EP0354620A1 - Elekrische Lampe mit einer lichtabsorbierenden Beschichtung - Google Patents

Elekrische Lampe mit einer lichtabsorbierenden Beschichtung Download PDFInfo

- Publication number

- EP0354620A1 EP0354620A1 EP89202045A EP89202045A EP0354620A1 EP 0354620 A1 EP0354620 A1 EP 0354620A1 EP 89202045 A EP89202045 A EP 89202045A EP 89202045 A EP89202045 A EP 89202045A EP 0354620 A1 EP0354620 A1 EP 0354620A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- light

- coating

- lamp

- bulb

- absorbing coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/02—Details

- H01J61/30—Vessels; Containers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01K—ELECTRIC INCANDESCENT LAMPS

- H01K1/00—Details

- H01K1/28—Envelopes; Vessels

- H01K1/32—Envelopes; Vessels provided with coatings on the walls; Vessels or coatings thereon characterised by the material thereof

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J5/00—Details relating to vessels or to leading-in conductors common to two or more basic types of discharge tubes or lamps

- H01J5/02—Vessels; Containers; Shields associated therewith; Vacuum locks

- H01J5/08—Vessels; Containers; Shields associated therewith; Vacuum locks provided with coatings on the walls thereof; Selection of materials for the coatings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01K—ELECTRIC INCANDESCENT LAMPS

- H01K9/00—Lamps having two or more incandescent bodies separately heated

- H01K9/08—Lamps having two or more incandescent bodies separately heated to provide selectively different light effects, e.g. for automobile headlamp

Definitions

- the invention relates to an electric lamp, the bulb of which is partially provided with a light-absorbing coating which contains iron oxide and manganese dioxide as colorants, which are contained in a silicon-containing binder.

- the silicon-containing binders usually consist of an organic silicon compound, which converts to silicon dioxide when heated. This silicon dioxide then acts as a glass frit for binding the colorants.

- the light-absorbing coating on the lamp bulb is often used to shield part of the emitted light.

- the lamp bulb is thus locally impermeable to light.

- Such lamps are e.g. Halogen light bulbs or high-pressure discharge lamps for automotive lighting; the latter can be provided with an outer bulb.

- the light-absorbing coating can be applied both outside and inside to the lamp bulb or the outer bulb. Since such lamps are subjected to high thermal loads, their bulbs usually consist of hard or quartz glass.

- the light-absorbing coating should be corrosion-resistant, firmly adhering to the lamp bulb and scratch-resistant.

- the colorants consist of iron oxide, cobalt oxide and manganese dioxide.

- Cobalt oxide CO3O4 has been considered a carcinogenic substance for some time, so that its use for coating electric lamps is no longer an option.

- the lamp known from GB-PS 13 34 329 in which the bulb coating contains cobalt oxide and carbonyl iron as colorants.

- an ethyl silicate paint is provided for the coating, which contains silicon as a black pigment. This color is relatively difficult to make and too translucent,

- the lamp according to DE-OS 28 37 280 has a light-absorbing coating which is made of carbonyl iron and silicon powder without silicon-containing binders.

- the coating is baked at a temperature of 530 ° C.

- this color can only be used for certain piston crown shapes and only by means of a complicated immersion process.

- the invention is therefore based on the object of providing an electric lamp with a technologically simple to install, well-adhering light-absorbing coating which is sufficiently opaque without the use of cobalt oxide.

- the colorants can be present in the starting mixture in the following proportions by weight: Magnetite: 14 to 20% Manganese dioxide: 8 to 16% Carbonyl iron: 14 to 21% Titanium dioxide: 5 to 12%.

- the starting mixture contains ethyl silicate as a binder, a firmly adhering coating is obtained.

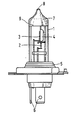

- the lamp is a 12 V, 55 W halogen lamp for use in a parabolic reflector of a motor vehicle headlight.

- the lamp has a bulb 1 made of quartz or hard glass. Inside the bulb 1 there are two incandescent filaments 2 and 3, of which the main incandescent filament 2 is arranged at the focal point of the parabolic reflector, while the low-beam incandescent filament 3 is partially surrounded by a dimming cap 4.

