EP0331542B1 - Verfahren und Vorrichtung zum Waschen von Wäsche in einer Waschmaschine - Google Patents

Verfahren und Vorrichtung zum Waschen von Wäsche in einer Waschmaschine Download PDFInfo

- Publication number

- EP0331542B1 EP0331542B1 EP89400301A EP89400301A EP0331542B1 EP 0331542 B1 EP0331542 B1 EP 0331542B1 EP 89400301 A EP89400301 A EP 89400301A EP 89400301 A EP89400301 A EP 89400301A EP 0331542 B1 EP0331542 B1 EP 0331542B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- washing

- additives

- additive

- machine

- wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005406 washing Methods 0.000 title claims description 99

- 238000000034 method Methods 0.000 title claims description 50

- 239000003599 detergent Substances 0.000 claims description 66

- 239000000203 mixture Substances 0.000 claims description 42

- 239000000654 additive Substances 0.000 claims description 34

- 239000007788 liquid Substances 0.000 claims description 29

- 230000009471 action Effects 0.000 claims description 21

- 239000003795 chemical substances by application Substances 0.000 claims description 17

- 230000000996 additive effect Effects 0.000 claims description 15

- 102000004190 Enzymes Human genes 0.000 claims description 9

- 108090000790 Enzymes Proteins 0.000 claims description 9

- 239000000463 material Substances 0.000 claims description 7

- 238000004061 bleaching Methods 0.000 claims description 5

- 239000007844 bleaching agent Substances 0.000 claims description 5

- 238000004891 communication Methods 0.000 claims description 5

- -1 peroxide compound Chemical class 0.000 claims description 5

- 239000012265 solid product Substances 0.000 claims description 5

- 239000000126 substance Substances 0.000 claims description 5

- 238000005282 brightening Methods 0.000 claims description 4

- 239000003086 colorant Substances 0.000 claims description 4

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 claims description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 3

- 239000000460 chlorine Substances 0.000 claims description 3

- 229910052801 chlorine Inorganic materials 0.000 claims description 3

- 239000006260 foam Substances 0.000 claims description 3

- 239000004519 grease Substances 0.000 claims description 3

- 239000001301 oxygen Substances 0.000 claims description 3

- 229910052760 oxygen Inorganic materials 0.000 claims description 3

- 230000002093 peripheral effect Effects 0.000 claims description 3

- 239000012190 activator Substances 0.000 claims description 2

- 239000004480 active ingredient Substances 0.000 claims description 2

- 230000000844 anti-bacterial effect Effects 0.000 claims description 2

- 239000012736 aqueous medium Substances 0.000 claims description 2

- 239000003899 bactericide agent Substances 0.000 claims description 2

- 239000003054 catalyst Substances 0.000 claims description 2

- 239000008187 granular material Substances 0.000 claims description 2

- 239000004745 nonwoven fabric Substances 0.000 claims description 2

- 239000013543 active substance Substances 0.000 claims 1

- 239000000499 gel Substances 0.000 claims 1

- 239000007903 gelatin capsule Substances 0.000 claims 1

- 239000008188 pellet Substances 0.000 claims 1

- 239000000470 constituent Substances 0.000 description 49

- 239000003826 tablet Substances 0.000 description 38

- 239000000047 product Substances 0.000 description 19

- 230000008569 process Effects 0.000 description 16

- 230000008901 benefit Effects 0.000 description 9

- 239000002775 capsule Substances 0.000 description 7

- 238000004090 dissolution Methods 0.000 description 7

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 description 6

- 150000001875 compounds Chemical class 0.000 description 5

- 238000009792 diffusion process Methods 0.000 description 5

- 239000004615 ingredient Substances 0.000 description 5

- 239000011324 bead Substances 0.000 description 4

- 238000005192 partition Methods 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 239000004382 Amylase Substances 0.000 description 3

- 102000013142 Amylases Human genes 0.000 description 3

- 108010065511 Amylases Proteins 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 3

- 239000004372 Polyvinyl alcohol Substances 0.000 description 3

- 235000019418 amylase Nutrition 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 230000003287 optical effect Effects 0.000 description 3

- 238000004806 packaging method and process Methods 0.000 description 3

- 229920002451 polyvinyl alcohol Polymers 0.000 description 3

- 239000011734 sodium Substances 0.000 description 3

- 229910052708 sodium Inorganic materials 0.000 description 3

- 239000000725 suspension Substances 0.000 description 3

- 229920000742 Cotton Polymers 0.000 description 2

- 239000004115 Sodium Silicate Substances 0.000 description 2

- PJANXHGTPQOBST-VAWYXSNFSA-N Stilbene Natural products C=1C=CC=CC=1/C=C/C1=CC=CC=C1 PJANXHGTPQOBST-VAWYXSNFSA-N 0.000 description 2

- BGRWYDHXPHLNKA-UHFFFAOYSA-N Tetraacetylethylenediamine Chemical compound CC(=O)N(C(C)=O)CCN(C(C)=O)C(C)=O BGRWYDHXPHLNKA-UHFFFAOYSA-N 0.000 description 2

- 230000000295 complement effect Effects 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 230000003111 delayed effect Effects 0.000 description 2

- 238000009472 formulation Methods 0.000 description 2

- 239000007937 lozenge Substances 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 239000002609 medium Substances 0.000 description 2

- 229920000058 polyacrylate Polymers 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 229960001922 sodium perborate Drugs 0.000 description 2

