EP0400616A1 - Dispositif pour positionner plusieurs pots de fleurs - Google Patents

Dispositif pour positionner plusieurs pots de fleurs Download PDFInfo

- Publication number

- EP0400616A1 EP0400616A1 EP90110279A EP90110279A EP0400616A1 EP 0400616 A1 EP0400616 A1 EP 0400616A1 EP 90110279 A EP90110279 A EP 90110279A EP 90110279 A EP90110279 A EP 90110279A EP 0400616 A1 EP0400616 A1 EP 0400616A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- profile sections

- flower pots

- connecting pieces

- profile

- coaster

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G7/00—Flower holders or the like

- A47G7/02—Devices for supporting flower-pots or cut flowers

- A47G7/04—Flower tables; Stands or hangers, e.g. baskets, for flowers

- A47G7/044—Hanging flower-pot holders, e.g. mounted on walls, balcony fences or the like

Definitions

- the invention relates to a device for setting up several plants planted in flower pots.

- a wide variety of flower boxes and plant troughs are known for several plants, which are mainly set up or hung outdoors. It is only pointed out to the balcony facilities and the flower facilities in public or private places.

- the plants are planted in the planting soil or planting substrate introduced into the flower box or plant trough. The need for potting soil or planting substrate is therefore very high, especially when a plant comprises several flower boxes or plant troughs.

- the need for potting soil or plant substrate for a plant is only a fraction of the need for a flower pot in a flower box or plant trough.

- the flower pots are set in a row in a holder which in the area of the pot edge of the set Flower pots has two profile sections running parallel to one another, the clear distance between which is matched to the outer dimension of the pot edge of the set flower pots, that the flower pots are set up on at least one further profile section and that all profile sections are held in their association with one another by end elements on end elements.

- the holder holds commercially available flower pots with plants that require a minimum of potting soil or plant substrate.

- the holder with the flower pots enables a plant arrangement that corresponds to the plants planted in flower boxes or plant troughs.

- the bracket allows for multiple training of the planting system, which is not possible with flower boxes or plant troughs.

- profile sections assigned to the pot edge of the set flower pots are rotatably mounted on the end elements and have a projecting retaining web which can be screwed onto the pot edge of the set flower pots and that the profile sections can be fixed in the angular position securing the flower pots. The flower pots are then held securely in the holder.

- a simple fixing of the profile sections on the end elements is created in that the end elements are provided with connecting pieces onto which profile sections designed as hollow profile sections can be attached.

- the connection is made using easy-to-create plug connections.

- the holder can be expanded in stages and the profile sections form continuous lines which can be used for irrigation.

- the profile sections are advantageously designed as pipe sections.

- a further embodiment provides that the holder is placed in a saucer pan that extends over the top of the profile sections on which the flower pots are placed. Irrigation can take place over the profile sections on which the flower pots are placed.

- the coaster tray can be filled so far that the flower pots are partially in the water. After a predetermined time, the excess water can be drained so that the flower pots are aerated again through their perforated bottom.

- the coaster pan is composed of channel-like profile sections with conically widening side walls, the joints of which lie in the area of the end elements and are sealed by means of sealing elements, then the coaster pan can be expanded in stages like the holder. It is advantageously provided that the profile sections, the end elements and Profile sections of the coaster tray form a kit for creating brackets of any length.

- the irrigation over the profile sections on which the flower pots are placed takes place according to an embodiment in such a way that the connecting pieces of the end elements for the profile sections on which the flower pots are placed have stops distributed over the circumference, which are the distance between the attached profile section of the plate-shaped closure element and that the inner walls of the profile sections are held at a predetermined distance from the further outer surface of the connection piece by means of longitudinal spacing webs of the connection piece. Between the stops, the end element and the end face of the profile section plugged onto the connecting piece, arc-shaped outlet slots are created which merge into part-shell-shaped outlet channels between the spacer webs and open into the interior of the profile sections.

- the outlet channels are secured against contamination by the profile sections, since they can be kept so small at least in one direction that parts of the potting soil or foreign parts cannot penetrate into the outlet channels, even if the excess water is routed through the line network expires or is suctioned off.

- the water only emerges during irrigation at the plug connections between the profile sections and the connecting pieces of the end elements.

- the design is such that at least three stops and spacing webs distributed over the circumference are provided, which extend only over a small angular range of the circumference of the connecting piece. It is advantageously provided that the spacers connect to the stops and extend to the end faces of the connecting pieces. This facilitates the manufacture of the closure element, which is produced as an injection molded part made of metal or plastic.

