EP0342399A1 - Dispositif pour désamorcer des projectiles non explosés - Google Patents

Dispositif pour désamorcer des projectiles non explosés Download PDFInfo

- Publication number

- EP0342399A1 EP0342399A1 EP89107510A EP89107510A EP0342399A1 EP 0342399 A1 EP0342399 A1 EP 0342399A1 EP 89107510 A EP89107510 A EP 89107510A EP 89107510 A EP89107510 A EP 89107510A EP 0342399 A1 EP0342399 A1 EP 0342399A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rotor

- insert

- impact

- swirl

- projectile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42C—AMMUNITION FUZES; ARMING OR SAFETY MEANS THEREFOR

- F42C15/00—Arming-means in fuzes; Safety means for preventing premature detonation of fuzes or charges

- F42C15/44—Arrangements for disarming, or for rendering harmless, fuzes after arming, e.g. after launch

Definitions

- the invention relates to an unexploded ordnance insert for a projectile detonator, in which an amplifier charge is ignited by an explosive core and the unexploded ordnance insert is located between the intensified charge and the explosives core, the unexploded ordnance insert having a rotor which can be moved from its focus into a safety position, and an inhibitor which after a delay time, the rotor is moved from its arming position to its safety position, with means which trigger the inhibitor mechanism as a result of the impact delay.

- Such a dud operation i.e. a device for disarming the detonator if it has not ignited in the target after a certain time is known in various embodiments. Attention is drawn in particular to US-A-4,726,294 (see also EP-A-0 227 919).

- This patent describes an impact detonator that can defuse itself in a projectile that has become a dud.

- this impact detonator there is a dud insert between an explosive core and an amplifier charge, which contains an escapement that moves a rotor from its arming position to its safety position after a certain delay. Means are provided which, due to the delay in impact - when the projectile hits the target - trigger the escapement.

- This known unexploded ordnance insert has the disadvantage that it cannot be retrofitted into existing detonators, but can only be installed in a new, appropriately designed detonator.

- the object which is to be achieved with the present invention is to create a dud insert which is independent of the structure of the detonator, so that it can be installed in existing projectile detonators.

- a first embodiment of this dud insert can be used for detonators of twistless projectiles.

- the dud insert according to the invention is characterized in that the dud insert is located in a cylindrical housing and has no organs protruding from the housing, such that the dud insert can be retrofitted into existing projectile detonators.

- the first embodiment of the dud insert for detonators of swirl projectiles is characterized in that the rotor is held in its focused position by the swirl, and that the means for triggering the inhibitor mechanism consist in the disappearance of the swirl, in that when the swirl disappears, the rotor is released by the spring force of the Inhibitor is moved to its safety position.

- the second embodiment of the unexploded ordnance insert for detonators of swirl-free projectiles is characterized in that the rotor is held in its focus by an impact sensor before it hits the target and that the means for triggering the inhibitor consist of this impact sensor by displacing the impact sensor due to the impact delay and the rotor is released and moved into its safety position by the spring force of the escapement.

- this unexploded ordnance insert is that it can be inserted into the projectile detonator or omitted as required, the projectile detonator working with or without unexploded ordinance working just as well.

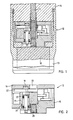

- the dud insert 12 has a housing 15 which is closed by a cover 16.

- a rotor 17 is rotatably mounted about an axis 18.

- This rotor 17 contains an explosive core 19 (FIG. 3) which, when the rotor 17 is in focus in the figure, is located vertically above a further explosive core 20.

- This second explosive core 20 is fixed in the middle of the housing 15.

- the booster charge 10 of the detonator can be ignited by the explosive core 11 (FIG. 1) of the detonator via the explosive cores 19 and 20 of the dud insert 12, thereby igniting the explosive charge of the projectile on which the detonator, not shown is attached.

- the rotor 17 has at its lower end a sleeve 21 which serves to mount the rotor 17 in the housing 15.

- the axis 18 is rigidly attached to a plate 22, with one end in the housing 15 and the other end in the cover 16.

- the axis 18 of the rotor 17 is also surrounded by a helical spring 23 which is anchored at one end in the housing 15 and at the other end in the plate 22. This spring 23 tends to turn the plate 22 clockwise (Fig.4).

