EP0247435B1 - Boîte pour tuyaux - Google Patents

Boîte pour tuyaux Download PDFInfo

- Publication number

- EP0247435B1 EP0247435B1 EP87106918A EP87106918A EP0247435B1 EP 0247435 B1 EP0247435 B1 EP 0247435B1 EP 87106918 A EP87106918 A EP 87106918A EP 87106918 A EP87106918 A EP 87106918A EP 0247435 B1 EP0247435 B1 EP 0247435B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- box according

- parts

- side wall

- hose

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C33/00—Hose accessories

Definitions

- the invention relates to a box for storing at least one hose or the like, in particular for fire-fighting vehicles according to the preamble of claim 1.

- a hose box for fire-fighting vehicles which is composed of individual essentially identical intermediate wall parts for the purpose of creating several hose compartments.

- Each intermediate wall part has a closed side wall and a closed circumferential edge running essentially perpendicularly thereto, which is interrupted on an end face on which an individual hose can be received.

- the individual intermediate wall parts are assembled to form the desired number of hose compartment compartments by means of pins arranged at right angles to the wall surfaces, which keep the distance between the intermediate wall parts and connect them to one another.

- Such a hose box construction is very complex and therefore expensive.

- the individual side wall parts must have cutouts, as must the base and rear wall parts in the contour.

- the pins or bolts that connect the side wall parts to each other must be very stable and require costly production. They have a tapered middle section in order to be able to fasten the ends of the webbing. Since different pins not only fasten adjacent side wall parts at a distance from one another, but also have to absorb the tensioning force of a webbing in the lateral direction, they are subjected to increased stress and may lead to breakage.

- the object of the invention is to provide a box structure of the type mentioned, which can be manufactured with the aid of structurally simple individual parts and assembled into a desired number of hose compartments.

- the essence of the invention is therefore identical design of the bottom, rear wall and lid parts of the hose box.

- These parts are preferably designed as a flat plate, the plate having a vertical continuous peripheral edge.

- the peripheral edge and plate are expediently integrated as a one-piece molded part.

- the plate has a substantially rectangular shape and the longitudinal sides of the peripheral edge of the plate have fastening holes for the lateral fastening of at least two hose box compartments.

- the narrow sides of the peripheral edge of the plate also have fastening holes which can be used for fastening a webbing at the end.

- Each individual plate is preferably made of plastic or aluminum.

- the long sides of the plate peripheral edge lie flat against adjacent side wall parts, and the edge of the long sides of the plate peripheral edge runs flush with the edge of the adjacent side wall parts.

- a flat cover part is thus inserted flush on the upper side between two lateral side wall parts.

- rear wall parts and / or base parts have a flush finish.

- the plate-like parts according to the invention can be assembled with differently dimensioned side wall parts for the purpose of forming single hose compartments or double hose compartments will.

- Enlarged side wall parts for double hose compartments can extend to the rear, for example to arrange two hoses one behind the other in the horizontal direction; Enlarged side wall parts can also extend upwards to accommodate two hoses one above the other in a double hose compartment. Double hose compartments can also be combined in combination with lateral single hose compartments. All individual parts of a box construction can be assembled using commercially available fastening material such as rivets and / or screws. The individual parts are simply formed molded parts, for example made of plastic or aluminum, and the side walls can also consist of wood. This results in inexpensive assembly and the use of different materials (mixed construction).

- a particular advantage of the invention is the integrated fastening of belt straps to the cover or base parts themselves, not to separate pins as in the prior art mentioned at the beginning. As a result, fewer individual parts are required. Nevertheless, the attachment is stable.

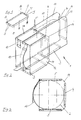

- a box (1) for storing at least one hose (2) or the like, for example a fire-fighting vehicle comprises side wall parts (11, 12) and base parts (3), rear wall parts (4) and cover parts (5).

- the last-mentioned individual parts (3, 4, 5) are of the same design in each hose box construction according to FIG. 1, so that there is a simplified production and nevertheless different compartment variants with differently dimensioned side wall parts (11 or 12) can be designed.

- a hose box with a double hose compartment and a further single hose compartment according to FIG. 2 can be formed with two rear wall parts (11) and a shortened side wall part (12) and seven individual parts according to FIG. 1.

- the individual parts (3, 4, 5) are in particular a rectangular flat plate (6) with an integrated vertical continuous peripheral edge (7), which has fastening holes (8) on the long sides and fastening holes (9) on the end faces.

- the fastening holes (8) serve to receive screws or rivets for the lateral fastening of side wall parts (11 or 12), the fastening holes (9) for fastening the end of belt straps (10), as is shown in particular in FIGS. 2 and 3 .

- FIG. 1 a desired compartment variant of a hose box can be produced by the invention with the aid of simple construction means.

- the flat, stable individual parts of FIG. 1 give the assembled construction a stable hold, and the ends of the belt strap (10) are also securely fastened via the fastening holes (9).

- the belt forces are from the whole Plate part added, not by separate individual pins as in the prior art.

