen Art zu schaffen, deren Befestigungs- und Kontaktfuß bei Gewährleistung eines zuverlässigen Haltes der Tragschiene besonders einfach herzustellen ist.The present invention is therefore based on the object to provide a protective conductor terminal of the generic type, the mounting and contact foot is particularly easy to manufacture while ensuring a reliable hold of the mounting rail.

Die erfindungsgemäße Lösung ergibt sich aus dem kennzeichnenden Teil des Patentanspruches 1.The solution according to the invention results from the characterizing part of

Ein derartiger Kontaktfuß ist ein einstückiges massives Metallteil, an dem nicht mehr gesondert Federmittel montiert werden müssen. Die angeformten Hakenelemente geben einen zuverlässigen Halt auf der Tragschiene, wobei sich herausgestellt hat, daß die einstückig an das massive Metallteil angeformten Federbeine ausgehend von dem hier üblicherweise eingesetzten Material, beispielsweise einer Kupferlegierung, aufgrund ihrer Geometrie z. B. als einstückig angeformte Federbeine durchaus die gewünschte Funktion erfüllen können, also einerseits die erforderliche Federwirkung haben und andererseits auch noch ausreichend elastisch für eine bequeme Handhabung sind.Such a contact foot is a one-piece solid metal part on which spring means no longer have to be mounted separately. The molded hook elements give a reliable hold on the mounting rail, and it has been found that the spring struts formed integrally on the solid metal part, starting from the material usually used here, for example a copper alloy, due to their geometry, for. B. as integrally molded struts can certainly perform the desired function, that is, on the one hand, have the required spring action and, on the other hand, are also sufficiently elastic for easy handling.

Man kann grundsätzlich einen derartigen Kontaktfuß in seiner endgültigen Form aus einer Metallplatte entsprechender Dicke herausstanzen. Möglich ist jedoch eine Ausgestaltung, nach der der Kontaktfuß durch Abtrennen von einem entsprechenden Profilstrang erhalten wird. Die Herstellung des Kontaktfußes läßt sich auf diese Weise praktisch abfallfrei durchführen.You can basically punch out such a contact foot in its final form from a metal plate of appropriate thickness. However, a configuration is possible according to which the contact foot is obtained by separating it from a corresponding profile strand. The production of the contact foot can be carried out practically waste-free in this way.

Weitere bevorzugte Ausgestaltungen, die insbesondere Lage, Anzahl und Form der Federbeine betreffen, sind in den Unteransprüchen gekennzeichnet.Further preferred configurations, which relate in particular to the position, number and shape of the struts, are characterized in the subclaims.

Ausführungsbeispiele einer Schutzleiterklemme gemäß der Erfindung werden nachstehend unter Bezugnahme auf die beigefügte Zeichnung näher beschrieben.

Es zeigen:

Figur 1- eine Schutzleiterklemme gemäß der Erfindung in Seitenansicht auf die offene Klemmenseite,

Figur 2- eine weitere Ausführungsform einer Schutzleiterklemme in Seitenansicht,

Figur 3- eine weitere Ausführungsform einer Schutzleiterklemme in Seitenansicht.

Show it:

- Figure 1

- a protective conductor terminal according to the invention in side view on the open terminal side,

- Figure 2

- another embodiment of a protective conductor terminal in side view,

- Figure 3

- a further embodiment of a protective conductor terminal in side view.

Die in den Figuren 1 und 2 dargestellten Schutzleiterklemmen haben die üblichen Isolierstoffgehäuse 1, in die Stromschienen 2 eingesetzt sind, die mit Leiteranschlüssen 3 beliebiger, bekannter Bauart bestückt sind. Die Stromschienen 2 sind elektrisch und mechanisch fest mit einem Befestigungs- und Kontaktfuß 4, 4' verbunden, der seinerseits der elektrischen Verbindung der Stromschiene sowie der mechanischen Verbindung der Klemme insgesamt mit einer Tragschiene 5 dient, die bei derartigen Schutzleiterklemmen als Schutzleiter-Sammelschiene dient.The protective conductor terminals shown in Figures 1 and 2 have the usual

Bei dem in Figur 1 dargestellten Ausführungsbeispiel einer derartigen Schutzleiterklemme weist der Befestigungs- und Kontaktfuß 4 zwei Hakenelemente 6 und 7 auf, die aufgrund ihrer Formgebung praktisch Federwirkung haben. An den Befestigungs- und Kontaktfuß 4 ist bei dieser Ausführungsform ein besonders langes Federbein 8 einstückig angeformt. Es beginnt auf der einen Seite in der Nähe des Hakenelementes 6 und verläuft von dort über einen erheblichen Teil der Tragschienenbreite auf das andere Hakenelement 7 zu. Bei dieser Ausgestaltung hat das Hakenelement 7 eine Lagerschräge 9, die so lang bemessen ist, daß unterschiedlich lange und unterschiedlich dicke Tragschienenschenkel unterschiedlicher Tragschienen Platz finden. Das Federbein 8 wirkt auf die Oberseite des auf der Lagerschräge 9 liegenden Tragschienenschenkels. Das gegenüberliegende, als Festlager dienende Hakenelement 6 hat eine Steuerschräge 10, der eine nutartige Aufnahme 11 für das freie Ende des anderen Tragschienenschenkels folgt. Beim Aufsetzen der Klemme auf die Tragschiene wird der Befestigungs- und Kontaktfuß zunächst in Schräglage mit dem Hakenelement 7 und dem Federbein 8 mit dem entsprechenden Tragschienenschenkel in Verbindung gebracht. Beim Herunterdrücken läuft der andere Tragschienenschenkel längs der Steuerschräge 10 auf die Aufnahme 11 zu, wobei sich andere Tragschienenschenkel entsprechend auf der Lagerschräge 9 des Hakenelementes 7 hochschieben. Die Endlage wird durch das Federbein 8 gesichert.In the exemplary embodiment of such a protective conductor terminal shown in FIG. 1, the fastening and

Mit dieser Ausführungsform können somit Tragschienenschenkel unterschiedlicher Ausgestaltung verwendet werden. Der Befestigungs- und Kontaktfuß 4 behält eine einfache Profilierung und hat ein besonders langes und von daher für die gewollte Funktion besonders geeignetes Federbein 8.With this embodiment, carrier rail legs of different configurations can thus be used. The fastening and

Im Rahmen des Erfindungsprinzipes sind weitere bauliche Ausgestaltungen und Ausführungsformen ohne weiteres möglich, die jeweils an bestimmte Anwendungsfälle optimiert angepaßt werden können. So ist in Figur 2 eine Schutzleiterklemme grundsätzlich gleichen Aufbaus dargestellt, die nun einen Befestigungs- und Kontaktfuß 4' hat, der, ausgehend etwa vom mittleren Bereich, zwei kürzere Federbeine 8' und 8'' aufweist, die jeweils von dort auf einen der Tragschienenschenkel zu verlaufen und mit dessen Oberseite zusammenwirken. Bei dieser Ausgestaltung sind die Hakenelemente 6 und 7 in ihrer Geometrie so gehalten, daß auch sie wieder Federwirkung haben. Neben den beiden eigentlichen Federbeinen wirken somit auch wieder die Hakenelemente 6 und 7 wie Federbeine. Die insgesamt erforderliche und gewünschte Federbeinwirkung läßt sich also auf insgesamt vier federnd wirkende Elemente verteilen, womit man bei entsprechender Ausgestaltung eine besonders sichere abgefederte Halterung auf der Tragschiene bei guter Handhabbarkeit bezüglich der Verrastung auf der Tragschiene erreichen kann.Within the framework of the principle of the invention, further structural configurations and embodiments are readily possible, each of which can be optimally adapted to specific applications. Thus, a protective conductor terminal of basically the same construction is shown in FIG. 2, which now has a fastening and