- the amount of outflow in the area of the outlet channels and outlet slots can be adjusted in such a way that the desired flow rate for irrigation via the profile sections can be determined by means of the height of the spacing webs and the dimension of the stops directed perpendicular to the plate-shaped closure element.

- a further embodiment provides that the profile sections assigned to the pot edge of the flower pots are provided with a continuous longitudinal slot outside the retaining web.

- one embodiment provides that the end elements have a perpendicular, at least in the area of the end faces of the end element covered by the saucer troughs have standing on the end element and projecting at least on one side and that the saucer pan (s) is (are) sealed by means of sealing compound as sealing elements against the contact web. If the contact web protrudes on both sides of the closing element, then it can close a composite device at the ends or connect two successive coaster trays tightly to one another.

- a large-area seal is achieved in that the sealing compound is applied as strands to the outside of the sealing web, which is (are) deformable when the closure element is inserted into the coaster pan (s). If the termination element is used as the end termination, then a single strand is sufficient, while in the case of an interconnection of coaster trays, preferably two strands, one per coaster tray, are applied. Due to the pressure exerted on the closure element, the strands of sealing compound are compressed, whereby they expand to the sides and seal in strips.

- the distance of the lower connecting piece of the closing element to the facing inner wall of the contact web is smaller than the wall thickness of the profile sections pushed onto these connecting pieces and that the end faces of the contact web form stops for the plug-on movement of the profile sections, then the connecting pieces can be attached the closing element can be simplified since the sliding movement of the profile sections intended for irrigation is limited by the contact web of the closing element. At the front of the profile sections there remains a sufficient opening for the liquid to pass through.

- the contact web is integrally formed on the end element and that the end element with all the connecting pieces and the contact web is designed and manufactured as a plastic injection-molded part.

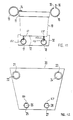

- FIG. 1 shows schematically how a flower pot 10 is held in a holder with four profile sections 13, 15, 17 and 18.

- the flower pot 10 stands with its bottom 12 on the two profile sections 17 and 18, which are designed as tubular sections.

- the two other profile sections 13 and 15 are arranged in the region of the pot edge 11 and are rotatably supported by the ends on the connecting pieces 21 and 23 of a closing element 20.

- Radially projecting retaining webs 14 and 16 are integrally formed on the profile sections 13 and 14. If the profile sections are rotated so that the holding web points upward, as shown in the profile section 15, the flower pots 10 can be placed in the holder.

- the clear distance between the profile sections 13 and 15 is matched to the outer dimension of the pot rim 11, so that the flower pot 10 cannot move laterally between the profile sections 13 and 15 running parallel to one another.

- the profile sections 13 and 15 are rotated so that the holding webs 14 and 16 cover the pot edge 11, as the Retaining web 14 of the profile section 13 can be seen.

- This setting of the profile sections 13 and 15 is secured.

- the two holding webs 14 and 16 can e.g. be firmly connected to each other by means of cross bars. This connection can be additionally secured via a lock or the like.

- the holder is placed in a saucer pan 30 so that the flower pots 10 can be watered. To do this, however, it is necessary that the saucer trough 30 projects over the top of the profile sections 17 and 18 on which the flower pots 10 are placed. If the saucer pan 30 is filled, the flower pots 10 are partially in the water and suck in water through the perforated bottom 12. After a while, the excess water can be drained off again. For this purpose, the profile sections 17 and 18 can be used, as will be shown.

- the closing element 20 is designed as a plate in which the connecting pieces 21, 23, 25 and 27 are introduced, in such a way that they protrude on both sides of the plate.

- These connecting pieces are designed with their outer diameters on the inner diameter of the profile sections 13, 15, 17 and 18 designed as pipe sections that simple plug connections are created.

- the connecting pieces 21, 23, 25 and 27 have through holes 22, 24, 26 and 28, so that the profile sections are lined up Form brackets through lines. This is particularly important for the profile sections 17 and 18 and the connecting pieces 25 and 27, since these are used for irrigation.

- the coaster tray 30 can be composed of profile sections 30 '. These profile sections 30 'are groove-like with conically widening side walls so that they are stackable. The profile sections 30 'abut each other in the region of the end elements 20 and are sealed there by means of a sealing element 31. The profile sections 30 'are then still carried by means of a holder 32 which e.g. fixes the bracket to a railing, building or the like.

- the sealing of the joint between abutting profile sections 30 ' can be solved in different ways. The same also applies to the end of the assembled holder, the sealing also having to be made towards the end element 20.

- FIG. 5 and 6 show how irrigation can take place via the profile sections 17 and 18. Shown in longitudinal and cross-section is a connection point between a closing element 20 with a connecting piece 45 and the two profile sections 40 and 42.

