EP0534136B1 - Dispositif de fermeture avec capuchon de protection - Google Patents

Dispositif de fermeture avec capuchon de protection Download PDFInfo

- Publication number

- EP0534136B1 EP0534136B1 EP92114256A EP92114256A EP0534136B1 EP 0534136 B1 EP0534136 B1 EP 0534136B1 EP 92114256 A EP92114256 A EP 92114256A EP 92114256 A EP92114256 A EP 92114256A EP 0534136 B1 EP0534136 B1 EP 0534136B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cap

- closure according

- connecting element

- closure

- membrane

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J1/00—Containers specially adapted for medical or pharmaceutical purposes

- A61J1/05—Containers specially adapted for medical or pharmaceutical purposes for collecting, storing or administering blood, plasma or medical fluids ; Infusion or perfusion containers

- A61J1/10—Bag-type containers

Definitions

- the invention relates to a closure element according to the preamble of patent claim 1.

- US-A-4,899,903 describes a closure element in the form of a tube closure which has a cap which can be broken off via a line of weakness. In both cases, the closure element is pushed onto a part of the hose or tube which is tapered in cross section, which results in the disadvantage that the hose or tube must be specially adapted to the closure element. Another disadvantage arises with regard to the breaking off process itself, since it is not ensured that the free hose or pipe end is not damaged by the breaking off process.

- US Pat. No. 4,303,067 shows a closure element, in particular for a medical bag, which is welded between two bag films and has a breakable cap part.

- the disadvantage here is that the breakable cap part is not protected against unwanted actuation, so that when handling the bag there is a risk that the cap part breaks off at the predetermined breaking point.

- EP-A1-11 144 also shows a closure for a bag, in which a cap part or closure element can be separated from the connector part by means of a pull ring.

- This is a solution in which the closure element is torn open.

- the disadvantage is that on the one hand considerable forces are required for tearing open and on the other hand there is always the risk that the tear ring itself will tear off and / or the closure element will not be opened sufficiently. By applying a tensile force to open the closure, there is still the possibility that the remaining bag will be damaged or its contents may leak out in an undesired manner.

- AT-PS 322 113 describes a medical container, the dispensing opening of which is closed with a conical cap. The cap is pushed over the dispensing opening, no break-off arrangement is provided. It follows from this that sterilization and handling have many disadvantages.

- a container with a breakable cap part is also known from WO 84/03436.

- a closure element of the type specified in the preamble of claim 1 is known from US-A-4,915,704.

- the closure element designed as a tube closure has a cap which closes the outlet opening of a connector part and which can be broken off via a line of weakness.

- the known closure element also has a handle placed over the cap, which serves on the one hand as a protective cap and on the other hand as a calibration aid. The handle is held by the breakable part of the cap.

- the disadvantage is that the ingress of contaminating particles into the interior of the connector after breaking off the cap part cannot be prevented.

- the invention has for its object to provide a closure element of the type mentioned, which on the one hand allows undisturbed outflow of the fluid with simple and reliable handling and on the other hand prevents the penetration of contaminating particles or the like.

- the closure element according to the invention is characterized by a number of significant advantages.

- the closure membrane provides the possibility of continuing to seal the outlet opening of the hose or tube or of the container to the environment after breaking off the cap part. At least penetration of contaminating particles or the like is avoided, so that a fluid can flow out unhindered by the subsequent connection of the closure element to a connection element or the like.

- This has the further advantage that there is no need for additional closure or valve elements in the interior of the container, hose or tube can be.

- a detachable protective cap is applied over the cap part and at least part of the connector part.

- This protective cap prevents the cap part from accidentally breaking off and also serves as a tamper-evident device.

- the protective cap is screwed to the connector part by means of a thread. In this way, an easy and targeted loosening of the protective cap can be achieved without the risk that the operating personnel will accidentally break off the cap part when loosening the protective cap.

- the protective cap it is also possible to couple the protective cap to break off the cap part when the protective cap is loosened, for example by means of an integrated mechanism or the like, so that the cap part is broken off when the protective cap is removed or unscrewed.

