EP0379291A2 - Drehventile für Blechblasinstrumente - Google Patents

Drehventile für Blechblasinstrumente Download PDFInfo

- Publication number

- EP0379291A2 EP0379291A2 EP90300215A EP90300215A EP0379291A2 EP 0379291 A2 EP0379291 A2 EP 0379291A2 EP 90300215 A EP90300215 A EP 90300215A EP 90300215 A EP90300215 A EP 90300215A EP 0379291 A2 EP0379291 A2 EP 0379291A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve body

- casing

- resin

- ceramic

- rotary valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D9/00—Details of, or accessories for, wind musical instruments

- G10D9/04—Valves; Valve controls

Definitions

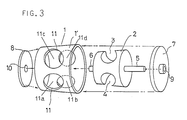

- openings 11 of round shapes are provided for the flow of air.

- the axle member 5 is connected to a cam rod (not shown in Fig. 3).

- the valve body 2 is rotated by means of the cam rod to a predetermined position and held at the position.

- a plurality of such rotary valves are provided in the cylindrical tubes of a brass instrument and, thus, such a wind instrument is constructed so that the paths of air flow can be changed in multiple ways.

- the openings 11a and 11b in Fig. 3 are connected to the cylindrical tubes of a brass wind instrument, respectively.

- the openings 11a and 11b communicate with the groove 4 of the valve body 2, for example, in the normal position of the valve body, and air flows from the opening 11a to the opening 11b via the groove 4.

- the openings 11c and 11d are connected with a cylindrical tube (not shown in FIG. 3).

- valve bodies and casings in conventional rotary valves have been made of brass, the axle members or valve axes and holes of bearings are apt to wear into looseness in a short period of use. Moreover, rust is often produced between the valve body and casing, which impairs smooth rotation of the valve body.

- a brass valve body can rotate smoothly by slightly oiling the valve with a lubricating oil and by the lubricating action of the water produced on outer surfaces of the valve body through dew condensation of the moisture contained in the breath of an instrument player. Thus, the valve body sometimes fails to rotate smoothly when humidity in air is so low or temperature is so warm that the dew condensation does not take place.

- a rotary valve for a brass wind instrument which comprises a valve body rotatably contained in a casing therefor, characterized in that the valve body comprises a machinable ceramic-resin composite material and the casing comprises a machinable ceramic-resin composite material or a metal material, the machinable ceramic containing substantially continuous micropores and being impregnated with a resin material, the resin material being hardened, and the composite material being machine-processed.

- both the valve body and casing comprise the ceramic-resin composite.

- the rotary valve can comprise valve axle members or axes of a hard ceramic (e.g. harder than the machinable ceramic) or anti-corrosive metal which are connected to the valve body and are supported by the bearings of a hard ceramic or anti-corrosive hard metal attached to the casing.

- the outer surface of the rotary valve can be substantially covered with a metal case which is readily brazed or soldered.

- the rotary valve according to the invention can be produced by a method which comprises: impregnating a machinable ceramic article containing substantially continuous micropores with a liquid resin material and hardening the resin material, machine-processing the resulting machinable ceramic-resin composite article into a shape of the valve body or shapes of the valve body and casing, and assembling the valve body into a rotary valve having the valve body rotatably contained in the casing.

- the machinable ceramics used in the present invention preferably have substantially continuous micropores, so that the ceramics can be effectively impregnated with resin materials.

- the amount of the micropores in the ceramics expressed by water absorption capacity (the weight increase of a ceramic owing to absorbed water when the ceramic is soaked in water for about 24 hours), is usually about 3 to 40 % by weight and preferably about 5 to 25 % by weight.

- the diameter of the micropores is desired to be considerably small in view of strength and homogeneity.

- the average diameter thereof is usually not more than 100 microns, preferably not more than 10 microns, more preferably not more than 5 microns, and typically about 5 to 0.1 micron.

- the ceramic material used in the working examples given below had a machinability (cutting speed) of more than 70 meters/minute without cutting fracture.

- the machinable ceramics used in the invention can be produced from a raw material mixture comprising, for example, 20 to 50 parts of CaO, 45 to 70 parts of SiO2 and 0.1 to 25 parts of MgO on a weight basis by molding the mixture and then sintering the resulting molded article at a maximum temperature of not lower than 1000°C and generally not higher than 1400°C, preferably not lower than 1100°C, more preferablly not lower than 1150°C and typically 1200 to 1350°C.