- the webbing fastener can be a buckle fastener or a Velcro fastener.

- the hose box construction mentioned in FIG. 2 is intended for receiving vertically arranged individual hoses. With a corresponding 90 ° rotation of the box, horizontal arrangement of hoses (or wire ropes, etc.) is also possible.

- the individual parts of FIG. 1 are arranged flush with the (upper) edge (13) of the adjacent side wall parts (11, 12).

- the side wall parts (11, 12) can have a bevel (14), which preferably runs at an angle of 45 ° to the horizontal or vertical.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Fire-Extinguishing By Fire Departments, And Fire-Extinguishing Equipment And Control Thereof (AREA)

- Thermally Insulated Containers For Foods (AREA)

- Packaging Of Machine Parts And Wound Products (AREA)

- Installation Of Indoor Wiring (AREA)

- Packaging Of Annular Or Rod-Shaped Articles, Wearing Apparel, Cassettes, Or The Like (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Purses, Travelling Bags, Baskets, Or Suitcases (AREA)

- Fittings On The Vehicle Exterior For Carrying Loads, And Devices For Holding Or Mounting Articles (AREA)

Claims (16)

- Boîte (1) pour recevoir au moins un tuyau (2), un câble ou analogue, notamment pour des véhicules de pompiers, comportant une partie de fond, une partie de paroi latérale, une partie de paroi arrière et une partie de couvercle ainsi qu'une ceinture avant (10) pour fixer le tuyau concerné dans le boîtier ou analogue, caractérisée en ce que la partie de fond, la partie de paroi arrière et la partie de couvercle (3, 4, 5) sont identiques.

- Boîte selon la revendication 1, caractérisée en ce que la partie de fond, la partie de paroi arrière et la partie de couvercle (3, 4, 5) sont des plaques planes (6) à bord périphérique (7) continu vertical.

- Boîte selon la revendication 2, caractérisée en ce que le bord périphérique (7) fait corps avec la plaque (6).

- Boîte selon la revendication 2 ou 3, caractérisée en ce que la plaque (6) a une forme essentiellement rectangulaire.

- Boîte selon l'une des revendications 2 à 4, caractérisée en ce que le grand côté du bord périphérique de la plaque (7) comporte des orifices de fixation (8) pour la fixation latérale d'au moins deux compartiments de boîtes pour tuyaux.

- Boîte selon la revendication 4 ou 5, caractérisée en ce que le petit côté du bord périphérique (7) de la plaque comporte des orifices de fixation (9) pour fixer frontalement la ceinture (10).

- Boîte selon l'une des revendications 1 à 6, caractérisée en ce que la plaque (6) est en matière synthétique ou en aluminium.

- Boîte selon l'une des revendications 1 à 7, caractérisée en ce que les grands côtés du bord périphérique (7) de la plaque rejoignent à plat les parties de paroi latérale adjacentes (11, 12).

- Boîte selon la revendication 8, caractérisée en ce que le bord des grands côtés du bord périphérique (7) de la plaque est à fleur avec le bord supérieur (13) des parties de paroi latérale (11, 12) adjacentes.

- Boîte selon l'une des revendications 1 à 9, caractérisée en ce que pour le rangement d'au moins deux tuyaux ou analogues ou d'un seul tuyau de grande longueur, elle comporte des parties de paroi latérale (11) augmentées.

- Boîte selon la revendication 10, caractérisée en ce que les parties de paroi latérale augmentées (11) s'étendent vers l'arrière et au moins deux parties de fond en forme de plaque (3) sont prévues (figure 2).

- Boîte selon la revendication 10, caractérisée en ce que les parties de paroi latérale (11), augmentées s'étendent vers le haut et au moins deux parties de paroi arrière (4) en forme de plaques sont prévues.

- Boîte selon la revendication 11 ou 12, caractérisée en ce qu'avec un compartiment latéral pour un seul tuyau, on réalise de manière combinée un compartiment pour un double tuyau (figure 2).

- Boîte selon l'une des revendications 1 à 13, caractérisée en ce que les parties de paroi latérales (11, 12) possèdent au niveau de la partie de paroi arrière (4) au moins une partie tronquée (14).

- Boîte selon l'une des revendications 1 à 14, caractérisée en ce que les parties de paroi latérales (11, 12) sont en bois, en matière synthétique ou en aluminium.