- 235000019351 sodium silicates Nutrition 0.000 description 2

- YKLJGMBLPUQQOI-UHFFFAOYSA-M sodium;oxidooxy(oxo)borane Chemical compound [Na+].[O-]OB=O YKLJGMBLPUQQOI-UHFFFAOYSA-M 0.000 description 2

- PJANXHGTPQOBST-UHFFFAOYSA-N stilbene Chemical compound C=1C=CC=CC=1C=CC1=CC=CC=C1 PJANXHGTPQOBST-UHFFFAOYSA-N 0.000 description 2

- 235000021286 stilbenes Nutrition 0.000 description 2

- 239000004753 textile Substances 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- QDCPNGVVOWVKJG-VAWYXSNFSA-N 2-[(e)-dodec-1-enyl]butanedioic acid Chemical compound CCCCCCCCCC\C=C\C(C(O)=O)CC(O)=O QDCPNGVVOWVKJG-VAWYXSNFSA-N 0.000 description 1

- QYLJIYOGHRGUIH-CIUDSAMLSA-N Arg-Ile Chemical compound CC[C@H](C)[C@@H](C(O)=O)NC(=O)[C@@H](N)CCCNC(N)=N QYLJIYOGHRGUIH-CIUDSAMLSA-N 0.000 description 1

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 1

- 108091005804 Peptidases Proteins 0.000 description 1

- ABLZXFCXXLZCGV-UHFFFAOYSA-N Phosphorous acid Chemical compound OP(O)=O ABLZXFCXXLZCGV-UHFFFAOYSA-N 0.000 description 1

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 1

- 241000206607 Porphyra umbilicalis Species 0.000 description 1

- 239000004365 Protease Substances 0.000 description 1

- 102100037486 Reverse transcriptase/ribonuclease H Human genes 0.000 description 1

- DBMJMQXJHONAFJ-UHFFFAOYSA-M Sodium laurylsulphate Chemical compound [Na+].CCCCCCCCCCCCOS([O-])(=O)=O DBMJMQXJHONAFJ-UHFFFAOYSA-M 0.000 description 1

- 102000005158 Subtilisins Human genes 0.000 description 1

- 108010056079 Subtilisins Proteins 0.000 description 1

- 239000011149 active material Substances 0.000 description 1

- 238000005054 agglomeration Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- NKWPZUCBCARRDP-UHFFFAOYSA-L calcium bicarbonate Chemical compound [Ca+2].OC([O-])=O.OC([O-])=O NKWPZUCBCARRDP-UHFFFAOYSA-L 0.000 description 1

- 229910000020 calcium bicarbonate Inorganic materials 0.000 description 1

- 239000004927 clay Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000001143 conditioned effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 229940090960 diethylenetriamine pentamethylene phosphonic acid Drugs 0.000 description 1

- 238000004851 dishwashing Methods 0.000 description 1

- MOTZDAYCYVMXPC-UHFFFAOYSA-N dodecyl hydrogen sulfate Chemical compound CCCCCCCCCCCCOS(O)(=O)=O MOTZDAYCYVMXPC-UHFFFAOYSA-N 0.000 description 1

- 229940043264 dodecyl sulfate Drugs 0.000 description 1

- 229940060296 dodecylbenzenesulfonic acid Drugs 0.000 description 1

- DUYCTCQXNHFCSJ-UHFFFAOYSA-N dtpmp Chemical compound OP(=O)(O)CN(CP(O)(O)=O)CCN(CP(O)(=O)O)CCN(CP(O)(O)=O)CP(O)(O)=O DUYCTCQXNHFCSJ-UHFFFAOYSA-N 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 150000002191 fatty alcohols Chemical class 0.000 description 1

- 230000009474 immediate action Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000002736 nonionic surfactant Substances 0.000 description 1

- 239000003605 opacifier Substances 0.000 description 1

- 210000000056 organ Anatomy 0.000 description 1

- 239000002304 perfume Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 230000000750 progressive effect Effects 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 150000004760 silicates Chemical class 0.000 description 1

- 235000019333 sodium laurylsulphate Nutrition 0.000 description 1

- 239000002689 soil Substances 0.000 description 1

- 239000002195 soluble material Substances 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 239000000375 suspending agent Substances 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 239000010457 zeolite Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/02—Devices for adding soap or other washing agents

- D06F39/024—Devices for adding soap or other washing agents mounted on the agitator or the rotating drum; Free body dispensers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F7/00—Casings, e.g. crankcases

- F02F7/006—Camshaft or pushrod housings

Definitions

- the present invention relates to the field of machine washing and cleaning of linen.

- European patent application No. 85400652.5 published under No. 0151549, in the name of the applicant, describes an original method of washing laundry in the machine with a liquid detergent.

- a device is used containing a liquid detergent and comprising non-blocked vents. This device is placed with the laundry to be washed in the drum of the machine and the machine is started, letting the washing cycle take place, the detergent thus progressively passing through the laundry and the washing bath as soon as the machine is started. on the way.

- a predetermined quantity of liquid detergent is poured into the device, which for this purpose has a filling orifice and, at the end of the washing, the device is recovered which can be reused.

- Such a device comprises at least one filling orifice and vents for the gradual release of the liquid within the laundry during washing.

- the device comprises a body and an attached assembly, which is intended for filling and / or diffusing the liquid.

- Such an assembly can be permanently mounted on the body or on the contrary be removable.

- Such an assembly may include a central filling orifice and vents distributed around its periphery.

- the filling orifice has the form of a chimney plunging inside the body. It will also be noted that an advantageous arrangement in practice consists in giving the device an essentially spherical shape. However, this form is in no way limiting and it is possible, for example, to implement other forms of revolution.

