EP0464530B1 - Device for over-lapping and depositing sheets cut off from a web by a cross cutter - Google Patents

Device for over-lapping and depositing sheets cut off from a web by a cross cutter Download PDFInfo

- Publication number

- EP0464530B1 EP0464530B1 EP91110300A EP91110300A EP0464530B1 EP 0464530 B1 EP0464530 B1 EP 0464530B1 EP 91110300 A EP91110300 A EP 91110300A EP 91110300 A EP91110300 A EP 91110300A EP 0464530 B1 EP0464530 B1 EP 0464530B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cams

- braking

- conveying

- sheet

- sheets

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/66—Advancing articles in overlapping streams

- B65H29/6609—Advancing articles in overlapping streams forming an overlapping stream

- B65H29/6618—Advancing articles in overlapping streams forming an overlapping stream upon transfer from a first conveyor to a second conveyor advancing at slower speed

- B65H29/6627—Advancing articles in overlapping streams forming an overlapping stream upon transfer from a first conveyor to a second conveyor advancing at slower speed in combination with auxiliary means for overlapping articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/68—Reducing the speed of articles as they advance

- B65H29/686—Pneumatic brakes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/42—Piling, depiling, handling piles

- B65H2301/421—Forming a pile

- B65H2301/4212—Forming a pile of articles substantially horizontal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2406/00—Means using fluid

- B65H2406/10—Means using fluid made only for exhausting gaseous medium

- B65H2406/13—Means using fluid made only for exhausting gaseous medium pressure arrangement for compensating weight of handled material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2406/00—Means using fluid

- B65H2406/30—Suction means

- B65H2406/32—Suction belts

Definitions

- the invention relates to a device for overlapping and depositing sheets, which are cut off from a material web with a cross cutter, consisting of a conveying device directly downstream of the cross cutter, which feeds the sheets for their continuation up to a stacking point, and one of the floating bars Combined conveying and braking device immediately upstream of the stacking station, which consists of a camshaft arranged above the conveying path of the sheet, equipped with conveying and braking cams and rotating in time with the cross cutter, and of sliding and braking elements assigned to the conveying and braking cams below the conveying path, wherein the conveying and braking cams rotate at the conveying speed and the braking elements at the braking speed and only the conveying cams of the interacting conveying cams and sliding elements and of the interacting braking cams and braking elements only act on the braking elements to determine the speed of the bends.

- Cross cutters of this or a similar type are known (DT 25 321 880 B2, DE 23 48 320 C3, DE 30 07 435 C2).

- the sheets are brought out of the conveying plane in the region of their rear edge by means of cams of a camshaft acting on them and brought into the effective range of a braking device.

- the part of the conveying and braking device arranged below the conveyor path consists of arranged on a common shaft, associated with the conveying cams, freely rotatable guide rollers and associated with the brake cams, non-rotatably seated on the shaft and rotating with it.

- the invention has for its object to provide a device of the type mentioned, which allows braking of the sheet with a comparatively low braking pressure.

- the effective braking area is increased compared to that in the prior art of the same type, because braking is carried out with twice the number of brake cams and, moreover, because of the suction belts over a longer distance. Switching from conveying to braking takes place without interruption because of the distance from Sliding elements and suction belts corresponding length of the cams the braking process is only initiated at the moment when the conveying process on the sliding elements is ended.

- the camshaft in the drive is advanced by means of a differential with increasing conveying speed in the running direction, so that the cams push the end of the bow somewhat further forward, and behind the end of the cams a longer piece of the end of the bow remains free, which corresponds to the increase in the braking distance of the arch.

- braking is initiated earlier and a longer braking distance is thus permitted, in order to reduce the arc to the speed that is not critical for storage without increasing the braking pressure.

- the suction area of the suction belts for braking lies in the running circle of the cams and has at least a length that corresponds to the length of the cams.

- the suction belts following this brake conveyor line can form a pure conveyor line running outside the circulation circle of the cams and circulate at such a speed that their respective path over the two lines is covered in the time of the sheet sequence. This prevents friction between the overlapping sheets in the area of the suction belts.

- the first conveyor element of the conveyor device which cooperates with the cams below the conveyor track, is a conveyor roller.

- the conveyor rollers of the conveyor are arranged in the gaps between the cams and the disks. This results in a compact structure.

- a slide rod is preferably arranged between the conveyor roller and the suction belts, the contact point of which with the cams is at a distance in each case from the contact points of the conveyor roller or the suction belts of the length of the cams.

- a material web 1 is fed to a cross cutter, which consists of a bar 2 with a lower knife 3 attached thereto and a rotating knife 4 cooperating therewith on a knife drum 5.

- the cross cutter 2-5 cuts the material web 1 into individual sheets 6.

- the sheets 6 are conveyed, on the one hand, by blowing air-fed floating bars 7 arranged below the conveyor track and, on the other hand, a conveyor device which consists of upper conveyor rollers 8 and a lower conveyor roller 9.

- the arrangement is such that the beginning of the material web 1 has been detected by the conveyor device 8, 9 when the material web 1 is cut crosswise. In this way, an accurate conveying of the sheets 6 is ensured at a speed predetermined by the conveying device 8, 9.

- the floating slats 7 extend as far as the conveyor roller 9. Suspended strips 10 adjoin the conveyor rollers 8 and are arranged above the conveying path of the sheets 6. These floating slats 10 extend largely over a stacking point 11. The floating slats 7 and 10 have a promoting effect on the sheets.

- the material web 1 and the sheet 6 cut from it by the cross cutter 2-5, namely the leading sheet, which is held at its end by the conveying device 8, 9, are pulled taut due to the conveying effect of the floating strips 7, 10.

- a combined conveying and braking device is provided behind the conveying device 8, 9 and immediately in front of the shelf 11.

- a slide rod 16 and a suction table 17 are arranged below the conveying plane.

- Suction belts 18 run over rollers 19a, b, c.

- a rotating shaft 20 is mounted, on which disks 21 are provided at a distance from one another in the area of gaps left by the floating bars 10, which are equipped with congruent cams 22 which perform the guiding, conveying and braking task together with those below the conveying plane arranged elements 16 to 19 meet. Since the conveyor rollers 8 are immersed in the circulation of the cams 22, they are in their gaps, i.e. arranged in alignment with the floating slats 10 (FIG. 2).