- the raw material can comprise the above-mentioned CaO/SiO2/MgO components, based on the total weight of the raw material, in an amount of not less than 60%, preferably not less than 70% and more preferably not less than 80%; and the raw material can contain not more than 20 % of other alkali/alkaline-earth metal oxide components and not more than 20% of other sintering mineral components based on the total weight of the raw material.

- the sintered ceramics used as a basic material of the rotary valve are preferably those having a composition of CaO, SiO2 and MgO which is defined by the region or area surrounded by points 1, 2, 3, 4, 5, 6 and 7 in FIG. 4.

- Each of the points 1 ⁇ 7 in FIG. 4 corresponds to the compositions shown in the following table. (% by weight) Point CaO SiO2 MgO 1 25.7 55.5 18.8 2 35.4 51.6 13.0 3 36.5 51.3 12.2 4 47.4 51.6 1.0 5 45.9 53.1 1.0 6 31.2 61.7 7.1 7 30.2 61.5 8.3

- the above-mentioned sintered ceramics containing CaO-MgO-SiO2 component systems are very good in cut-machinability.

- the ⁇ -wollastonite ( ⁇ CaO ⁇ SiO2) contained in the raw material is aggregated crystals of triclinic system which have grown in the form of platelets and has an excellent cut-machinability.

- monoclinic ⁇ -wollastonite is crystallized out of the ⁇ CaO ⁇ SiO2, which results in imparing the cut-machinability thereof.

- MgO is added to the ⁇ -wollastonite in order to raise the transition temperature of the ⁇ -wollastonite to ⁇ -wollastonite.

- the resulting mixture can be fired at the high temperature to obtain good machinability of the ⁇ -wollastonite and high mechanical strength.

- the amount of MgO is too much, the resulting sintered ceramic becomes too hard and the machinability thereof is decreased.

- sintered ceramics having a composition within a region surrounded by points 1-7 in Fig. 4 are preferred. It is also possible to use sintered ceramics of CaO ⁇ SiO2 component systems sintered at a lower temperature, although the strength of the ceramics is decreased.

- the sintered ceramic article which has been formed upon firing into a predetermined shape is degassed in a vacuum apparatus.

- the degassed sintered ceramic article can be satisfactorily impregnated with a resin by soaking the article in a liquid resin (preferably with pressurization of the liquid resin).

- the impregnated liquid resin is then hardened by heating or the like.

- acrylic resins e.g. polymethyl methacrylate (PMMA)

- epoxy resins epoxy resins

- saturated or unsaturated polyester resins silicone resins, and mixtures thereof.

- voids formed in the sintered article are substantially filled with the resin so that the article no longer significantly absorbs water, is not significantly air permeable, the bending strength thereof is increased and non-vibration property thereof is much enhanced.

- the ceramic article After impregnation with a resin as mentioned above, the ceramic article can be processed into parts having predetermined shapes by optionally utilizing working machines such as lathes and boring machines. Since the sintered ceramic article is excellent in cut-machinability, it can be subjected to processing such as drilling, grooving, etc. without generating cracks, chipping or the like to give a finished product having very high surface precision with respect to the outer surfaces of the valve body and the inner surfaces of the casing.

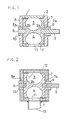

- FIG.1 is a longitudinal sectional view of a rotary valve of a brass wind according to an embodiment of the present invention.

- the casing 1 including terminal plates 7, 8 (about 1 ⁇ 4 mm in thickness) and the valve body 2 are made from a machinable ceramic impregnated with a resin.

- the terminal plates 7, 8 are bored openings 7a and 8a, respectively, and bearings 9 and 10 made from a hard ceramic such as alumina, zirconia or the like are inserted into the openings 7a and 8a, respectively.

- the terminal plates 7, 8 themselves may be made from a hard ceramic such as alumina, zirconia or the like. In such a case, the terminal plates 7, 8 and the bearings 9, 10 may be integrally formed.

- axle members 5 and 6 which are made from a hard ceramic such as alumina, zirconia or the like.

- the axle members 5 and 6 are inserted to the bearings 9 and 10 and supported thereby, respectively.

