EP0341131A1 - Verfahren und Raum zur thermischen Behandlung mit einer Abkühlungsstufe - Google Patents

Verfahren und Raum zur thermischen Behandlung mit einer Abkühlungsstufe Download PDFInfo

- Publication number

- EP0341131A1 EP0341131A1 EP89401182A EP89401182A EP0341131A1 EP 0341131 A1 EP0341131 A1 EP 0341131A1 EP 89401182 A EP89401182 A EP 89401182A EP 89401182 A EP89401182 A EP 89401182A EP 0341131 A1 EP0341131 A1 EP 0341131A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- enclosure

- gas

- treatment

- gases

- cooling phase

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000001816 cooling Methods 0.000 title claims abstract description 26

- 238000000034 method Methods 0.000 title claims abstract description 25

- 238000007669 thermal treatment Methods 0.000 title 1

- 239000007789 gas Substances 0.000 claims abstract description 40

- 239000012530 fluid Substances 0.000 claims abstract description 14

- 238000002347 injection Methods 0.000 claims abstract description 6

- 239000007924 injection Substances 0.000 claims abstract description 6

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 claims description 16

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 8

- 229910002092 carbon dioxide Inorganic materials 0.000 claims description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 8

- 238000010411 cooking Methods 0.000 claims description 6

- 230000001954 sterilising effect Effects 0.000 claims description 6

- 238000004659 sterilization and disinfection Methods 0.000 claims description 6

- 239000007788 liquid Substances 0.000 claims description 5

- 229910052757 nitrogen Inorganic materials 0.000 claims description 4

- 238000005507 spraying Methods 0.000 claims description 4

- 239000001569 carbon dioxide Substances 0.000 claims description 3

- 238000007710 freezing Methods 0.000 claims description 3

- 238000007654 immersion Methods 0.000 claims description 3

- 230000008014 freezing Effects 0.000 claims description 2

- 238000007599 discharging Methods 0.000 claims 1

- 239000012071 phase Substances 0.000 description 6

- 238000010438 heat treatment Methods 0.000 description 5

- 235000013305 food Nutrition 0.000 description 4

- 239000000203 mixture Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 2

- 238000005192 partition Methods 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 230000000844 anti-bacterial effect Effects 0.000 description 1

- 230000000721 bacterilogical effect Effects 0.000 description 1

- 230000003385 bacteriostatic effect Effects 0.000 description 1

- 239000010836 blood and blood product Substances 0.000 description 1

- 229940125691 blood product Drugs 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000005660 chlorination reaction Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 239000013505 freshwater Substances 0.000 description 1

- 239000007792 gaseous phase Substances 0.000 description 1

- 239000013529 heat transfer fluid Substances 0.000 description 1

- 239000005457 ice water Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 238000009928 pasteurization Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 238000004321 preservation Methods 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D3/00—Devices using other cold materials; Devices using cold-storage bodies

- F25D3/10—Devices using other cold materials; Devices using cold-storage bodies using liquefied gases, e.g. liquid air

- F25D3/102—Stationary cabinets

Definitions

- the present invention relates to an enclosure for heat treatment as well as to a heat treatment method comprising a cooling phase using cryogenic fluid.

- loads of numerous products or objects are treated by cooking and / or sterilization then cooling.

- This treatment generally includes a hot step, sterilization or cooking followed by cooling.

- the hot stage can be carried out with steam, which is very satisfactory in terms of processing speed and temperature uniformity within the products. Cooling is necessary for the subsequent handling of the objects in the case of sterilization or preservation. products in the case of food products.

- Cooling for economic reasons (speed) or for reasons of quality of the cooked products (in the case of food products) must be carried out according to temperature profiles over time which are precise and restrictive for manufacturers.

- the immersion technique allows more homogeneous cooling, but this process is limited to positive cooling on the order of + 10 ° C, and for treatment times on the order of 2 hours.

- both immersion and the spraying of chilled water require storage of water conditioning at + 1 or 2 ° C, including cold groups (size and high cost, significant maintenance); they are incompatible with the cooling of unpackaged bulk products; and finally they require treatment of the water before use to obtain a bactericidal state (chlorination for example), the suitable bacteriological agent tending to degrade the material by physico-chemical attack (inter-granular corrosion).