- the conveyor roller 9, the slide rod 16, the rollers 19a and 19b, including the suction belts 18, are assigned to the circular path of the cams 22 upon contact (FIGS. 3 to 5). So there is the contact point A between the rollers 8 and the conveyor roller 9, for the cam 22 with the conveyor roller 9 the contact point B, with the slide rod 16 the contact point C, with the rollers 19a and 19b including the suction belts 18 the start and end contact point D and E and without contact with the cam 22 for the respective arc end with the suction belts 18, the final contact point F.

- the dimensions of the elements 16 to 19 are chosen so that the distances CD and possibly BC with the cam length GH (all along the circumferential circle the cam (22) measured) match well, while the distance DE should at least correspond to the cam length GH.

- the distances AB and EF are completely independent of the cam length GH because the cam 22 does not contact points A and E anyway. The most important thing is the correspondence of the distance CD with the cam length GH, because this is the only way to switch seamlessly from delivery to braking.

- the distance BC should at most be equal to the cam length GH because this ensures that the sheet is conveyed in a defined manner even after leaving point A.

- the speed of the sheet 6, as long as the cam 22 on the conveyor roller 9 and / or the slide rod 16 is active, is equal to that specified by the conveyor device 8, 9, so that the conveyor at point C hardly requires any force due to the cam 22 rotating at the conveying speed. Therefore, to maintain the speed of the sheet 6, it is sufficient that the coefficient of friction between the cam 22 rotating at the conveying speed and the sheet 6 is greater than the coefficient of friction between the sheet 6 and the surface of the slide rod 16, especially since the floating strips 10 exert a slight pull on the sheet 6 exercise. Otherwise, the time for an undesired change in speed at point C is very short. For example, with 36,000 sheets per hour of 0.63 m length and a distance of the contact points BC or CD of 5% of the sheet length, the conveying time of the sheet end at contact point C is only 5 milliseconds.

- the overlapping and depositing of the sheet 6 is initiated by pressing the cams 22 on the end region of the sheet 6, whereby the sheet 6 is brought below the conveying plane, ie below the underside of the floating slats 10, while its end is still by the rollers 8 and Roller 9 is promoted at contact point A ( Figure 3).

- the start G of the cams 22 reaches the contact point B on the roller 9, so that the further conveyance of the sheet 6 is independent of the length of the sheet end, which the contact point A has not yet passed through.

- the conveying device 8, 9 Since the conveying device 8, 9 has a slight advance compared to the material web 1 fed by the cross cutter 3-5, its beginning at the end of the leading, vertically downwardly deflected sheet 6 has both a vertical and a longitudinal distance, so that when braking there is no danger of contact between the beginning of the material web 1 and the downwardly deflected end of the sheet 6.

- the braking of the sheet 6 begins at the contact of the start G of the cam 22 with the beginning of the brake conveyor section DE, ie the contact point D of the roller 19a guiding the suction belts 18 (FIG. 5) and should be ended at the latest when the end of the sheet 6 ends Start of the brake conveyor at D reached. Even within the sheet following stroke, the end of the sheet 6 is further conveyed via the brake conveyor section DE to the end E, so that at the end of the sheet following cycle the brake conveyor section DE is released along its entire length for braking the next sheet.

- the brake conveyor section DE is fully utilized for braking and on the other hand it is ensured that the braking section DE is free when the cam 22 takes the next sheet onto the suction belts 18 presses, the length of a free end of the arc 6 behind the end H of the cam 22 is adjusted accordingly via a speed-dependent phase adjustment in the drive of the camshaft 20.

- the braking distance corresponds to the sum of the length GH covered by the cam and the length of the end area not covered.

- the point K is at the end of the floating slats 10, to which a slide comb 23 is attached, which guides the sheets arriving quickly but only slowly passing onto the stacking point 11.

- Three beginnings of the arch 6 form a stabilizing S-curve, in which the impact of each abutment of an arch 6 on the stop strips 13 is absorbed elastically.

- the air flow in the conveying direction below the floating strips 10 escapes through the sliding comb 23 via the stop strips 13.

- Deviating from the described mode of operation of the device is the mode of operation when starting and stopping, that is to say at an extremely low conveying speed.

- the curve end lies under the cam 22. Since the braking distance is very short at this low conveying speed, the curve end has not yet reached position D when braking is complete. Therefore, when the sheet 6 is further conveyed by the suction belts 18, the end of the sheet will not yet have reached point E by the end of the sheet follower cycle, so that the full length of the brake conveyor line DE is not available for the subsequent sheet.

- the resulting lower braking force for the following arc is not disadvantageous but even advantageous because it then increases the braking distance by moving its end closer to point D.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Separation, Sorting, Adjustment, Or Bending Of Sheets To Be Conveyed (AREA)

- Delivering By Means Of Belts And Rollers (AREA)

Description

Die Erfindung bezieht sich auf eine Vorrichtung zum Überlappen und Ablegen von Bogen, die mit einem Querschneider von einer Materialbahn abgeschnitten werden, bestehend aus einer dem Querschneider unmittelbar nachgeordneten Fördervorrichtung, die die Bogen zu deren Weiterführung bis über eine Stapelstelle reichenden Schwebeleisten zuführt, sowie einer der Stapelstelle unmittelbar vorgeordneten kombinierten Förder- und Bremsvorrichtung, die aus einer oberhalb der Förderbahn der Bogen angeordneten, mit Förder- und Bremsnocken bestückten, im Takt des Querschneiders umlaufenden Nockenwelle und aus unterhalb der Förderbahn den Förder- und und Bremsnocken zugeordneten Gleit- und Bremselementen besteht, wobei die Förder- und Bremsnocken mit Fördergeschwindigkeit und die Bremselemente mit Bremsgeschwindigkeit umlaufen und von den zusammenwirkenden Fördernocken und Gleitelementen nur die Fördernocken und von den zusammenwirkenden Bremsnocken und Bremselementen nur die Bremselemente geschwindigkeitsbestimmend auf die Bogen einwirken.The invention relates to a device for overlapping and depositing sheets, which are cut off from a material web with a cross cutter, consisting of a conveying device directly downstream of the cross cutter, which feeds the sheets for their continuation up to a stacking point, and one of the floating bars Combined conveying and braking device immediately upstream of the stacking station, which consists of a camshaft arranged above the conveying path of the sheet, equipped with conveying and braking cams and rotating in time with the cross cutter, and of sliding and braking elements assigned to the conveying and braking cams below the conveying path, wherein the conveying and braking cams rotate at the conveying speed and the braking elements at the braking speed and only the conveying cams of the interacting conveying cams and sliding elements and of the interacting braking cams and braking elements only act on the braking elements to determine the speed of the bends.

