EP0222684B1 - Montage de contacts pour interrupteur à charge à basse tension avec des contacts principaux et des contacts d'amorçage d'arc - Google Patents

Montage de contacts pour interrupteur à charge à basse tension avec des contacts principaux et des contacts d'amorçage d'arc Download PDFInfo

- Publication number

- EP0222684B1 EP0222684B1 EP86730160A EP86730160A EP0222684B1 EP 0222684 B1 EP0222684 B1 EP 0222684B1 EP 86730160 A EP86730160 A EP 86730160A EP 86730160 A EP86730160 A EP 86730160A EP 0222684 B1 EP0222684 B1 EP 0222684B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- arc

- contact

- arcing

- contact arrangement

- contacts

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010791 quenching Methods 0.000 claims description 12

- 230000001154 acute effect Effects 0.000 claims description 3

- 238000005266 casting Methods 0.000 claims description 3

- 239000003302 ferromagnetic material Substances 0.000 claims description 3

- 229910001208 Crucible steel Inorganic materials 0.000 claims description 2

- 230000000171 quenching effect Effects 0.000 description 10

- 230000000694 effects Effects 0.000 description 5

- 238000000034 method Methods 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 230000008878 coupling Effects 0.000 description 3

- 238000010168 coupling process Methods 0.000 description 3

- 238000005859 coupling reaction Methods 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 230000005294 ferromagnetic effect Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000005303 weighing Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H9/00—Details of switching devices, not covered by groups H01H1/00 - H01H7/00

- H01H9/30—Means for extinguishing or preventing arc between current-carrying parts

- H01H9/44—Means for extinguishing or preventing arc between current-carrying parts using blow-out magnet

- H01H9/446—Means for extinguishing or preventing arc between current-carrying parts using blow-out magnet using magnetisable elements associated with the contacts

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H9/00—Details of switching devices, not covered by groups H01H1/00 - H01H7/00

- H01H9/30—Means for extinguishing or preventing arc between current-carrying parts

- H01H9/46—Means for extinguishing or preventing arc between current-carrying parts using arcing horns

Definitions

- the invention relates to a contact arrangement for low-voltage circuit breakers with main contacts for guiding a continuous current and with burn-off contacts for igniting a switching arc in the entry area of an arc quenching chamber, and with arcing horns for transferring the switching arc into the arc quenching chamber, with at least two main contact contact piece supports being arranged next to one another and at least one burn-off contact piece support is arranged at a distance therefrom.

- a contact arrangement of this type is known for example from DE-A-2 218 420.

- Such contact arrangements are usually selected in order to be able to transmit a high current over a longer period of time with the contact arrangement being heated as little as possible. In principle, this is achieved in that the main contacts operate without arcing and are consequently not exposed to erosion which affects the contact surfaces. If such a contact arrangement is opened for switching off, then the currents initially flowing through the main contacts are commutated to the burn-off contacts, so that only the switching arc is applied to them.

- the object of the invention is to provide such a configuration of the contact arrangement which allows a relatively narrow, i.e. to be able to use the arc extinguishing chamber which is essentially matched to the burn-off contacts even if an arcing is to be expected at the main contacts.

- an arc guide made of a ferromagnetic material is arranged in the space between the main contact contact piece supports and the burn-off contact piece contact piece.

- the effect of the arc guide piece is based on the known phenomenon that arcs are attracted by ferromagnetic parts and can thus be guided in a desired direction (see e.g. DE-A-1 690 137).

- the proposed arc guiding pieces attract and take over partial arcs occurring in the event of an overload at the main contacts. Based on known commutation processes, they then reach, for example, the burn-off contact or the arcing horns and combine at these parts to form a uniform switching arc. Since only this is to be transferred into the arc quenching chamber, it is sufficient to adapt the dimensions of the arc quenching chamber to the burnout contacts. As a result of its smaller volume, the arc quenching chamber can be manufactured more cheaply than the known design with widened quenching plates.

- the arc guiding pieces For the transfer of the partial arcs from the main contacts to the burn-off contact, it has proven to be advantageous to carry out the arc guiding pieces with an approximately triangular shape, one side of the triangular shape in each case the main contacts and another side the space between the upper edge of the main contacts and the upper edge of the associated burnout contact covered. In this way, effective guiding edges for the partial arcs are formed.

- two edges of the triangular shape can be arranged so that they are at an acute angle, which leads to the arcing horn of the associated break contact. In this way it can be achieved that the partial arcs only meet the main arc at the arcing horn and the additional stress on the burnout contacts is avoided.

- the arc guide pieces provided according to the invention can be stamped and bent parts made of sheet steel, or they can be ferromagnetic castings. It has been found that the mass of the arc guide pieces, i.e. for a given area their thickness has an influence on the desired effect. Depending on the desired effect, it may therefore be advisable to use arc guiding pieces that are more or less thick. When it is designed as a cast part, it proves to be advantageous to provide a thick-walled part for guiding arcs and a thin-walled part for fastening.

- both the fixed part and the movable part of the contact arrangement can be provided with arcing elements, or both parts of the contact arrangement can be arcing elements. It has been shown that a suitable effect can already be achieved by appropriate equipping of the fixed part. The invention is explained in more detail below with reference to the exemplary embodiments shown in the figures.

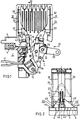

- Figure 1 shows the contact arrangement of a Po. les of a low voltage circuit breaker in a partially sectioned side view.

- FIG. 2 shows the section 11-11 in FIG. 1, the left and right parts of FIG. 2 showing different embodiments.