- the present invention provides a solution to the lack of temperature uniformity while maintaining efficient cooling kinetics whatever the load to be cooled (product in sealed packaging or product in bulk).

- the temperature setpoint can be negative.

- the method and the enclosures according to the invention can be implemented and used in the food industries, the pharmaceutical industries, in hospital pharmacy, in the chemical, plastics and composites industries, for the heat treatment of materials and in industry electronic.

- the present invention relates to a heat treatment chamber for a load comprising at least one door, internal walls delimiting a treatment space and gas recirculation passages, means for circulating the gases in the treatment space and said passages, characterized in that said means for circulating the gases extract the gases from said space and send them into said passages and in that the enclosure is further provided with means for injecting fluid cryogenic and gas evacuation means.

- the treatment can therefore according to the invention take place in a single enclosure, so that all of the treatment, even when it comprises a final phase of deep-freezing, can be carried out without manipulation of one enclosure in another enclosure, and without handling or movement of the load in the enclosure where the cooling is perfectly homogeneous.

- the enclosures are generally cylindrical and heat-insulated, using steam as the heat transfer fluid and intended to treat products in cooking, pasteurization, sterilization, or any other type of heat treatment, followed by cooling.

- enclosures are autoclaves, capable of working under pressure.

- the present invention also relates to a method of treatment in an enclosure of a load of products and / or objects comprising a cooling phase, characterized in that to carry out the cooling phase, a flow of cryogenic gas is circulated to through the charge, a cryogenic fluid is injected into the flow of gas leaving the charge and the cooled gas is recirculated to make it pass through the charge again in the same direction.

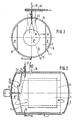

- Figure 1 shows a partial sectional view along A of an enclosure according to the invention and Figure 2 shows an axial sectional view along B.

- Figure 3 shows the temperature versus time for different coolants.

- the cylindrical enclosure 1 with heat-insulated walls capable of withstanding an overpressure comprises a door 2 .

- a load 3 of products to be treated is placed in the treatment space 4 delimited by the walls 5.5 ′ of the enclosure 1 , the partitions 6.6 ′ , the door 2 and the truncated cone disposed at the end of the enclosure opposite door 2 .

- the partitions 6,6 ′ and the cone 7 delimit passages 9,9 ′, 9 ⁇ .

- the fan 8 is capable of sucking the gas flow out of the treatment space 4 by the cone 7 .

- the opening 10 of the truncated cone 7 is opposite the fan 8 .

- the wall of the enclosure 1 is crossed near the fan 8 by at least one pipe 11 for supplying cryogenic fluid provided inside the enclosure 1 with a spray nozzle 12 directing the sprayed fluid towards the fan blades 13 .

- FIG. 1 Three nozzles are provided, as shown in FIG. 1 where a pipe 14 provided with a valve 15 makes it possible to distribute the cryogenic fluid coming from a reservoir not shown in three nozzles, but only one nozzle 12 is shown in detail. The number of nozzles depends on the capacity of the autoclave.

- a gas discharge orifice 16 is also provided in the wall 5 of the enclosure.

- the evacuation of gases is controlled by a valve 17 .

- the nozzle 12 can be a nozzle for spraying carbon dioxide or liquid nitrogen.

- the fan 8 When the fan 8 is operating, it circulates the gases as indicated in the figures by the arrows. The gas flow passes through the load 3 placed in the treatment space in the direction of the fan 8 which flows back towards the space 9 ⁇ . During this passage through the charge, it heats up giving its frigories. The cryogenic fluid injected by the nozzle (s) on the blades is refluxed with the gas heated in the space 9 ⁇ . In space 9 ⁇ , the mixture of gas and the cryogenic fluid supply recirculates through passages 9 and 9 ′ towards the opposite end of the autoclave, and crosses the load in the direction of the fan.

- the method according to the invention can prohibit any contact between the gas and the load during the recirculation.

- the pressure is regulated by the valve 17 closing the orifice 16 for the gas outlet.

- the orifice 16 is placed as close as possible to the end of the load, and if possible after the load on the side of the fan.

- the fan serves as a "flow or ventilated atmosphere + intake” mixer and delivers a homogeneous gas in temperature on its periphery.