Querschneider dieser oder ähnlicher Art sind bekannt (DT 25 321 880 B2, DE 23 48 320 C3, DE 30 07 435 C2). Bei all diesen bekannten Querschneidern werden die Bogen im Bereich ihrer Hinterkante mittels auf sie einwirkender Nocken einer Nockenwelle aus der Förderebene heraus und in den Wirkungsbereich einer Bremsvorrichtung gebracht. Bei dem bekannten Querschneider der eingangs genannten Art besteht der unterhalb der Förderbahn angeordnete Teil der Förder- und Bremsvorrichtung aus auf einer gemeinsamen Welle angeordneten, den Fördernocken zugeordneten, frei drehbaren Führungsrollen und den Bremsnocken zugeordneten, drehfest auf der Welle sitzenden und mit ihr umlaufenden Bremsscheiben. Bei diesem Querschneider besteht die Gefahr, daß bei stark abgebremstem Bogen das Bogenende den Bereich der Führungsrollen noch nicht verlassen hat, wenn die Förderwirkung durch die Fördernocken wieder einsetzt. Die erneute Einwirkung von Förderkräften auf den Bogen führt zu einer Überbeanspruchung des Bogens durch Wiederbeschleunigung und Stauchung seines Endes.Cross cutters of this or a similar type are known (DT 25 321 880 B2, DE 23 48 320 C3, DE 30 07 435 C2). In all of these known cross cutters, the sheets are brought out of the conveying plane in the region of their rear edge by means of cams of a camshaft acting on them and brought into the effective range of a braking device. In the known cross cutter of the type mentioned, the part of the conveying and braking device arranged below the conveyor path consists of arranged on a common shaft, associated with the conveying cams, freely rotatable guide rollers and associated with the brake cams, non-rotatably seated on the shaft and rotating with it. With this cross cutter, there is a risk that when the sheet is strongly braked, the sheet end has not yet left the area of the guide rollers when the conveying action by the conveying cams resumes. The renewed action of conveying forces on the bow leads to an overuse of the bow by re-acceleration and compression of its end.

Bei einem verbesserten Querschneider genannter Art (DE 38 36 604) wird eine sichere Trennung zwischen Förderung und Bremsung bei möglichst lückenlosem Wechsel von Förderung auf Bremsung erreicht. Bei diesem Querschneider ebenso wie bei den zuvor genannten ist der Bremsweg auf Ringen sehr kurz, so daß ein harter Druck vom Bremsnocken auf den vom Bremsring unterstützten Bogen ausgeübt werden muß. Bei schnellen Querschneidern mit frischem beidseitigen Druck hinter Druckmaschinen wird das Druckbild beschädigt, insbesondere wenn es zur Schonung des Papiers unvollständig getrocknet wurde und Spitzen von Borsten, mit denen Nocken bestückt sein können, hart darübergleiten.In the case of an improved cross cutter of the type mentioned (DE 38 36 604), a safe separation between conveying and braking is achieved with a change from conveying to braking as complete as possible. In this cross cutter as well as in the aforementioned, the braking distance on rings is very short, so that hard pressure from the brake cam must be exerted on the bow supported by the brake ring. In the case of fast cross cutters with fresh double-sided printing behind printing machines, the printed image is damaged, in particular if it has been incompletely dried to protect the paper and tips of bristles with which cams can be fitted glide hard over them.

Um die an einer Stapelstelle abzulegenden Bogen unmittelbar vor dem Ablegen auf eine für das Ablegen unkritische Geschwindigkeit abzubremsen, ist es ferner bekannt (DE 39 20 407 A1), unter der Förderbahn unmittelbar vor der Stapelstelle in einem Saugkasten langsam laufende Förderwalzen und oberhalb der Förderbahn eine Nockenwelle mit Nocken anzuordnen. Mittels der Nocken wird der Bogen aus der Förderbahn nach unten abgelenkt und gegen die Förderwalzen gedrückt, gegen die er dann aufgrund des im Saugkasten herrschenden Unterdrucks gezogen wird. Da auch in diesem Fall der Kontakt der Förderwalzen mit dem Bogen auf einen sehr schmalen Bereich beschränkt ist, läßt sich eine große Bremswirkung nur bei entsprechend hohem Kontaktdruck erreichen, was aber für ein frisches Druckbild nachteilig ist.In order to decelerate the sheets to be deposited at a stacking point to a speed that is not critical for the depositing immediately before depositing, it is also known (DE 39 20 407 A1), under the conveyor track directly in front of the stacking point in a suction box, slowly moving conveyor rollers and above the conveyor track Arrange camshaft with cams. By means of the cams, the sheet is deflected downward from the conveyor track and pressed against the conveyor rollers, against which it is then pulled due to the negative pressure prevailing in the suction box. Since the contact of the conveyor rollers with the sheet is limited to a very narrow area in this case too, a great braking effect can only be achieved with a correspondingly high contact pressure, which is disadvantageous for a fresh print image.

Der Erfindung liegt die Aufgabe zugrunde, eine Vorrichtung der eingangs genannten Art zu schaffen, die eine Abbremsung der Bogen mit einem vergleichsweise niedrigen Bremsdruck ermöglicht.The invention has for its object to provide a device of the type mentioned, which allows braking of the sheet with a comparatively low braking pressure.

Diese Aufgabe wird erfindungsgemäß dadurch gelöst, daß sowohl das Fördern als auch das Bremsen jedes Bogens gleiche Nocken von gleichbleibendem Radius durch ihren Kontakt zuerst mit den Gleitelementen und danach mit Saugbändern herbeiführen, die am Umlaufkreis der Nocken nacheinander angeordnet sind und vom Gleitelement entlang des Umfangkreises der Nocken einen Abstand haben, der der Länge der Nocken entlang des Umfangkreises der Nocken entspricht.This object is achieved in that both the conveying and the braking of each arc bring the same cams of constant radius through their contact first with the sliding elements and then with suction belts, which are arranged one after the other on the circuit of the cam and from the sliding element along the circumferential circle of the Cams have a distance that corresponds to the length of the cams along the circumferential circle of the cams.