- the plate 22 has a toothed segment 24 which is in engagement with a toothed wheel 25.

- This gearwheel 25 is part of a gearwheel transmission which consists of seven gearwheels 25, 26, 27, 28, 29, 30 and 31, by which an unrest 32 is driven.

- Both the seven gears 25 - 31 and the restlessness 32 are rotatably mounted in the housing 15 and in the cover 16.

- the restlessness 32 with the gears 25 - 31, in a manner known per se, causes the plate 22 with the toothed segment 24 to be underneath the action of the spring 23 can only rotate relatively slowly in a clockwise direction.

- the primer core 19 located in the rotor 17 projects through a recess 33 in the plate 22 into a recess 34 (FIG. 17) in the cover 16. If the plate 22 rotates clockwise under the action of the spring 23, then it abuts with an edge 35 of the recess 33 against the explosive core 19 and is therefore also able to rotate the rotor 17 clockwise. If, however, the plate 22 rotates counterclockwise against the action of the spring 23, then it abuts the explosive core 19 with a second edge 36 of the recess 33 and is therefore also able to rotate the rotor 17 counterclockwise.

- the center of gravity of the plate 22 is no longer in the middle, but at the point labeled ST (FIG. 4).

- the spin acceleration of the projectile when firing strives to turn the plate 22 counterclockwise and thereby pivot the rotor 17 into its focus position.

- the center of gravity of the rotor 17 is designated SR.

- a locking pin 37 is mounted in the rotor 17 so as to be displaceable in the axial direction of the projectile.

- a spring 38 which is supported on the one hand on a shoulder 39 of the bore 40, in which the locking pin 37 is guided, and on the other hand on a shoulder 41 of the locking pin 37, tends to push the pin 37 out of the rotor 17.

- This locking bolt 37 has at one end a conical tip which can protrude into corresponding bores in the housing 15 of the dud insert 12 in order to hold the rotor 17 in its armed position as well as in its safety position.

- the unexploded ordnance insert 42 according to FIGS. 10-16 differs from the described unexploded ordnance insert 12 for swirl projectiles only in the different shape of the rotor 43 and the plate 44, and also by an additional drop impact sensor 45 according to FIGS. 15 and 16.

- the plate 44 has a semicircular recess 46 into which the explosive core 47 of the rotor 43 projects.

- the explosive core 47 there are two locking bolts 48 and 49 in the rotor 43, which are of the same design as the locking bolt 37 (FIG. 9) of the first dud insert 12.

- the senor 45 has a displaceable sleeve 50, which has a flange 51 at its upper end.

- the sleeve 50 also has two radial bores 52, in which spherical locking bodies 53 are arranged. In the uppermost position of the sleeve 50, these blocking bodies 53 protrude into recesses 54 in a bore 55 of the rotor 43, in which the sensor 45 is slidably mounted.

- An inertial body 56 is arranged displaceably in the interior of the pot-shaped sleeve 50.

- a spring 57 which is supported on the one hand on the bottom of the cup-shaped sleeve 50 and on the other hand on a shoulder 58 of the inertial body 56, tends to push the inertial body 56 upward out of the sleeve 50.

- the inertial body 56 has a circumferential groove 59 and two longitudinal grooves 60, into which the two locking bodies 53 can protrude.

- the inertial body 56 also has a pin 61 which prevents the blocking bodies 53 from falling completely out of the bore 52 when the inertial body 56 is in its lowermost position. In this lowest position of the inertial body 56, the two locking bodies 53 no longer protrude into the cutouts 54 in the bore 55 of the rotor 43.

- the plate 44 consists of two riveted discs 62 and 63.

- the upper disc 63 has a first segment-shaped recess 64, into which the flange 51 of the sleeve 50 can penetrate in such a way that the plate 44 prevents any rotation is secured.

- the upper disk 63 also has a second elongated recess 65, which enables the plate 44 to be rotated through 45 ° when the flange 51 of the sleeve projects into this recess 65.

- the lower disk 62 has a single recess 66 into which the flange 51 of the sleeve 50 can penetrate in such a way that the plate 44 is secured against rotation in the clockwise direction. As can be seen from FIG.

- the flange 51 projects into one or the other of the recesses in the disk 63 and in the lower position of the sleeve 50, the flange 51 is located in the region of the lower disk 62.