- the device is filled with liquid detergent and it is thus placed filled in the drum of the machine, where the laundry is already located, the liquid detergent contained in the device diffusing gradually during washing in the medium. washing and in the laundry.

- a controlled predissolution of the detergent is carried out in the device, physically preventing the detergent from leave the device in particulate form, in a massive and uncontrolled manner, while allowing the washing liquid to penetrate inside the device, so as to allow the gradual release of the pre-dissolved detergent within the medium containing the laundry in washing course.

- a metering and diffusing device suitable for implementing such a method comprises a body capable of being filled with the desired quantity of particulate detergent, removable means for closing off this body, the body or said means having holes or vents for releasing the detergent. Means separate the part of the device comprising the holes or vents from the part comprising the particulate detergent, these means being designed to allow the washing water to pass freely and to practically prevent the massive and uncontrolled exit of the particulate detergent.

- the device has the general shape of a body of revolution which can be closed by a removable cap. It comprises at least one plate mounted inside the device for separating the cap and the part of the body containing the particulate detergent, said plate itself having at least one orifice whose surface is less than that of the holes or vents of the cap.

- document EP-A-0 288 346 which benefits from the priority of French patent application 8704167 filed on March 25, 1987 by the applicant, relates to a process for washing linen and container for its implementation ".

- This document was only published on October 26, 1988 and is therefore opposable to the present request only under Article 54 (3) OBE. It describes a process for washing laundry in the machine which is introduced into the drum of the washing machine a container or device, containing a predetermined amount of detergent composition, advantageously liquid, this container being designed to allow the gradual diffusion of the composition during washing.

- the constituents of the detergent composition which are not of satisfactory mutual compatibility are conditioned separately in individual compartments of said container, each of said compartments having openings, so that when the container is placed in the drum and when the machine is started, the constituents of the detergent composition diffuse simultaneously and separately during the washing.

- a container with two compartments one of which may in particular contain the bleaching constituents intended to release oxygen or active chlorine while the other contains the rest of the detergent composition.

- the Applicant has continued its work in the general field of machine washing technique, the subject of its aforementioned European patent application 0151549. It was desirable, in fact, to have a simple process, which can be implemented with inexpensive devices, for simultaneously solving several technical problems which arise with the detergent compositions currently available on the market.

- the first problem to be solved is to allow the user to have a method and a device for adapting the washing conditions to the state of soiling of the laundry, thereby providing "à la carte washing". This problem is general and it exists as well for liquid detergent compositions as for the compositions in particulate form.

- a further problem results from the fact that it is desirable to wash the laundry with a detergent composition, the constituents of which exert their activity at the optimal time, as well as intervening in the washing process, for example to ensure a protective role for parts of the washing machine, only to fulfill their specific function during washing, which is the case for example with enzymes, softeners, agents which have a stain-removing action on grease stains, peroxygen compounds, bleaching catalysts , bleach activators, bactericides, foam regulators, optical brighteners and other similar constituents with specific functions.

- Such constituents must be available at determined instants of the washing cycle and the technical problem to be solved is to find a simple and practical process for presenting these constituents so as to make them available for the washing process according to a predetermined and optimal sequence.

- the invention provides a solution to the problems which have just been mentioned, whatever the type of detergent used, and this by taking advantage of the currently existing devices which are for example described in the aforementioned European patent application 0152359 and which have proven in practice, very suitable for the implementation of the general washing technique described in particular in the European patent application 0151549 mentioned above.

- the subject of the invention is a method of washing clothes in a drum machine, in which a device comprising an external body and non-blocked vents is used, the body of the device with a dose of a basic detergent composition, one or more additives (s) packaged separately, according to the state of soiling of the laundry to be washed, being provided for said additive (s) being provided (s) to be placed in a housing (s) located in a non-deformable hollow element inside the device, the device containing the basic detergent composition and the said additive (s) are placed ) selected with the laundry to be washed in the drum of the machine, and the machine is started by letting the washing cycle take place, said device at the end of the washing cycle, being recovered and able to be re used.

- the method is applicable to detergent compositions in which certain constituents have a specific mode of action on soiling. It can also be used in the case where certain constituents have insufficient compatibility with others within the detergent composition.

- Nonlimiting examples of constituents which, in the process according to the invention, can be separated from the detergent composition proper are: bleaching agents, such as agents releasing chlorine or active oxygen (peroxygen compound), brightening agents, anti-redeposition agents of stains, enzymes, softeners, agents exerting a stain-removing action of grease stains.

- bleaching agents such as agents releasing chlorine or active oxygen (peroxygen compound)

- brightening agents such as agents releasing chlorine or active oxygen (peroxygen compound)

- anti-redeposition agents of stains such as enzymes, softeners, agents exerting a stain-removing action of grease stains.

- Such constituents have a specific action on soiling, which is exerted either at the start of the washing cycle, or during it. It is also possible to use the process of the invention to use agents which do not, strictly speaking, have a direct action on the soiling, but which can nevertheless intervene in a machine washing process. This is particularly the case for agents ensuring protection of the internal parts and organs of the washing

- the fact of associating with the device at least one constituent having a specific mode of action on the dirtiness means as well that such a constituent is made integral with the device as soon as it is put in place. machine and from the start of the washing cycle or that such a constituent is presented in a separate form to produce its effects during the washing cycle, in combination with the other constituents contained in the device.

- the constituents presented in separate form can be contained in bags or sachets, for example by individual dose, in a nonwoven material or on the contrary in a material soluble in the washing bath (for example in polyvinyl alcohol PVA).

