EP0335939B1 - Hydraulic drive system - Google Patents

Hydraulic drive system Download PDFInfo

- Publication number

- EP0335939B1 EP0335939B1 EP88908928A EP88908928A EP0335939B1 EP 0335939 B1 EP0335939 B1 EP 0335939B1 EP 88908928 A EP88908928 A EP 88908928A EP 88908928 A EP88908928 A EP 88908928A EP 0335939 B1 EP0335939 B1 EP 0335939B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressure

- valve

- drive

- piston

- hydraulic cylinder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004080 punching Methods 0.000 claims abstract description 5

- 238000004049 embossing Methods 0.000 claims abstract description 4

- 230000009471 action Effects 0.000 claims description 4

- 230000005284 excitation Effects 0.000 claims 1

- 210000003918 fraction a Anatomy 0.000 claims 1

- 238000003754 machining Methods 0.000 description 7

- 230000001419 dependent effect Effects 0.000 description 6

- 238000004891 communication Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 2

- 230000007935 neutral effect Effects 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000001404 mediated effect Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/002—Drive of the tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/16—Control arrangements for fluid-driven presses

Definitions

- the invention relates to a hydraulic drive device for a machine element, e.g. a punching or embossing tool which, in the course of a machining cycle of a workpiece, executes a rapid feed movement leading to it with the same direction of movement, then the working stroke and then a rapid return movement returning to the starting position, and with the further ones mentioned in the preamble of patent claim 1 , generic characteristics.

- a machine element e.g. a punching or embossing tool which, in the course of a machining cycle of a workpiece, executes a rapid feed movement leading to it with the same direction of movement, then the working stroke and then a rapid return movement returning to the starting position, and with the further ones mentioned in the preamble of patent claim 1 , generic characteristics.

- the operating pressure-dependent switchover from rapid feed mode to load feed mode is often selected, i.e., if the pressure in the drive pressure chambers of the differential cylinder exceeds a threshold value, it is controlled by means of a pressure-dependent one Area changeover valve switched from rapid feed operation to load feed operation.

- the object of the invention is therefore to improve a hydraulic drive device of the type mentioned in such a way that a needs-based switching of the drive device from rapid feed operation to load feed operation and from this again to rapid feed operation or final hurry -Return operation, regardless of the thickness of a workpiece to be machined.

- the surface switching valve provided below as an exclusively pressure-dependent controlled valve, in which the response pressure can be defined in a defined manner by the closing force of a non-return valve which can be set according to claim 2, in combination with a directional valve which, as it were, generates the "hysteresis" is required so that the drive device does not switch back to the rapid feed operation "too early", a time saving is an important advantage over known drive devices and, due to the simplicity of the overall structure, a high level of functional reliability is also achieved.

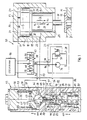

- the hydraulic drive device according to the invention shown in FIG. 1, to the details of which is expressly referred to, designated overall by 10, is assumed without restriction of generality as a drive head for a punching or embossing machine, with the drive element for a tool 11, by means of which a workpiece 12, for example a steel plate, a piercing or can be subjected to formative cold deformation, a total designated 13 hydraulic cylinder is provided, which is designed in the special embodiment shown as a double-acting, linear hydraulic cylinder.

- This hydraulic cylinder 13 is assumed to be arranged as "standing”, i.e. with a vertical course of its central longitudinal axis 14 with respect to a horizontally arranged machine table 16, by which the machine frame, which is otherwise not shown, is represented, on which the housing 17 of the hydraulic cylinder 13 is also fixedly mounted on the frame.

- the workpiece 12 resting on the machine table 16 can be fixed to the machine table 16 by means of a holding device (not shown).

- the hydraulic cylinder 13 is designed as a differential cylinder whose piston 18, which can be moved up and down, within the cylinder bore 19 delimits two drive pressure chambers 21 and 22 in a pressure-tight manner, through their valve-controlled, common or alternative action with the outlet pressure P of a pressure supply, generally designated 23 -Aggregate and possibly pressure relief of one of the two drive pressure chambers 21 or 22, the feed and retraction strokes of the piston 18 or the tool 11 required for the machining of work pieces 12 can be controlled as required.

- F 2 denotes the effective cross-sectional area of the housing bore 29 which is offset from the cylinder bore 19, in which the cylinder piston 18 is displaceably guided in a pressure-tight manner, by an inner housing step 28, in which the housing bore 29, which is fixedly connected to the piston 18, for example in one piece executed, cylindrical piston rod 31 is slidably guided pressure-tight, at the lower, free end of the tool 11 is attached.

- F 3 denotes the effective amount of the essentially circular “differential area” 32, on which a pressure coupled into the lower drive pressure chamber 22 acts on the cylinder piston 18 in the sense of generating the force K 2 .

- the area ratio F, / F 3 has the value 2/1.

- the maximum amount of this feed force K 3 is - at the value 2/1 of the area ratio F, / F 3 chosen for the explanation - limited to 50% of the maximum achievable feed force K 1 which can be achieved if only the upper drive pressure chamber 21 with the outlet pressure P the auxiliary pressure source 23 is acted upon, but the lower drive pressure chamber 22 is relieved to the tank 34 of the pressure supply unit 23.

- the lower drive pressure chamber 22 is acted upon by the outlet pressure of the pressure supply unit 23 and the upper drive pressure chamber 21 toward the tank 34 of the pressure supply unit 23 relieved, which, in the configuration shown for this purpose in FIG. 1, consists of a high pressure pump 36 and a pressure relief valve 37 that can be adjusted to a desired outlet pressure range.

- an electrically controllable directional control valve 38 is provided, which as Basic position 0 has a neutral center position "centered" by return springs 39 and 41, in which the pressure supply unit 23 operates in circulation mode.

- this directional control valve 38 can be controlled, in each case from its basic position, into alternative functional positions I and 11, one of which - the functional control I of the feed direction of the piston movement and the other - the Function position 11 - the retraction direction of the piston or tool motion are assigned.

- the control signals required for the motion control for the control magnets 42 and 43 of the directional control valve 38 are generated by a driver stage 44, which in turn can be electronically controlled manually, for example via hand switches not shown or automatically in the sense of the required motion sequence.

- the directional control valve 38 is designed as a 3/3-way valve, via which only the connection of the drive pressure chamber 21, which is larger in cross section, as shown in FIG. 1, is either connected to the high pressure outlet 46 of the pressure supply Unit 23 or at its tank port 47 is controllable.

- the high-pressure outlet 46 of the pressure supply unit 23 is the directional control valve 38 with the supply connection via a first flow-through flow path 49 51 of the upper - larger - drive pressure chamber 21 of the hydraulic cylinder 13 connected, but this is blocked against the tank connection 47.

- the functional position II of the directional control valve 38 is the upper drive pressure chamber 21 of the hydraulic cylinder 13 via a second flow-through flow path 52 of the directional control valve 38 with the tank connection 47 Pressure supply unit 23 connected, but blocked against its high pressure outlet 46.

- This surface switch valve 53 which is shown in FIG. 1 in its basic position corresponding to the non-activated state of the drive device 10, is, on the one hand, a pressure-controlled directional valve which, depending on the pressures in the drive pressure chambers 21 and 22 of the drive hydraulic cylinder 13 prevail, automatically connecting the annular drive pressure chamber 22 of the hydraulic cylinder to the high-pressure outlet 46 of the pressure supply unit 23, as required, in which case the maximum usable feed force for machining the workpiece 12 is given by the relationship (3) , but a relatively high feed rate can be used, alternatively the pressure relief of this drive pressure chamber 22 to the tank 34 of the pressure supply unit 23 is imparted if an increased feed force is required for the machining of the workpiece 12, the maximum amount of which is given by the relationship (1) is given, in which case the feed rate that can still be used is reduced by the factor FiF1.

- this surface changeover valve 53 fulfills the function that after it had been switched into its functional position which mediated the pressure relief of the annular drive pressure chamber 22 and thereby enabled the use of an increased feed force, only then again in its pressurization of the annular drive pressure chamber 22 mediating function position is switched back after the for - eg penetrating - machining of the workpiece 12, the required requirement for feed force on the tool 11 has become lower by a defined minimum amount ⁇ K than the amount of the feed force or the operating pressure in the drive pressure spaces 21 and 22 of the hydraulic cylinder 13, by exceeding which the switching of the surface switching valve 53 in which the pressure relief of the annular drive pressure chamber 22 was triggered.