Bei dem in Figur 3 dargestellten Ausführungsbeispiel ist ein Befestigungs- und Kontaktfuß 4'' vorgesehen, bei dem das eine Hakenelement 7' einen verlängerten Federweg aufweist. Hierzu ist im dargestellten Ausführungsbeispiel das Hakenelement 7' seitlich über die Tragschiene hinaus verlängert und dann wieder C-förmig zum entsprechenden Tragschienenschenkel rückgebogen. An seinem mit diesem Tragschienenschenkel zusammenwirkenden Ende hat das Hakenelement 7' eine Lagerschräge 9'. Bei dieser Ausgestaltung ist es aufgrund des verlängerten Federweges des Hakenelementes 7' in besonderem Maße möglich, einen Toleranzausgleich zu den unterschiedlich ausfallenden Abmaßen der Tragschienen zu gewährleisten. Durch diese C-förmige Ausgestaltung des Hakenelementes 7' wird in besonderem Maße eine Kraft in horizontaler Richtung eingebracht, die den Festanschlag des gegenüberliegenden Hakenelementes 6 immer zuverlässig gegen die Tragschiene zieht. Auch bei beträchtlichen Toleranzen für die Tragschienenabmaße wird dadurch sichergestellt, daß der metallische Teil der Baugruppe in jedem Fall auch ohne Mithilfe des Isolierstoffgehäuses 1 sicher auf der Tragschiene 5 sitzt.In the exemplary embodiment shown in FIG. 3, a fastening and

Bei dieser Ausführungsform ist ferner wieder nur ein Federbein 8''' vorgesehen, das im Hinblick auf die Federungseigenschaften der Anordnung im übrigen aber für sich genommen relativ kurz sein kann und sich im dargestellten Ausführungsbeispiel etwa von der Mitte dieses Befestigungs- und Kontaktfußes 4'' hin zu dem C-förmig ausgebildeten Hakenelement 7' erstreckt.In this embodiment, only one spring strut 8 '''is again provided, which, however, can be relatively short in itself with regard to the suspension properties of the arrangement and is shown in FIG Exemplary embodiment extends approximately from the center of this fastening and contact

Claims (9)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4203184A DE4203184C3 (en) | 1992-02-05 | 1992-02-05 | Protective conductor terminal |

| DE4203184 | 1992-02-05 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0554519A2 true EP0554519A2 (en) | 1993-08-11 |

| EP0554519A3 EP0554519A3 (en) | 1994-04-27 |

| EP0554519B1 EP0554519B1 (en) | 1996-09-18 |

Family

ID=6450956

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92118478A Expired - Lifetime EP0554519B1 (en) | 1992-02-05 | 1992-10-29 | Grounding terminal |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5334054A (en) |

| EP (1) | EP0554519B1 (en) |

| JP (1) | JP2509432B2 (en) |

| AT (1) | ATE143180T1 (en) |

| DE (2) | DE4203184C3 (en) |

| ES (1) | ES2092614T3 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6329335B1 (en) | 1997-03-07 | 2001-12-11 | Henkel Kommanditgesellschaft Auf Aktien | Detergent tablets |

| EP1357642A3 (en) * | 2002-04-26 | 2004-11-24 | WIELAND ELECTRIC GmbH | Connection device |

| CN109983627A (en) * | 2016-11-21 | 2019-07-05 | 菲尼克斯电气公司 | Busbar for connection terminal |

| EP3540861A1 (en) * | 2018-03-14 | 2019-09-18 | OMRON Corporation | Socket |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5425655A (en) * | 1993-10-20 | 1995-06-20 | The West Bend Company | Appliance enclosure and related terminal block |

| DE4409206C1 (en) * | 1994-03-17 | 1995-05-11 | Phoenix Contact Gmbh & Co | Base for an electrical protective-earth conductor terminal, as well as such a protective-earth conductor terminal |

| FR2732518B1 (en) * | 1995-03-29 | 1997-04-30 | Entrelec Sa | CONNECTION ARRANGEMENT FOR ELECTRICAL CONDUCTIVE WIRES AND MODULE, IN PARTICULAR OF THE JUNCTION BLOCK TYPE, EQUIPPED WITH SUCH AN ARRANGEMENT |