- the closure membrane is designed as an elastic membrane. This can be made of rubber or the like, for example, so that the membrane can be pierced to remove the liquid.

- the membrane can also have a slotted design, as a result of which the individual wings of the membrane open when a pouring or draining element is inserted and enable an unimpeded flow of fluid.

- the connector part in the connection area of the cap part has a cylindrical recess of larger diameter than the channel-shaped recess into which the membrane is inserted and into which a pipe socket of the cap part can be inserted.

- the pipe socket of the cap part thus squeezes the disk-shaped closure membrane, so that it does not have to be attached by additional measures.

- a secure connection of the cap part to the connector part is ensured, which can be designed to be sufficiently tight to ensure an excellent seal during sterilization and in the sterilized state.

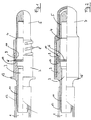

- the closure element shown in FIGS. 1 and 2 can be connected to a hose or tube 12, the tube or hose 12 not having to be adapted to the closure element. Rather, the closure element comprises a tubular connecting tube 11 which is bevelled on its front side and which can be inserted into the hose or the tube. Adjacent to the connecting pipe 11 is a collar 13 which serves as a stop for a protective cap 7 to be described below.

- the connecting pipe 11 has a free, central cross section, which is only slightly smaller than the cross section of the outlet opening 1 of the pipe or hose 12.

- a cylindrical tubular area Adjacent to the collar 13, a cylindrical tubular area is provided on the closure element, which has a cylindrical recess 9, the diameter of which is larger than the diameter of the connecting tube.

- the transition to the cylindrical recess 9 takes place via a shoulder 14, against which a disk-shaped closure membrane 6 can be placed.

- a pipe socket 10 is inserted, which, as can be seen from FIG. 1, clamps the closure membrane 6 together with paragraph 14.

- the pipe socket 10 is connected via a predetermined breaking point 4 to a cap part 5, which seals the outlet opening 1 or the central interior of the closure element to the environment and can be broken off if necessary.

- a thread 8 is provided, which can be single or multiple threads.

- the thread 8 serves to screw the protective cap 7 shown in FIG. 2 onto the closure element in order to cover both the cap part and the pipe socket 10 connected to it, and also the connector part 2 of the closure element and protect against damage.

- the closure element according to the invention has the following advantages: the flow rate through the channel-shaped recess 3 of the closure element can be greater than 1.5 l / min. Furthermore, no parts required for sealing are provided which can penetrate into the outlet opening 1 in an uncontrolled manner and thus into the container, the tube or the hose. In particular, additional sealing elements can essentially be dispensed with, otherwise the particulate loading of the sealing elements is zero. Furthermore, the cap part 5 ensures a tamper-evident closure, so that it can be easily and immediately determined whether the closure element has already been opened. Since the connector part 2 has a connecting tube 11, the closure element can be connected to any container, etc.

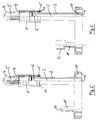

- FIGS. 3 to 6 relate to the closure element according to the invention. These embodiments differ from the embodiment of FIGS. 1 and 2 first in that an additional ring seal 15 is provided in order to seal the protective cap 7 against the connector part 2 when the closure cap 7 is screwed on. This seal makes it possible to screw the protective cap 7 on tightly even after the cap part 5 has broken.

- the tubular connector part 2 is provided with a flange 20.

- the exemplary embodiments further show that the tubular Connector part 2 is connected in one piece to a foot element 17, the channel-shaped recess 3 of the connector part 2 opening into an inlet chamber 16 of the foot element 17.

- the foot element 17 has a boat-like shape in plan view, it has two convexly outwardly curved side walls which converge at an acute angle on side edges 21, 22. The plate-like foot element 17 can thus be welded into the seam of a foil bag.

- cap part 5 can be provided with corrugation or profiling in order to facilitate the breaking off process.

- a filler neck 18 is also formed on the foot element 17, the interior of which is connected to the inlet chamber 16.

- the filler neck 18 is sealed from the environment by means of a pierceable closure part 19.