- this ensures that, as long as possible, the highest possible feed rate of the tool 11 can be used and, on the other hand, it ensures that after the drive device 10 has been switched to an increased feed force, it does not switch back "too early” to a reduced feed force ", which could lead to undesired vibrations and, as a result, to the tool 11" stopping ".

- the surface changeover valve 53 is designed in more detail as follows:

- the surface changeover valve 53 comprises a first valve chamber 57 which is permanently connected to the tank connection 47 of the pressure supply unit 53 via a relief flow path 58 and is therefore kept depressurized .

- This valve chamber 57 is sealed off to the outside by an adjusting screw 61, which forms the end end wall of the valve housing, which is designated as a whole by 59.

- a valve closing spring 62 is adjustable, which acts on a centering piece 63 which presses a valve body, which is designed as a ball 64, of a seat valve designated overall by 66 against its valve seat 67, ie into the closed position of this seat valve 66, which is pushed through the inner, that is, the clear diameter towards the smaller edge of a conical depression, which in turn serves to center the valve ball 64, is formed in an intermediate wall 69 of the valve housing 59.

- a valve channel 72 opening into the central valve chamber 71 extends between this valve seat 67 and a central valve chamber 71.

- the central valve chamber 71 is in constant communication with the annular drive pressure chamber 22 of the hydraulic cylinder 13 via a first hydraulic control line 73.

- the central valve chamber 71 is by the one, the diameter smaller bore 74 of a step bore 76 designated overall, designated step 76 of the housing 59, the diameter of which is larger bore step 77 at the other end of the housing 59 is sealed pressure-tight by a housing cover 78 forming the end wall of the valve housing 59 there.

- a stage piston In the two bore stages 74 and 77 of the stage bore 76, a stage piston, designated overall by 82, is displaceably guided in a pressure-tight manner with a piston stage 79 and 81, respectively, the smaller piston stage 79 of which forms an axially movable boundary of the central valve chamber 71, and its diameter after a larger piston stage 81, on the one hand, it forms the axially movable boundary of an annular chamber 85, which is axially fixed to the housing by the annular housing stage 83 which mediates between the smaller bore stage 74 and the larger bore stage 77, and further the axially movable boundary of a control chamber 84 forms, the housing-fixed axial boundary is formed by the housing cover 78.

- This control chamber 84 is kept in constant communication with the larger drive pressure chamber 21 of the drive hydraulic cylinder 13 via a second hydraulic control line 86.

- the stepped piston 82 is urged toward the valve ball 64 by a - weakly preloaded - return spring 87, which is supported on the inside of the housing cover 78, on which it rests in the basic position shown in FIG. 1 with a plunger-shaped, axial extension supports its smaller piston stage 79.

- the outer diameter of this tappet-shaped extension 88 is significantly smaller than the diameter of the valve channel 72 through which it passes.

- the smaller piston stage 79 is offset from the larger piston stage 81 by an annular groove-shaped constriction 89, which is penetrated by a transverse bore 91 opening into the annular chamber 85.

- This transverse bore 91 is in constant communication with the central valve chamber 71 via a central longitudinal bore 92 which penetrates the smaller piston stage 79 and its plunger-shaped extension 88 in the axial direction and one or more transverse bore (s) 93 in the plunger-shaped extension 88.

- the smaller bore step 74 seen in the axial direction, is provided in its central region with an annular groove-shaped, radial extension 94, which is permanently connected to the high-pressure outlet 46 of the pressure supply unit 23 via a third control or pressure supply line 95.

- the edge formed by the radially inner edge 96 of the upper groove flank 97 facing the central valve chamber 71 according to FIG. 1 forms a control edge fixed to the housing, with which the outer edge 98 of the annular end face 99 of the smaller piston stage 79 bounding the central valve chamber 51 cooperates as a movable control edge can.

- the movable control edge 98 of the stepped piston 82 has a positive overlap with the control edge 96 fixed to the housing, this overlap D.X1 corresponding only to a small fraction of the stroke X 1 that the stepped piston 82 out of its illustrated basic position in the opening direction of the seat valve 66, that is to say in the direction of the arrow 101, and also only a small fraction of that stroke X 2 which the stepped piston 82 can carry out in the opposite direction, that is to say in the direction of the arrow 102.

- the bias of the valve closing spring 62 is set so high that the force with which the valve ball 64 is pressed against the circular valve seat 67 approximately corresponds to the force, e.g. 90% of that force corresponds when the valve ball 66 is acted upon by the maximum outlet pressure of the pressure supply unit 23 within the circular area bordered by the valve seat 67. Assuming a maximum outlet pressure of the pressure supply unit 23 of 300 bar, the pretensioning of the closing spring 62 is accordingly set to a value equivalent to a "closing pressure" of 270 bar.

- the preload is the Return spring 87 negligible and equivalent to a pressure of only a few, for example 5 bar.

- the valve seat 67 within which the outlet pressure P of the pressure supply unit 23 can act on the valve ball 64, according to the amount with F 4 and the cross-sectional area of the larger piston stage 81 of the stepped piston 82, which also with the outlet pressure P.

- A is a predeterminable fraction of the area ratio of the order of 20%, by which the area ratio FJF4 should always be greater than the area ratio F, / F 3 of the areas of the piston 18 of the hydraulic cylinder 13 that can be pressurized.

- the drive device 10 works in more detail as follows:

- the pressure supply unit 23 is switched on, the directional control valve 38 is first controlled in its energized position II.

- the larger drive pressure chamber 21 of the hydraulic cylinder 13 and the control chamber 84 of the surface changeover valve 53 to the tank 34 of the pressure supply unit 23 are relieved, while at the same time the output pressure of the pressure supply unit 23 into the annular groove 94 of the housing 59 of the surface changeover valve 53, the central valve chamber 71 and the annular chamber 85 thereof and via the first control line 73 is coupled into the annular pressure chamber 22 of the hydraulic cylinder 13.

- the piston 18 of the hydraulic cylinder 13 thereby initially reaches its upper end position, the basic position shown in FIG.

- step piston 82 of the surface switch valve 53 which is in total on one of the cross-sectional area F 5 of its larger piston step 81 with the outlet pressure of the pressure supply Actuated, is pushed into its lower end position, shown in FIG. 2, ie removed from the valve ball 64.

- This functional position of the surface switching valve 53 in combination with the excited position 11 of the directional control valve 38 also corresponds to the retracting operation of the hydraulic cylinder 18 after the tool 11 has carried out its working stroke.

- the directional control valve 38 In order to initiate its feed operation from the basic position of the hydraulic cylinder piston 18, the directional control valve 38 is switched into its functional position I by energizing its first control magnet 42. As a result, both the upper drive pressure chamber 21 of the hydraulic cylinder 13 and the control chamber 84 of the surface changeover valve 53 are connected to the high-pressure outlet 46 of the pressure supply unit 23 via the flow-through flow path 49 of the directional control valve 38.

- the stepped piston 82 of the surface changeover valve 53 is now relieved of pressure since it is pressurized with neutral pressure both via the central valve chamber 71 and the annular chamber 85 and via the control chamber 84 with the outlet pressure P of the pressure supply unit.

- the weak return spring 87 is now able to move the stepped piston in the direction of the valve ball 64, but the stepped piston is dynamic, ie through that from the high pressure pump 36 to the annular groove extension 94 of the valve housing and over the control edges 96 and 98 of the housing or the stepped piston is held in a negative overlap of these control edges, depending on the amount of pressure oil flowing into the annular drive pressure chamber 22 of the drive cylinder 13.

- the tool 11 is moved in rapid feed mode in the direction of the workpiece 12, this feed movement taking place in the drive pressure chambers 21 and 22 of the hydraulic cylinder 13 with only moderate pressure development.

- the stepped piston is thereby displaced further in the sense of lifting the valve ball 64 from its seat, as a result of which the communicating connection of the central valve chamber 71, which previously existed via the notch 103, with the groove-shaped extension 94, which is under the high outlet pressure of the pressure supply unit 23, is canceled.

- the stepped piston moves into the “upper” end position shown in FIG. 3, in which the annular drive pressure chamber 22 is relieved to the tank 34 of the pressure supply unit 23 via the central valve chamber 71 and the valve chamber 57, which is arranged “above” anyway and is without pressure .

- the high output pressure of the pressure supply unit 23 is now only applied to the upper, larger drive pressure chamber 21 of the hydraulic cylinder 13, which is now with a lower feed rate in load feed mode speed, but executes its working stroke with a correspondingly increased force. If the workpiece 12 is machined, for example punctured, the pressure in the drive pressure chamber 21 falling again, the corresponding pressure drop also occurs in the control chamber 84 of the surface changeover valve 53, so that the valve closing spring 62 pushes the stepped piston 82 back towards its basic position can Because of the different area ratios FJF4 and F, / F 3 provided in accordance with the relationship (4), however, the pressure is below which the output pressure of the pressure supply unit 23 is again applied to the annular drive pressure chamber 22 via the area changeover valve 53, less than the pressure at which it had previously been switched to pressurizing only the larger drive pressure chamber 21.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Fluid-Pressure Circuits (AREA)

- Control Of Presses (AREA)

- Press Drives And Press Lines (AREA)

Abstract

Description

Die Erfindung betrifft eine hydraulische Antriebsvorrichtung für ein Maschinenelement, z.B. ein Stanz- oder ein Prägewerkzeug, das im Verlauf eines Bearbeitungszyklus eines Werkstückes eine zu diesem hinführende Eil-Vorschubbewegung hierauf mit derselben Bewegungsrichtung den Arbeitshub und anschließend eine in die Ausgangsstellung zurückführende Eil-Rückzugsbewegung ausführt, und mit den weiteren, im Oberbegriff des Patentanspruchs 1 genannten, gattungsbestimmenden Merkmalen.The invention relates to a hydraulic drive device for a machine element, e.g. a punching or embossing tool which, in the course of a machining cycle of a workpiece, executes a rapid feed movement leading to it with the same direction of movement, then the working stroke and then a rapid return movement returning to the starting position, and with the further ones mentioned in the preamble of patent claim 1 , generic characteristics.

Antriebsvorrichtungen dieser Art sind allgemein bekannt.Drive devices of this type are generally known.

Problematisch bei solchen Antriebsvorrichtungen ist die lastgerechte Umschaltung des als Antriebselement vorgesehenen Differential-Hydrozylinders vom Eil-Vorschub-Betrieb, in dem sowohl die größere als auch die kleinere Arbeitsfläche des Antriebskolbens druckbeaufschlagt ist, die maximal erreichbare Vorschubkraft aber um das Verhältnis der kleineren zur größeren Kolbenfläche reduziert ist, in den Last-Vorschub-Betrieb, bei dem nur die größere Kolbenfläche mit dem Ausgangsdruck des Druckversorgungs-Aggregats beaufschlagt ist, die kleinere Kolbenfläche aber druckentlastet ist, was notwendig wird, wenn die im Eil-Vorschub-Betrieb entfaltbare Vorschubkraft nicht ausreicht, um z.B. das Werkstück bei einer stanzenden Bearbeitung zu durchstoßen. Wählt man eine wegabhängige Steuerung des Übergangs vom Eil-Vorschub-Betrieb in den Last- Vorschub-Betrieb, so hat dies den Nachteil, daß in Fällen, in denen die im Eil-Vorschub-Betrieb entfaltbare Vorschubkraft ausreichen würde, mithin im Eil-Vorschub-Betrieb weitergearbeitet werden könnte, zu große Zykluszeiten in Kauf genommen werden müssen. Um diesbezügliche Zeiteinsparungen erzielen zu können, wird daher vielfach die Betriebsdruck-abhängige Umschaltung vom Eil-Vorschub-Betrieb in den Last Vorschub-Betrieb gewählt, d.h., es wird, wenn der Druck in den Antriebsdruckräumen des Differentialzylinders einen Schwellenwert übersteigt, mittels eines druckabhängig gesteuerten Flächen-Umschaltventils vom Eil-Vorschub- Betrieb in den Last-Vorschub-Betrieb umgeschaltet. Es muß dann aber dafür Sorge getragen werden, daß der Last-Vorschub-Betrieb hinreichend lange aufrecht erhalten wird, um sicherzustellen, daß das druckabhängig gesteuerte Ventil nicht "zu früh" wieder auf Eil-Vorschub-Betrieb umschaltet, was zu unerwünschten Schwingungen und im Extremfall zu einem annähernden Stillstand des Werkzeuges führen könnte.The problem with such drive devices is the load-appropriate switching of the differential hydraulic cylinder provided as the drive element from the rapid feed operation, in which both the larger and the smaller working surface of the drive piston are pressurized, but the maximum achievable feed force is reduced by the ratio of the smaller to the larger piston area is reduced to load-feed operation, in which only the larger piston area is acted upon by the outlet pressure of the pressure supply unit, but the smaller piston area is relieved of pressure, which is necessary if the feed force that can be developed in rapid feed operation is not sufficient for example to pierce the workpiece during punching machining. If one chooses a path-dependent control of the transition from the rapid feed operation to the load feed operation, this has the disadvantage that in cases in which the feed force that can be developed in the rapid feed operation would be sufficient, therefore in the rapid feed operation -Operation could be continued, too long cycle times have to be accepted. In order to be able to save time in this regard, the operating pressure-dependent switchover from rapid feed mode to load feed mode is often selected, i.e., if the pressure in the drive pressure chambers of the differential cylinder exceeds a threshold value, it is controlled by means of a pressure-dependent one Area changeover valve switched from rapid feed operation to load feed operation. However, care must then be taken to ensure that the load feed operation is maintained for a sufficiently long time to ensure that the pressure-controlled valve does not switch back to the rapid feed operation "too early", which leads to undesirable vibrations and im In extreme cases, the tool could come to a near standstill.

Um dies zu vermeiden, könnte daran gedacht werden, das druckabhängig gesteuerte Ventil mit einer elektromagnetischen Halte-Steuerung auszurüsten, derart, daß es zusätzlich mit einem Steuermagneten versehen ist, der, sobald das Ventil - druckabhängig - vom Eil-Vorschub- Betrieb auf dem Last-Vorschub-Betrieb umgeschaltet wird, das Ventil für eine definierte Zeitspanne in der den Last-Vorschub-Betrieb vermittelnden Funktionsstellung hält. Dies hätte jedoch, um optimal kurze Zykluszeiten ausnutzen zu können zur Folge, daß die Verzögerungszeit, für die das druckabhängig schaltende Ventil mittels des Steuermagneten in seiner Lastbetrieb-Funktionsstellung gehalten wird, jeweils auf die Materialstärke des zu bearbeitenden Materials eingestellt werden müßte, was nicht nur mit erheblichem Zeitaufwand verbunden wäre, sondern auch in vielen Fällen Fehleinstellungen zur Folge hätte, die wiederum zu unnötig hohen Zykluszeiten führen würden.In order to avoid this, it could be thought of to equip the pressure-controlled valve with an electromagnetic hold control, in such a way that it is additionally provided with a control magnet which, as soon as the valve is pressure-dependent, from the rapid feed operation on the load Feed mode is switched over, the valve remains in the functional position mediating the load feed mode for a defined period of time. However, in order to be able to utilize optimally short cycle times, this would have the consequence that the delay time for which the pressure-dependent switching valve is held in its load operation functional position by the control magnet would have to be adjusted to the material thickness of the material to be processed, which not only would take a considerable amount of time, but would also result in incorrect settings in many cases, which in turn would lead to unnecessarily high cycle times.

Aufgabe der Erfindung ist es daher, eine hydraulische Antriebsvorrichtung der eingangs genannten Art dahingehend zu verbessern, daß eine bedarfsgerechte Umschaltung der Antriebsvorrichtung von Eil-Vorschub-Betrieb auf Last- Vorschub-Betrieb und von diesem wieder auf Eil- Vorschub-Betrieb bzw. abschließendem Eil-Rückzugsbetrieb, unabhängig von der Dicke eines zu bearbeitenden Werkstückes.The object of the invention is therefore to improve a hydraulic drive device of the type mentioned in such a way that a needs-based switching of the drive device from rapid feed operation to load feed operation and from this again to rapid feed operation or final hurry -Return operation, regardless of the thickness of a workpiece to be machined.

Diese Aufgabe wird erfindungsgemäß durch die im kennzeichnenden Teil des Patentanspruchs 1 genannten Merkmale gelöst.This object is achieved by the features mentioned in the characterizing part of claim 1.