| DE59507650D1 (en) * | 1995-06-28 | 2000-02-24 | Siemens Ag | End bracket for securing the position of terminal blocks |

| US5816867A (en) * | 1996-08-22 | 1998-10-06 | Allen Bradley Company, Llc | Curved wire spring clamp with optimized bending stress distribution |

| DE19646696C1 (en) * | 1996-11-12 | 1998-04-30 | Puls Elektronische Stromversor | Fixing bracket for sheet-metal housing of electrical apparatus esp power supply unit |

| DE19708911C1 (en) * | 1997-03-05 | 1998-07-30 | Weidmueller Interface | Protective conductor connection |

| DE19729327C1 (en) * | 1997-07-09 | 1998-10-29 | Wieland Electric Gmbh | Protective conductor terminal/clamp |

| DE19818704C1 (en) * | 1998-04-19 | 1999-11-04 | Wago Verwaltungs Gmbh | Mounting foot with protective conductor function for electrical connector block |

| FR2792464B1 (en) * | 1999-04-15 | 2001-09-14 | Realisations Jlp | ELECTRICAL CONNECTION TERMINAL AND STRIP FORMED FROM A STACK OF SUCH TERMINALS |

| KR100322350B1 (en) * | 2000-01-19 | 2002-02-07 | 윤흥식 | link strip for terminal |

| DE10041279C2 (en) * | 2000-08-22 | 2002-11-21 | Phoenix Contact Gmbh & Co | Electrical terminal block |

| US6543957B1 (en) | 2000-09-14 | 2003-04-08 | Puls Elecktronische Stromversorgungen Gmbh | Holder and housing comprising at least one holder |

| GB2381132A (en) * | 2001-10-16 | 2003-04-23 | Channell Ltd | Telecommunication connector for connection to an earth rail |

| DE10315668B4 (en) * | 2002-08-28 | 2007-06-06 | Conrad Stanztechnik Gmbh | terminal |

| DE10324144B4 (en) * | 2003-05-26 | 2005-09-01 | Phoenix Contact Gmbh & Co. Kg | Electrical terminal and metallic protective conductor terminal for use in an electrical terminal |

| EP1615307A1 (en) * | 2004-07-06 | 2006-01-11 | Puls Elektronische Stromversorgungs GmbH | Holder for fixing a housing to a rail, and housing or electrical device comprising a holder |

| DE102005040657A1 (en) * | 2005-08-26 | 2007-03-15 | Phoenix Contact Gmbh & Co. Kg | Electrical connection terminal |

| JP4760429B2 (en) * | 2006-02-15 | 2011-08-31 | 富士電機機器制御株式会社 | Rail mounting structure for electrical equipment |

| JP2007299936A (en) * | 2006-04-28 | 2007-11-15 | Sunx Ltd | Attaching structure of electronic device |

| DE102006049019B4 (en) * | 2006-10-13 | 2009-11-26 | Phoenix Contact Gmbh & Co. Kg | Mounting plate with fixing means for an electrical device |

| DE102007041979B3 (en) * | 2007-09-05 | 2009-03-19 | Conrad Stanztechnik Gmbh | Conductor rail arrangement for electrical connection device, particularly neutral feeder clamp, protective conductor clamp or terminal clamp, has conductor rail which forms angled lug along one of bases of two longitudinal limbs |

| DE202008015309U1 (en) * | 2008-02-02 | 2009-08-13 | Weidmüller Interface GmbH & Co. KG | Mounting system for electrical and / or mechanical components |

| EP2086077A3 (en) * | 2008-02-02 | 2013-07-24 | Weidmüller Interface GmbH & Co. KG | Fitting system for electric and/or mechanical components |

| JP5043725B2 (en) * | 2008-03-14 | 2012-10-10 | 東洋技研株式会社 | Mounting rail fixing bracket |

| DE102009010918A1 (en) | 2009-02-27 | 2010-09-09 | Agfeo Gmbh & Co. Kg | Device for installing data transmission network over line, is fastened to support rail, where device comprises adapter and bell transformer, and support rail is cap rail, where line is current line |

| US8727797B2 (en) | 2009-09-29 | 2014-05-20 | Panduit Corp. | Rail adapter with grounding means |

| FR3026238B1 (en) * | 2014-09-23 | 2016-10-21 | Abb France | PART OF CONDUCTIVE BAR FOR AN ELECTRICAL APPLIANCE |

| DE102014115048A1 (en) * | 2014-10-16 | 2016-04-21 | Phoenix Contact Gmbh & Co. Kg | Terminal device with a busbar |

| DE102016113480A1 (en) * | 2016-07-21 | 2018-01-25 | Wago Verwaltungsgesellschaft Mbh | Metallic contact foot of a protective conductor connection element and protective conductor connection element |

| EP3376617B1 (en) * | 2017-03-14 | 2019-01-09 | Sick AG | Attachment device |

| GB2598948B (en) * | 2020-09-21 | 2022-10-12 | Hager Engineering Ltd | Connection device for an electrical apparatus |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH532253A (en) * | 1972-04-05 | 1972-12-31 | Oskar Woertz Inh H & O Woertz | Electrical clamp for attachment to a profile rail with flanges |

| DE7712331U1 (en) * | 1977-04-20 | 1977-11-17 | Wago-Kontakttechnik Gmbh, 4950 Minden | Terminal block for connecting and connecting electrical lines |

| CH629038A5 (en) * | 1978-06-13 | 1982-03-31 | Sprecher & Schuh Ag | Protective-earth conductor terminal strip for DIN rails |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR83883E (en) * | 1963-06-24 | 1964-10-31 | Telemecanique Electrique | Elastic device for fixing electrical terminals intended to be mounted in line on a c-shaped profile |

| DE7829303U1 (en) * | 1978-09-30 | 1981-11-05 | Wago-Kontakttechnik Gmbh, 4950 Minden | Device for snap fastening of electrical devices, terminal blocks or the like. on mounting rails |

| EP0233458B1 (en) * | 1986-01-23 | 1991-06-26 | Siemens Aktiengesellschaft | Protective-cable terminal |

| DE3732267C1 (en) * | 1987-09-25 | 1988-09-22 | Phoenix Elekt | Electrical terminal block |

| DE3805158A1 (en) * | 1988-02-15 | 1989-08-24 | Wago Verwaltungs Gmbh | SERIES TERMINAL FOR THE TWO-WIRE POWER SUPPLY OF ELECTRICAL OR ELECTRONIC COMPONENTS, IN PARTICULAR INITIATORS |

| DE3903752A1 (en) * | 1989-02-06 | 1990-08-09 | Wago Verwaltungs Gmbh | PROTECTIVE LADDER TERMINAL |

| DE58908455D1 (en) * | 1989-05-12 | 1994-11-03 | Weidmueller Interface | Terminal block arrangement. |

-

1992

- 1992-02-05 DE DE4203184A patent/DE4203184C3/en not_active Expired - Fee Related

- 1992-10-29 EP EP92118478A patent/EP0554519B1/en not_active Expired - Lifetime

- 1992-10-29 AT AT92118478T patent/ATE143180T1/en active

- 1992-10-29 DE DE59207184T patent/DE59207184D1/en not_active Expired - Lifetime

- 1992-10-29 ES ES92118478T patent/ES2092614T3/en not_active Expired - Lifetime

-

1993

- 1993-01-25 US US08/008,544 patent/US5334054A/en not_active Expired - Lifetime

- 1993-02-02 JP JP5015291A patent/JP2509432B2/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH532253A (en) * | 1972-04-05 | 1972-12-31 | Oskar Woertz Inh H & O Woertz | Electrical clamp for attachment to a profile rail with flanges |

| DE7712331U1 (en) * | 1977-04-20 | 1977-11-17 | Wago-Kontakttechnik Gmbh, 4950 Minden | Terminal block for connecting and connecting electrical lines |

