EP0356474B1 - Canal de distribution d'huile lubrifiante - Google Patents

Canal de distribution d'huile lubrifiante Download PDFInfo

- Publication number

- EP0356474B1 EP0356474B1 EP89901845A EP89901845A EP0356474B1 EP 0356474 B1 EP0356474 B1 EP 0356474B1 EP 89901845 A EP89901845 A EP 89901845A EP 89901845 A EP89901845 A EP 89901845A EP 0356474 B1 EP0356474 B1 EP 0356474B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plug

- channel

- socket

- tube

- lubricating oil

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000010687 lubricating oil Substances 0.000 title claims abstract description 11

- 238000002485 combustion reaction Methods 0.000 claims abstract description 5

- 238000007789 sealing Methods 0.000 claims description 7

- 230000002093 peripheral effect Effects 0.000 claims 2

- 230000037431 insertion Effects 0.000 claims 1

- 238000003780 insertion Methods 0.000 claims 1

- 238000003754 machining Methods 0.000 abstract description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000001143 conditioned effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01M—LUBRICATING OF MACHINES OR ENGINES IN GENERAL; LUBRICATING INTERNAL COMBUSTION ENGINES; CRANKCASE VENTILATING

- F01M11/00—Component parts, details or accessories, not provided for in, or of interest apart from, groups F01M1/00 - F01M9/00

- F01M11/02—Arrangements of lubricant conduits

Definitions

- the invention relates to a channel for the distribution of lubricating oil in a piston internal combustion engine according to the preamble of claim 1.

- the lubricating oil conditioned in the filter and oil cooler is supplied to various consumption points via the channel and through branch bores running in the transverse walls.

- Each channel section comprises two flange-like connecting parts fastened by screws, each with a sleeve and a tube which can be inserted sealingly into the sleeves of the two associated connecting parts. Sealing surfaces for the connection parts are formed around the mouths of the transverse wall passages of the channel.

- crankcase in the region of the channel by the design of the components for the channel sections between the transverse walls.

- the advantages achieved by the invention are, in particular, that there is a reduction in the manufacturing costs of the crankcase, that the weight and number of components of a duct section to be mounted between two transverse walls are reduced, that there are low manufacturing costs for socket and plug-in pipe, and that assembly and Disassembly of the components of the channel section can be carried out quickly and easily.

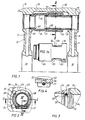

- a channel serving to distribute lubricating oil extends in the longitudinal direction of a piston internal combustion engine through a plurality of transverse walls 11, 12 of the crankcase 13, which is only partially shown.

- the transverse wall passages 14, 15 of the channel are designed as bores, from which branch holes 16, 17 depart, which the lubricating oil different consumption points, for. B. the crankshaft bearings 18, 19.

- the channel is formed from two axially joined components, which are sealed to one another and to the transverse wall passages 14, 15.

- the channel-forming components used between the transverse walls 11, 12 consist of a plug-in tube 23 and a socket tube 24 which receives the plug-in tube 23 in a sleeve 25 and which can be axially displaced relative to one another in the installed state.

- the mouth of the sleeve 25 is designed as a radially slotted clamp 26 with a screw as a clamping device 27.

- a radial groove for receiving a sealing ring 20, 21, 22 is arranged on the outer circumference of the free ends of the plug-in pipe 23 and the socket pipe 24 as well as on the end of the plug-in pipe 23 inserted in the socket 25.

- the three radial grooves advantageously have the same dimensions, so that only a single size of the sealing ring is required.

- the wall 28 of the sleeve 25 is axially adjacent to the clamp 26 located at the mouth of the sleeve 25 with two diametrically opposite openings 29, 30. Furthermore, two adjacent circumferential grooves 31, 32 are formed on the outer circumference in the middle part of the plug-in tube 23, which are located axially in relation to the openings 29, 30 in the wall 28 of the sleeve 25 and to the tensioning device 27 of the clamp 26.

- the plug-in tube 23 is pushed into the sleeve tube 24 up to the stop on the base 37 of the sleeve 25.

- the overall length of the parts joined into one another is shortened to such an extent that they can be inserted with axial play between the transverse walls 11, 12 (see FIG. 1a).

- the plug-in pipe 23 and the socket pipe 24 are in the aligned position with the drilled transverse wall passages 14, 15, the plug-in pipe is made with the aid of a tool which is supported through the openings 29, 30 in the visible circumferential groove 32 and on the end face of the clamp clip 26 23 pushed out of the sleeve 25.

- the circumferential groove 32 reaches the edge of the openings 29, 30 in the region of the clamp 26.

- the tool is then moved so that it is now accessible in the second adjacent circumferential groove 31, which is in the openings 29, 30 has become supported.