- the bulb 1 is filled with an inert gas and a halogen compound, so that a tungsten-halogen circuit can arise during operation of the lamp.

- the lamp bulb 1 is seated in a base 5 with connecting lugs 6.

- the dome 7 of the lamp bulb 1 with the pump stem melting 8 is provided on the outside with a light-absorbing coating 9.

- These Coating contains magnetite, manganese dioxide, carbonyl iron and titanium dioxide as colorants, which are contained in a silicon-containing binder.

- the coating 9 can consist of the following starting mixture: amount material 430 g Titanium dioxide 690 g Manganese IV oxide 70 g Sodium metaphosphate 1900 ml Ethyl silicate solution 150 ml Monobutyl glycol ether 80 ml Glycol 500 ml Ethanol denatured 96% 930 g Carbonyl iron EN 8 900 g Magnetite If necessary, a wetting agent can be added.

- All substances are placed together with about 3 kg of porcelain balls with a diameter of 13 mm in a 5 liter porcelain ball mill and milled therein on a roller table at 60 revolutions per minute for 18 hours.

- the finished mixture is then sieved through a metal gauze sieve with a mesh size of 0.1 mm. The mixture is then ready for use.

- the lamp bulbs 1 are dipped with this tip 7 into this mixture, then dried and subjected to a heat treatment by heating the bulbs with the applied coating 9 in a drying oven and the lamps are operated by applying a 12 V voltage source.

- the blackened tips 7 are then heated to red heat (1000 ° C.) by means of a ring burner with an oxidizing flame.

- red heat 1000 ° C.

- the ethyl silicate is converted into silicon dioxide and the iron powder is oxidized and baked so that the coating adheres firmly to the piston.

- the coating 9 has a thickness of approximately 0.005 mm.

- the light transmission values of the tips of the lamps produced in this way correspond approximately to those achieved by dipping twice with the colors previously used on an industrial scale.

Landscapes

- Vessels And Coating Films For Discharge Lamps (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

- Glass Compositions (AREA)

- Paints Or Removers (AREA)

- Common Detailed Techniques For Electron Tubes Or Discharge Tubes (AREA)

- Adhesives Or Adhesive Processes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3827451 | 1988-08-12 | ||

| DE3827451A DE3827451C1 (zh) | 1988-08-12 | 1988-08-12 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0354620A1 true EP0354620A1 (de) | 1990-02-14 |

Family

ID=6360758

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89202045A Withdrawn EP0354620A1 (de) | 1988-08-12 | 1989-08-07 | Elekrische Lampe mit einer lichtabsorbierenden Beschichtung |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0354620A1 (zh) |

| JP (1) | JPH0287456A (zh) |

| KR (1) | KR900003957A (zh) |

| CN (1) | CN1040458A (zh) |

| DD (1) | DD284097A5 (zh) |

| DE (1) | DE3827451C1 (zh) |

| HU (1) | HU201422B (zh) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0503429A2 (de) * | 1991-03-14 | 1992-09-16 | Patent-Treuhand-Gesellschaft für elektrische Glühlampen mbH | Einseitig gesockelte elektrische Lampe |

| WO1996015548A1 (en) * | 1994-11-10 | 1996-05-23 | Philips Electronics N.V. | Electric lamp |

| WO1999049498A1 (en) * | 1998-03-26 | 1999-09-30 | Koninklijke Philips Electronics N.V. | Electric lamp |

| EP1083588A1 (de) * | 1999-09-01 | 2001-03-14 | Philips Corporate Intellectual Property GmbH | Farbige Signalleuchte mit eisenoxidpigmentbeschichteter Lampe |

| US7740900B2 (en) | 2001-09-13 | 2010-06-22 | Koninklijke Philips Electronics N.V. | Method of preparing a light-absorbing coating |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2001020641A1 (en) * | 1999-09-13 | 2001-03-22 | Koninklijke Philips Electronics N.V. | Electric lamp |

| DE10040887A1 (de) * | 2000-08-18 | 2001-08-30 | Philips Corp Intellectual Pty | Halogen-Glühlampe für Kraftfahrzeuge |

| EP1921664A1 (en) * | 2006-11-09 | 2008-05-14 | Koninklijke Philips Electronics N.V. | Electric lamp with light-absorbing coating, precursor suspension for such a coating and method of making such a lamp |

| WO2014206432A1 (de) | 2013-06-28 | 2014-12-31 | Trumpf Laser- Und Systemtechnik Gmbh | VERFAHREN ZUR MASCHINELLEN BEARBEITUNG, INSBESONDERE ZUR MASCHINELLEN SCHWEIßBEARBEITUNG UND STEUERVORRICHTUNG FÜR EINE EINSTELLEINRICHTUNG EINER PROZESSGASZUFUHR |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2034987A (en) * | 1931-06-12 | 1936-03-24 | Morita Kikujiro | Process for coating glass sheets |

| CH384147A (de) * | 1957-12-10 | 1964-11-15 | Jenaer Glaswerk Schott & Gen | Verfahren zur Herstellung lichtabsorbierender Schichten |

| DE2136012A1 (de) * | 1971-07-19 | 1973-02-01 | Patra Patent Treuhand | Elektrische lampe mit lichtabdeckendem ueberzug |

| GB1422491A (en) * | 1973-01-15 | 1976-01-28 | Narva Veb | Electric lamp with light-impermeable coating |

| DE3043464A1 (de) * | 1979-11-23 | 1981-06-04 | Gte Products Corp., Wilmington, Del. | Lampe mit lichtundurchlaessiger beschichtung |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2837280A1 (de) * | 1978-08-25 | 1980-03-06 | Patra Patent Treuhand | Elektrische lampe mit lichtabdeckendem ueberzug |

-

1988

- 1988-08-12 DE DE3827451A patent/DE3827451C1/de not_active Expired

-

1989

- 1989-08-07 EP EP89202045A patent/EP0354620A1/de not_active Withdrawn

- 1989-08-09 CN CN89105638A patent/CN1040458A/zh active Pending

- 1989-08-09 DD DD89331615A patent/DD284097A5/de not_active IP Right Cessation

- 1989-08-09 JP JP1204903A patent/JPH0287456A/ja active Pending

- 1989-08-09 KR KR1019890011310A patent/KR900003957A/ko not_active Application Discontinuation

- 1989-08-09 HU HU894076A patent/HU201422B/hu not_active IP Right Cessation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2034987A (en) * | 1931-06-12 | 1936-03-24 | Morita Kikujiro | Process for coating glass sheets |

| CH384147A (de) * | 1957-12-10 | 1964-11-15 | Jenaer Glaswerk Schott & Gen | Verfahren zur Herstellung lichtabsorbierender Schichten |

| DE2136012A1 (de) * | 1971-07-19 | 1973-02-01 | Patra Patent Treuhand | Elektrische lampe mit lichtabdeckendem ueberzug |

| GB1422491A (en) * | 1973-01-15 | 1976-01-28 | Narva Veb | Electric lamp with light-impermeable coating |

| DE3043464A1 (de) * | 1979-11-23 | 1981-06-04 | Gte Products Corp., Wilmington, Del. | Lampe mit lichtundurchlaessiger beschichtung |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0503429A2 (de) * | 1991-03-14 | 1992-09-16 | Patent-Treuhand-Gesellschaft für elektrische Glühlampen mbH | Einseitig gesockelte elektrische Lampe |

| EP0503429A3 (en) * | 1991-03-14 | 1992-12-23 | Patent-Treuhand-Gesellschaft Fuer Elektrische Gluehlampen Mbh | Single-cap lamp |

| WO1996015548A1 (en) * | 1994-11-10 | 1996-05-23 | Philips Electronics N.V. | Electric lamp |

| US5619102A (en) * | 1994-11-10 | 1997-04-08 | U.S. Philips Corporation | Electric lamp |

| CN1089481C (zh) * | 1994-11-10 | 2002-08-21 | 皇家菲利浦电子有限公司 | 电灯 |

| WO1999049498A1 (en) * | 1998-03-26 | 1999-09-30 | Koninklijke Philips Electronics N.V. | Electric lamp |

| US6270237B1 (en) | 1998-03-26 | 2001-08-07 | U.S. Philips Corporation | Electric lamp with an anti-reflecting layer |

| EP1083588A1 (de) * | 1999-09-01 | 2001-03-14 | Philips Corporate Intellectual Property GmbH | Farbige Signalleuchte mit eisenoxidpigmentbeschichteter Lampe |

| US7740900B2 (en) | 2001-09-13 | 2010-06-22 | Koninklijke Philips Electronics N.V. | Method of preparing a light-absorbing coating |