- These constituents can also be capsules or tablets or lozenges soluble in the washing bath, as well as granules, sheets, for example nonwoven, impregnated or coated with active ingredients, or materials having the consistency of a dough.

- the actual detergent composition is in liquid or granular form and is supplied individually to the user.

- the latter also has specific action products or constituents which are offered to him separately and, for example, have characteristic shades or colors for each of them, so that the user can, according to the indications given to him , adapt the formulation of the detergent composition to the precise need for washing, depending on the state of soiling of the laundry.

- the problem of insufficient incompatibility of certain constituents of the detergent composition can be solved.

- a separate and deferred action of certain constituents, such as the bleaching agents thanks to their separate presentation, allowing them to dissolve more slowly during the washing cycle.

- the method of the invention can be implemented with a very simple device or container, for example of the general type described in the European patent application published under No. 0152359 or in the aforementioned French patent application No. 8707413.

- the device or container may include housings, for example in its outer periphery, capable of receiving the separate constituents in any of the forms which have been previously mentioned.

- a container comprising a body of revolution and an assembly, removable or not, with a central filling orifice having a chimney shape, and vents distributed around its periphery

- the constituents of said composition which are intended to be associated with the container, and which are for example presented in the form of a sachet of nonwoven material or soluble in the bath of washing.

- a container comprising a double chimney, one allowing filling with the actual detergent composition and the other serving for placing the bags, which then have a specific housing. If these sachets are made of non-woven material, they are simply collected at the end of the washing operation.

- the chimney or chimneys in question can be left free at their upper part or on the contrary comprise a clip-on cover or a movable cover, for example with a hinge, so as to enclose the constituents in their housings and to let them diffuse through the vents of the container. , together with the rest of the detergent composition.

- these separate constituents can also be presented in a different form, for example a liquid or a gel.

- these separate constituents of the actual detergent composition can be placed in the container in a special housing.

- the container can be supplied to the user with a housing thus filled in advance, in which case it suffices to fill the container with the detergent and to clear the opening of this housing, to allow the diffusion of the detergent as well as of the constituent already put in place.

- the method of the invention can be implemented with a very wide variety of devices or containers, the examples given above being only indicative and in no way limitative.

- the invention therefore also relates to a device for implementing the method described above.

- the device is intended to be reused and to be placed with the laundry in the drum of a washing machine and comprises a substantially spherical external body, non-deformable during a washing cycle, intended to receive a detergent and having vents not closed, and also comprises a hollow element which cannot be deformed during a washing cycle, said hollow element being placed completely inside said external body and connected to the latter, having at least one opening for communication. with the outside and comprising, in addition to its wall, means for holding in place for an additive, said means delimiting with the hollow element at least one housing for said additive, said housing being at least partially open during washing.

- the invention provides a simple and effective solution to the technical problems mentioned at the start of this specification.

- certain methods of washing laundry in the machine have involved the use of a machine capable of taking up the separate ingredients of a detergent formulation in separate tanks.

- This technical solution is extremely complicated, since it is not only necessary to modify the structure of the machines but to provide expensive programming equipment that comes into operation as the washing cycle proceeds.

- the process of the invention takes advantage of all the advantages of simplicity and efficiency of the general washing technique which is the subject of European patent application 0151549.

- the advantages of this technique namely better washing efficiency and elimination of detergent losses in the machine's drain circuit, the invention adds great flexibility in the washing conditions. the user being able to realize “à la carte washing", depending on the type and condition of the laundry to be washed and soiling to be removed.

- the invention also relates to the packaging of containers of washing products for a washing machine, intended to be introduced into said machine.

- Washing machines for washing dishes or dishes include at least one compartment intended to receive a washing product, washing machines for washing linen generally even comprising several compartments for receiving various products for washing and / or softening and / or purifying and which are hereinafter generally referred to as "detergents".

- the compartments are designed to empty into the machine during the washing cycle.

- Each product is in the form of a powder or a liquid and it is the user himself who fills the corresponding compartment, from a packaging or a container of bulk product.

- such a detergent container for a washing machine intended to be introduced into said machine, contains a determined dose of product for a washing cycle.

- the container is already ready for use, which avoids, in particular, any manipulation of product and any dosing problem.

- a shape that is particularly well suited for a container according to the invention is the spherical shape.

- the containers according to the invention can be packaged in any way.

- an original packaging is advantageously used which is remarkable in that it groups together a plurality of containers, containing products which are distinct by the nature of the articles to be washed and / or the function of the product, and which differ from each other by different brands and / or colors.

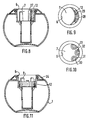

- Fig. 1 is an axial section of a device incorporating constituents presented in the form of tablets or lozenges.

- Fig. 2 is a detail view of FIG. 1.

- Fig. 3 is a view similar to FIG. 1 illustrating a device where certain components are presented in a sachet or pocket.

- Fig. 4 is a perspective view of a variant device using tablets.

- Fig. 5 is an axial section of the device of FIG. 4.

- Fig. 6 is a detailed view of an element of the device in FIGS. 4 and 5.

- Fig. 7 is a perspective view of a tablet usable in the method of the invention.

- Fig. 8 is an axial section of a device showing another embodiment with constituents presented in the form of tablets.

- Fig. 9 is a top view of the part of FIG. 8 containing the tablets.

- Fig. 10 is a view similar to FIG. 9 and illustrating an alternative embodiment.

- Fig. 11 is an axial section of another device usable with tablets.

- Fig. 12 is an axial section of a device incorporating tablets at its upper part.

- Fig. 13 is an axial section of a device comprising a housing for the tablets at its lower part.