- the dud insert 12 for swirl projectiles is in the state shown in FIG. 4, the edge 35 of the recess 33 abutting the explosive core 19.

- the center of gravity SR of the rotor 17 located in the safety position coincides with the igniter axis and the center of gravity ST of the plate 22 is such that the plate 22 can rotate counterclockwise under the action of the swirl.

- the toothed segment 24 drives the gears 25 - 31, whereby the rest 32 is braked by the unrest 32 and the plate 22 rotates only relatively slowly.

- the rotor 17 also begins to rotate counterclockwise until it reaches the position reached according to Fig. 6.

- the center of gravity ST of the plate 22 is then diagonally opposite.

- the plate 22 can therefore no longer be rotated under the action of the swirl.

- the rotor 17 is in its focus, so that the projectile can be ignited.

- the spring 23 is able to close the plate 22 in a clockwise direction turn until the edge 35 of the recess 33 of the plate 22 abuts the explosive core 19 (see FIG.

- the rotor 17 also rotates clockwise until it returns to its starting position according to FIG. In this safety position of the rotor 17, it is no longer possible to ignite the projectile using the detonator.

- the locking pin 37 projects into a corresponding bore in the housing 15 and is held in this position by the force of the spring.

- the unexploded ordnance insert is designed in such a way that, under the action of the unrest 32, the plate 22 rotates so slowly both clockwise and counterclockwise that first the safety of the fore-pipe is guaranteed and after the impact the rotor 17 hits the target after, for example, one to two seconds Occupies a safe position.

- the dud insert 42 for spinless ammunition is in the position shown in FIG.

- the rotor 43 is in its safety position.

- the impact sensor 45 is in its initial position according to FIG. 15a.

- the sleeve 50 protrudes with its flange 51 into the recess 64 of the disk 63, whereby any rotation of the plate 44 is prevented.

- the locking body 53 protrude into the recesses 54 in the Bore 55 of the housing 43 and prevent the sleeve 50 from moving.

- the inertial body 56 Due to the launch acceleration, the inertial body 56 is displaced against the force of the spring 57 and reaches its lowest position according to FIG. 15b.

- the locking body 53 can also move radially inwards and release the sleeve 50, which then also shifts to its lowest position according to FIG. 15b.

- the spring 23 is thus able to turn the plate 44 clockwise from the position shown in FIG. 10 to the position shown in FIG. 11.

- the locking pin 48 is freely displaceable and the rotor 43 can move counterclockwise from the position shown in FIG. 11 to the position shown in FIG. turn it into focus and the projectile can be ignited.

- the sensor 45 with its sleeve 50 moves back into its initial position, FIG.

- the plate 44 can also rotate clockwise from its position according to FIG. 12 to the position according to FIG. 13.

- the second locking pin 49 is no longer held by the plate 44 and the rotor 43 can rotate counterclockwise from the position shown in FIG. 13 to the position shown in FIG. 14, i.e. to its second safety position and the projectile can no longer be fired.

- the rotor 43 rotates counterclockwise from the position shown in FIG. 11 into the position shown in FIG. 12, the locking pin 49 moves in an elongated hole 67, since it has not yet been released by the plate 44.

- FIG. 9 there are two blind holes 68 and 69 in the plate 22, of which one or the other blind hole is located above the locking bolt 37. 4 there is a blind bore 68 and according to FIG. 5 the blind hole 69 above the locking pin 37.

- the locking pin 37 can only be moved according to FIG. 9 into its release position against the force of the spring 38 if one or the other blind hole 68 or 69 is located above the locking pin 37.

- the locking pin 37 is therefore not displaceable when the plate 22 is not in one of the two positions according to FIGS. 4 and 5. This locking of the locking pin 37 against an upward displacement by the plate 22 ensures that the rotor 17 cannot be moved inadvertently.

- a stop 70 which is designed as a bolt, prevents the rotor 43 from rotating further clockwise.