| CH629038A5 (en) * | 1978-06-13 | 1982-03-31 | Sprecher & Schuh Ag | Protective-earth conductor terminal strip for DIN rails |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6329335B1 (en) | 1997-03-07 | 2001-12-11 | Henkel Kommanditgesellschaft Auf Aktien | Detergent tablets |

| EP1357642A3 (en) * | 2002-04-26 | 2004-11-24 | WIELAND ELECTRIC GmbH | Connection device |

| CN109983627A (en) * | 2016-11-21 | 2019-07-05 | 菲尼克斯电气公司 | Busbar for connection terminal |

| EP3540861A1 (en) * | 2018-03-14 | 2019-09-18 | OMRON Corporation | Socket |

| US10511109B2 (en) | 2018-03-14 | 2019-12-17 | Omron Corporation | Socket with locking parts to secure to a rail |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0554519B1 (en) | 1996-09-18 |

| EP0554519A3 (en) | 1994-04-27 |

| US5334054A (en) | 1994-08-02 |

| DE4203184A1 (en) | 1993-08-12 |

| ES2092614T3 (en) | 1996-12-01 |

| DE4203184C2 (en) | 1993-12-02 |

| JPH06318477A (en) | 1994-11-15 |

| DE4203184C3 (en) | 1996-11-21 |

| JP2509432B2 (en) | 1996-06-19 |

| DE59207184D1 (en) | 1996-10-24 |

| ATE143180T1 (en) | 1996-10-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0554519B1 (en) | Grounding terminal | |

| EP3745538A1 (en) | Conductor connecting terminal | |

| EP1100150B1 (en) | Spring clamp for large conductor cross-sections | |

| EP0334975B1 (en) | Conductor terminal | |

| DE4409206C1 (en) | Base for an electrical protective-earth conductor terminal, as well as such a protective-earth conductor terminal | |

| DE69905932T2 (en) | POWER RAIL FOR ELECTRICAL POWER DISTRIBUTION | |

| EP3282518A1 (en) | Spring-loaded terminal for contacting an electric conductor | |

| EP0086316B1 (en) | Plug-in contact device for the establishment of an electrical connection between two bus-bars | |

| DE69303065T2 (en) | Connector clamp with saddle of variable thickness and with a bordered nut | |

| EP3261185B1 (en) | Contact insert of a spring force terminal block and spring force terminal block | |

| DE3732267C1 (en) | Electrical terminal block | |

| AT506801B1 (en) | NH-FUSE CIRCUIT DEVICE | |

| EP1182735B1 (en) | Electrical terminal block | |

| DE102006041803B4 (en) | Device for attaching a device to a mounting rail | |

| DE19818704C1 (en) | Mounting foot with protective conductor function for electrical connector block | |

| DE7717019U1 (en) | Series disconnect terminal | |

| DE3418667A1 (en) | Terminal device having one or more connecting terminals for electrical contact elements, for transformers or the like | |

| DE2427476C3 (en) | Electrical switching equipment | |

| DE2701720C2 (en) | Toggle switch | |

| DE1246079B (en) | Connection terminal, especially in device sockets | |

| DE2039054B1 (en) | Electrical connection terminal, in particular high-current terminal block | |

| EP1026801B1 (en) | Break contact block for drawer type switchgear | |

| DE2051781A1 (en) | Screw terminals for electrical lines | |

| DE370088C (en) | Rotary switch with columnar base | |

| DE3128157C2 (en) | Electrical terminal block |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19940322 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19960229 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 143180 Country of ref document: AT Date of ref document: 19961015 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| REF | Corresponds to: |

Ref document number: 59207184 Country of ref document: DE Date of ref document: 19961024 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19961101 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2092614 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20101014 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20101022 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20101021 Year of fee payment: 19 Ref country code: IT Payment date: 20101026 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20111021 Year of fee payment: 20 Ref country code: FR Payment date: 20111103 Year of fee payment: 20 Ref country code: CH Payment date: 20111024 Year of fee payment: 20 Ref country code: ES Payment date: 20111026 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59207184 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59207184 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20121028 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 143180 Country of ref document: AT Kind code of ref document: T Effective date: 20121029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20121028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20121030 |