Durch die hiernach vorgesehene Gestaltung des Flächen-Umschaltventils als ein ausschließlich druckabhängig gesteuertes Ventil, bei dem durch die gemäß Anspruch 2 einstellbare Schließkraft eines Rückschlagventils der Ansprechdruck definiert einstellbar ist, in Kombination mit einem Wege-Ventil, das gleichsam die "Hysterese" erzeugt, die erforderlich ist, damit die Antriebsvorrichtung nicht "zu früh" auf Eil-Vorschub- Betrieb zurückschaltet, wird unter Gesichtspunkten der Zeiteinsparung ein wesentlicher Vorteil gegenüber bekannten Antriebsvorrichtungen und durch die Einfachheit des Gesamtaufbaues auch eine hohe Funktionszuverlässigkeit erzielt.Due to the design of the surface switching valve provided below as an exclusively pressure-dependent controlled valve, in which the response pressure can be defined in a defined manner by the closing force of a non-return valve which can be set according to claim 2, in combination with a directional valve which, as it were, generates the "hysteresis" is required so that the drive device does not switch back to the rapid feed operation "too early", a time saving is an important advantage over known drive devices and, due to the simplicity of the overall structure, a high level of functional reliability is also achieved.

In Kombination hiermit ist die gemäß Anspruch 3 vorgesehene einfache Gestaltung des Richtungs-Steuerventils möglich.In combination with this, the simple design of the directional control valve provided according to claim 3 is possible.

Weitere Einzelheiten und Merkmale der Erfindung ergeben sich aus der nachfolgenden Beschreibung eines speziellen Ausführungsbeispiels anhand der Zeichnung. Es zeigen:

- Fig. 1 eine schematische Darstellung einer erfindungsgemäßen hydraulischen Antriebsvorrichtung, bei der das Antriebselement und das Flächen-Umschaltventil jeweils im Schnitt längs ihrer zentralen Längsachsen dargestellt sind und

- Fig. 2 und 3 entsprechende Längsschnitt-Darstellungen des Flächen-Umschaltventils gemäß Figur 1, die verschiedenen Betriebszuständen der Antriebsvorrichtung gemäß Figur 1 entsprechen.

- Fig. 1 is a schematic representation of a hydraulic drive device according to the invention, in which the drive element and the surface switching valve are each shown in section along their central longitudinal axes and

- 2 and 3 corresponding longitudinal sectional views of the surface switching valve according to Figure 1, which correspond to different operating states of the drive device according to Figure 1.

Die in der Figur 1, auf deren Einzelheiten ausdrücklich verwiesen sei, dargestellte, erfindungsgemäße, insgesamt mit 10 bezeichnete hydraulische Antriebsvorrichtung sei ohne Beschränkung der Allgemeinheit als Antriebskopf für eine Stanz- oder eine Prägemaschine vorausgesetzt, bei der als Antriebselement für ein Werkzeug 11, mittels dessen ein Werkstück 12, z.B. eine Stahlplatte, einer durchstoßenden oder prägenden Kalt-Verformung unterworfen werden kann, ein insgesamt mit 13 bezeichneter Hydrozylinder vorgesehen ist, der beim dargestellten, speziellen Ausführungsbeispiel als doppelt wirkender, linearer Hydrozylinder ausgebildet ist.The hydraulic drive device according to the invention shown in FIG. 1, to the details of which is expressly referred to, designated overall by 10, is assumed without restriction of generality as a drive head for a punching or embossing machine, with the drive element for a

Dieser Hydrozylinder 13 sei als "stehend" angeordnet vorausgesetzt, d.h. mit vertikalem Verlauf seiner zentralen Längsachse 14 bezüglich eines horizontal angeordneten Maschinentisches 16, durch den das im übrigen nicht dargestellte Maschinengestell repräsentiert sei, an dem gestellfest, auch das Gehäuse 17 des Hydrozylinders 13 fest montiert ist.This

Das auf dem Maschinentisch 16 aufliegende Werkstück 12 ist mittels einer nicht eigens dargestellten Haltevorrichtung an dem Maschinentisch 16 fixierbar.The

Der Hydrozylinder 13 ist als DifferentialZylinder ausgebildet, dessen insgesamt mit 18 bezeichneter, auf- und abverschiebbarer Kolben innerhalb der Zylinderbohrung 19 zwei Antriebsdruckräume 21 und 22 druckdicht gegeneinander abgrenzt, durch deren ventilgesteuerte, gemeinsame oder alternative Beaufschlagung mit dem Ausgangsdruck P eines insgesamt mit 23 bezeichneten Druckversorgungs-Aggregats und ggf. Druckentlastung je eines der beiden Antriebsdruckräume 21 oder 22, die für die Bearbeitung von Werkstrücken 12 erforderlichen Vorschub-und Rückzugs-Hübe des Kolbens 18 bzw. des Werkzeuges 11 bedarfsgerecht steuerbar sind.The

Der effektive Betrag der den gemäß der Darstellung der Figur 1 oberen Antriebsdruckraum 21 beweglich begrenzenden Kolbenfläche 24 ist gleich der Querschnittsfläche F1 der Zylinderbohrung 19.The effective amount of the top according to the illustration of Figure 1 the

Durch eine Beaufschlagung dieses oberen Antriebsdruckraumes 21 mit dem Ausgangsdruck P des Druckversorgungsaggregats 23 wird somit auf den Kolben 18 eine in Richtung des Pfeils 26 wirkende, d.h. zum Werkstück 12 hin gerichtete Kraft K1 ausgeübt, gemäß der Beziehung

In dieser Beziehung ist mit F2 die wirksame Querschnittsfläche der gegenüber der Zylinderbohrung 19, in welcher der Zylinderkolben 18 druckdicht verschiebbar geführt ist, durch eine innere Gehäusestufe 28 abgesetzten Gehäusebohrung 29 bezeichnet, in welcher die mit dem Kolben 18 fest verbundene, mit diesem z.B. einstückig ausgeführte, zylindrische Kolbenstange 31 druckdicht verschiebbar geführt ist, an deren unterem, freiem Ende das Werkzeug 11 befestigt ist.In this respect, F 2 denotes the effective cross-sectional area of the

Mit F3 ist der wirksame Betrag der im wesentlichen kreisringförmigen "Differenzfläche" 32 bezeichnet, auf welcher ein in den unteren Antriebsdruckraum 22 eingekoppelter Druck auf den Zylinderkolben 18 im Sinne der Erzeugung der Kraft K2 wirkt.F 3 denotes the effective amount of the essentially circular “differential area” 32, on which a pressure coupled into the lower

Für das zur Erläuterung gewählte, spezielle Ausführungsbeispiel sei angenommen, daß das Flächenverhältnis F,/F3 den Wert 2/1 habe.For the specific exemplary embodiment chosen for explanation, it is assumed that the area ratio F, / F 3 has the value 2/1.

Wenn beide Antriebsdruckräume 21 und 22 mit dem Ausgangsdruck P der Hilfsdruckquelle 23 beaufschlagt sind, so ist die für den Zustell- und Arbeitsvorschub des Werkzeuges 11 maximal ausnutzbare Kraft K3, die in Richtung des zu dem Pfeil 26 parallelen Pfeils 33 wirkt, dem Betrage nach durch die Beziehung

Der Maximalbetrag dieser vorschubkraft K3 ist - bei dem zur Erläuterung gewählten Wert 2/1 des Flächenverhältnisses F,/F3 - auf 50% der maximal erzielbaren Vorschubkraft K1 beschränkt, die erzielbar ist, wenn lediglich der obere Antriebsdruckraum 21 mit dem Ausgangsdruck P der Hilfsdruckquelle 23 beaufschlagt ist, der untere Antriebsdruckraum 22 jedoch zum Tank 34 des Druckversorgungs-Aggregats 23 hin entlastet ist.The maximum amount of this feed force K 3 is - at the value 2/1 of the area ratio F, / F 3 chosen for the explanation - limited to 50% of the maximum achievable feed force K 1 which can be achieved if only the upper

Um den Kolben 18 in seine jeweils am Beginn eines Bearbeitungstaktes eingenommene, in der Figur 1 dargestellte Grundstellung zu bringen, wird der untere Antriebsdruckraum 22 mit dem Ausgangsdruck des Druckversorgungs-Aggregats 23 beaufschlagt und der obere Antriebsdruckraum 21 zum Tank 34 des Druckversorgungs-Aggregats 23 hin entlastet, das in der aus der Figur 1 ersichtlichen, hierfür üblichen Gestaltung aus einer Hochdruckpumpe 36 und einem auf einen erwünschten Ausgangsdruckbereich einstellbaren Druckbegrenzungsventil 37 besteht.In order to bring the