- the same stop 70 prevents the rotor 43 from rotating further counterclockwise. The stop 70 thus limits the rotation of the rotor 43 such that it can only be rotated clockwise from the position shown in FIG. 10 to the position shown in FIG. 14 and vice versa.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Toys (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH182788 | 1988-05-16 | ||

| CH1827/88 | 1988-05-16 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0342399A1 true EP0342399A1 (fr) | 1989-11-23 |

Family

ID=4219524

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89107510A Withdrawn EP0342399A1 (fr) | 1988-05-16 | 1989-04-26 | Dispositif pour désamorcer des projectiles non explosés |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4915028A (fr) |

| EP (1) | EP0342399A1 (fr) |

| JP (1) | JPH01318900A (fr) |

| IL (1) | IL90304A0 (fr) |

| NO (1) | NO891579L (fr) |

| ZA (1) | ZA893614B (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6050195A (en) * | 1998-12-03 | 2000-04-18 | The United States Of America As Represented By The Secretary Of The Army | Self neutralizing fuze |

| US7552682B2 (en) * | 2006-12-20 | 2009-06-30 | Alliant Techsystems Inc. | Accelerometer mounting for a penetrator and method thereof |

| US7549374B2 (en) * | 2006-12-20 | 2009-06-23 | Alliant Techsystems Inc. | Fuze mounting for a penetrator and method thereof |

| US8424456B2 (en) * | 2009-10-05 | 2013-04-23 | Amtec Corporation | Non-dud signature training cartridge and projectile |

| US9217627B2 (en) | 2013-03-21 | 2015-12-22 | Kms Consulting, Llc | Training ammunition cartridge with reactive liquid materials for marking a point of impact |

| US11506474B1 (en) * | 2021-06-03 | 2022-11-22 | Aura Technologies, Llc | Spin-stabilized fuze assembly |

| WO2023277816A2 (fr) * | 2021-06-29 | 2023-01-05 | St Engineering Advanced Material Engineering Pte. Ltd. | Dispositif de sécurité et d'armement |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2513158A (en) * | 1947-12-01 | 1950-06-27 | Us Navy | Cavity liner |

| US2947249A (en) * | 1953-02-06 | 1960-08-02 | Charles C Vogt | Mine case and instrument mounting system |

| GB930284A (en) * | 1961-01-10 | 1963-07-03 | Clevite Corp | Torpedoes and like underwater devices |

| US3157125A (en) * | 1963-07-01 | 1964-11-17 | Honeywell Inc | Rotor safety lock for munition fuze |

| US3175125A (en) * | 1961-04-14 | 1965-03-23 | Red Jacket Mfg Company | Motor control box |

| US3732822A (en) * | 1966-01-12 | 1973-05-15 | F Thomanek | Explosive encapsulated device |

| EP0206978A1 (fr) * | 1985-06-06 | 1986-12-30 | Mefina S.A. | Fusée de projectile à percussion |

| EP0227919A1 (fr) * | 1985-12-17 | 1987-07-08 | Werkzeugmaschinenfabrik Oerlikon-Bührle AG | Fusée d'impact pour projectile |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL101169C (fr) * | 1951-04-13 | |||

| US3045597A (en) * | 1960-09-21 | 1962-07-24 | Sidney S Linn | Centrifugal type safety and arming spring for fuze applications |

| CH594869A5 (fr) * | 1975-06-27 | 1978-01-31 | Oerlikon Buehrle Ag | |

| BE859035A (fr) * | 1976-11-05 | 1978-01-16 | Sormel Sa | Dispositif de securite a volet pour chaine pyrotechnique |

| DE3108659C2 (de) * | 1981-03-07 | 1985-01-03 | Gebrüder Junghans GmbH, 7230 Schramberg | Sicherungsvorrichtung für Zünder von drallfreien bzw. drallarmen Geschossen |

| DE3635084A1 (de) * | 1986-10-15 | 1988-04-21 | Junghans Gmbh Geb | Zuendeinrichtung |

-

1989

- 1989-04-18 NO NO89891579A patent/NO891579L/no unknown

- 1989-04-26 EP EP89107510A patent/EP0342399A1/fr not_active Withdrawn

- 1989-05-02 JP JP1112283A patent/JPH01318900A/ja active Pending

- 1989-05-12 US US07/350,913 patent/US4915028A/en not_active Expired - Fee Related