- the connecting piece 45 protrudes on both sides of the plate of the closing element 20.

- the connecting piece 45 carries four stops 46 distributed in 90 ° division over the circumference with the end faces 41 and 43, which limit the push-on movement of the profile sections 40 and 42.

- the plate of the closure element 20 and the end faces of the profile sections 40 and 42 arise arcuate outlet slots 48, which merge into outlet channels 49, which open into the interior of the profile sections 40 and 42.

- longitudinally spaced webs 47 are formed, which extend up to the end faces of the connecting piece 45.

- the stops 46 and the spacer webs 47 only extend over a small angular range, so that the outlet channels 49 can have a large area, even if the height of the spacer webs 47 is very small. This is important for the retention of parts of the potting soil and foreign parts so that the outlet channels 49 and the outlet slots 48 do not become blocked.

- the height of the spacer webs 47 and the dimension of the stops 46 perpendicular to the plate of the closure element 20 are parameters with which the discharge quantity during the irrigation can be varied and set per section of the assembled holder.

- the excess water from the coaster trough 30 can also flow back to the pump via the outlet slots 48 and the outlet channels 49.

- the pump supplies water via the lines which are formed by the profile sections 17 and 18.

- the connecting pieces 25 and 27 of the closure element 20 therefore have through holes, as shown at 50 in FIGS. 5 and 6.

- the profile sections or the connecting pieces 25 and 27 of the closure element 20 are closed by means of plugs.

- the plate-shaped closing element 20 with the connecting pieces 21, 22 and 25, 26 can also be provided with a contact web 60 which in the exemplary embodiment projects on both sides of the closing element 20.

- the contact web 60 is perpendicular to the plate-shaped end element 20 and is integrally formed on the end element 20 produced in the plastic injection molding process with the connecting pieces 21, 22, 25 and 26, specifically in the region of the end face which is covered by the coaster trays 30 and 30 ' .

- the closure element 20 can be used both for the termination of a free end of a coaster pan and for connecting two coaster coaster panes 30 and 30 '. This means that only one type of cover element 20 needs to be provided.

- two strands 61 and 62 of a sealing compound are applied to an intermediate connection on the outside of the contact web 60, which run at a distance from one another and transversely to the longitudinal direction of the coaster trays 30 and 30 '.

- the end element 20 thus prepared is introduced in the area of the joint of the two coaster trays 30 and 30 ', which can be supported or hung up, the one coaster tray 30 covering the strand 61 and the coaster tray 30' covering the strand 60. If the end element 20 is pressed against the coaster trays 30 and 30 ', then the strands 61 and 62 of the sealing compound are deformed, expanding laterally and forming strip-shaped sealing elements, as shown with 61' and 62 'in Fig. 10.

- This sealing and connection has the advantage that it can be easily removed and renewed. This is a considerable advantage for the device which is designed as a kit and can be expanded as required.

- the distance between the lower connecting piece 25 and 26 to the facing inside of the contact web 60 is chosen to be smaller than the wall thickness of the profile sections 42 which can be pushed onto the connecting piece 25 and 26. This ensures that the end faces of the contact web Form 60 stops that limit the push-on movement of the profile sections 42.

- the end face of the profile sections 42 is therefore at a predetermined distance from the plate-shaped closure element 20, so that sufficient opening remains between the connecting piece 20 and the profile section 42 for the passage of the liquid.

- FIG. 11 essentially corresponds to FIG. 1.

- the flower pot 10 no longer stands directly on the further profile sections 17 and 18.

- the further profile sections 17 and 18 are provided with molded spacer webs 51 and 53, which can also run into a support edge 55, as the spacer web 53 shows.

- the support of the flower pot 10 on the base 12 is limited to a minimum support surface and the ventilation of the flower pot 10 is improved when watering after the base 12 has been released.

- the spacer webs 51 and 53 are aligned vertically when the device is assembled, the further profile sections 17 and 18 are provided with molded-on inner webs 52 and 54, which position the further profile sections 17 and 18 in the only in a very specific position of the further profile sections External grooves 56 and 57 of the connecting pieces 25 and 27 on the closure element 20 according to FIG. 12 can be inserted.

- the inner webs 52 and 54 are matched to the outer grooves 56 and 57 and formed so that the others attached to the connecting pieces 25 and 27 Profile sections 17 and 18, the spacers 51 and 53 project vertically upwards in the direction of the flower pot 10 and are fixed non-rotatably.