Zur Steuerung der alternativen Bewegungsrichtungen des Zylinderkolbens 18 bzw. des Werkzeuges 11, nämlich Zustell- bzw. Eilvorschub- und Arbeits- bzw. Lastvorschub-Bewegung einerseits und Rückzungsbewegung bis in die Grundstellung andererseits, ist ein elektrisch ansteuerbares Richtungs-Steuerventil 38 vorgesehen, das als Grundstellung 0 eine durch Rückstellfedern 39 und 41 "zentrierte", neutrale Mittelstellung hat, in welcher das Druckversorgungs-Aggregat 23 im Umlaufbetrieb arbeitet.To control the alternative directions of movement of the

Durch alternative Erregung je eines von zwei Steuermagneten 42 bzw. 43 ist dieses Richtungs-Steuerventil 38, jeweils aus seiner Grundstellung heraus in alternative Funktionsstellungen I bzw. 11 steuerbar, deren eine - die Funktionssteuerung I der Vorschub-Richtung der Kolbenbewegung und deren andere - die Funktionsstellung 11 - der Rückzugs-Richtung der Kolben- bzw. Werkzeugbewegung zugeordnet sind. Die für die Bewegungssteuerung erforderlichen Ansteuersignale für die Steuermagnete 42 und 43 des Richtungs-Steuerventils 38 werden von einer Treiberstufe 44 erzeugt, die ihrerseits manuell, z.B. über nichtdargestellte Handtaster oder auch selbsttätig im Sinne des erforderlichen Bewegungsablaufes elektronisch gesteuert sein kann.By alternately energizing one of two

Bei dem dargestellten, speziellen Ausführungsbeispiel ist das Richtungs-Steuereventil 38 als 3/3-Wege-Ventil ausgebildet, über das lediglich der Anschluß des dem Querschnitt nach größeren, gemäß der Darstellug der Figur 1 oberen Antriebsdruckraumes 21 entweder an den Hochdruckausgang 46 des Druckversorgungs- Aggregats 23 oder an dessen Tankanschluß 47 steuerbar ist.In the special embodiment shown, the

In der Grundstellung 0 des Richtungs-Steuerventils 38 ist der obere Antriebsdruckraum 21 des Hydrozylinders 13 sowohl gegen den Hochdruck- ausgang 46 als auch gegen den Tankanschluß 47 des Druckversorgungsaggregats 23 abgesperrt, während der Hochdruckausgang 46 und der Tankanschluß 47 des Druckversorgungsaggregats 23 über einen Umlauf-Strömungspfad 48 des Richtungs-Steuerventils 38 miteinander verbunden sind.In the basic position 0 of the

In der bei Erregung des einen Steuermagneten 42 mit einem Ausgangssignal der Treiberstufe 44 eingenommenen, erregten Stellung I des Richtungs-Steuerventils 38 ist der Hochdruck- ausgang 46 des Druckversorgungs-Aggregats 23 über einen ersten Durchfluß-Strömungspfad 49 der Richtungs-Steuerventils 38 mit dem Versorgungsanschluß 51 des oberen - größeren - Antriebsdruckraumes 21 des Hydrozylinders 13 verbunden, dieser aber gegen den Tankanschluß 47 abgesperrt.In the excited position I of the

In der hierzu alternativen, bei Erregung des zweiten Steuermagneten 43 mit einem Ausgangssignal der Treiberstufe 44 eingenommenen Funktionsstellung II des Richtungs-Steuerventils 38 ist der obere Antriebsdruckraum 21 des Hydrozylinders 13 über einen zweiten Durchfluß-Strömungspfad 52 des Richtungs-Steuerventils 38 mit dem Tankanschluß 47 des Druckversorgungs-Aggregats 23 verbunden, jedoch gegen dessen Hochdruck-Ausgang 46 abgesperrt.In the alternative to this, when the

Zur Steuerung der darüber hinaus erforderlichen Druckbeaufschlagung bzw. Entlastung des zweiten, ringraumförmigen Antriebsdruckraumes 22 des Hydrozylinders 13, wodurch im Ergebnis die Geschwindigkeit und der Maximalbetrag der Kraft steuerbar sind, mit denen das Werkzeug 11 seine Vorschub- und Arbeitsbewegungen ausführt, ist ein insgesamt mit 53 bezeichnetes "Flächen-Umschaltventil" vorgesehen, zu dessen Erläuterung nunmehr auch auf die Einzelheiten der Figuren 2 und 3 verweisen sei, welche zwei weitere Funktionsstellungen des Flächen-Umschaltventils 53 zeigen.In order to control the additional pressurization or relief of the second annular

Dieses Flächen-Umschaltventil 53, das in der Figur 1 in seiner dem nicht aktivierten Zustand der Antriebsvorrichtung 10 entsprechenden Grundstellung dargestellt ist, ist, seiner Funktion nach, einerseits ein druckgesteuertes Wege-Ventil, das, je nachdem, welche Drücke in den Antriebsdruckräumen 21 und 22 des Antriebs-Hydrozylinders 13 herrschen, selbsttätig bedarfsgerecht den Anschluß des ringraumförmigen Antriebsdruckraumes 22 des Hydrozylinders an den Hochdruckausgang 46 des Druckversorgungs-Aggregates 23 vermittelt, in welchem Falle die für die Bearbeitung des Werkstückes 12 maximal ausnutzbare Vorschubkraft durch die Beziehung (3) gegeben ist, dafür aber eine relativ hohe Vorschubgeschwindigkeit ausnutzbar ist, alternativ dazu die Druckentlastung dieses Antriebsdruckraumes 22 zum Tank 34 des Druckversorgungs-Aggregates 23 hin vermittelt, wenn für die Bearbeitung des Wekstückes 12 eine erhöhte Vorschubkraft erforderlich ist, deren maximaler Betrag durch die Beziehung (1) gegeben ist, in welchem Falle aber die dann noch ausnutzbare Vorschubgeschwindigkeit um den Faktor FiF1 reduziert ist. Zum anderen erfüllt dieses Flächen-Umschaltventil 53 die Funktion, daß es, nachdem es in seine die Druckentlastung des ringraumförmigen Antriebsdruckraumes 22 vermittelnde und dadurch die Ausnutzung einer erhöhten Vorschubkraft ermöglichende Funktionsstellung geschaltet worden war, erst dann wieder in seine erneut die Druckbeaufschlagung des ringraumförmigen Antriebsdruckraumes 22 vermittelnde Funktionsstellung zurückgeschaltet wird, nachdem der für die - z.B. durchstoßende - Bearbeitung des Werkstückes 12 erforderliche Bedarf an Vorschubkraft am Werkzeug 11 um einen definierten Mindestbetrag ΔK niedriger geworden ist als derjenige Betrag der Vorschubkraft bzw. des Betriebsdruckes in den Antriebsdruckräumen 21 und 22 des Hydrozylinders 13, durch dessen Überschreiten die Umschaltung des Flächen-Umschaltventils 53 in dessen die Druckentlastung des ringraumförmigen Antriebsdruckraumes 22 ausgelöst wurde.This

Hierdurch wird einerseits erreicht, daß, solange wie möglich, eine möglichst hohe Vorschubgeschwindigkeit des Werkzeuges 11 ausnutzbar bleibt und andererseits sichergestellt, daß, nachdem die Antriebsvorrichtung 10 auf eine erhöhte Vorschubkraft umgeschaltet worden war, nicht "zu früh" wieder auf eine reduzierte Vorschubkraft "zurückgeschaltet" wird, was zu unerwünschten Schwingungen und als Folge davon zu einem "Stehenbleiben" des Werkzeuges 11 führen könnte.On the one hand, this ensures that, as long as possible, the highest possible feed rate of the

Zu diesem Zweck ist das Flächen-Umschaltventil 53 mehr im einzelnen wie folgt ausgebildet: Das Flächen-Umschaltventil 53 umfaßt eine erste Ventilkammer 57, welche über einen Entlastungs-Strömungspfad 58 permanent mit dem Tankanschluß 47 des Druckversorgungs- Aggregats 53 verbunden und dadurch drucklos gehalten ist.For this purpose, the