Also Published As

| Publication number | Publication date |

|---|---|

| HU201422B (en) | 1990-10-28 |

| JPH0287456A (ja) | 1990-03-28 |

| KR900003957A (ko) | 1990-03-27 |

| DD284097A5 (de) | 1990-10-31 |

| CN1040458A (zh) | 1990-03-14 |

| DE3827451C1 (zh) | 1989-10-12 |

| HUT50533A (en) | 1990-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2835574C2 (zh) | ||

| DE69314907T2 (de) | Vorrichtung zur Herstellung und Abdichtung einer Lampenstromzuführung und Verfahren zu deren Herstellung | |

| DE2431128C2 (de) | Quecksilberdampf-Hochdrucklampe | |

| DE3827451C1 (zh) | ||

| DE68911587T2 (de) | Hochdruckmetallhalogenidentladungslampe. | |

| DE2522243A1 (de) | Fluoreszierende anzeigevorrichtung | |

| DE2732060C2 (de) | Elektrische Leuchtstofflampe | |

| DE2424974A1 (de) | Elektrode mit kohlenstoff-beschichteten flaechen fuer dampfentladungslampe | |

| DE2707583A1 (de) | Glimmlampe mit blau-weissem licht | |

| DE1489445B1 (de) | Elektrode fuer eine Quecksilberdampfhochdrucklampe mit Halogenidfuellung | |

| EP0076503B1 (de) | Einseitig gesockelte Niederdruckentladungslampe und Verfahren zur Herstellung | |

| DE10341816A1 (de) | Keramische Lichtbogenröhre mit internem Wulst | |

| DE3140839A1 (de) | Flaechenfoermige quecksilberdampf-niederdruckentladungslampe | |

| EP0118834B1 (de) | Einseitig gesockelte Niederdruckentladungslampe und Verfahren zur Herstellung | |

| DE3307763A1 (de) | Einseitig gesockelte niederdruckentladungslampe | |

| CH272702A (de) | Lichtquelle für Beleuchtung, Bestrahlung, Scheinwerfer und/oder Projektion. | |

| DE889806C (de) | Lichtquelle fuer Bestrahlung, Beleuchtung, Scheinwerfer und Projektion | |

| DE762566C (de) | Elektrische Scheinwerfergluehlampe, deren Lampengefaess aus einer parabolisch geformten und mit Spiegelbelag versehenen dickwandigen Schale aus Glas oder keramischem Werkstoff besteht | |

| DE702410C (de) | Aus Hohlglasbausteinen bestehende Gebaeudewand | |

| DE696952C (de) | Elektrische Mischlichtlampe, bei der der Lichtbogen einer Quecksilberhochdruckentladung zur Heizung eines ihn umschliessenden Gluehkoerpers dient | |

| DE3037223A1 (de) | Entladungslampe | |

| DE733786C (de) | Elektrische Mischlichtlampe, bestehend aus einer Gasentladungsroehre mit durch die Entladung aufgeheizten Gluehelektroden, einem mit dieser Roehre in Reihe geschalteten und deren Vorschaltwiderstand bildenden Gluehdraht sowie einer die Entladungsroehre und den Gluehdraht gasdicht umschliessenden Aussenhuelle | |

| DE599243C (de) | Elektrische Metalldampflampe fuer Beleuchtungs- und Bestrahlungszwecke | |

| DE1489445C (de) | Flektrode fur eine Quecksilberdampf hochdrucklampe mit HalogemdfuUung | |

| DE807636C (de) | Lampenfassung oder Leuchtenkappe fuer elektrische Gluehlampen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE ES FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19900808 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19930302 |