- the second sliding stroke of the plug-in pipe 23 is ended when the conical shoulders 34 formed on the free ends of the plug-in and socket pipe 23, 24 face the conical extensions 33 of the transverse wall passages 14, 15 with a small distance.

- the screw can be screwed into the clamp 26 and tightened.

- the clamp 26 is thereby clamped on the plug pipe 23, so that there is no longer any axial displacement between the plug and socket pipe 23, 24.

- the radial consist of the screw from the axis of the sleeve 25 is selected so that the screw shaft engages radially in the circumferential groove 32 (see Fig. 4). This provides additional protection against inadvertent pushing together of the plug-in tube 23 and the socket tube 24 if the tension of the clamp 26 should decrease.

- the tapered shoulders 34 on the plug and socket pipe 23, 24 have a small axial distance in the assembled state compared to the tapered extensions 33 of the transverse wall passages 14, 15, which absorbs different thermal expansions between the crankcase 13 and the channel-forming components.

- the tapered shoulders 34 also act as an axial limitation for the back and forth movement of the clamped channel-forming components, which results during the operation of the piston internal combustion engine.

- Two radially projecting cams 35 are formed on the outer circumference of the socket pipe 24. In the installed state, the cams 35 prevent rotation by contacting the contour 36 of the crankcase 13 of plug pipe 23 and sleeve pipe 24 about their common longitudinal axis. As a result, the accessibility of the tensioning device 27 of the clamp 26 and the openings 29, 30 is retained in the installed position, which facilitates disassembly that is required later.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Lubrication Of Internal Combustion Engines (AREA)

- Lubrication Details And Ventilation Of Internal Combustion Engines (AREA)

- Shafts, Cranks, Connecting Bars, And Related Bearings (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

- Cylinder Crankcases Of Internal Combustion Engines (AREA)

Abstract

Claims (5)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3805708 | 1988-02-24 | ||

| DE3805708A DE3805708C1 (fr) | 1988-02-24 | 1988-02-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0356474A1 EP0356474A1 (fr) | 1990-03-07 |

| EP0356474B1 true EP0356474B1 (fr) | 1991-10-16 |

Family

ID=6348024

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89901845A Expired - Lifetime EP0356474B1 (fr) | 1988-02-24 | 1989-02-01 | Canal de distribution d'huile lubrifiante |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US4961479A (fr) |

| EP (1) | EP0356474B1 (fr) |

| JP (1) | JPH0684723B2 (fr) |

| KR (1) | KR900700722A (fr) |

| CN (1) | CN1015320B (fr) |

| DE (2) | DE3805708C1 (fr) |

| ES (1) | ES2012917A6 (fr) |

| SU (1) | SU1766273A3 (fr) |

| WO (1) | WO1989008182A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4004846C1 (en) * | 1990-02-16 | 1991-01-03 | Mtu Friedrichshafen Gmbh | Oil distribution system for IC engine - uses lengths of pipe with ends sealed into partitions in crankcase |

| DE10329762A1 (de) * | 2003-07-02 | 2005-01-27 | Mtu Friedrichshafen Gmbh | Abdeckplatte für ein Kurbelgehäuse |

| DE102015007909A1 (de) * | 2015-06-20 | 2016-12-22 | Man Truck & Bus Ag | Schottwandkonstruktion mit integrierter Flüssigkeitsförderfunktion |

| CN105351027A (zh) * | 2015-11-04 | 2016-02-24 | 中国北方发动机研究所(天津) | 一种组合式的主油道 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE962838C (de) * | 1943-05-18 | 1957-04-25 | Maybach Motorenbau G M B H | OElzufuehrung zu Kurbelwellen in Brennkraftmaschinen, insbesondere fuer Kraftfahrzeuge |

| CH397330A (de) * | 1962-10-06 | 1965-08-15 | Sulzer Aktiengeselslchaft Geb | Kurbelwellenlager einer Kolbenmaschine |

| US3313284A (en) * | 1964-10-30 | 1967-04-11 | Sealed Power Corp | Cylinder wall lubrication |

| US3855987A (en) * | 1974-01-14 | 1974-12-24 | Gen Motors Corp | Rotary engine oil lubrication system |

| DE3703047C1 (de) * | 1987-02-03 | 1988-06-23 | Mtu Friedrichshafen Gmbh | Schmieroelkanal |

-

1988

- 1988-02-24 DE DE3805708A patent/DE3805708C1/de not_active Expired

- 1988-12-21 ES ES8803881A patent/ES2012917A6/es not_active Expired - Lifetime

-

1989

- 1989-01-19 CN CN89100395A patent/CN1015320B/zh not_active Expired

- 1989-02-01 EP EP89901845A patent/EP0356474B1/fr not_active Expired - Lifetime

- 1989-02-01 KR KR1019890701949A patent/KR900700722A/ko not_active Application Discontinuation

- 1989-02-01 WO PCT/DE1989/000058 patent/WO1989008182A1/fr active IP Right Grant

- 1989-02-01 US US07/427,838 patent/US4961479A/en not_active Expired - Fee Related

- 1989-02-01 DE DE8989901845T patent/DE58900375D1/de not_active Expired - Lifetime

- 1989-02-01 JP JP1501687A patent/JPH0684723B2/ja not_active Expired - Lifetime

- 1989-10-20 SU SU894742226A patent/SU1766273A3/ru active

Non-Patent Citations (1)

| Title |

|---|

| Patent Abstracts of Japan, vol. 8, No. 164, M313, abstract of JP 59- 60017, publ 1984-04-05 (HONDA GIKEN KOGYO K.K) see detail 24 * |

Also Published As

| Publication number | Publication date |

|---|---|

| KR900700722A (ko) | 1990-08-16 |

| SU1766273A3 (ru) | 1992-09-30 |

| EP0356474A1 (fr) | 1990-03-07 |

| ES2012917A6 (es) | 1990-04-16 |

| US4961479A (en) | 1990-10-09 |

| DE3805708C1 (fr) | 1989-03-30 |

| DE58900375D1 (de) | 1991-11-21 |

| CN1035343A (zh) | 1989-09-06 |

| WO1989008182A1 (fr) | 1989-09-08 |

| JPH02503342A (ja) | 1990-10-11 |

| JPH0684723B2 (ja) | 1994-10-26 |

| CN1015320B (zh) | 1992-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69410480T2 (de) | Befestigung eines oberseitig gespeisten kraftstoffeinspritzventils in einem integrierten luft-kraftstoffsystem | |

| DE3706136C1 (de) | Verfahren zur Herstellung eines Kettenspanners | |

| DE202005021715U1 (de) | Nockenwelle mit gegeneinander verdrehbaren Nocken für insbesondere Kraftfahrzeuge | |

| EP0080603A1 (fr) | Dispositif d'injection de combustible pour moteurs à combustion interne | |

| EP0469334B1 (fr) | Procédé pour changer la position angulaire des arbres d'un moteur à combustion interne | |

| WO1991019887A1 (fr) | Dispositif pour la distribution d'huile dans un arbre a cames | |

| DE3843659C2 (de) | Anschlußvorrichtung zwischen einer Kraftstoffrohrleitung und einem Einspritzventil einer Brennkraftmaschine | |

| DE69422601T2 (de) | Verbindungsleitung | |

| EP0568075A1 (fr) | Raccord à fiche pour tubes flexibles ou conduites de tuyaux, notamment pour conduites de carburant de machines à combustion interne | |

| DE10025591B4 (de) | Dichte Verbindung zweier Teile, wovon jedes rechtwinklig zusammenstoßende Verbindungsoberflächen besitzt | |

| EP1722096B1 (fr) | Injecteur de carburant avec un raccordement de fuite conçu | |

| EP0356474B1 (fr) | Canal de distribution d'huile lubrifiante | |

| DE4336952B4 (de) | Motorölkühler für eine Hubkolbenbrennkraftmaschine | |

| DE19541676A1 (de) | Abgassammelleitungsverbindung | |

| EP0172401B1 (fr) | Raccord pour conduits à canaux multiples | |

| DE2541988C2 (de) | Blockiervorrichtung für die Welle eines Turboladers | |

| DE1937444A1 (de) | Einspritzgeraete | |

| EP1288485A1 (fr) | Tuyau d'admission avec bride de fixation et insert pour renforcer la bride | |

| EP1283351A2 (fr) | Système d'admission pour un moteur à combustion interne | |

| EP0744531B1 (fr) | Culasse pour une machine à combustion interne | |

| DE2830506A1 (de) | Einrichtung zur zufuhr von schmieroel in die zylinderbuchse einer brennkraftmaschine | |

| DE2733302A1 (de) | Abgaskasten fuer mehrzylinder-brennkraftmaschinen, insbesondere fuer kraftfahrzeuge | |

| DE10159106A1 (de) | Brennkraftmaschine | |

| EP0472515B1 (fr) | Moteur à combustion interne avec un guide de canalisation venant de la chambre d'huile | |

| DE4004846C1 (en) | Oil distribution system for IC engine - uses lengths of pipe with ends sealed into partitions in crankcase |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19891013 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE FR GB IT LI |

|

| 17Q | First examination report despatched |

Effective date: 19910327 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB IT LI |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 58900375 Country of ref document: DE Date of ref document: 19911121 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 711B |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 711H |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930113 Year of fee payment: 5 Ref country code: DE Payment date: 19930113 Year of fee payment: 5 Ref country code: CH Payment date: 19930113 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930120 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19940228 Ref country code: CH Effective date: 19940228 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941031 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19941101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050201 |