- Boîte selon l'une des revendications 1 à 14, caractérisée en ce que les parties de paroi latérale (11, 12) et les plaques (6) sont réalisées dans des matériaux différents.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87106918T ATE68982T1 (de) | 1986-05-28 | 1987-05-13 | Schlauchkasten. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3618014 | 1986-05-28 | ||

| DE19863618014 DE3618014A1 (de) | 1986-05-28 | 1986-05-28 | Schlauchkasten |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0247435A2 EP0247435A2 (fr) | 1987-12-02 |

| EP0247435A3 EP0247435A3 (en) | 1989-03-22 |

| EP0247435B1 true EP0247435B1 (fr) | 1991-10-30 |

Family

ID=6301833

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87106918A Expired - Lifetime EP0247435B1 (fr) | 1986-05-28 | 1987-05-13 | Boîte pour tuyaux |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0247435B1 (fr) |

| AT (1) | ATE68982T1 (fr) |

| DE (2) | DE3618014A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19820856C2 (de) * | 1998-05-09 | 2000-02-24 | Reg Reifen Entsorgungsgesellsc | Lager- und Transportbehälter für Reifen oder Fahrzeugräder |

| ES2608343B1 (es) * | 2015-09-04 | 2018-05-07 | Lidia MENA SALADO | Equipo para instalaciones y control de mangueras planas |

| CN206492128U (zh) * | 2017-02-17 | 2017-09-15 | 中国民航科学技术研究院 | 一种耐火防爆应急处置箱 |

| ES1223719Y (es) * | 2018-11-29 | 2019-04-17 | Ojeda Juan Jesus Romero | Carrete portatil para mangueras de extincion de incendios |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1868927U (de) * | 1962-12-04 | 1963-03-14 | Kloeckner Humboldt Deutz Ag | Schlauchfaecher-einsatz fuer feuerloeschfahrzeuge. |

| GB1406904A (en) * | 1972-03-14 | 1975-09-17 | Kanebo Ltd | Portable fire-hose |

-

1986

- 1986-05-28 DE DE19863618014 patent/DE3618014A1/de not_active Withdrawn

-

1987

- 1987-05-13 EP EP87106918A patent/EP0247435B1/fr not_active Expired - Lifetime

- 1987-05-13 DE DE8787106918T patent/DE3774175D1/de not_active Expired - Lifetime

- 1987-05-13 AT AT87106918T patent/ATE68982T1/de not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| EP0247435A2 (fr) | 1987-12-02 |

| EP0247435A3 (en) | 1989-03-22 |

| DE3618014A1 (de) | 1987-12-03 |

| ATE68982T1 (de) | 1991-11-15 |

| DE3774175D1 (de) | 1991-12-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19726500B4 (de) | Trennvorrichtung für eine Kabelbahn | |

| DE602004004731T2 (de) | Verbinder für einen Schienenschlitz | |

| DE2713804C2 (de) | Fahrzeuggepäckträger | |

| DE4004829C2 (fr) | ||

| WO2018007204A1 (fr) | Véhicule automobile | |

| EP1344712A2 (fr) | Pièce composite, en particulier pour une pièce rapportée ou un panneau de carosserie automobile | |

| DE2947403A1 (de) | Fahrzeuggepaecktraeger | |

| DE19941714C2 (de) | Haltevorrichtung in einem Kraftfahrzeug | |

| EP0247435B1 (fr) | Boîte pour tuyaux | |

| DE4017160C2 (de) | Seitenschutz | |

| DE68903348T2 (de) | Aufbauten vom typ sattelauflieger mit plane. | |

| EP0588761A1 (fr) | Dispositif pour la fixation de la charge | |

| DE9312947U1 (de) | Vorrichtung zum Fixieren von Fördergütern in Fahrzeugen | |

| EP1029810A1 (fr) | Ensemble de séparation flexible | |

| WO2005118382A1 (fr) | Motocyclette comprenant un dispositif de fixation pour sacoche laterale | |

| DE3424690C2 (de) | Selbsttragende Omnibus-Karosserie | |

| DE3622018A1 (de) | Vorrichtung zum sichern von lasten in kraftfahrzeugen | |

| DE9413049U1 (de) | Vorrichtung zum Befestigen einer Abdeckleiste für Nuten von Kraftwagen-Aufbauten | |

| DE102021103507B4 (de) | Reling für ein Kraftfahrzeug | |

| DE10061349C2 (de) | Vorrichtung für eine Zugentlastung dynamisch beanspruchter Leitungen in einer Energieführungskette | |

| DE2418313C2 (de) | Rahmenkonstruktion, die einen Lastboden beispielsweise eines Lastfahrzeuges umgibt | |

| DE19617454A1 (de) | Schutzgitter bzw. Trennwand für den Innenraum von Kraftfahrzeugen | |

| DE7701184U1 (de) | Kabine für ein Motorfahrzeug | |

| DE10259388A1 (de) | Vorrichtung zum Sichern von Ladegut auf einer Fläche | |

| EP0168348A1 (fr) | Fixation de carrosserie sur un châssis |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE FR GB LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE FR GB LI |

|

| 17P | Request for examination filed |

Effective date: 19890826 |

|

| 17Q | First examination report despatched |

Effective date: 19901213 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB LI |

|

| REF | Corresponds to: |

Ref document number: 68982 Country of ref document: AT Date of ref document: 19911115 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3774175 Country of ref document: DE Date of ref document: 19911205 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030509 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20030516 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20030522 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030528 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20030822 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040513 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040513 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050131 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |