EP0441174A2 - Procédé et outil de formage pour refouler un nipple - Google Patents

Procédé et outil de formage pour refouler un nipple Download PDFInfo

- Publication number

- EP0441174A2 EP0441174A2 EP91100805A EP91100805A EP0441174A2 EP 0441174 A2 EP0441174 A2 EP 0441174A2 EP 91100805 A EP91100805 A EP 91100805A EP 91100805 A EP91100805 A EP 91100805A EP 0441174 A2 EP0441174 A2 EP 0441174A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- nipple

- tube

- flank

- pushed

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21K—MAKING FORGED OR PRESSED METAL PRODUCTS, e.g. HORSE-SHOES, RIVETS, BOLTS OR WHEELS

- B21K1/00—Making machine elements

- B21K1/14—Making machine elements fittings

- B21K1/16—Making machine elements fittings parts of pipe or hose couplings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C37/00—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape

- B21C37/06—Manufacture of metal sheets, bars, wire, tubes or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape of tubes or metal hoses; Combined procedures for making tubes, e.g. for making multi-wall tubes

- B21C37/15—Making tubes of special shape; Making tube fittings

- B21C37/20—Making helical or similar guides in or on tubes without removing material, e.g. by drawing same over mandrels, by pushing same through dies ; Making tubes with angled walls, ribbed tubes and tubes with decorated walls

- B21C37/205—Making helical or similar guides in or on tubes without removing material, e.g. by drawing same over mandrels, by pushing same through dies ; Making tubes with angled walls, ribbed tubes and tubes with decorated walls with annular guides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D17/00—Forming single grooves in sheet metal or tubular or hollow articles

- B21D17/02—Forming single grooves in sheet metal or tubular or hollow articles by pressing

- B21D17/025—Forming single grooves in sheet metal or tubular or hollow articles by pressing by pressing tubes axially

Definitions

- the invention relates to a method for producing a molded nipple on a thin-walled, small-caliber metal pipe for motor vehicle construction, in particular on a fuel, brake or hydraulic line, the nipple on its outer contour by upsetting the pipe end with several axially spaced apart from one another, annular circumferential thickenings are provided, each of which has a radially outwardly rising flank in the axial section and a radially inwardly steeply descending, possibly radially or undercut descending flank, and where both flanks merge into one another as sharply as possible.

- the invention further relates to a molding tool for performing the method and a nipple produced by the method.

- Such thin-walled, small-caliber metal pipes are used as fuel, brake or hydraulic lines in motor vehicle construction.

- a hose made of elastic plastic or rubber is attached to the molded nipple. So that the hose is held securely on the nipple without a hose clamp and tightness between the nipple and hose is guaranteed, the flank facing away from the free end of the nipple must fall as steeply as possible in the radial direction towards the pipe axis and the transition between the two flanks should be as sharp as possible.

- the invention is therefore based on the object of demonstrating a method for producing a molded nipple on a thin-walled, small-caliber metal tube for motor vehicle construction of the type mentioned at the outset, with which the nipples in the required quality can be produced as inexpensively as possible and without substantial contamination of the tube.

- the invention is based on the object of demonstrating a mold which is particularly suitable for carrying out the method and advantageous configurations of a nipple produced by the method.

- the invention is therefore based on the idea of combining upsetting with a press in which the flow limit of the metal is exceeded so that it is displaced into the appropriately designed cavities of the mold surrounding the nipple and completely fills these cavities.

- the mandrel resting on the inner tube wall supports the inner wall, so that the metal can only be displaced radially outwards. Since the inner contour of the pushed-together molded parts corresponds to the desired outer contour of the nipple and since the metal is also displaced into the outermost corners of the cavities of the molded parts due to the high axial pressure applied, the flanks of the thickenings have the desired sharp-edged transition and also any desired inclination to the pipe axis.

- the flank facing away from the nipple end can be designed so that it runs perpendicular to the axis or, if necessary, also forms an undercut. This ensures the required tightness and pull-off force between the nipple and the attached hose.

- a further advantage of the method according to the invention is that welded tubes can also be provided with the desired nipples by this method and that it is also possible to apply the thickened portions without the original inside diameter of the tube being narrowed.

- the tube in the area of the nipple also remains essentially smooth on the inside, so that flow changes in the area of the nipple are avoided. In contrast to the method described at the beginning, no material is removed during the manufacture of the nipple and no oil is required.

- the wall thickness of the tube can also be essentially maintained over the entire length of the nipple. Inexpensive molds and machines can be used to carry out the method, the tools having a long service life.

- the nipple can be formed in one step and there is no need to deburr later. With the same outside diameter of the thickenings it is possible to use weaker pipes. The process is suitable for large series, simple, machine-safe and independent of the pipe length.

- An advantageous mold for carrying out the method according to claim 1 consists of several, each half a tube circumference, axially collapsible molded parts, the inner contour of which, when pushed together, corresponds to the outer contour of the finished nipple and each of which has the largest diameter of an annular thickening of the nipple extends to the largest diameter of the adjacent thickening of the nipple, and also consists of a compression ram movable axially relative to the shaped parts and the pipe end, and a mandrel which can be pushed into the pipe end, at least along the length of the nipple to be produced, and which bears against the inner wall of the pipe.

- the method according to the invention is suitable for small-caliber, thin-walled metal pipes, in particular steel pipes, in the diameter range D of 6 to 15 mm and a wall thickness d of 0.7 to 1 mm.

- the metal tube can be a drawn metal tube, a longitudinally welded metal tube or a metal tube wound from strips using the Bundy method.

- a nipple 1a is to be formed, which has a plurality of annular thickenings 2 arranged at axial distances from one another. In the embodiment shown, three such thickenings 2 are formed.

- each of these thickenings has, in axial section, a flank 2a, which faces the nipple end 1b and rises radially outwards and which includes an angle ⁇ of, for example, approximately 15 ° with the pipe axis A.

- each thickening 2 has on its side facing away from the nipple end 1b a radially inward steeply falling flank 2b, which includes an angle ⁇ of at least 70 ° with the pipe axis A.

- the angle ⁇ can also be 90 °. If the angle ⁇ is greater than 90 °, the flank 2b forms an undercut. The transition from the gently rising flank 2a to the steeply descending flank 2b should be as sharp as possible. Small rounding radii of around 0.15 mm are permitted.

- the particularly suitable mold for carrying out the method consists of a clamping jaw 3, a compression ram 4, a plurality of compression washers 5 and a mandrel 6.

- the compression ram 4 and the compression washers 5 are longitudinally divided in the axial direction perpendicular to the plane of the drawing, so that from the side to the Pipe end 1 created and laterally removed from this.

- the upsetting punch 4 and the mandrel 6 can each be formed in one piece.

- the outside diameter of the cylindrical mandrel 6 corresponds to the inside diameter D1 of the undeformed pipe end 1.

- the mandrel has such a large axial length that it extends over the entire nipple area during the deformation process.

- the upsetting punch 4 is provided with a cylindrical recess 7 which is intended to receive the pipe end 1.

- the compression punch 4 has a truncated cone-shaped recess 8, the inclination of which towards the tube axis and the extent thereof in the radial direction corresponds exactly to the flank 2a of the thickening 2 to be produced with it.

- the upsetting disk 5 is provided at its end facing the upsetting punch 4 with a recess 9 which serves to shape the flank 2b and forms the negative shape of this flank 2b.

- the upsetting disk 5 is provided with a recess 10, which is used to shape the gently rising flank 2a of the next thickening 2.

- the underlying upsetting disk 5 is designed in exactly the same way as the one described above.

- the clamping jaw 3 has a truncated cone-shaped recess 11, which is intended to shape the steeply falling flank 2b.

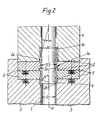

- the two upsetting disks 5 are kept at an axial distance from one another when the tool is open, as shown in FIG. 1. If the molded parts 3, 4, 5 of the molding tool are completely pushed together axially, as is shown in FIG. 2, then the inner contour of the molded parts 3, 4, 5 corresponds to that with the recesses 8 to 11 formed cavities exactly the outer contour of the nipple 1a to be manufactured.

- the two upsetting disks 5 each extend from the largest diameter D2 of an annular thickening 2 to the largest diameter of the adjacent thickening 2.

- the two mold halves containing the clamping jaws 3 and the upsetting disks 5 are slightly apart, so that the tube end 1 can be inserted or inserted into the opened mold.

- the mold halves are then brought closer to one another, the jaw halves 3 resting firmly on the pipe end 1 and securing it against axial displacement.

- the compression punch 4 and the mandrel 6 are moved in the axial direction B towards the pipe end, the mandrel 6 entering the metal pipe 1.

- the upsetting punch 4 With further movement of the upsetting punch 4, the lower end face of the upper upsetting disk 5 comes into contact and finally also the nipple end 1b on the shoulder 12 of the upsetting punch 4.

- the pressure of the upsetting punch 4 and also the length of the tube end 1 which originally protrudes upward above the clamping jaws 3 are coordinated with one another in such a way that the metal of the compressed tube end 1 begins to flow into the cavities of the pushed-together molded parts 3 formed by the indentations 8 to 11 , 4, 5 is displaced and completely fills them, as shown in Fig. 2. This completes the actual molding process.

- the mold halves are then moved radially apart again and the compression die 4 together with the mandrel 6 is moved axially upward in the opposite direction of the arrow B.