- the cylinder-like portion 1′ of the casing 1, terminal plates 7, 8, and bearings 9, 10 are bonded with an adhesive such as epoxy resins or the like. Also, the axle members 5, 6 are inserted into the above-mentioned concave holes 2a, 2b and bonded thereto with an adhesive.

- the machinable ceramic impregnated with a resin has very high strength and toughness due to the resin contained therein. Thus, there is no generation of fractures or the like during processing.

- the machinable ceramic impregnated with a resin has a specific gravity of about 2 ⁇ 2.5 similar to the ceramics or slightly higher than that by the weight of the resin and is light in weight. Thus, the rotary valves are light in weight.

- brass metal has a specific gravity of about 7.

- the axle members 5, 6 are simple round bars, and the bearings 9, 10 have a simple cylindrical shape.

- the axle members 5, 6 and bearings 9, 10 can be readily produced with high precision by means of a usual ceramic processing method, and the production cost is low.

- FIG.1 represents the same parts as shown in FIG.3.

- the casing 1 including terminal plates 7, 8 and the valve body 2 can be readily produced with high precision by using the machinable ceramic-resin composite.

- the valve body 2 can rotate very easily because of its light weight and good lubricating action, and is excellent in corrosion resistance.

- the axle members 5, 6 and the bearings 9, 10 are made from the hard material, the wear resistance of the bearings is very high.

- FIG. 2 is a longitudinal sectional view of a rotary valve according to another working example of the present invention.

- the casing 1 including terminal plates 7, 8 are substantially covered with a case 12 made of a metal material (e.g. brass). Since the metal case 12 can be connected to metal tubes 13 by means of brazing or soldering, ordinary craftsmen of the musical instruments can readily make or repair a brass wind instruments equipped with such rotary valves.

- a metal material e.g. brass

- the casing 1 can be produced from a metal material, although the casing is preferred to comprise the ceramic-resin composite material.

- the casing is of a soft metal such as brass metal as conventionally employed, the inside surfaces of the casing can be plated with a harder metal such as nickel or chromium. Where a metal casing 1 is used, the metal case 12 is not always needed.

- xonotlite and 10 parts by weight of talc (CaO: 44% by weight, SiO2: 53% by weight, MgO: 3% by weight) were dry-blended in an Eirich mixer for 5 minutes, and then 16% (outer percentage) by weight of water was added thereto.

- the resulting mixture was allowed to stand under a sealed state for 24 hours to give a raw mixture material in which the water content thereof has been homogenized.

- the raw material was placed in molds for a valve body and a cylinder-like portion of the casing and therminal plates, and molded at 450 Kgf/cm2.

- the molded articles were dried at 80°C for 24 hours and then fired.

- the firing was carried out in an electric furnace by raising temperature therein from room temperature to 1250°C at a rate of 10°C/min., firing the molded articles at 1250°C for 60 minutes, and then allowing the articles to cool to room temperature in the furnace.

- the resulting sintered article has a composition of ⁇ -wollastonite ( ⁇ CaO ⁇ SiO2) in which Mg is dissolved. It had a water absorption capacity of 10.3% and was very excellent in cut-machinablility. It had a bending strength of 500 Kg/cm2.

- the sintered ceramic article was placed in a vacuum apparatus and liquid PMMA was introduced with pressure to impregnate the ceramic article with the PMMA in the vacuum apparatus.

- the resin was hardened.

- the ceramic article thus impregnated with the resin had a water absorption capacity and air permeability of almost zero, which showed that the water absorption property and air permeability thereof had been eliminated.

- the machinable ceramic-resin composite material thus obtained was lathed, bored by means of a super-hard drill, and cut-machined to give the parts (i.e. the casing of about 2mm in thickness and the valve body) of the rotary valve shown in FIGS. 1 and 3.

- the parts i.e. the casing of about 2mm in thickness and the valve body

- a rotary valve as shown in FIG. 2 was produced.

- the rotary valve was produced from the machinable porous ceramic articles not impregnated with resin, as in Example 1 for comparison.

- the horn equipped with the resulting valves produced poor sound tones with some noises.