- Fig. 14 is an axial section illustrating an alternative construction of a device element.

- Fig. 15 is an axial section illustrating another alternative construction.

- a body 1 of generally spherical shape and an attached assembly 2 to which the body 1 is connected by a planar surface 4 extending radially and extended by a cylindrical surface 5 extending upwards.

- the attached assembly 2 comprises an upper part 6 in the form of a bowl providing a central opening 7.

- the wall of the bowl 6 has peripheral perforations 8.

- the bowl 6 is extended downwards by a cylindrical part 9 in the form of a plunging chimney inside the device 1, which is intended to serve as a container for the detergent composition: Furthermore, the attached assembly 2 also has parts 10, projecting outwards and at the periphery, which come to bear on the surface 4 of the body 1 and essentially serve as gripping means.

- the process of the invention can advantageously be implemented with this type of device, which makes it possible to associate certain separate constituents of the basic detergent composition, which is introduced into the body 1.

- a number of tablets containing ingredients or constituents having a specific function for washing are placed inside the chimney 9.

- the internal surface of the chimney 9 can have annular projections 13 making it possible to provide therebetween housings where the tablets 12 are housed respectively.

- the chimney is limited by a wall 14 situated at a level intermediate of its height, which makes it possible not to be forced to insert a tablet in the chimney to its lowest level.

- the chimney 9 has been illustrated as having longitudinal side openings, which are usual in devices of this type already used. However, for the needs of the invention, it may be advantageous to provide a chimney with full walls, so that the detergent composition, for example liquid, introduced into the body 1 does not immediately come into contact with the tablets housed in the fireplace.

- the detergent composition for example liquid

- the drawing of Figures 1 and 2 illustrates tablets housed in the chimney, but the same provisions could be applied with constituents presented in the form of capsules or any other structure having sufficient strength to be inserted and maintained in the chimney.

- FIG. 3 shows a cover 16 movable around a hinge 18 and capable of being manipulated by a ring 17.

- This cover can be useful if the material of the bag 15 is a nonwoven fabric which does not dissolve in the washing bath, in which case it is better to avoid that, at the end of it, the bag escapes the device and could possibly damage the mechanical parts of the washing machine.

- the cover 16 is folded down at the top of the chimney, so that it is closed.

- the chimney 9 presents, as it is usual, longitudinal openings 19 also making it possible to bring the sachet into contact with the washing liquid, to ensure the diffusion of the constituent that it contains. If the bag 15 is formed of a water-soluble material such as polyvinyl alcohol, it is sufficient to place it in the chimney which then does not need to be sealed at its upper part.

- Figures 4 to 6 illustrate an alternative embodiment according to which tablets of constituents having a specific function for washing are placed not in the chimney as indicated in Figures 1 to 3 but in the bowl 6 of the set 2 attached on the body 1.

- a part 20 is provided which is pressed inside the bowl by enclosing the tablets.

- This part 20 is shown in perspective in Figure 6. We see that it has skirts 21, 22 having the shape of cylindrical walls which extend vertically to match the vertical walls of the bowl 6, but only over a limited area thereof, while passages or orifices 23, 24, 25 are also provided to then allow the diffusion of the active products in the washing bath.

- the part 20 also has at its upper part two recesses 26, facing each other, which facilitate gripping of this part.

- Figure 4 clearly shows the situation of the device when the part 20 is put in place and pressed inside the bowl 6. This same arrangement appears in section in Figure 5, where we also see two tablets 12 housed in bowl 6.

- Figure 7 illustrates a tablet that can be used in any of the aforementioned devices, as well as in those which will be illustrated below.

- This kind of tablet can be obtained directly by compacting a substance having an activity in a washing process, for example a mineral compound such as a peroxygen compound, in particular sodium perborate.

- a substance having an activity in a washing process for example a mineral compound such as a peroxygen compound, in particular sodium perborate.

- constituents with a specific function which are not capable by themselves of being put into tablet form and which must then be incorporated into a matrix or support capable of dissolving under washing conditions.

- This matrix can for example consist of calcium bicarbonate.

- FIG. 8 illustrates a variant of device according to which tablets or capsules are simply housed in compartments formed in the bowl 6.

- FIG. 9 is a top view of the bowl 6 and of the central opening 7 , that a crescent-shaped partition 27 extends through the bowl to form, with radial partitions 28, 29 housings into which tablets or capsules 12 can be inserted.

- FIG. 10 illustrates a variant according to which the partitions 27, 28 29 are replaced by cylindrical walls 31, 32, 33 which constitute respective cells in which can be accommodated tablets or capsules 30, in the form of a stick.

- FIG. 11 shows a device comprising a tablet 12 which is housed in the bottom of the bowl 6.

- an annular bead 34 has simply been provided inside the bowl 6. in place of the tablet 12, it suffices to push it inside the bowl and the tablet is then held at its upper part.

- the bead 34 does not need to be continuous. It suffices that the wall 6 has projections acting as stops when the tablet has been pressed. Since all the parts in question are made of plastic, the flexibility of the walls and beads allows the placement of tablets or capsules without any difficulty.

- FIG. 12 shows a device of the kind comprising a cover 35 screwed onto the body 1 by means of a complementary thread 36.

- the cover 35 which comprises a cylindrical wall 37 making it possible to provide a housing for inside which can be accommodated a tablet 12.

- FIG. 13 illustrates a device which is distinguished by the fact that the chimney 9 is limited by a wall 14 and that the lower part of the body 1 is arranged to form a housing 42 capable of receiving tablets 12, which can be kept there in place by annular beads, such as 43.