- the shaping of the thickenings 2 can optionally also be carried out in succession in a multi-stage process with so-called follow-up tools.

- Each of these follow-on tools has a split jaw, an upset punch and a mandrel.

- the first follow-up tool With the first follow-up tool, the thickening which is furthest away from the nipple end 1b is first formed, and then the remaining thickenings are successively formed in two further follow-up tools.

- the pipe end 1 should only be deformed to such an extent that the diameter ratio of the outer diameter D3 of the nipple 1a is in the range between two annular ones Thickenings 2 to the largest diameter D2 of the thickening 2 is equal to or less than 1.15, preferably equal to or less than 1.12.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Forging (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19904004008 DE4004008C1 (fr) | 1990-02-09 | 1990-02-09 | |

| DE4004008 | 1990-02-09 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0441174A2 true EP0441174A2 (fr) | 1991-08-14 |

| EP0441174A3 EP0441174A3 (en) | 1992-01-15 |

Family

ID=6399813

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19910100805 Withdrawn EP0441174A3 (en) | 1990-02-09 | 1991-01-23 | Method and form tool for heading a nipple |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0441174A3 (fr) |

| CA (1) | CA2058063A1 (fr) |

| DE (1) | DE4004008C1 (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1999011964A1 (fr) * | 1997-09-04 | 1999-03-11 | Helmut Held | Element de tubage et son procede de fabrication |

| WO1999029448A1 (fr) * | 1997-12-08 | 1999-06-17 | Coflex, S.A. De C.V. | Procede de fabrication de tenons pour raccords de tuyaux d'arrosage et raccord ainsi obtenu |

| WO2002002255A1 (fr) * | 2000-06-30 | 2002-01-10 | Witzig & Frank Gmbh | Procede et dispositif pour la production de raccords tubulaires a la presse en acier, notamment en acier special |

| US20130040161A1 (en) * | 2010-02-25 | 2013-02-14 | Schuler Cartec Gmbh & Co. Kg | Method and tool for producing a component and a component produced by forming |

| WO2015177015A1 (fr) * | 2014-05-22 | 2015-11-26 | Bremboflex S.P.A. | Procédé de fabrication d'un raccord de tuyau flexible pour un tuyau flexible |

| WO2020254033A1 (fr) * | 2019-06-18 | 2020-12-24 | CONTITECH KüHNER GMBH & CIE KG | Procédé et dispositif de fabrication d'un raccord de tuyau |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201209814D0 (en) * | 2012-06-01 | 2012-07-18 | Edwards Ltd | A gas pipe for a vacuum dry pump and a method of making same |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2535470A (en) * | 1943-11-11 | 1950-12-26 | Grinnell Corp | Method of flaring tubing |

| US3595047A (en) * | 1969-02-19 | 1971-07-27 | Caterpillar Tractor Co | Method of forming o-ring grooves |

| DE3742496A1 (de) * | 1986-12-15 | 1988-06-16 | Nippon Steel Corp | Verfahren zur bearbeitung der enden einer stahlroehre durch stauchen und pressen |

| DE3803709C1 (en) * | 1988-02-04 | 1989-05-11 | Mannesmann Ag, 4000 Duesseldorf, De | Small-calibre thin-walled metal tube for motor-vehicle construction |

| DE3741446A1 (de) * | 1987-12-08 | 1989-06-22 | Festo Kg | Anschlussverbindungsstueck |

-

1990

- 1990-02-09 DE DE19904004008 patent/DE4004008C1/de not_active Expired - Fee Related

-

1991

- 1991-01-23 EP EP19910100805 patent/EP0441174A3/de not_active Withdrawn

- 1991-12-19 CA CA 2058063 patent/CA2058063A1/fr not_active Abandoned

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2535470A (en) * | 1943-11-11 | 1950-12-26 | Grinnell Corp | Method of flaring tubing |

| US3595047A (en) * | 1969-02-19 | 1971-07-27 | Caterpillar Tractor Co | Method of forming o-ring grooves |

| DE3742496A1 (de) * | 1986-12-15 | 1988-06-16 | Nippon Steel Corp | Verfahren zur bearbeitung der enden einer stahlroehre durch stauchen und pressen |

| DE3741446A1 (de) * | 1987-12-08 | 1989-06-22 | Festo Kg | Anschlussverbindungsstueck |

| DE3803709C1 (en) * | 1988-02-04 | 1989-05-11 | Mannesmann Ag, 4000 Duesseldorf, De | Small-calibre thin-walled metal tube for motor-vehicle construction |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1999011964A1 (fr) * | 1997-09-04 | 1999-03-11 | Helmut Held | Element de tubage et son procede de fabrication |