Bei der erfindungsgemäßen Vorrichtung ist die wirksame Bremsfläche gegenüber derjenigen beim gattungsgleichen Stand der Technik vergrößert, weil die Bremsung mit einer doppelten Anzahl an Bremsnocken erfolgt und darüber hinaus wegen der Saugbänder auf einer längeren Strecke. Die Umschaltung von Förderung auf Bremsung erfolgt ohne Unterbrechung, weil aufgrund der dem Abstand von Gleitelementen und Saugbändern entsprechenden Länge der Nocken der Bremsvorgang erst in dem Augenblick eingeleitet wird, wenn der Fördervorgang an den Gleitelementen beendet wird.In the device according to the invention, the effective braking area is increased compared to that in the prior art of the same type, because braking is carried out with twice the number of brake cams and, moreover, because of the suction belts over a longer distance. Switching from conveying to braking takes place without interruption because of the distance from Sliding elements and suction belts corresponding length of the cams the braking process is only initiated at the moment when the conveying process on the sliding elements is ended.

Nach einer Ausgestaltung der Erfindung ist vorgesehen, daß die Nockenwelle im Antrieb über ein Differential mit zunehmender Fördergeschwindigkeit in Laufrichtung vorverstellt wird, so daß die Nocken das Ende der Bogen etwas weiter vorn drücken, und hinter dem Ende der Nocken ein längeres Stück des Endes des Bogens frei bleibt, das der Vergrößerung des Bremsweges des Bogens entspricht. Bei dieser Ausgestaltung wird gezielt die Abbremsung früher eingeleitet und damit ein längerer Bremsweg zugelassen, um ohne Erhöhung des Bremsdruckes den Bogen auf die für die Ablage unkritische Geschwindigkeit herabzusetzen. Ferner kann mit dieser Ausgestaltung erreicht werden, daß auch bei unterschiedlichen Fördergeschwindigkeiten einerseits für den Bremsvorgang die volle Länge des von den Nocken überstrichenen Bereichs der Saugbänder ausgenutzt wird, andererseits für den Folgebogen diese volle Länge wieder freigegeben wird, weil am Ende der Abbremsung der Bogen mit seinem am Anfang der Bremsförderstrecke angekommenen Ende durch die Saugbänder aus der Bremsförderstrecke gefördert wird. Wegen der geschwindigkeitsabhängigen Phasenverstellung kann die Geschwindigkeit der Saugbänder auf einen konstant niedrigen Proportionalwert der Fördergeschwindigkeit gehalten werden. Das bringt gegenüber herkömmlichen Querschneidern (DE 30 07 435 C2 und DE 38 36 604 A1) große Vorteile, weil bei einer Geschwindigkeit der Saugbänder von zum Beispiel 5% der Fördergeschwindigkeit der an seinem Ende von den Saugbändern gehaltene Bogen mit 5% der Geschwindigkeit voll bis über den Stapel gefördert wird und der überlappende Bogen den überlappten Bogen nicht mehr durch Reibung über diese 5% hinaus beschleunigen kann.According to one embodiment of the invention, it is provided that the camshaft in the drive is advanced by means of a differential with increasing conveying speed in the running direction, so that the cams push the end of the bow somewhat further forward, and behind the end of the cams a longer piece of the end of the bow remains free, which corresponds to the increase in the braking distance of the arch. In this embodiment, braking is initiated earlier and a longer braking distance is thus permitted, in order to reduce the arc to the speed that is not critical for storage without increasing the braking pressure. Furthermore, it can be achieved with this configuration that even at different conveying speeds, the full length of the area covered by the cams of the suction belts is used for the braking process, on the other hand, this full length is released again for the following sheet, because at the end of braking the sheet with its end at the beginning of the brake conveyor line is conveyed out of the brake conveyor line by the suction belts. Because of the speed-dependent phase adjustment, the speed of the suction belts can be kept at a constant low proportional value of the conveying speed. This brings great advantages over conventional cross cutters (DE 30 07 435 C2 and DE 38 36 604 A1), because at a speed of the suction belts of, for example, 5% of the conveying speed, the sheet held at its end by the suction belts is fully up to 5% of the speed is conveyed over the stack and the overlapping sheet can no longer accelerate the overlapped sheet by friction beyond this 5%.

Nach einer weiteren Ausgestaltung der Erfindung liegt der Saugbereich der Saugbänder für das Bremsen im Laufkreis der Nocken und hat wenigstens eine Länge, die der Länge der Nocken entspricht. Die Saugbänder im Anschluß an diesen Bremsförderstrecke können einen außerhalb des Umlaufkreises der Nocken verlaufenden reine Förderstrecke bilden und mit einer solchen Geschwindigkeit umlaufen, daß ihr jeweiliger Weg über die beiden Strecken jeweils in der Zeit der Bogenfolge zurückgelegt wird. Dadurch wird vermieden, daß es zu einer Reibung zwischen den einander überlappenden Bogen im Bereich der Saugbänder kommt.According to a further embodiment of the invention, the suction area of the suction belts for braking lies in the running circle of the cams and has at least a length that corresponds to the length of the cams. The suction belts following this brake conveyor line can form a pure conveyor line running outside the circulation circle of the cams and circulate at such a speed that their respective path over the two lines is covered in the time of the sheet sequence. This prevents friction between the overlapping sheets in the area of the suction belts.

Nach einer weiteren Ausgestaltung der Erfindung ist das erste, unterhalb der Förderbahn mit den Nocken zusammenwirkende Förderelement der Fördervorrichtung eine Förderwalze . Die Förderrollen der Fördervorrichtung sind in den Lücken zwischen den Nocken und den Scheiben angeordnet sein. Dadurch ergibt sich ein kompakter Aufbau. Zwischen der Förderwalze und den Saugbändern ist vorzugsweise ein Gleitstab angeordnet, dessen Kontaktstelle mit den Nocken von den Kontaktstellen der Förderwalze bzw. der Saugbänder jeweils einen Abstand der Länge der Nocken hat.According to a further embodiment of the invention, the first conveyor element of the conveyor device, which cooperates with the cams below the conveyor track, is a conveyor roller. The conveyor rollers of the conveyor are arranged in the gaps between the cams and the disks. This results in a compact structure. A slide rod is preferably arranged between the conveyor roller and the suction belts, the contact point of which with the cams is at a distance in each case from the contact points of the conveyor roller or the suction belts of the length of the cams.