- the closure part 19 can, for example, as shown in Fig. 4, be in the form of a pierceable ball made of silicone or rubber. This is inserted into a cylindrical holder element 23, which is connected in one piece to the filler neck 18, and the ball is clamped by bending or flanging the edge of the holder element 23.

- the foot element 17 can be made of polycarbonate or a similar material, for example, in order to facilitate welding into a foil bag.

Landscapes

- Health & Medical Sciences (AREA)

- Hematology (AREA)

- Pharmacology & Pharmacy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Closures For Containers (AREA)

- Pens And Brushes (AREA)

- Air Bags (AREA)

- Cable Accessories (AREA)

Claims (12)

- Dispositif de fermeture pour un orifice de sortie (1) d'un récipient, d'un tuyau ou d'un tube, comportant

une pièce de jonction (2) pourvu d'un creux central en forme de canal (3) et susceptible d'être attachée à l'orifice de sortie (1),

une pièce de capuchon (5) bouchant ledit creux (3) vers l'extérieur, ayant un point destiné à la rupture (4) et étant jointe à ladite pièce de jonction (2) de manière détachable,

un capuchon de protection amovible (7) mis pardessus la pièce de capuchon (5) et pour le moins par-dessus une partie de la pièce de jonction (2),

ledit dispositif étant caractérisé en ce

que ladite pièce de jonction (2) est pourvue d'un filet extérieur (8) et ledit capuchon de protection (7) est boulonné à ladite pièce de jonction (2),

que ledit capuchon de protection (7) est rendue étanche vers ladite pièce de jonction (2) au moyen d'un anneau d' étanchéité (15), et

que l'on a disposé une membrane (6) dans ledit creux en forme de canal (3) de la pièce de jonction (2). - Dispositif de fermeture d'après la revendication 1, caractérisé en ce que la membrane (6) est développée comme membrane élastique.

- Dispositif de fermeture d'après la revendication 1 ou 2, caractérisé en ce que la membrane (6) est développée comme membrane fendue.

- Dispositif de fermeture d'après l'une des revendications 1 à 3, caractérisé en ce que, dans l'intention de casser la pièce de capuchon (5) lors de l'enlèvement du capuchon de protection (7), celui-ci est assemblé avec ladite pièce de capuchon (5).

- Dispositif de fermeture d'après l'une des revendications 1 à 4, caractérisé en ce que, au secteur de connexion de la pièce de capuchon (5), la pièce de jonction comporte un creux cylindrique (9) d'un diamètre plus grand que le creux en forme de canal, où la membrane est insérée et dans lequel on peut introduire une tubulure (10) de la pièce de capuchon (5).

- Dispositif de fermeture d'après la revendication 5, caractérisé en ce que, avec du serrage de la membrane, la tubulure (10) et la pièce de jonction (2) sont reliées l'une à lautre d'une manière directe et indissoluble.

- Dispositif de fermeture d'après l'une des revendications 1 à 6, caractérisé en ce que, pour son raccordement à l'orifice de sortie (1), la partie de jonction (2) est munie d'un tuyau de raccordement (11).

- Dispositif de fermeture d'après l'une des revendications 1 à 7, caractérisé en ce que la partie de jonction (2) est connectée à un élément de base (17) présentant une chambre d'admission (16).

- Dispositif de fermeture d'après la revendication 8, caractérisé en ce que l'élément de base (17) est développé sous la forme d'un élément aplati, avec deux faces latérales bombées et susceptible d'être soudé dans un sachet en feuille, d'où s'allonge la pièce de jonction (2) sous forme tubulaire.

- Dispositif de fermeture d'après l'une des revendications 8 ou 9, caractérisé en ce que l'élément de base (17) présente une tubulure de remplissage (18) connectée avec la chambre d'admission (16).

- Dispositif de fermeture d'après la revendication 10, caractérisé en ce que la tubulure de remplissage (18) est obturée au moyen d'un élément de fermeture (19) que l'on peut rouvrir.