| WO1999029448A1 (fr) * | 1997-12-08 | 1999-06-17 | Coflex, S.A. De C.V. | Procede de fabrication de tenons pour raccords de tuyaux d'arrosage et raccord ainsi obtenu |

| WO2002002255A1 (fr) * | 2000-06-30 | 2002-01-10 | Witzig & Frank Gmbh | Procede et dispositif pour la production de raccords tubulaires a la presse en acier, notamment en acier special |

| US6843096B2 (en) | 2000-06-30 | 2005-01-18 | Witzig & Frank Gmbh | Process and device for producing press fittings from steel, in particular special steel |

| US20130040161A1 (en) * | 2010-02-25 | 2013-02-14 | Schuler Cartec Gmbh & Co. Kg | Method and tool for producing a component and a component produced by forming |

| US8893540B2 (en) * | 2010-02-25 | 2014-11-25 | Schuler Cartec Gmbh & Co. Kg | Method and tool for producing a component and a component produced by forming |

| WO2015177015A1 (fr) * | 2014-05-22 | 2015-11-26 | Bremboflex S.P.A. | Procédé de fabrication d'un raccord de tuyau flexible pour un tuyau flexible |

| US10710137B2 (en) | 2014-05-22 | 2020-07-14 | Bremboflex S.P.A. | Method of making a hose connection for a hose |

| WO2020254033A1 (fr) * | 2019-06-18 | 2020-12-24 | CONTITECH KüHNER GMBH & CIE KG | Procédé et dispositif de fabrication d'un raccord de tuyau |

| US11951531B2 (en) | 2019-06-18 | 2024-04-09 | Contitech Techno-Chemie Gmbh | Method and device for producing a hose nipple |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0441174A3 (en) | 1992-01-15 |

| CA2058063A1 (fr) | 1992-06-21 |

| DE4004008C1 (fr) | 1990-11-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0523215B1 (fr) | Procede et dispositif de formage hydrostatique de corps creux en metal deformable a froid | |

| EP2475922B1 (fr) | Tuyau, raccord vissé et procédé de fabrication associé | |

| DE69524496T2 (de) | Verfahren und Vorrichtung zum Herstellen eines metallischen Wellrohres | |

| DE19614656A1 (de) | Verfahren zum Erhöhen der Wandungsstärke bei Hohlprofilen | |

| EP0193589B1 (fr) | Appareil et procédé pour produire les douilles de serrage pour tuyaux | |

| DE4446506A1 (de) | Vorrichtung zum Aufweiten von Hohlkörpern | |

| WO2010037551A2 (fr) | Procédé et dispositif pour réaliser un filetage extérieur sans enlèvement de matière sur des pièces creuses en métal | |

| EP0347369A2 (fr) | Procédé et dispositif d'élargissement hydraulique de profils creux | |

| DE19520099C2 (de) | Rohrverbindung und Verfahren zu ihrer Herstellung | |

| EP1446248A1 (fr) | Procede et dispositif pour elargir et faconner des corps de boite | |

| DE3226868A1 (de) | Dauerhaft dichte gewindelose rohrverbindung | |

| DE2642743A1 (de) | Verfahren und vorrichtung zum herstellen eines mehrfach gekruemmten rohres | |

| EP0955107B1 (fr) | Procédé de déformation d'un tube de départ à section circulaire dans un profilé en forme de U et dispositif pour la réalisation dudit procédé | |

| DE19719629C2 (de) | Verfahren und Einrichtung zur Herstellung von Kraftfahrzeugachsgehäusen | |

| DE4004008C1 (fr) | ||

| EP0649689A1 (fr) | Méthode et dispositif pour la fabrication des raccords à compression | |

| DE4004443C2 (de) | Vorrichtung zum Herstellen eines Faltenbalgrohres, vorzugsweise geringen Durchmessers | |

| DE4032424C2 (de) | Verfahren und Vorrichtung zur Herstellung von gefalzten Rohren | |

| EP2205371A2 (fr) | Procédé pour fabriquer des systèmes à double tube | |

| DE69322965T2 (de) | Verfahren zur herstellung von rohrförmigen elementen mit integralen äusserlichen vorsprüngen | |

| DE19941577C2 (de) | Rohrverbindung und Verfahren zu ihrer Herstellung | |

| DE19903684B4 (de) | Werkzeug zum Querfließpressen | |

| EP3560623A1 (fr) | Procédé et dispositif de fabrication d'un produit final à partir d'un produit intermédiaire par formage | |

| DE3029621A1 (de) | Form- und nutvorrichtung fuer rohrenden | |

| DE10135515A1 (de) | Umformwerkzeug |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19920225 |

|

| 17Q | First examination report despatched |

Effective date: 19930223 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19930623 |