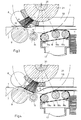

Im folgenden wird die Erfindung anhand einer ein Ausführungsbeispiel darstellenden Zeichnung näher erläutert. Im einzelnen zeigen:

Figur 1- eine Vorrichtung zum Überlappen und Ablegen von durch einen Querschneider von einer Materialbahn abgeschnittenen Bogen in schematischer Darstellung in Seitenansicht,

Figur 2- die Vorrichtung gemäß

Figur 1 in Aufsicht

und - Fig. 3-5

- die Vorrichtung gemäß

Figur 1 in verschiedenen Phasen des Brems- und Überlappungsvorgangs der Bogen als vergrößerter Ausschnitt derFigur 1 im Querschnitt.

- Figure 1

- 1 shows a device for overlapping and depositing sheets cut from a material web by a cross cutter in a schematic illustration in side view,

- Figure 2

- the device of Figure 1 in supervision

and - Fig. 3-5

- the device according to Figure 1 in different phases of the braking and overlapping process of the sheet as an enlarged section of Figure 1 in cross section.

Gemäß Fig. 1 und 2 wird eine Materialbahn 1 einem Querschneider zugefördert, der aus einem Balken 2 mit einem daran befestigtem unteren Messer 3 und einem damit zusammenwirkenden umlaufenden Messer 4 auf einer Messertrommel 5 besteht. Der Querschneider 2-5 schneidet die Materialbahn 1 in einzelne Bogen 6. Die Bogen 6 werden einerseits von unterhalb der Förderbahn angeordneten, blasluftgespeisten Schwebeleisten 7 und andererseits einer Fördervorrichtung, die aus oberen Förderrollen 8 und einer unteren Förderwalze 9 besteht, gefördert. Dabei ist die Anordnung so getroffen, daß der Anfang der Materialbahn 1 von der Fördervorrichtung 8,9 erfaßt worden ist, wenn die Materialbahn 1 quergeschnitten wird. Auf diese Art und Weise ist eine genaue Förderung der Bogen 6 mit durch die Fördervorrichtung 8,9 vorgegebener Geschwindigkeit sichergestellt. Die Schwebeleisten 7 erstrecken sich bis an die Förderwalze 9 heran. An die Förderrollen 8 schließen sich Schwebeleisten 10 an, die oberhalb der Förderbahn der Bogen 6 angeordnet sind. Diese Schwebeleisten 10 erstrecken sich weitgehend über eine Stapelstelle 11. Die Schwebeleisten 7 und 10 wirken fördernd auf die Bogen ein. Die Materialbahn 1 und der von ihr durch den Querschneider 2-5 abgeschnittene Bogen 6, und zwar der vorlaufende Bogen, der an seinem Ende durch die Fördervorrichtung 8,9 gehalten wird, werden aufgrund der Förderwirkung der Schwebeleisten 7,10 straffgezogen.1 and 2, a

Die auf einer absenkbaren Palette 12 befindliche Ablage 11, wo die ankommenden Bogen 6 sich übereinander ablegen, wird stirnseitig durch Anschlagleisten 13 und seitlich durch anstellbare Führungsleisten 14,15 begrenzt.The

Hinter der Fördervorrichtung 8,9 und unmittelbar vor der Ablage 11 ist eine kombinierte Förder- und Bremsvorrichtung vorgesehen. Dafür sind unterhalb der Förderebene ein Gleitstab 16 und ein Saugtisch 17 angeordnet. Saugbänder 18 laufen über Walzen 19a,b,c. Oberhalb der Förderebene ist eine umlaufende Welle 20 gelagert, auf der mit Abstand voneinander im Bereich von von den Schwebeleisten 10 gelassenen Lücken Scheiben 21 vorgesehen sind, die mit deckungsgleichen Nocken 22 bestückt sind, die die Führungs-, Förder- und Bremsaufgabe zusammen mit den unterhalb der Förderebene angeordneten Elementen 16 bis 19 erfüllen. Da die Förderrollen 8 in den Umlaufkreis der Nocken 22 eintauchen, sind sie in deren Lücken, d.h. fluchtend zu den Schwebeleisten 10 angeordnet (Fig. 2).A combined conveying and braking device is provided behind the

Die Förderwalze 9, der Gleitstab 16, die Walzen 19a und 19b unter Einbeziehung der Saugbänder 18 sind der Kreisbahn der Nocken 22 auf Berührung zugeordnet (Fig. 3 bis 5). So gibt es zwischen den Rollen 8 und der Förderwalze 9 die Kontaktstelle A, für den Nocken 22 mit der Förderwalze 9 die Kontaktstelle B, mit dem Gleitstab 16 die Kontaktstelle C, mit den Walzen 19a und 19b einschließlich den Saugbändern 18 die Anfangs- und Endkontaktstelle D und E und ohne Kontakt mit dem Nocken 22 für das jeweilige Bogenende mit den Saugbändern 18 die Schlußkontaktstelle F. Die Abmessungen der Elemente 16 bis 19 sind so gewählt, daß die Abstände CD und möglichst auch BC mit der Nockenlänge GH (alle entlang des Umfangkreises der Nocken (22) gemessen) gut übereinstimmen, während der Abstand DE mindestens der Nockenlänge GH entsprechen sollte. Die Abstände AB und EF sind völlig unabhängig von der Nockenlänge GH, weil der Nocken 22 mit den Punkten A und E ohnehin nicht kontaktiert. Am wichtigsten ist die Übereinstimmung des Abstandes CD mit der Nockenlänge GH, weil nur so eine lückenlose Umschaltung von Förderung auf Bremsung möglich ist.The

Der Abstand BC sollte höchstens gleich der Nockenlänge GH sein, weil dadurch gewährleistet wird, daß der Bogen auch nach Verlassen der Stelle A definiert gefördert wird.The distance BC should at most be equal to the cam length GH because this ensures that the sheet is conveyed in a defined manner even after leaving point A.