Diese Ventilkammer 57 ist durch eine gleichsam die eine Endstirnwand des insgesamt mit 59 bezeichneten Ventilgehäuses bildende Stellschraube 61 dicht nach außen abgeschlossen. Durch Verdrehen dieser Stellschraübe 61 ist die Vorspannung einer Ventil-Schließfeder 62 einstellbar, die an einem Zentrierstück 63 angreift, das einen als Kugel 64 ausgebildeten Ventilkörper eines insgesamt mit 66 bezeichneten Sitzventils gegen dessen Ventilsitz 67, d.h. in die Schließstellung dieses Sitzventils 66 drängt, der durch den inneren, d.h. dem lichten Durchmesser nach kleineren Rand einer ihrerseits zur Zentrierung der Ventilkugel 64 dienenden, konischen Vertiefung einer Zwischenwand 69 des Ventilgehäuses 59 gebildet ist. Zwischen diesem Ventilsitz 67 und einer zentralen Ventilkammer 71 erstreckt sich ein in die zentrale Ventilkammer 71 mündender Ventilkanal 72. Die zentrale Ventilkammer 71 steht über eine erste hydraulische Steuerleitung 73 in ständig kommunizierender Verbindung mit dem ringraumförmigen Antriebsdruckraum 22 des Hydrozylinders 13. Die zentrale Ventilkammer 71 ist durch die eine, dem Durchmesser nach kleinere Bohrungsstufe 74 einer insgesamt mit 76 bezeichneten Stufenbohrung des Gehäuses 59 gehäusefest begrenzt, deren dem Durchmesser nach größere Bohrungsstufe 77 am anderen Ende des Gehäuses 59 durch einen die dortige Endstirnwand des Ventilgehäuses 59 bildenden Gehäusedeckel 78 druckdicht abgeschlossen ist.This

In den beiden Bohrungsstufen 74 und 77 der Stufenbohrung 76 ist mit je einer Kolbenstufe 79 bzw. 81 entsprechenden Durchmessers ein insgesamt mit 82 bezeichneter Stufenkolben druckdicht verschiebbar geführt, dessen kleinere Kolbenstufe 79 eine axial-bewegliche Begrenzung der zentralen Ventilkammer 71 bildet, und dessen dem Durchmesser nach größere Kolbenstufe 81 einerseits dei axial-bewegliche Begrenzung einer Ringkammer 85 bildet, die in axialer Richtung gehäusefest durch die zwischen der kleineren Bohrungsstufe 74 und der größeren Bohrungsstufe 77 vermittelnde, ringförmige Gehäusestufe 83 begrenzt ist, und weiter die axial-bewegliche Begrenzung einer Steuerkammer 84 bildet, deren gehäusefeste axiale Begrenzung durch den Gehäusedeckel 78 gebildet ist. Diese Steuerkammer 84 ist über eine zweite hydraulische Steuerleitung 86 in ständig kommunizierender Verbindung mit dem größeren Antriebsdruckraum 21 des Antriebs-Hydrozylinders 13 gehalten.In the two

Der Stufenkolben 82 wird durch eine - schwach vorgespannte - Rückstellfeder 87, die sich an der Innenseite des Gehäusedeckels 78 abstützt, in Richtung auf die Ventilkugel 64 hin gedrängt, an der er sich in der in der Figur 1 dargestellten Grundstellung mit einem stößelförmigen, axialen Fortsatz seiner kleineren Kolbenstufe 79 abstützt. Der Außendurchmesser dieses stößelförmigen Fortsatzes 88 ist deutlich kleiner als der Durchmesser des Ventilkanals 72, durch den er hindurchtritt. Die kleinere Kolbenstufe 79 ist gegenüber der größeren Kolbenstufe 81 durch eine ringnutförmige Einschnürung 89 abgesetzt, die von einer in die Ringkammer 85 mündenden Querbohrung 91 durchsetzt ist. Diese Querbohrung 91 steht über eine die kleinere Kolbenstufe 79 und deren stößelförmigen Fortsatz 88 in axialer Richtung durchsetzenden, zentralen Längsbohrung 92 und eine oder mehrere Querbohrung(en) 93 des stößelförmigen Fortsatzes 88 in ständig kommunizierender Verbindung mit der zentralen Ventilkammer 71.The

Die kleinere Bohrungsstufe 74 ist, in axialer Richtung gesehen, in ihrem mittleren Bereich mit einer ringnutförmigen, radialen Erweiterung 94 versehen, die über eine dritte Steuer- bzw. Druckversorgungsleitung 95 permanent mit dem Hochdruckausgang 46 des Druckversorgungs- aggregats 23 verbunden ist. Die durch den radial inneren Rand 96 der gemäß Figur 1 oberen, der zentralen Ventilkammer 71 zugewandten Nutflanke 97 gebildete Kante bildet eine gehäusefeste Steuerkante, mit der der äußere Rand 98 der die zentrale Ventilkammer 51 begrenzenden ringförmigen Stirnfläche 99 der kleineren Kolbenstufe 79 als bewegliche Steuerkante kooperieren kann.The

In der dargestellten Grundstellung des Stufenkolbens steht die bewegliche Steuerkante 98 des Stufenkolbens 82 in positiver Überlappung mit der gehäusefesten Steuerkante 96, wobei diese Überlappung D.X1 nur einem kleinen Bruchteil desjenigen Hubes X1 entspricht, den der Stufenkolben 82 aus seiner dargestellten Grundstellung heraus in Öffnungsrichtung des Sitzventils 66, d.h. in Richtung des Pfeils 101 ausführen kann, und auch nur einem kleinen Bruchteil desjenigen Hubes X2, den der Stufenkolben 82 in der Gegenrichtung, d.h. in Richtung des Pfeils 102 ausführen kann. In der dargestellten Grundstellung des Stufenkolbens 82 ist die durch die ringnutförmige Erweiterung 94 und die kleinere Kolbenstufe 59 begrenzte Ringkammer, ungeachtet der Überlappung D.X1 der beweglichen Steuerkante 98 und der gehäusefesten Steuerkante 96 nicht hermetisch gegen die zentrale Ventilkammer 71 abgesperrt, sondern steht mit dieser durch eine periphere Randkerbe 103 mit einem kleinen Überström-Querschnitt noch in kommunizierender Verbindung, die jedoch aufgehoben wird, wenn der Stufenkolben einen kleinen Bruchteil AX2 seines möglichen Hubes in Richtung des Pfeils 101 ausgeführt hat, wonach die mit dem Hochdrukkausgang 46 des Druckversorgungs- Aggregats 23 in kommunizierender Verbindung stehende, ringnutförmige Erweiterung 94 der kleineren Bohrungsstufe 74 gegen die zentrale Ventilkammer 71 abgesperrt ist.In the illustrated basic position of the stepped piston, the

Die Vorspannung der Ventilschließfeder 62 ist bzw. wird so hoch eingestellt, daß die Kraft, mit der die Ventilkugel 64 gegen den kreislinienförmigen Ventilsitz 67 gedrängt wird, annähernd der Kraft entspricht, z.B. 90% derjenigen Kraft entspricht, wenn die Ventilkugel 66 innerhalb der durch den Ventilsitz 67 berandeten Kreisfläche mit dem maximalen Ausgangsdruck des Druckversorgungs-Aggregats 23 beaufschlagt ist. Einen maximalen Ausgangsdruck des Durckversorgungs-Aggregats 23 von 300 bar vorausgesetzt, wird demgemäß die Vorspannung der Schließfeder 62 auf einen einem "Schließdruck" von 270 bar äquivalenten Wert eingestellt.The bias of the

Demgegenüber ist die Vorspannung der Rückstellfeder 87 vernachlässigbar und einem Druck von nur wenigen, z.B. 5 bar, äquivalent. Bezeichnet man die durch den Ventilsitz 67 berandete Kreisfläche, innerhalb derer auf die Ventilkugel 64 der Ausgangsdruck P des Druckversorgungs-Aggregates 23 wirken kann, dem Betrage nach mit F4 und die Querschnittsfläche der größeren Kolbenstufe 81 des Stufenkolbens 82, die ebenfalls mit dem Ausgangsdruck P des Druckversorgungs-Aggregates 23 beaufschlagbar ist, mit Fs, so sind diese Flächen bei dem Flächen-Umschaltventil 53 so dimensioniert, daß sie der folgenden Beziehung genüeen:

Die insoweit ihrem Aufbau nach erläuterte Antriebsvorrichtung 10 arbeitet mehr im einzelnen wie folgt: Mit dem Einschalten des Druckversorgungs-Aggregates 23 wird zunächst das Richtungs-Steuerventil 38 in dessen erregte Stellung II gesteuert. Dadurch werden der größere Antriebsdruckraum 21 des Hydrozylinders 13 und die Steuerkammer 84 des Flächen-Umschaltventils 53 zum Tank 34 des Druckversorgungs-Aggregats 23 hin entlastet, während gleichzeitig der Ausgangsdruck des Druckversorgungs-Aggregates 23 in die ringnutförmige Erweiterung 94 des Gehäuses 59 des Flächen-Umschaltventils 53, dessen zentrale Ventilkammer 71 und dessen Ringkammer 85 sowie über die erste Steuerleitung 73 in den ringraumförmigen Antriebsdruckraum 22 des Hydrozylinders 13 eingekoppelt wird. Der Kolben 18 des Hydrozylinders 13 gelangt dadurch zunächst in seine obere Endstellung, die in der Figur 1 dargestellte Grundstellung, während der Stufenkolben 82 des Flächen-Umschaltventils 53, der insgesamt auf einer der Querschnittsfläche F5 seiner größeren Kolbenstufe 81 mit dem Ausgangsdruck des Druckversorgungs-Aggregates beaufschlagt ist, in seine, in der Figur 2 dargestellte, untere, d.h. von der Ventilkugel 64 entfernte Endstellung gedrängt wird. Diese Funktionsstellung des Flächen-Umschaltventils 53 in Kombination mit der erregten Stellung 11 des Richtungs-Steuerventils 38 entspricht auch dem Rückzugsbetrieb des Hydrozylinders 18, nachdem das Werkzeug 11 seinen Arbeitshub ausgeführt hat.The

Um aus der Grundstellung des Hydrozylinderkolbens 18 heraus dessen Vorschubbetrieb einzuleiten, wird das Richtungs-Steuerventil 38 durch Erregung seines ersten Steuermagneten 42 in seine Funktionsstellung I umgeschaltet. Hierdurch werden sowohl der obere Antriebsdruckraum 21 des Hydrozylinders 13 als auch die Steuerkammer 84 des Flächen-Umschaltventils 53 über den Durchfluß-Strömungspfad 49 des Richtungs-Steuerventils 38 an den Hochdruck- Ausgang 46 des Druckversorgungs-Aggregats 23 angeschlossen. Der Stufenkolben 82 des Flächen-Umschaltventils 53 ist nunmehr druckentlastet, da er sowohl über die zentrale Ventilkammer 71 und die Ringkammer 85 als auch über die Steuerkammer 84 mit dem Ausgangsdruck P des Druckversorgungs-Aggregats gleichsam neutral druckbeaufschlagt ist. Die schwache Rückstellfeder 87 ist jetzt in der Lage, den Stufenkolben in Richtung auf die Ventilkugel 64 zu verschieben, wobei jedoch der Stufenkolben dynamisch, d.h. durch das von der Hochdruckpumpe 36 zu der ringnutförmigen Erweiterung 94 des Ventilgehäuses und über die Steuerkanten 96 und 98 des Gehäuses bzw. des Stufenkolbens in negativer Überlappung dieser Steuerkanten gehalten bleibt, je nachdem, welche Druckölmenge in den ringförmigen Antriebsdruckraum 22 des Antriebszylinders 13 überströmt. Das Werkzeug 11 wird im Eil-Vorschubbetrieb in Richtung auf das Werkstück 12 zu bewegt, wobei diese Vorschubbewegung sich bei nur mäßiger Druckentfaltung in den Antriebsdruckräumen 21 und 22 des Hydrozylinders 13 vollzieht. Sobald das Werkzeug 11 auf das Werkstück 12 auftrifft, tritt in den Antriebsdruckräumen 21 und 22 eine Erhöhung des Druckes ein, die sich über die Steuerleitungen 73 und 86 auch der zentralen Ventilkammer 71, der Ringkammer 85 und der Steuerkammer 84 gleichmäßig mitteilt. Reicht die Vorschubkraft im Eilvorschubbetrieb nicht aus, um das Werkstück 12 zu durchstoßen, mit der Folge, daß der Betriebsdruck in den Antriebsdruckräumen 21 und 22 bis auf nahezu den Maximalwert des Ausgangsdruckes P des Druckversorgungs-Aggregates 23 ansteigt, so wird schließlich die Schließkraft der Schließfeder 62 überwunden, und die Kugel 64 hebt von dem Ventilsitz 87 ab, mit der Folge, daß die zentrale Ventilkammer 71 in kommunizierende Verbindung mit der drucklosen Ventilkammer 57 gelangt und der weiteren, hiermit verknüpften Folge, daß nunmehr der Stufenkolben 82 nur noch mit seiner größeren, die Steuerkammer 84 beweglich begrenzenden Kolbenstufe 81 dem hohen Ausgangsdruck des Druckversorgungs- Aggregats 23 ausgesetzt ist. Der Stufenkolben wird dadurch weiter im Sinne eines Abhebens der Ventilkugel 64 von ihrem Sitz verschoben, wodurch die zuvor noch über die Einkerbung 103 bestehende kommunizierende Verbindung der zentralen Ventilkammer 71 mit der unter dem hohen Ausgangsdruck des Druckversorgungs- Aggregats 23 stehenden nutförmigen Erweiterung 94 aufgehoben wird. Dadurch gelangt der Stufenkolben in die in der Figur 3 dargestellte, "obere" Endstellung, in welcher der ringförmige Antriebsdruckraum 22 über die zentrale Ventilkammer 71 und die "darüber" angeordnete, ohnehin drucklose Ventilkammer 57 zum Tank 34 des Druckversorgungs-Aggregats 23 hin entlastet ist. Mit dem hohen Ausgangsdruck des Druckversorgungs-Aggregats 23 beaufschlagt ist jetzt nur noch der obere, größere Antriebsdruckraum 21 des Hydrozylinders 13, der nunmehr im Last-Vorschubbetrieb zwar mit geringerer Vorschubgeschwindigkeit, jedoch mit entsprechend erhöhter Kraft seinen Arbeitshub ausführt. Ist das Werkstück 12 bearbeitet, z.B. durchstoßen, wobei der Druck im Antriebsdruckraum 21 wieder abfällt, so tritt der entsprechende Druckabfall auch in der Steuerkammer 84 des Flächen-Umschaltventils 53 ein, so daß die Ventilschließfeder 62 den Stufenkolben 82 wieder in Richtung auf seine Grundstellung zurückzudrängen vermag. Wegen der gemäß der Beziehung (4) vorgesehenen unterschiedlichen Flächen-Verhältnisse FJF4 und F,/F3 ist jedoch der Druck, bei dessen Unterschreiten der ringförmige Antriebsdruckraum 22 über das Flächen-Umschaltventil 53 wieder mit dem Ausgangsdruck des Druckversorgungs-Aggregats 23 beaufschlagt wird, geringer als der Druck, bei dem zuvor auf alleinige Druckbeaufschlagung des größeren Antriebsdruckraumes 21 umgeschaltet worden war. Dadurch wird erreicht, daß ein Übergang von dem "langsamen" Last-Vorschub- betrieb auf den wieder mit größerer Vorschubgeschwindigkeit erfolgenden Abschluß eines Arbeitstaktes im Eil-Vorschubbetrieb des Werkzeuges 11 erst dann erfolgt, wenn der Bedarf an erhöhter Vorschubkraft mit Sicherheit gedeckt ist, und es wird auch ein erschütterungsfreier und damit schonender Ablauf der Umschaltvorgänge gewährleistet.In order to initiate its feed operation from the basic position of the