- the cryogenic fluid and the flow thus mix perfectly during their passage through the space 9 ⁇ and the passages 9 and 9 ′ before passing through the charge.

- the arrangement of the nozzle in the treatment space 4 and not in the space 9 ⁇ has an advantage because the propeller shaft is protected, since it is located in an area not interested in ventilation.

- the orientation of the nozzle and its positioning in the autoclave, preferably near the fan allow when the solenoid valve opens a total transformation of the liquid CO2 into the gaseous phase by delivering the maximum of frigories.

- the nozzle directs the jet of CO2 towards the "reaction" propeller for ventilating the autoclave so as to almost instantaneously mix the supply of CO2 with the ventilated atmosphere.

- the pressure in the autoclave can be regulated.

- liquid nitrogen can be used.

- the method according to the invention can be adapted to many types of treatment, both cooking and cooling of packaged foodstuffs or the sterilization and cooling of objects for the pharmaceutical industry and the treatment of blood products in bags. .

- the temperature must drop from a cooking temperature of the order of 60 ° to 90 ° C, in less than two hours, to a temperature of 10 ° C at its core.

- This profile can be respected with CO2 for example, as it appears on figure 3, in a sure way (3 ° C reached) and faster than with forced air (cooled on finned exchanger by fresh water in circulation ) or sprayed 2 ° C ice water.

- An advantage of the process according to the invention appears when consumable products packaged under gas are cooked and then cooled. Indeed, it is then important that the pressure remains relatively constant during the entire treatment in the enclosure, especially for the appearance of the product.

- the pressure profile is easily controllable when all the treatment is carried out under cold gas or even hot then cold.

- the method according to the invention also comprises, or as a cold step, the freezing of the products.

- CO2 in particular has an advantageous bacteriostatic effect compared to water or air.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Food Preservation Except Freezing, Refrigeration, And Drying (AREA)

- Apparatus For Disinfection Or Sterilisation (AREA)

- Freezing, Cooling And Drying Of Foods (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8805879A FR2630818B1 (fr) | 1988-05-02 | 1988-05-02 | Enceinte et procede de traitement thermique comportant une phase de refroidissement |

| FR8805879 | 1988-05-02 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0341131A1 true EP0341131A1 (de) | 1989-11-08 |

| EP0341131B1 EP0341131B1 (de) | 1993-09-29 |

Family

ID=9365908

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89401182A Expired - Lifetime EP0341131B1 (de) | 1988-05-02 | 1989-04-26 | Verfahren und Raum zur thermischen Behandlung mit einer Abkühlungsstufe |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US4878353A (de) |

| EP (1) | EP0341131B1 (de) |

| AU (1) | AU632746B2 (de) |

| CA (1) | CA1332111C (de) |

| DE (1) | DE68909484T2 (de) |

| ES (1) | ES2044162T3 (de) |

| FR (1) | FR2630818B1 (de) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5879732A (en) | 1996-09-10 | 1999-03-09 | Boc Group, Inc. | Food processing method |

| JP3346716B2 (ja) * | 1997-02-14 | 2002-11-18 | 東京エレクトロン株式会社 | 基板冷却方法および基板冷却装置 |

| US7905154B2 (en) * | 2004-11-29 | 2011-03-15 | Jones Jr Arthur T | Apparatus and method of contaminant detection for food industry |

| EP2193307B1 (de) * | 2007-08-28 | 2014-04-23 | Air Products and Chemicals, Inc. | Vorrichtung und verfahren zur bereitstellung von kondensations- und frostfreien oberflächen auf kryogenen komponenten |

| US9587873B2 (en) * | 2012-03-27 | 2017-03-07 | Global Cooling, Inc. | Energy efficient biological freezer with vial management system |

| CN106766514A (zh) * | 2016-12-02 | 2017-05-31 | 青岛海尔股份有限公司 | 冷藏冷冻设备 |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1588664A (de) * | 1967-10-13 | 1970-04-17 | ||

| FR2019050A1 (de) * | 1968-09-27 | 1970-06-26 | Universal Oil Prod Co | |

| FR2462673A1 (fr) * | 1979-08-03 | 1981-02-13 | Carboxyque Francaise | Enceinte de refrigeration |

| US4304293A (en) * | 1979-06-18 | 1981-12-08 | Helmholtz-Institut Fur Biomedizinische Technik | Process and apparatus for freezing living cells |