- 1989-05-15 IL IL90304A patent/IL90304A0/xx unknown

- 1989-05-15 ZA ZA893614A patent/ZA893614B/xx unknown

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2513158A (en) * | 1947-12-01 | 1950-06-27 | Us Navy | Cavity liner |

| US2947249A (en) * | 1953-02-06 | 1960-08-02 | Charles C Vogt | Mine case and instrument mounting system |

| GB930284A (en) * | 1961-01-10 | 1963-07-03 | Clevite Corp | Torpedoes and like underwater devices |

| US3175125A (en) * | 1961-04-14 | 1965-03-23 | Red Jacket Mfg Company | Motor control box |

| US3157125A (en) * | 1963-07-01 | 1964-11-17 | Honeywell Inc | Rotor safety lock for munition fuze |

| US3732822A (en) * | 1966-01-12 | 1973-05-15 | F Thomanek | Explosive encapsulated device |

| EP0206978A1 (fr) * | 1985-06-06 | 1986-12-30 | Mefina S.A. | Fusée de projectile à percussion |

| EP0227919A1 (fr) * | 1985-12-17 | 1987-07-08 | Werkzeugmaschinenfabrik Oerlikon-Bührle AG | Fusée d'impact pour projectile |

Also Published As

| Publication number | Publication date |

|---|---|

| ZA893614B (en) | 1990-01-31 |

| NO891579L (no) | 1989-11-17 |

| NO891579D0 (no) | 1989-04-18 |

| IL90304A0 (en) | 1989-12-15 |

| US4915028A (en) | 1990-04-10 |

| JPH01318900A (ja) | 1989-12-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0364670B1 (fr) | Grenade | |

| DE3883821T2 (de) | Sicherung für eine Submunition. | |

| DE69015046T2 (de) | Zündvorrichtung einer Zündkette für Submunitionskörpern. | |

| EP0158700B1 (fr) | Fusée pour projectile secondaire | |

| DE3624713A1 (de) | Zuender fuer ein fallschirm- oder bandstabilisiertes, im flug rotierendes bomblett | |

| DE19983923B4 (de) | Selbstzerstörender Aufprallzünder | |

| DE1578457A1 (de) | Aufschlagzuender | |

| EP0411258A2 (fr) | Dispositif d'allumage pour une sous munition | |

| DE2838381C2 (de) | Sicherheitsvorrichtung für Zündvorrichtungen | |

| EP0342399A1 (fr) | Dispositif pour désamorcer des projectiles non explosés | |

| EP0042957B1 (fr) | Fusée pour projectiles à rotation | |

| DE69305907T2 (de) | Sicherheits- und Schärfvorrichtung für Zünder von Geschossen mit einem Erschütterungsschutzmittel | |

| DE4303128C2 (de) | Zündvorrichtung für Geschosse, Raketen, Bomblets und Minen mit einer pyrotechnischen Selbstzerlegervorrichtung | |

| EP0046906A2 (fr) | Dispositif de sécurité pour la fusée d'un projectile à giration | |

| EP0104138B1 (fr) | Dispositif pour armer et neutraliser une fusée électrique pour munition | |

| EP0318997B1 (fr) | Dispositif de sécurité pour une fusée à autodestruction par combustion pour utilisation dans des bombes | |

| CH657450A5 (de) | Beharrungszuender fuer drallgeschosse mit selbstzerlegereinrichtung. | |

| DE69609255T2 (de) | Vorrichtung zum Zünden einer Treibladung für eine aus einem Trägergeschoss geworfene Submunition | |

| DE2400947C3 (de) | Sicherungs- und Entsicherungsvorrichtung für GeschoDzünder | |

| EP0227919B1 (fr) | Fusée d'impact pour projectile | |

| DE2247209A1 (de) | Mechanischer selbstzerlegbarer momentanzuender mit sprengkapsel- und flugbahnsicherung | |

| DE102004016356A1 (de) | Verbesserter Submunitionszünder | |

| DE69313830T2 (de) | Zünd- und selbstzerlegungssystem für submunition | |

| DE60301401T2 (de) | Selbst-Zerlegerzünder für drallstabilisierte Geschosse | |

| AT208267B (de) | Aufschlagzünder mit Zündkapsel für nichtrotierende Geschoße |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE CH DE FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19891207 |

|

| 17Q | First examination report despatched |

Effective date: 19910205 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19911207 |