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88908928T ATE60113T1 (en) | 1987-10-16 | 1988-10-15 | HYDRAULIC DRIVE DEVICE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3735123 | 1987-10-16 | ||

| DE19873735123 DE3735123A1 (en) | 1987-10-16 | 1987-10-16 | HYDRAULIC DRIVE DEVICE |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0335939A1 EP0335939A1 (en) | 1989-10-11 |

| EP0335939B1 true EP0335939B1 (en) | 1991-01-16 |

Family

ID=6338497

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88908928A Expired - Lifetime EP0335939B1 (en) | 1987-10-16 | 1988-10-15 | Hydraulic drive system |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4958548A (en) |

| EP (1) | EP0335939B1 (en) |

| JP (1) | JP2581789B2 (en) |

| DE (2) | DE3735123A1 (en) |

| WO (1) | WO1989003484A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105102145A (en) * | 2013-04-10 | 2015-11-25 | Smc株式会社 | Punch apparatus |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4341607A1 (en) * | 1993-02-02 | 1994-08-04 | Putzmeister Maschf | Transport system for shredded scrap-metal in viscous material |

| DE4414779C1 (en) * | 1994-04-25 | 1995-11-02 | Mannesmann Ag | Multifunction valve |

| DE19543876A1 (en) * | 1995-11-24 | 1997-05-28 | Rexroth Mannesmann Gmbh | Method and device for controlling a hydraulic system of an implement |

| DE19623549A1 (en) * | 1996-06-13 | 1997-12-18 | I T E C Gmbh | Machine and tool control system |

| US7305914B2 (en) * | 2004-01-28 | 2007-12-11 | The United States Of America, As Represented By The Administrator Of The Environmental Protection Agency | Hydraulic actuator control valve |

| DE102006029523B4 (en) * | 2006-06-27 | 2014-10-23 | Damcos A/S | locking device |

| WO2010123987A1 (en) * | 2009-04-24 | 2010-10-28 | Alcoa Inc. | Pressure relief valve |

| ES2665767T3 (en) | 2015-07-06 | 2018-04-27 | Feintool International Holding Ag | Equipment and procedure for removing / ejecting an internally formed stamping / part reticle and ejection of a cut piece in a precision cutting press |

| AT524160B1 (en) | 2020-08-19 | 2022-06-15 | Engel Austria Gmbh | Hydraulic drive device for a shaping machine |

| US20230226999A1 (en) * | 2022-01-19 | 2023-07-20 | Deere & Company | Remote start system and method for a work machine |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE224443C (en) * | ||||

| DE2119594A1 (en) * | 1971-04-22 | 1972-11-02 | Robert Bosch Gmbh, 7000 Stuttgart | Control for a pressure medium motor |

| DE2021857C3 (en) * | 1970-05-05 | 1978-08-10 | G.L. Rexroth Gmbh, 8770 Lohr | Brake valve |

| DE2244443A1 (en) * | 1972-09-11 | 1974-03-21 | Bosch Gmbh Robert | SWITCHING VALVE FOR MONITORING THE CONNECTION OF A WORKING CYLINDER WITH A RESERVOIR |

| DE2314590A1 (en) * | 1973-03-23 | 1974-09-26 | Parker Hannifin Corp | VALVE ARRANGEMENT |

| DE2424973C3 (en) * | 1974-05-22 | 1980-01-31 | Montan-Hydraulik Gmbh & Co Kg, 4755 Holzwickede | Device for controlling hydraulic drives |

| US4205591A (en) * | 1976-05-04 | 1980-06-03 | Fmc Corporation | Multiple speed hoisting system with pressure protection and load control |

| US4256017A (en) * | 1979-04-05 | 1981-03-17 | The Bendix Corporation | Differential area electrohydraulic doser actuator |

| US4461449A (en) * | 1980-05-01 | 1984-07-24 | The Boeing Company | Integral hydraulic blocking and relief valve |

| US4445421A (en) * | 1981-11-06 | 1984-05-01 | The Charles Stark Draper Laboratory, Inc. | Helicopter swashplate controller |

| US4765227A (en) * | 1982-05-28 | 1988-08-23 | Teledyne Hyson | Die cylinder assembly |

| DE3407878C1 (en) * | 1984-03-02 | 1985-06-27 | Hermann Hemscheidt Maschinenfabrik Gmbh & Co, 5600 Wuppertal | Non-return valve for the stamps of walking frames |

| DE3408909A1 (en) * | 1984-03-10 | 1985-09-12 | BBC Aktiengesellschaft Brown, Boveri & Cie., Baden, Aargau | HYDRAULIC DRIVE |

| SE451396B (en) * | 1985-09-19 | 1987-10-05 | Mats Hugdahl | PROCEDURE FOR EXCELLENT POSITIONING OF LOADING PRESSURE FLUID CYLINDER |

| US4727797A (en) * | 1986-07-03 | 1988-03-01 | Titon Hardware Limited | Secondary window ventilators |

-

1987

- 1987-10-16 DE DE19873735123 patent/DE3735123A1/en not_active Withdrawn

-

1988

- 1988-10-15 WO PCT/DE1988/000635 patent/WO1989003484A1/en active IP Right Grant

- 1988-10-15 EP EP88908928A patent/EP0335939B1/en not_active Expired - Lifetime

- 1988-10-15 US US07/368,318 patent/US4958548A/en not_active Expired - Lifetime

- 1988-10-15 DE DE8888908928T patent/DE3861589D1/en not_active Expired - Lifetime

- 1988-10-15 JP JP63508122A patent/JP2581789B2/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105102145A (en) * | 2013-04-10 | 2015-11-25 | Smc株式会社 | Punch apparatus |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3735123A1 (en) | 1989-06-29 |

| JP2581789B2 (en) | 1997-02-12 |

| WO1989003484A1 (en) | 1989-04-20 |

| EP0335939A1 (en) | 1989-10-11 |

| DE3861589D1 (en) | 1991-02-21 |

| US4958548A (en) | 1990-09-25 |

| JPH02501634A (en) | 1990-06-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2384834B1 (en) | Hydraulic die cushion with a hydraulic cylinder | |

| DE2249181C3 (en) | Hydraulic steering limitation for power steering systems, in particular for motor vehicles | |

| DE10206630B4 (en) | Method and device for high-speed pressing of workpieces | |

| CH661227A5 (en) | HYDRAULIC DRIVE DEVICE. | |

| EP0335939B1 (en) | Hydraulic drive system | |

| EP0339247B1 (en) | Hydraulic steering device for the drive control of a double-acting hydraulic cylinder | |

| DE2600948B2 (en) | Unit of force as a working organ, e.g. for presses for shaping, compacting, etc. | |

| DE2338267B2 (en) | Two-stage pneumatic-hydraulic pressure transducer | |

| EP0333052A2 (en) | Drawing apparatus for shaping sheet metal blanks | |

| DE2336512C2 (en) | Valve | |

| WO2010051913A1 (en) | Hydraulic force transducer | |

| DE3039667A1 (en) | Hydraulic stamping press safety operating control - uses damping cylinders for initial raising of ram with simultaneous function testing | |

| EP3115190A1 (en) | Device and method for controlling the principal drive of a precision cutting press | |

| DE2432774B2 (en) | Press, especially fine blanking press | |

| DE1106571B (en) | Overpressure device for pressure medium motors | |

| EP0559651B1 (en) | Hydraulically driven machine with two drive cylinders | |

| DE2758973B1 (en) | Screw press | |

| DE2223708C3 (en) | Control for hydraulic open-die forging presses | |

| DE9413273U1 (en) | Clamping module for machine tool clamping device | |

| DE2733399C2 (en) | Unit of force as a working organ, e.g. for presses for forming, compacting, etc. | |

| DE2223431A1 (en) | HYDRAULIC CONTROL DEVICE, IN PARTICULAR FOR FORGING PRESSES | |

| DE2818008A1 (en) | Impact drive for extrusion press - has auxiliary piston on valve seat to balance and release main piston | |

| DE2065816C3 (en) | Overload protection for press - by cushion in upper ram acting on overload protection cylinders of upper and lower ram drive | |

| DD207298A3 (en) | HYDRAULIC PRESS | |

| DE2064353A1 (en) | Hydraulic metal powder press for the dry and wet pressing process |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19891007 |

|

| 17Q | First examination report despatched |

Effective date: 19900221 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 60113 Country of ref document: AT Date of ref document: 19910215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3861589 Country of ref document: DE Date of ref document: 19910221 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960911 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19960916 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960919 Year of fee payment: 9 Ref country code: BE Payment date: 19960919 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971031 Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19971031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971031 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971031 |

|

| BERE | Be: lapsed |

Owner name: SCHULZE ECKEHART Effective date: 19971031 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20010914 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021015 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20021015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051015 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20061122 Year of fee payment: 19 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080501 |