| CA1128329A (en) * | 1981-04-24 | 1982-07-27 | Douglas Hurst | Cryogenic treatment of materials |

| EP0069688A2 (de) * | 1981-05-29 | 1983-01-12 | Jean-Paul Keller | Verfahren zur Tiefkühlung und zur Verpackung einzelner Produkte und Vorrichtung zur Durchführung dieses Verfahrens |

| FR2526927A1 (fr) * | 1982-05-14 | 1983-11-18 | Anhydride Carbonique Ind | Cellule de surgelation et de refroidissement |

| EP0170580A1 (de) * | 1984-07-12 | 1986-02-05 | Carboxyque Francaise | Verfahren und Vorrichtung zur Kühlung einer Produktladung |

| FR2593593A1 (fr) * | 1986-01-28 | 1987-07-31 | Carboxyque Francaise | Procede et appareil pour realiser dans un objet mou une cavite cylindrique |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4399658A (en) * | 1978-02-08 | 1983-08-23 | Safeway Stores, Incorporated | Refrigeration system with carbon dioxide injector |

| US4237700A (en) * | 1979-04-20 | 1980-12-09 | Airco, Inc. | Methods and apparatus for providing refrigeration |

| FR2530004A1 (fr) * | 1982-07-07 | 1984-01-13 | Air Liquide | Dispositif de congelation de produits biologiques conditionnes en tubes, ampoules ou paillettes |

| US4481782A (en) * | 1983-01-25 | 1984-11-13 | The Boc Group, Inc. | Methods and apparatus for refrigerating products |

| US4475351A (en) * | 1983-08-09 | 1984-10-09 | Air Products And Chemicals, Inc. | Dual-flow cryogenic freezer |

| US4644754A (en) * | 1984-01-11 | 1987-02-24 | Carboxyque Francaise | Process and apparatus for cooling a charge of products |

| FR2558337B1 (fr) * | 1984-01-19 | 1986-05-02 | Air Liquide | Dispositif de congelation de produits biologiques conditionnes en paillettes |

-

1988

- 1988-05-02 FR FR8805879A patent/FR2630818B1/fr not_active Expired - Fee Related

- 1988-09-09 US US07/244,516 patent/US4878353A/en not_active Ceased

-

1989

- 1989-04-26 DE DE89401182T patent/DE68909484T2/de not_active Expired - Lifetime

- 1989-04-26 ES ES89401182T patent/ES2044162T3/es not_active Expired - Lifetime

- 1989-04-26 EP EP89401182A patent/EP0341131B1/de not_active Expired - Lifetime

- 1989-05-01 CA CA000598309A patent/CA1332111C/fr not_active Expired - Fee Related

- 1989-05-01 AU AU33888/89A patent/AU632746B2/en not_active Ceased

-

1990

- 1990-04-12 US US07/507,883 patent/USRE33852E/en not_active Expired - Lifetime

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1588664A (de) * | 1967-10-13 | 1970-04-17 | ||

| FR2019050A1 (de) * | 1968-09-27 | 1970-06-26 | Universal Oil Prod Co | |

| US4304293A (en) * | 1979-06-18 | 1981-12-08 | Helmholtz-Institut Fur Biomedizinische Technik | Process and apparatus for freezing living cells |

| FR2462673A1 (fr) * | 1979-08-03 | 1981-02-13 | Carboxyque Francaise | Enceinte de refrigeration |

| CA1128329A (en) * | 1981-04-24 | 1982-07-27 | Douglas Hurst | Cryogenic treatment of materials |

| EP0069688A2 (de) * | 1981-05-29 | 1983-01-12 | Jean-Paul Keller | Verfahren zur Tiefkühlung und zur Verpackung einzelner Produkte und Vorrichtung zur Durchführung dieses Verfahrens |

| FR2526927A1 (fr) * | 1982-05-14 | 1983-11-18 | Anhydride Carbonique Ind | Cellule de surgelation et de refroidissement |

| EP0170580A1 (de) * | 1984-07-12 | 1986-02-05 | Carboxyque Francaise | Verfahren und Vorrichtung zur Kühlung einer Produktladung |

| FR2593593A1 (fr) * | 1986-01-28 | 1987-07-31 | Carboxyque Francaise | Procede et appareil pour realiser dans un objet mou une cavite cylindrique |