Landscapes

- Cultivation Receptacles Or Flower-Pots, Or Pots For Seedlings (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3917909 | 1989-06-01 | ||

| DE3917909 | 1989-06-01 | ||

| DE3927194 | 1989-08-17 | ||

| DE19893927194 DE3927194C1 (fr) | 1989-06-01 | 1989-08-17 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0400616A1 true EP0400616A1 (fr) | 1990-12-05 |

Family

ID=25881491

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90110279A Withdrawn EP0400616A1 (fr) | 1989-06-01 | 1990-05-30 | Dispositif pour positionner plusieurs pots de fleurs |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0400616A1 (fr) |

| DE (1) | DE3927194C1 (fr) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29721553U1 (de) * | 1997-12-08 | 1998-02-19 | Rubner, Günter, 35716 Dietzhölztal | Vorrichtung zur Aufnahme eines Gefäßes |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1889669A (en) * | 1931-01-13 | 1932-11-29 | Thomas L Knipe | Floral display stand |

| CH172673A (de) * | 1934-03-02 | 1934-10-31 | Geiger Adalbert | An Fensterbänken, Balkonbrüstungen usw. anzubringender Blumenstockrahmen. |

| FR2608365A1 (fr) * | 1986-12-18 | 1988-06-24 | Imbert Jacques | Porte-fleurs a usage de jardiniere |

| EP0285733A1 (fr) * | 1987-04-08 | 1988-10-12 | Societe Arax S.A.R.L. | Support de pots ou container notamment pour plantes |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1582719B1 (de) * | 1967-06-24 | 1970-07-02 | Daebritz Konrad | Blumentopf-Verschiebevorrichtung |

-

1989

- 1989-08-17 DE DE19893927194 patent/DE3927194C1/de not_active Expired - Lifetime

-

1990

- 1990-05-30 EP EP90110279A patent/EP0400616A1/fr not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1889669A (en) * | 1931-01-13 | 1932-11-29 | Thomas L Knipe | Floral display stand |

| CH172673A (de) * | 1934-03-02 | 1934-10-31 | Geiger Adalbert | An Fensterbänken, Balkonbrüstungen usw. anzubringender Blumenstockrahmen. |

| FR2608365A1 (fr) * | 1986-12-18 | 1988-06-24 | Imbert Jacques | Porte-fleurs a usage de jardiniere |

| EP0285733A1 (fr) * | 1987-04-08 | 1988-10-12 | Societe Arax S.A.R.L. | Support de pots ou container notamment pour plantes |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3927194C1 (fr) | 1990-09-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102018129987B4 (de) | Vorrichtung zur automatischen Bewässerung | |

| EP1705298A2 (fr) | Module de caniveau de rétention | |

| EP0374898A1 (fr) | Table de plantes | |

| DE2603018B2 (de) | Behälter für Pflanzen | |

| DE3927194C1 (fr) | ||

| EP0445197A1 (fr) | Bac pour pots de fleurs. | |

| DE1684819A1 (de) | Umzaeunung aus genormten vorgefertigten Teilen | |

| DE8906725U1 (de) | Vorrichtung zum Aufstellen mehrerer Blumentöpfe | |

| DE4309601A1 (de) | Anstauvorrichtung für die Anzucht von Pflanzen oder Aussaaten und Wanne zu deren Herstellung | |

| DE202020105637U1 (de) | Vorrichtung zur Aufnahme von Pflanztöpfen | |

| DE9204442U1 (de) | Anstauvorrichtung für die Anzucht von Pflanzen oder Aussaaten und Wanne zu deren Herstellung | |

| EP3262925B1 (fr) | Colonne verte | |

| DE4014935A1 (de) | Begruenbare laermschutzwand aus recycling-kunststoff | |

| DE19848401A1 (de) | Variables Arbeitsplatz-Möbelsystem mit vertikalen Säulen und horizontalen Quertraversen | |

| DE3513370A1 (de) | Wasserbelueftungsrohr | |

| DE19612223C2 (de) | Bewässerungsventil | |

| DE3917203C2 (fr) | ||

| DE8713639U1 (de) | Bewässerungsrinne für Pflanzen od. dgl. | |

| EP4385317A1 (fr) | Module de plantation pour jardin suspendu | |

| DE19808466A1 (de) | Heizkörper mit Stützvorrichtung | |

| DE8913120U1 (de) | Gartenbeetbegrenzungselement | |

| DE29817108U1 (de) | Installationssystem für Heizungsanlagen | |

| DE8627868U1 (de) | Zerlegbarer Anzucht- und Transportkasten für Kulturpflanzen | |

| DE8629715U1 (de) | Pflanzbehälter | |

| DE4407743C2 (de) | Vorrichtung zum Aufnehmen mehrerer bepflanzter Töpfe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19901130 |

|

| 17Q | First examination report despatched |

Effective date: 19920701 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19930503 |