An den Stellen A,B und C ist die Geschwindigkeit des Bogens 6, solange der Nocken 22 an der Förderwalze 9 und/oder dem Gleitstab 16 wirksam ist, gleich der von der Fördervorrichtung 8,9 vorgegebenen, so daß die Förderung an der Stelle C durch den mit Fördergeschwindigkeit umlaufenden Nocken 22 kaum Kraft erfordert. Deshalb genügt zur Aufrechterhaltung der Geschwindigkeit des Bogens 6, daß der Reibwert zwischen dem mit Fördergeschwindigkeit umlaufenden Nocken 22 und dem Bogen 6 größer ist als der Reibwert zwischen dem Bogen 6 und der Oberfläche des Gleitstabes 16, zumal die Schwebeleisten 10 einen leichten Zug auf den Bogen 6 ausüben. Im übrigen ist die Zeit für eine ungewollte Geschwindigkeitsänderung an der Stelle C sehr klein. Beispielsweise bei 36000 Bogen je Stunde von 0,63 m Länge und einem Abstand der Kontaktstellen BC bzw. CD von 5% der Bogenlänge beträgt die Förderzeit des Bogenendes an der Kontaktstelle C nur 5 Millisekunden.At points A, B and C, the speed of the

Das Überlappen und Ablegen des Bogens 6 wird durch das Drücken der Nocken 22 auf dem Endbereich des Bogens 6 eingeleitet, wodurch der Bogen 6 unter die Förderebene, d.h. unter die Unterseite der Schwebeleisten 10 gebracht wird, während sein Ende noch durch die Rollen 8 und die Walze 9 an der Kontaktstelle A gefördert wird (Figur 3). Der Anfang G der Nocken 22 erreicht die Kontaktstelle B auf der Walze 9, so daß die Weiterförderung des Bogens 6 unabhängig von der Länge des Bogenendes ist, die die Kontaktstelle A noch nicht durchlaufen hat.The overlapping and depositing of the

Bei weiterer Drehung der Nockenwelle 20 erreichen die Nocken 22 mit ihrem Anfang die Kontaktstelle C des Gleitstabes 16, so daß dort die Weiterförderung des Bogens 6 auch noch gesichert ist, wenn das Ende des Bogens 6 die Kontaktstelle B passiert und/oder das Ende H der Nocken 22 die Kontaktstelle B der Walze 9 verläßt (Fig.4).With further rotation of the

Alsbald ist ein neuer Anfang der Materialbahn 1 von der Fördervorrichtung 8,9 erfaßt (Fig.5), der unter die Schwebeleisten 10 hinter dem Ende H der Nocken 22 vorwärtsgeführt wird und dabei den vorlaufenden Bogen 6 überlappt.Immediately a new start of the

Da die Fördervorrichtung 8,9 gegenüber der vom Querschneider 3-5 zugeführten Materialbahn 1 eine geringe Voreilung hat, hat ihr Anfang zum Ende des vorlaufenden, in der Höhe nach unten abgelenkten Bogens 6 sowohl einen Höhen- als auch einen Längsabstand, so daß beim Bremsen zwischen dem Anfang der Materialbahn 1 und dem nach unten abgelenkten Ende des Bogens 6 keine Berührungsgefahr besteht.Since the conveying

Die Bremsung des Bogens 6 beginnt beim Kontakt des Anfangs G des Nockens 22 mit dem Anfang der Bremsförderstrecke DE, d.h. der Kontaktstelle D der die Saugbänder 18 führenden Walze 19a (Fig.5) und sollte spätestens beendet sein, wenn das Ende des Bogens 6 den Anfang der Bremsförderstrecke bei D erreicht. Noch innerhalb des Bogenfolgetaktes wird der Bogen 6 mit seinem Ende über die Bremsförderstrecke DE bis zum Ende E weiter gefördert, so daß am Ende des Bogenfolgetaktes die Bremsförderstrecke DE auf ihrer gesamten Länge für die Abbremsung des nächsten Bogens freigegeben ist. Damit auch bei unterschiedlichen Fördergeschwindigkeiten einerseits die Bremsförderstrecke DE für die Bremsung voll ausgenutzt wird und andererseits gewährleistet ist, daß die Bremsstrecke DE frei ist, wenn der Nocken 22 den nächsten Bogen auf die Saugbänder 18 drückt, wird über eine geschwindigkeitsabhängige Phasenverstellung im Antrieb der Nockenwelle 20 die Länge eines freien Endes des Bogens 6 hinter dem Ende H des Nockens 22 entsprechend eingestellt. Bei während der Produktion üblichen Fördergeschwindigkeit - ausgenommen also bei Anfahren und Anhalten - entspricht der Bremsweg der Summe der durch den Nocken abgedeckten Länge GH und der Länge des nicht abgedeckten Endbereichs.The braking of the

Die Weiterförderung jeweils eines Bogens 6 auf der abgeknickten Strecke EF schützt diesen Bogen vor einem Schub durch Reibung durch den abbremsenden Folgebogen. Sowohl bei hohen als auch niedrigen Fördergeschwindigkeiten wird das Ende jedes Bogens 6 D gemäß dem Zahlenbeispiel mit 5% seiner ursprünglichen Geschwindigkeit auf den Stapel 11 geführt. Sowie drei Bogen 6 mit ihren Enden gleichzeitig über die Kontaktstellen D,E und F gefördert werden, nähern sich ihre Anfänge über die Stellen K,L und M den Anschlagleisten 13 (Figur 1). Über die kurze Strecke von der Stelle M bis zu den Anschlagleisten 13, die der Bogen nach Verlassen der Stelle F ohne Förderung durch die Saugbänder 18 zurücklegen muß, wird der Bogen 6 von dem Folgebogen durch Reibung mitgenommen. Die Stelle K liegt am Ende der Schwebeleisten 10, an der ein Gleitkamm 23 angebracht ist, der die dort schnell ankommenden, aber nur langsam weitergleitenden Bogen auf die Stapelstelle 11 führt. Drei Anfänge der Bogen 6 bilden dabei eine stabilisierende S-Kurve, in der der Stoß jeden Anschlags eines Bogens 6 an die Anschlagleisten 13 elastisch aufgefangen wird. Die Luftströmung in Förderrichtung unterhalb der Schwebeleisten 10 entweicht durch den Gleitkamm 23 über die Anschlagleisten 13.The further conveyance of one

Von der beschriebenen Betriebsweise der Vorrichtung abweichend ist die Betriebsweise beim Anfahren und Anhalten, also bei extrem kleiner Fördergeschwindigkeit. Bei dieser Betriebsweise liegt das Bogenende unter dem Nocken 22. Da bei dieser kleinen Fördergeschwindigkeit der Bremsweg sehr kurz ist, hat das Bogenende die Stelle D noch nicht erreicht, wenn die Abbremsung beendet ist. Deshalb wird bei weiterer Förderung des Bogens 6 durch die Saugbänder 18 das Ende des Bogens den Punkt E bis zum Ende des Bogenfolgetaktes noch nicht erreicht haben, so daß für den Folgebogen nicht die volle Länge der Bremsförderstrecke DE zur Verfügung steht. Die dadurch bedingte kleinere Bremskraft für den Folgebogen ist jedoch nicht nachteilig sondern sogar vorteilhaft, weil sie den Bremsweg anschließend vergrößert, indem sein Ende dem Punkt D näherrückt.Deviating from the described mode of operation of the device is the mode of operation when starting and stopping, that is to say at an extremely low conveying speed. In this mode of operation, the curve end lies under the

Claims (7)

- Device for the overlap and delivery of sheets (6) which are cut off from a material web (1) by means of a cross-cutter (2-5), consisting of a conveyor device (8, 9) which immediately follows the cross-cutter (2-5) and which feeds the sheets (6) for their further guidance to suspended fences (10) extending over a stacking point (11), and of a combined conveying and braking device (16-22) which immediately precedes the stacking point (11) and which consists of a camshaft (20) arranged above the conveying track of the sheets (6), equipped with conveying and braking cams (22) and rotating in time with the cross-cutter (2-5), and of sliding (16) and braking (18) elements assigned to the conveying and braking cams (22) underneath the conveying track, the conveying and braking cams (22) rotating at conveying speed and the braking elements (18) at braking speed, and, of the interacting conveying cams and sliding elements (16), only the conveying cams and, of the interacting braking cams and braking elements (18), only the braking elements (18) acting on the sheets (6) in a speed-determining manner, characterized in that both the conveyance and the braking of each sheet (6) are brought about by like cams (22) of uniform radius as a result of their contact first with the sliding elements (16) and thereafter with the braking elements (18), designed as suction bands, which are arranged successively on the circle of rotation of the cams (22) and which are at a distance (CD) from the sliding element (16) along the circumferential circle of the cams (22) corresponding to the length (GH) of the cams (22) along the circumferential circle of the cams (22).

- Device according to Claim 1, characterized in that, in the drive, the camshaft (20) is preadjusted with an increasing conveying speed in the running direction by means of a differential, so that the cams (22) press the end of the sheets (6) somewhat further forwards and there remains free behind the end (4) of the cams (22) a longer piece of the end of the sheets (6) which corresponds to the increase in the braking travel of the sheet (6).

- Device according to Claim 1 or 2, characterized in that the braking region (DE) of the suction bands (18) is located in the circle of rotation of the cams (22) and has at least a length corresponding to the length (GH) of the cams (22).

- Device according to one of Claims 1 to 3, characterized in that the suction bands (18) form after the braking region (DE) a conveying region (EF) extending outside the circle of rotation of the cams and rotate at such a speed that their respective travel over the two regions (DE, EF) is in each case completed within the time of the sheet sequence.

- Device according to one of Claims 1 to 3, characterized in that the first conveying element (9) interacting with the cams (22) underneath the conveying track and belonging to the conveyor device (8, 9) is a conveying roller.

- Device according to one of Claims 1 to 5, characterized in that between the conveying element (9) arranged underneath the conveying track and the suction bands (18) is located a sliding bar (16), of which the contact point (C) with the cams (22) is at a respective distance from the contact points (B, D) of the conveying roller (9) and of the suction bands (18) which corresponds to the length (GH) of the cams (22).

- Device according to one of Claims 1 to 6, characterized in that the rollers (8) of the conveyor device (8, 9) are arranged in the gaps between the cams (22) and their discs (21).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4020398 | 1990-06-27 | ||

| DE4020398A DE4020398C1 (en) | 1990-06-27 | 1990-06-27 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0464530A2 EP0464530A2 (en) | 1992-01-08 |

| EP0464530A3 EP0464530A3 (en) | 1992-08-19 |

| EP0464530B1 true EP0464530B1 (en) | 1994-11-30 |

Family

ID=6409147

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91110300A Expired - Lifetime EP0464530B1 (en) | 1990-06-27 | 1991-06-22 | Device for over-lapping and depositing sheets cut off from a web by a cross cutter |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5186450A (en) |

| EP (1) | EP0464530B1 (en) |

| JP (1) | JPH0825681B2 (en) |

| DE (2) | DE4020398C1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4238386C1 (en) * | 1992-11-13 | 1994-05-05 | Heidelberger Druckmasch Ag | Device for cross cutting continuously fed material |

| EP0697989B1 (en) * | 1993-05-05 | 1996-11-13 | Vits Maschinenbau Gmbh | Device for stream feeding of sheets onto a stack |

| DE4316413A1 (en) * | 1993-05-17 | 1994-11-24 | Heidelberger Druckmasch Ag | Device for taking specimens from rotary cross-cutters |

| DE4316400C2 (en) * | 1993-05-17 | 1997-12-11 | Heidelberger Druckmasch Ag | Device for removal of specimens removed from a flow |

| CH689977A5 (en) * | 1994-05-11 | 2000-02-29 | Bobst Sa | Braking device of plate elements in a receiving station of a processing machine such elements. |

| US6145833A (en) * | 1998-06-02 | 2000-11-14 | Marquip, Inc. | Rotary brush sheet deceleration device |