Also Published As

| Publication number | Publication date |

|---|---|

| AU632746B2 (en) | 1993-01-14 |

| FR2630818A1 (fr) | 1989-11-03 |

| ES2044162T3 (es) | 1994-01-01 |

| FR2630818B1 (fr) | 1990-09-14 |

| CA1332111C (fr) | 1994-09-27 |

| DE68909484T2 (de) | 1994-05-11 |

| DE68909484D1 (de) | 1993-11-04 |

| EP0341131B1 (de) | 1993-09-29 |

| AU3388889A (en) | 1989-11-02 |

| USRE33852E (en) | 1992-03-24 |

| US4878353A (en) | 1989-11-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3214928A (en) | Method and apparatus for freezing food products | |

| US4994294A (en) | Temperature controlled food processing apparatus and method | |

| US5036673A (en) | Method and apparatus for freezing products | |

| US4478861A (en) | Preparation of a frozen food product for later use | |

| US10259161B2 (en) | Deposition of materials for edible solid freeform fabrication | |

| CA2954344C (fr) | Installation de decongelation ou de temperage de produits alimentaires congeles | |

| JPH10150964A (ja) | 食品処理装置 | |

| AU2003263880B2 (en) | Method and apparatus for surface crust freezing of food products | |

| US20100050656A1 (en) | Continuous food product cooling system | |

| JP2004523228A (ja) | 食品冷却方法及び装置 | |

| CA1332111C (fr) | Enceinte et procede de traitement thermique comportant une phase de refroidissement | |

| US5836166A (en) | Cooling apparatus | |

| EP0155886A1 (de) | Verfahren und Vorrichtung zur Kühlung eines viskosen Produktes, insbesondere eines Nahrungsmittels | |

| EP0297010B1 (de) | Autoklav | |

| EP0601952B1 (de) | Verfahren zur thermischen Behandlung von Nahrungsmitteln, insbesondere zum Kochen von Gemüse und Anlage zur Durchführung des Verfahrens | |

| AU2006278443B2 (en) | Crust freezing system | |

| KR20020014828A (ko) | 밤의 껍질을 박피하는 장치 및 그 방법 | |

| JP2004054569A (ja) | 容器入り飲料の加熱装置及びこれを用いた自動販売機 | |

| Anderson et al. | Continuous steam sterilization segmented-flow aseptic processing of particle foods | |

| WO1984000472A1 (fr) | Procede et installation de hachage et de pre-emballage de chair hachee sous atmosphere et temperature controlees et leur application a la fabrication de chair hachee a partir de carcasses de volailles | |

| RU2159399C1 (ru) | Аппарат для консервирования пищевых продуктов | |

| JP2004213514A (ja) | 容器入り飲料の加熱装置及びこれを用いた自動販売機 | |

| JPS59198961A (ja) | 冷凍食品の製法および装置 | |

| RO138346A2 (ro) | Echipament multifuncţional de congelare rapidă | |

| JP3148968B2 (ja) | 連続搬送式の業務用筒型フリーザー |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19890429 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE CH DE ES FR IT LI LU NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19900913 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE ES FR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 68909484 Country of ref document: DE Date of ref document: 19931104 |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2044162 Country of ref document: ES Kind code of ref document: T3 |

|

| EPTA | Lu: last paid annual fee | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 89401182.4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20020314 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20020319 Year of fee payment: 14 Ref country code: SE Payment date: 20020319 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030427 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030430 |

|

| EUG | Se: european patent has lapsed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080418 Year of fee payment: 20 Ref country code: FR Payment date: 20080313 Year of fee payment: 20 Ref country code: DE Payment date: 20080320 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080329 Year of fee payment: 20 Ref country code: BE Payment date: 20080416 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080325 Year of fee payment: 20 |

|

| BE20 | Be: patent expired |

Owner name: SOC. NOUVELLE DES ETS J. *LAGARDE Effective date: 20090426 Owner name: *CARBOXYQUE FRANCAISE Effective date: 20090426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090426 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090427 |

|

| NLV7 | Nl: ceased due to reaching the maximum lifetime of a patent |

Effective date: 20090426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090427 |