- FIG. 14 schematically shows a chimney arrangement 9 according to which a diametrical partition 44 extends inside the chimney, to produce two cylindrical compartments 45, 46 of semi-circular section.

- the compartment 45 is the only one to be placed in communication with the part of the device corresponding to the bowl 6 where the liquid detergent enters the device and diffuses during the washing.

- the other compartment 46 is not in communication with the liquid and can accommodate at least one tablet 12 and / or a bag 15, as shown.

- the cylindrical wall 47 of the chimney 9 delimiting the compartment 46 is generally full, while the compartment 45 has openings 19, as indicated above.

- FIG. 15 illustrates another variant of chimney 9 comprising an external cylindrical part 49 provided with orifices 19, which is placed in communication with the bowl 6 for filling and diffusing the liquid detergent composition, and an internal part 50, delimited by a cylindrical wall 48 with a circular base.

- the part 50 can receive at least one tablet 12 and / or a sachet 15, as shown. This part 50 is thus separated from the part of the device intended to contain the liquid detergent composition.

- the same basic liquid detergent composition is used, which is introduced into the device at a dose of approximately 180 g.

- This composition is as follows: Ingredients % in weight Dodecenyl succinic acid 12 Dodecyl benzene sulfonic acid 12 Alkyl sulfonic acid 4 Fatty alcohols C12 - C16 - 7 moles of ethylene oxide per mole of alcohol 16 Citric acid 1 Protease (Maxatase R) - (1.5 AU / g) 0.9 Amylase (Maxamyl R) - (300,000 KNU / g) 0.2 Phosphonic acid 0.8 Ethanol 8 Minor constituents, such as optical brightening agent, foam regulator based on silicone emulsion, dye, perfume, opacifier. Water Complement to 100

- this basic liquid detergent composition is combined with at least one additive having a specific function.

- additives are given, indicating their percentage by weight equivalent relative to the basic liquid detergent composition.

- the actual weights of the solid product will vary according to the active concentrations of the additives or active constituents which they contain. It is clear that the physical presentation: capsules, tablets, sachets, etc ... must be taken into consideration to provide the appropriate amount of additives to be indicated.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Detergent Compositions (AREA)

Claims (17)

- Verfahren zum Waschen von Wäsche in einer Trommelwaschmaschine, bei welchem eine Vorrichtung verwendet wird, die einen Außenkörper (1) und nicht verschlossene Austrittsöffnungen (8) aufweist, wobei der Körper (1) der Vorrichtung mit einer Dosis einer Reinigungsmittel-Grundmischung gefüllt wird, sodann abhängig vom Verschmutzungszustand der zu waschenden Wäsche einer oder mehrere Zusätze (12, 15, 30) gewählt werden, wobei der gewählte Zusatz bzw. die gewählten Zusätze zur Anordnung in einer Aufnahme bzw. Aufnahmen (6, 9, 31, 32, 33, 37, 41, 48) vorgesehen sind, die sich in einem hohlen, nicht verformbaren Element im Inneren der Vorrichtung befinden, die die Reinigungsmittel-Grundmischung und den gewählten Zusatz bzw. die Zusätze enthaltende Vorrichtung mit der zu waschenden Wäsche in der Trommel der Maschine angeordnet wird, die Maschine in Gang gesetzt wird, um den Waschzyklus ablaufen zu lassen, und die Vorrichtung am Ende des Waschzyklus wiedergewonnen wird, um wiederverwendet zu werden.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, daß der gesondert konditionierende Zusatz bzw. die gesondert konditionierenden Zusätze aus den Zusätzen gewählt werden, die einen spezifischen Einwirkungsmodus auf die Verschmutzung und/oder eine unzureichende Kompatibilität mit dem Reinigungsmittel und/oder einem anderen Zusatz bzw. anderen Zusätzen aufweisen.

- Verfahren nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß der gesondert konditionierende Zusatz bzw. die gesondert konditionierenden Zusätze aus den Bleichmittelzusätzen gewählt werden, wie den Mitteln, die Chlor oder aktiven Sauerstoff freisetzen (peroxygene Mischung), den Bleichmittelkatalysatoren, den Bleichmittelaktivatoren, den Bakteriziden, den Schaumreglern, den Glänzern, den schmutzabweisenden Mitteln, den Enzymen, den Weichmachern, den Mitteln, die eine Fettflecklösewirkung aufweisen, oder den Zusätzen, die keine direkte Wirkung auf die Verschmutzungswirkung ausüben, aber in einem Maschinenwaschverfahren wirksam werden können, beispielsweise Zusätzen, welche die Organe und Innenteile der Waschmaschine schützen.

- Verfahren nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß der Zusatz bzw. die Zusätze aus jenen Zusätzen gewählt werden, die beispielsweise als individuelle Dosis in Taschen oder Beuteln (15) aus einem nicht gewebten Material oder im Gegensatz dazu aus einem im Waschbad löslichen Material enthalten sind, oder in Gelatinekapseln (30), Preßlingen (12) oder Pastillen sowie Körnern und Folien, die beispielsweise nicht gewebt und mit aktiven-Bestandteilen oder Materialien mit pastöser Konsistenz imprägniert oder überzogen sind.

- Verfahren nach Anspruch 5, dadurch gekennzeichnet, daß man einen gesondert konditionierenden Zusatz wählt, der teilweise mit einer im wässrigen Milieu undurchdringlichen Substanz überzogen ist.

- Verfahren nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß man den gesondert konditionierenden Zusatz bzw. die gesondert konditionierenden Zusätze in flüssiger Form oder in Gelform wählt.

- Verfahren nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, daß man den gesondert konditionierenden Zusatz bzw. die gesondert konditionierenden Zusätze nach charakteristischen Teints oder Farben wählt.

- Vorrichtung zur Durchführung des Verfahrens nach einem der Ansprüche 1 bis 7, die wiederverwenbar ist und mit der Wäsche in der Trommel einer Waschmaschine angeordnet wird und einen Außenkörper (1) aufweist, der im wesentlichen kugelförmig, während eines Waschzyklus nicht verformbar und dazu bestimmt ist, ein Reinigungsmittel aufzunehmen und nicht verschlossene Austrittsöffnungen (8) sowie auch ein hohles Element (6, 9) aufweist, das im Verlaufe des Waschzyklus nicht verformbar ist, wobei das hohle Element vollständig im Inneren des Außenkörpers (1) angeordnet und mit diesem verbunden ist, wobei es zumindest eine Öffnung (19, 23, 24, 25) aufweist, um eine Verbindung mit dem Außeren herzustellen und außer seiner Wandung Haltemittel (13, 14, 16, 20, 27 bis 29, 31 bis 34, 37, 43) für einen Zusatz aufweist, wobei diese Mittel mit dem hohlen Element zumindest eine Aufnahme für den Zusatz begrenzen, die während des Waschzyklus zumindest teilweise offen ist.

- Vorrichtung nach Anspruch 8, dadurch gekennzeichnet, daß die Haltemittel zumindest einen vorspringenden Teil (13, 34, 43) aufweisen, der an der Innenwand des Elementes (6, 9) befestigt ist.

- Vorrichtung nach Anspruch 9, dadurch gekennzeichnet, daß der vorspringende Teil aus einem weichen Material besteht, um das Anbringen der festen Produkte zu erleichtern.

- Vorrichtung nach den Ansprüchen 8 bis 10, dadurch gekennzeichnet, daß die Haltemittel eine Wand (14, 27 bis 29, 31 bis 33) aufweisen, die im Inneren des Elementes befestigt ist.

- Vorrichtung nach den Ansprüchen 8 bis 11, dadurch gekennzeichnet, daß die Haltemittel (37) an einem Deckel (35) befestigt sind, der oberhalb der Öffnung angeordnet ist.

- Vorrichtung nach den Ansprüchen 8 bis 12, dadurch gekennzeichnet, daß das hohle Element eine Küvette (6) aufweist, in deren Wand die Austrittsöffnungen (8) ausgebildet sind.

- Vorrichtung nach Anspruch 13, dadurch gekennzeichnet, daß die Haltemittel einen Teil (20) aufweisen, der zumindest einen Mantel (21, 22) und zumindest einen Durchgang oder eine Durchtrittsöffnung (23, 24, 25) hat und der die Elementöffnung teilweise verschließt.

- Vorrichtung nach einem der Ansprüche 6 bis 14, dadurch gekennzeichnet, daß das hohle Element einen Kamin (14) aufweist, der die Küvette (6) verlängert und in dessen Wand die Austrittsöffnungen (8) ausgebildet sind.

- Vorrichtung nach Anspruch 15, dadurch gekennzeichnet, daß die Haltemittel durch einen Deckel (16) gebildet sind, der an der Wand des Kamins (14) angelenkt ist.

- Vorrichtung nach Anspruch 15 oder 16, dadurch gekennzeichnet, daß eine Außenwand und/oder Umfangswand des Kamins zumindest teilweise offen ist.

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8801234 | 1988-02-03 | ||

| FR8801234A FR2626589A1 (fr) | 1988-02-03 | 1988-02-03 | Conteneur de produit de lavage pour machine a laver |

| FR8801657A FR2627198B1 (fr) | 1988-02-11 | 1988-02-11 | Procede perfectionne de lavage du linge en machine |

| FR8801657 | 1988-02-11 | ||

| FR888806821A FR2626590B3 (fr) | 1988-02-03 | 1988-05-20 | Conditionnement de conteneurs de produits de lavage pour machine a laver |

| FR8806821 | 1988-05-20 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0331542A2 EP0331542A2 (de) | 1989-09-06 |

| EP0331542A3 EP0331542A3 (en) | 1989-11-29 |

| EP0331542B1 true EP0331542B1 (de) | 1996-05-08 |

Family

ID=27251566

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89400301A Expired - Lifetime EP0331542B1 (de) | 1988-02-03 | 1989-02-02 | Verfahren und Vorrichtung zum Waschen von Wäsche in einer Waschmaschine |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0331542B1 (de) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108166218A (zh) * | 2018-01-03 | 2018-06-15 | 卢园园 | 一种自动增压式洗衣球 |

| CN110273264A (zh) * | 2018-03-15 | 2019-09-24 | 青岛海尔洗衣机有限公司 | 一种洗涤剂投放装置及洗衣机 |

| WO2020125938A1 (de) | 2018-12-17 | 2020-06-25 | Symrise Ag | Wirkstoffspendevorrichtung zur applikation von wirkstoffen auf wäsche |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0699410A1 (de) * | 1994-08-30 | 1996-03-06 | The Procter & Gamble Company | Dosiereinrichtung für Reinigungsmitteltabletten |

| DE19516312C1 (de) * | 1995-05-04 | 1996-08-08 | Henkel Kgaa | Vorrichtung zur Halterung tablettenartiger Körper, enthaltend waschaktive Substanzen |

| GB2323606B (en) | 1997-03-07 | 1999-12-29 | Unilever Plc | A process and a dispensing device for washing laundry in a washing machine |

| GB9912648D0 (en) * | 1999-06-01 | 1999-07-28 | Sweeney Edward | Louvre blind washing aid |

| GB0329327D0 (en) * | 2003-12-18 | 2004-01-21 | Unilever Plc | Process and dispensing device for washing laundry in a washing machine |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2321998A (en) * | 1942-04-04 | 1943-06-15 | Eastman Kodak Co | Two-compartment container |

| EP0288346A1 (de) * | 1987-03-25 | 1988-10-26 | THE PROCTER & GAMBLE COMPANY | Verfahren und Behälter zum Waschen von Wäsche |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB731233A (en) * | 1953-10-19 | 1955-06-01 | Alford Cartons | Improved carrier for substantially spherical articles |

| US3058586A (en) * | 1959-12-03 | 1962-10-16 | Gen Foods Corp | Technique of bundling |

| GB1307387A (en) * | 1969-02-18 | 1973-02-21 | Lion Fat Oil Co Ltd | Cleansing agent having a shell structure |

| FR2563250B1 (fr) * | 1984-04-18 | 1986-12-26 | Procter & Gamble France | Procede de lavage du linge en machine avec un detergent liquide, et dispositif pour son application |

| GB2157718B (en) * | 1984-04-18 | 1987-05-07 | Procter & Gamble | Device for washing linen in a machine with a liquid detergent and process employing the said device |

| US4588080A (en) * | 1985-01-07 | 1986-05-13 | Ginn Martin E | Staged detergent/fabric treating preparation for use in washing machines |

| FR2587001B1 (fr) * | 1985-09-11 | 1990-02-09 | Procter & Gamble France | Dispositif doseur et diffuseur, pouvant etre incorpore a un recipient, en particulier pour produits liquides |

-

1989

- 1989-02-02 EP EP89400301A patent/EP0331542B1/de not_active Expired - Lifetime

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2321998A (en) * | 1942-04-04 | 1943-06-15 | Eastman Kodak Co | Two-compartment container |

| EP0288346A1 (de) * | 1987-03-25 | 1988-10-26 | THE PROCTER & GAMBLE COMPANY | Verfahren und Behälter zum Waschen von Wäsche |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108166218A (zh) * | 2018-01-03 | 2018-06-15 | 卢园园 | 一种自动增压式洗衣球 |

| CN108166218B (zh) * | 2018-01-03 | 2020-03-17 | 徐纯纯 | 一种自动增压式洗衣球 |

| CN110273264A (zh) * | 2018-03-15 | 2019-09-24 | 青岛海尔洗衣机有限公司 | 一种洗涤剂投放装置及洗衣机 |

| WO2020125938A1 (de) | 2018-12-17 | 2020-06-25 | Symrise Ag | Wirkstoffspendevorrichtung zur applikation von wirkstoffen auf wäsche |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0331542A2 (de) | 1989-09-06 |

| EP0331542A3 (en) | 1989-11-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FR2627198A1 (fr) | Procede perfectionne de lavage du linge en machine | |

| EP0343070B1 (de) | Verfahren und Vorrichtung zum Waschen von Wäsche in einer Maschine mit einem pulverförmigen Waschmittel | |

| EP0329538B1 (de) | Vorrichtung zum Waschen von Wäsche in einer Waschmaschine | |

| EP0343069B1 (de) | Verfahren und Vorrichtung zum Waschen von Wäsche in einer Maschine mit einem pulverförmigen Waschmittel | |

| EP0288345B1 (de) | Behälter mit mehreren Unterteilungen für einmaligen Gebrauch, dessen Herstellung und Anwendung, insbesondere zum Waschen von Wäsche | |

| EP0151549B1 (de) | Verwendung einer ein flüssiges Waschmittel enthaltenden Vorrichtung zum Waschen von Wäsche in einer Trommelwaschmaschine | |

| US4835804A (en) | Multiple compartment container laundering method | |

| FR2669943A1 (fr) | Equipement pour le lavage du linge en machine et son mode de mise en óoeuvre. | |

| EP0331542B1 (de) | Verfahren und Vorrichtung zum Waschen von Wäsche in einer Waschmaschine | |

| US20060144099A1 (en) | Sequential dispensing a laundry additives during automatic machine laundering of fabrics | |

| FR2669944A1 (fr) | Dispositif pour le lavage du linge en machine et son mode de mise en óoeuvre. | |

| US20050188731A1 (en) | Systems, dispensers and methods for laundry additives | |

| EP0288346B1 (de) | Verfahren und Behälter zum Waschen von Wäsche | |

| EP0290332B1 (de) | Verfahren und Vorrichtung zum Waschen von Wäsche in einer Waschmaschine | |

| EP0038247B1 (de) | Wäschewaschmaschine mit Reinigungsmittelbehältern | |

| GB2327093A (en) | Detergent packaging and detergent dispensing combination | |

| CA2212322A1 (en) | Dispensing device for tablets | |

| FR2631640A1 (fr) | Procede et dispositif pour le lavage du linge en machine avec un produit particulaire | |

| WO2019013618A1 (en) | Prefilled single portion pack | |

| WO2018117988A1 (en) | Multipurpose detergent bottle cover | |

| FI89080B (fi) | Process foer tvaettning av linne samt behaollare foer utfoerande av processen | |

| JPH01249900A (ja) | リネンの洗浄法およびそれを実施するための容器 | |

| MXPA06006253A (en) | Automatic machine laundering of fabrics |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19891211 |

|

| 17Q | First examination report despatched |

Effective date: 19910924 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): GB |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): GB |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19960611 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030106 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040202 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040202 |