| RU2468980C1 (en) * | 2011-07-20 | 2012-12-10 | Общество С Ограниченной Ответственностью "Конструкторское Бюро "Дорс" (Ооо "Кб "Дорс") | Sheet stacker and method of its operation |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2348320C3 (en) * | 1973-09-26 | 1978-12-14 | Vits-Maschinenbau Gmbh, 4018 Langenfeld | Device for stacking individual sheets of the same length |

| DE2532880C3 (en) * | 1975-07-23 | 1978-05-18 | Vits-Maschinenbau Gmbh, 4018 Langenfeld | Device for shingling and depositing sheets conveyed one behind the other on a stack |

| GB1549203A (en) * | 1975-07-23 | 1979-08-01 | Vits Maschinenbau Gmbh | Device for overlapping sheets which are regularly individually conveyed one after the other |

| DE2841658C2 (en) * | 1978-09-25 | 1980-09-11 | Vits-Maschinenbau Gmbh, 4018 Langenfeld | Device for shingling and depositing sheets on a stack |

| DE2917250A1 (en) * | 1979-04-27 | 1980-10-30 | Gruner & Jahr | Printed matter even overlapping machine - has endless chain with members engaging leading edges of printed sheets on conveyor |

| DE3007435C2 (en) * | 1980-02-28 | 1984-02-09 | Vits-Maschinenbau Gmbh, 4018 Langenfeld | Cross cutter for material webs with downstream storage for the cut sheets |

| DE3418344A1 (en) * | 1984-05-17 | 1985-11-21 | Georg Spiess Gmbh, 8906 Gersthofen | DEVICE FOR FORMING AN ARC PACK |

| DE3920407A1 (en) * | 1988-08-03 | 1990-02-08 | Hilmar Vits | DEVICE FOR DEPOSING SHEETS AT A STACKING POINT |

| DE3836604A1 (en) * | 1988-10-27 | 1990-05-03 | Hilmar Vits | Cross-cutter for material webs with a downstream depository for the cut sheets |

| DD285326A5 (en) * | 1989-06-28 | 1990-12-12 | Veb Kombinat Polygraph "Werner Lamberz" Leipzig,Dd | SAUGBANDFOERDERER IN EXPENSES OF PRINTING MACHINES |

-

1990

- 1990-06-27 DE DE4020398A patent/DE4020398C1/de not_active Expired - Lifetime

-

1991

- 1991-06-22 EP EP91110300A patent/EP0464530B1/en not_active Expired - Lifetime

- 1991-06-22 DE DE59103640T patent/DE59103640D1/en not_active Expired - Fee Related

- 1991-06-27 JP JP3181581A patent/JPH0825681B2/en not_active Expired - Lifetime

- 1991-06-27 US US07/721,130 patent/US5186450A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US5186450A (en) | 1993-02-16 |

| JPH04313559A (en) | 1992-11-05 |

| EP0464530A2 (en) | 1992-01-08 |

| JPH0825681B2 (en) | 1996-03-13 |

| EP0464530A3 (en) | 1992-08-19 |

| DE4020398C1 (en) | 1992-02-13 |

| DE59103640D1 (en) | 1995-01-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69202534T2 (en) | Roll accumulator for sheets. | |

| EP0497002B1 (en) | Device for forming a gap in a stream of overlapping articles | |

| DE69126911T2 (en) | Double gathering machine | |

| EP0408893B1 (en) | Sheet depositing device for revolving transverse cutter | |

| EP0481172B1 (en) | Rotary printing machine for book and calendar printing, with two longitudinal folding devices | |

| DE2348320A1 (en) | DEVICE FOR STACKING INDIVIDUAL EQUIPMENT SHEETS ON A STACK | |

| DE4122214A1 (en) | DEVICE FOR TURNING A SHEET UNDER SIMULTANEOUSLY CHANGING THE CONVEYOR | |

| DE69702274T2 (en) | Device for collecting and stacking layered materials, and a stacking method | |

| CH654554A5 (en) | METHOD AND DEVICE FOR REMOVING FLAT PRODUCTS, preferably PRINTED PRODUCTS, WINDED ON A WINDING CORE. | |

| CH662330A5 (en) | DEVICE FOR GENERATING SPACES IN A MOVING STREAM OF OVERLAPPING PAPER SHEETS. | |

| DE2518374C2 (en) | Device for forming a helical stack of printed products continuously occurring in an imbricated flow | |

| DE4139888A1 (en) | DEVICE FOR BRAKING DOWN SHEETS TO BE PUT DOWN ON A PACK, IN PARTICULAR PAPER OR CARDBOARD SHEETS | |

| EP3533609B1 (en) | Device and method for processing sequentially printed sheets | |

| EP0464530B1 (en) | Device for over-lapping and depositing sheets cut off from a web by a cross cutter | |

| DE4013116A1 (en) | Stacking process for flat cardboard blanks - produces gap in overlapping flow for undisturbed removal of stack | |

| EP0697989B1 (en) | Device for stream feeding of sheets onto a stack | |

| DE2114865A1 (en) | Device for stacking sheets or sheets on top of each other | |

| DE2832660B2 (en) | Device for group-wise division of workpieces conveyed on top of each other in shingled form | |

| EP0999163B1 (en) | Device for creating a gap in a stream of sheets in shingled formation | |

| DE3007435C2 (en) | Cross cutter for material webs with downstream storage for the cut sheets | |

| EP0900757A2 (en) | Device for braking and delivering overlapping signatures | |

| DE2434360A1 (en) | DEVICE FOR STACKING LOOSE SHEETS OF PAPER | |

| DE2722414B2 (en) | Device for feeding tape or strip material to an edge banding machine | |

| DE3836604C2 (en) | ||

| EP1868931B1 (en) | Grouping device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HEIDELBERGER DRUCKMASCHINEN AKTIENGESELLSCHAFT |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: VITS, HILMAR |

|

| GBC | Gb: translation of claims filed (gb section 78(7)/1977) | ||

| 17P | Request for examination filed |

Effective date: 19920302 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES FR GB IT LI |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): CH DE GB LI |

|

| 17Q | First examination report despatched |

Effective date: 19940329 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE GB LI |

|

| REF | Corresponds to: |

Ref document number: 59103640 Country of ref document: DE Date of ref document: 19950112 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19950125 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19960520 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960718 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970622 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970630 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19970722 Year of fee payment: 7 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19970622 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990401 |