- Dispositif de fermeture d'après la revendication 11, caractérisé en ce que l'élément de fermeture (19) est développé comme élément que l'on peut percer.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE9110460U | 1991-08-23 | ||

| DE9110460U DE9110460U1 (de) | 1991-08-23 | 1991-08-23 | Verschlußelement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0534136A1 EP0534136A1 (fr) | 1993-03-31 |

| EP0534136B1 true EP0534136B1 (fr) | 1996-07-03 |

Family

ID=6870549

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92114256A Expired - Lifetime EP0534136B1 (fr) | 1991-08-23 | 1992-08-20 | Dispositif de fermeture avec capuchon de protection |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0534136B1 (fr) |

| AT (1) | ATE139899T1 (fr) |

| DE (2) | DE9110460U1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3034062A1 (fr) | 2014-12-19 | 2016-06-22 | Fresenius Kabi Deutschland GmbH | Système de connecteur ayant au moins deux ports de prélèvement |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6019751A (en) * | 1998-01-20 | 2000-02-01 | Bracco Research Usa | Universal connector and a medical container |

| FR2833483B1 (fr) * | 2001-12-17 | 2004-09-24 | Technoflex Ind | Embout perfuseur pour poche souple a usage medical |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE789393Q (fr) * | 1966-02-25 | 1973-01-15 | Scherico Ltd | Distributeur combine distribuant des fluides sous forme de gouttelettes, d'une pulverisation ou d'une mousse |

| AT322113B (de) * | 1971-11-26 | 1975-05-12 | Roncales Sa | Behälter mit einem röhrchen zum einspritzen von arzneimitteln |

| US4000739A (en) * | 1975-07-09 | 1977-01-04 | Cordis Corporation | Hemostasis cannula |

| US4133312A (en) * | 1976-10-13 | 1979-01-09 | Cordis Dow Corp. | Connector for attachment of blood tubing to external arteriovenous shunts and fistulas |

| FR2396699A1 (fr) * | 1977-07-05 | 1979-02-02 | Aguettant Lab | Dispositif de bouchage et de raccordement d'un recipient contenant un liquide sterile |

| DE2817102C2 (de) * | 1978-04-19 | 1985-01-24 | Dr. Eduard Fresenius, Chemisch-pharmazeutische Industrie KG, 6380 Bad Homburg | Anschlußstück für Kunststoffkanülen oder Venenkatheter |

| JPS5519160A (en) * | 1978-07-28 | 1980-02-09 | Terumo Corp | Protector for sampling needle of blood body fluids sampler |

| DE7832028U1 (de) * | 1978-10-27 | 1979-04-19 | Biotest-Serum-Institut Gmbh, 6000 Frankfurt | Verschluss fuer einen plastikinfusionsloesungsbeutel |

| DE3000903C1 (de) * | 1980-01-11 | 1989-09-21 | Fresenius Chem Pharm Ind | Verbindungseinrichtung zum Anschluss von Kanuelen,Kathetern oder Schlaeuchen |

| US4303067A (en) * | 1980-01-21 | 1981-12-01 | American Hospital Supply Corporation | Medical liquid bag having an improved additive port |

| US4723687A (en) * | 1981-03-16 | 1988-02-09 | Franz Kutterer | Tube with screw cap |

| DE3277609D1 (en) * | 1982-01-07 | 1987-12-17 | Fresenius Ag | Preservation bag |

| SE8301193D0 (sv) * | 1983-03-04 | 1983-03-04 | Haustrup Plastic As | Behallare |

| DE3809127C1 (fr) * | 1988-03-18 | 1989-04-13 | B. Braun Melsungen Ag, 3508 Melsungen, De | |

| US4915704A (en) * | 1988-06-27 | 1990-04-10 | Terumo Kabushiki Kaisha | Tube assembly with a breakaway plug |

-

1991

- 1991-08-23 DE DE9110460U patent/DE9110460U1/de not_active Expired - Lifetime

-

1992

- 1992-08-20 EP EP92114256A patent/EP0534136B1/fr not_active Expired - Lifetime

- 1992-08-20 DE DE59206694T patent/DE59206694D1/de not_active Expired - Lifetime

- 1992-08-20 AT AT92114256T patent/ATE139899T1/de active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3034062A1 (fr) | 2014-12-19 | 2016-06-22 | Fresenius Kabi Deutschland GmbH | Système de connecteur ayant au moins deux ports de prélèvement |

| WO2016097346A1 (fr) | 2014-12-19 | 2016-06-23 | Fresenius Kabi Deutschland Gmbh | Système de connecteurs comprenant au moins deux ports de prélèvement |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59206694D1 (de) | 1996-08-08 |

| EP0534136A1 (fr) | 1993-03-31 |

| ATE139899T1 (de) | 1996-07-15 |

| DE9110460U1 (de) | 1991-10-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10348016B4 (de) | Konnektor für medizinische Flüssigkeiten enthaltende Verpackungen und Verpackung für medizinische Flüssigkeiten | |

| EP2114345B1 (fr) | Capuchon de fermeture pour un récipient destiné à recevoir des liquides médicaux et récipient destiné à recevoir des liquides médicaux | |

| DE102008048988A1 (de) | Vorrichtung zum Anschluss einer Spritze an ein Behältnis oder eine Schlauchleitung | |

| DE29607437U1 (de) | Medizintechnische Anschlußvorrichtung | |

| WO2003099191A1 (fr) | Raccord pour emballages contenant des liquides medicinaux et emballage pour liquides medicinaux | |

| DE20210337U1 (de) | Filterverpackung | |

| EP3233016B1 (fr) | Système de connecteur ayant au moins deux ports de prélèvement | |

| EP0766955A1 (fr) | Système d'embout d'accès pour une poche | |

| EP0811560A2 (fr) | Fermeture de garantie pour ouvertures de récipients en forme de col | |

| EP0830874B1 (fr) | Dispositif de connecteur en particulier pour usage médical | |

| DE3006292A1 (de) | Aufbrechbares behaelter-verschlusselement, mit einem solchen verschlusselement versehener blutbeutel und verfahren zum verschliessen eines flexiblen behaelters mit einem solchen verschlusselement | |

| CH630453A5 (en) | Closure device in a flexible hose | |

| EP0534136B1 (fr) | Dispositif de fermeture avec capuchon de protection | |

| DE3217913C2 (de) | Steriler Behälter für medizinische Zwecke | |

| EP3104928B1 (fr) | Dispositif de raccordement stérile d'articles médicaux à usage unique | |

| DE4410875A1 (de) | Medizinische Beutelanordnung | |

| WO2014012692A1 (fr) | Fermeture plastique permettant l'ouverture d'un sachet tubulaire plastique fermé de manière aseptique | |

| EP0766956A1 (fr) | Récipient pour liquide médicale | |

| WO2021122268A1 (fr) | Raccord et système de raccordement pour un emballage médical et procédé de fourniture d'un liquide pour un emballage médical | |

| EP2421597A1 (fr) | Bouchon de rupture destiné à boucher un tuyau | |

| DE3244151A1 (de) | Medizinischer aufbewahrungsbeutel | |

| EP0343534B1 (fr) | Récipient pour conserver des liquides, en particulier des liquides corporels | |

| EP1721595B1 (fr) | Récipient pour délivrer des liquides médicaux | |

| DE29612534U1 (de) | Infusionsset | |

| EP0597220A2 (fr) | Dispositif médical de transfert |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19930925 |

|

| 17Q | First examination report despatched |

Effective date: 19950220 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT CH DE LI |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE LI |

|

| REF | Corresponds to: |

Ref document number: 139899 Country of ref document: AT Date of ref document: 19960715 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59206694 Country of ref document: DE Date of ref document: 19960808 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110829 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110831 Year of fee payment: 20 Ref country code: AT Payment date: 20110830 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59206694 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59206694 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 139899 Country of ref document: AT Kind code of ref document: T Effective date: 20120820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20120821 |