- the rotary valves rotated less smoothly.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Acoustics & Sound (AREA)

- Multimedia (AREA)

- Sliding Valves (AREA)

- Valve Housings (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP1002376A JPH02181787A (ja) | 1989-01-09 | 1989-01-09 | セラミックス製楽器 |

| JP2376/89 | 1989-01-09 | ||

| JP1074574A JPH02251994A (ja) | 1989-03-27 | 1989-03-27 | 金管楽器のロータリーバルブ |

| JP74574/89 | 1989-03-27 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0379291A2 true EP0379291A2 (de) | 1990-07-25 |

| EP0379291A3 EP0379291A3 (de) | 1990-12-27 |

Family

ID=26335739

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19900300215 Withdrawn EP0379291A3 (de) | 1989-01-09 | 1990-01-09 | Drehventile für Blechblasinstrumente |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0379291A3 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2670598A1 (fr) * | 1990-12-13 | 1992-06-19 | Holot Pierre Marie | Instrument de musique a vent a barillet. |

| WO1998005026A1 (de) * | 1996-07-30 | 1998-02-05 | Miraphone Graslitzer Musikinstrumentenerzeuger E.G. | Blechblasinstrument mit vorgefertigtem bauteil für die zylindermaschine |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4210056A (en) * | 1978-07-11 | 1980-07-01 | Ciccarelli Ronald R | Valve construction for brass wind instrument |

-

1990

- 1990-01-09 EP EP19900300215 patent/EP0379291A3/de not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2670598A1 (fr) * | 1990-12-13 | 1992-06-19 | Holot Pierre Marie | Instrument de musique a vent a barillet. |

| WO1998005026A1 (de) * | 1996-07-30 | 1998-02-05 | Miraphone Graslitzer Musikinstrumentenerzeuger E.G. | Blechblasinstrument mit vorgefertigtem bauteil für die zylindermaschine |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0379291A3 (de) | 1990-12-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4880707A (en) | Stick of composite materials and process for preparation thereof | |

| KR100749994B1 (ko) | 복합 회전도구 및 도구제작 방법 | |

| EP0339894B1 (de) | Verfahren zur Herstellung von zusammengesetzten Formkörpern mit komplexer innerer Geometrie | |

| US4972751A (en) | Rotary valves for brass wind instruments | |

| EP0379291A2 (de) | Drehventile für Blechblasinstrumente | |

| EP0377980B1 (de) | Keramik-Harzzusammensetzungen enthaltende Musikinstrumente | |

| JP4348583B2 (ja) | ダイヤモンドドリル及びその製造方法 | |

| Krishnamurthy et al. | Machining of polymeric composites | |

| DE3873542D1 (de) | Gasdurchlaessiger poroeser koerper, dessen herstellung sowie druckgiessform. | |

| JPH02275787A (ja) | 着色セラミック製品の製造法 | |

| JPS61281088A (ja) | 機械加工性に優れたセラミツク複合体 | |

| JP4912544B2 (ja) | 低熱伝導高剛性セラミックス | |

| KR20010080218A (ko) | 종이 이송롤러의 제조방법 | |

| JPS6362619A (ja) | 紡糸口金毛細管を形成させるための工具 | |

| JP3012234B1 (ja) | 紙送りロ―ラ及びその製造方法 | |

| SU1523257A1 (ru) | Расточной резец дл финишной обработки | |

| JP2005074532A (ja) | 回転工具 | |

| JPH05174520A (ja) | 記憶装置用高剛性支持体及び記憶装置 | |

| Hegeler et al. | Mechanical properties of carbon fibre-reinforced glasses | |

| Casstevens et al. | Rapid, Cost‐Effective Silicon Carbide Optical Component Manufacturing Technique | |

| JPS63210056A (ja) | セラミツクス加工体の製造法 | |

| Kim et al. | A Study on the Drilling Characteristics of Carbon Fiber Epoxy Composite Materials by Diamond Grit Electroplated Drills | |

| JPH0289812A (ja) | 静圧気体軸受 | |

| JP2002241871A (ja) | 切削加工可能な部分を有する金属−セラミックス複合材料及びその製造方法 | |

| JPH08229711A (ja) | ボーリングバー |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE FR GB LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB LI |

|

| 17P | Request for examination filed |

Effective date: 19910626 |

|

| 17Q | First examination report despatched |

Effective date: 19930224 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19940910 |