- the contact arrangement 1 according to FIGS. 1 and 2 comprises, in a known manner, a fixed part 2 and a movable part 3.

- An insulating block 4 serves as a support for the fixed part 2 of the contact arrangement 1, to which an upper connecting bar 5 is attached, which is also a fixed part Main contact is used and for this purpose is provided with a contact piece support 6 or a larger number of such contact piece supports.

- a fixed burn-off contact 7 is fastened close to the contact piece support 6, which is also provided with a contact piece support 10.

- the current band 12 establishes the electrically conductive connection with the movable part 3 of the contact arrangement 1, which is pivotably mounted about a hinge pin 13 arranged between the legs of the U-shaped current band 12.

- the movable part 3 comprises a carrier 14 on which the main contact lever 16, which is connected to the current band 12, is pivotably mounted about a hinge pin 15. These are provided at their upper end with contact piece supports 17 which cooperate with the fixed contact piece supports 6.

- the carrier 14 has a burn-off contact 20 which has a contact piece support 21 which interacts with the fixed contact piece support 10.

- Both the stationary part 2 and the movable part 3 of the contact arrangement 1 have an arcing horn 22 or 23 in order to convert switching arcs into an arcing chamber 24.

- FIG. 2 shows, there are two fixed contact piece supports 6 as main contacts. Accordingly, the movable part 3 of the contact arrangement 1 has two contact levers arranged next to one another with contact piece supports 17. Depending on the current that the circuit breaker should be able to handle with permissible heating, a larger number of main contacts can be provided. In order to illustrate this, two contact piece supports 6 are shown in the right part of FIG. 2, so that in this embodiment the contact arrangement has a total of four main contacts.

- the movable part of the contact arrangement 1 is connected in an articulated manner to the carrier 14 by means of a suitable type of drive device, not shown, via an insulating coupling 25 by means of a bolt 26.

- the contact arrangement 1 is closed by moving the isolating coupling 25 in the direction of the arrow 27, the contact piece supports 10 and 21 of the burn-off contacts first and then the contact piece supports 6 and 17 of the main contacts coming into contact with one another.

- the bearing pin 26 acts as a fixed pivot bearing of the carrier 14, so that pressure springs 30 arranged between the legs of the U-shaped curved current band act as contact force springs. If, on the other hand, the drive device is released and the isolating coupling 25 is thereby released, the compression springs 30 act as switch-off springs and transfer the contact arrangement into the switch-off position shown in FIG. 1.

- a switching arc occurs only at the burnout contacts, provided the current flowing through the contact arrangement does not exceed a certain level.

- the switching arc is then taken over by the arcing horns 22 and 23 and transferred to the arcing chamber 24.

- This process is favored in a known manner by guide rails 31 which, in the example shown, have a U-shaped profile and are dimensioned such that the tips of the arcing horns 22 and 23 lie between the legs 32 and 33 of the arc guide rails 31.

- each arc guide piece 40 is provided with an extension 41 which rests on the fixed connecting rail 5.

- a screw 42 is used to jointly fasten the connecting bar 5 and the arc guide piece 40 to the insulating block 4 by means of a threaded bush 43 embedded in the insulating block 4 the contact piece supports 6 reached.

- the further edges 45 and 46 act as leading edges of the partial arcs upwards in the direction of the arcing horns 22 and 23. These edges are at an acute angle to one another and are dimensioned such that they reach the arcing horn 22 beyond the contact piece support 10.

- the different embodiments shown in the left and right parts of FIG. 2 show that the size of the arc guide pieces can be easily adapted to the number of main contacts present.

- the lower edge 44 'of the arc guide piece 40' is longer, as is the edge 45 'leading to the arcing horn.

- the arc guide pieces 40 and 40 ' can be made of sheet steel with an angled portion for fastening. In the illustrated In the exemplary embodiment, however, the arc guide pieces are made of cast steel, since the parts of different thickness desired for guiding the arcs and for fastening can be produced more easily in this way. A relatively large thickness of the arc guide pieces, ie a correspondingly large mass of ferromagnetic material, can prove to be advantageous for the desired effect. Good results have been achieved, for example, in a circuit breaker for a rated current of 1600 A with two main contacts (left part of FIG. 2) in connection with two arc guiding pieces made of jet casting each weighing 60 g.

- the fixed part 2 of the contact arrangement 1 is provided with arcing elements.

- This arrangement has proven to be effective and has the advantage that the mass of the movable part 3 does not have to be increased by additional parts.

- the movable part 3 could also be provided with arc guide pieces, although it may be sufficient, in contrast to the solid arc guide pieces described, to use thinner material, e.g. made of sheet steel. In this case the magnification of the moving mass is so small that an influence on the mechanical switching process cannot be determined.

Landscapes

- Arc-Extinguishing Devices That Are Switches (AREA)

- Driving Mechanisms And Operating Circuits Of Arc-Extinguishing High-Tension Switches (AREA)

Claims (5)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19853539673 DE3539673A1 (de) | 1985-11-06 | 1985-11-06 | Kontaktanordnung fuer niederspannungs-leistungsschalter mit hauptkontakten und abbrennkontakten |

| DE3539673 | 1985-11-06 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0222684A1 EP0222684A1 (fr) | 1987-05-20 |

| EP0222684B1 true EP0222684B1 (fr) | 1990-01-17 |

Family

ID=6285499

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86730160A Expired - Lifetime EP0222684B1 (fr) | 1985-11-06 | 1986-10-16 | Montage de contacts pour interrupteur à charge à basse tension avec des contacts principaux et des contacts d'amorçage d'arc |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4720613A (fr) |

| EP (1) | EP0222684B1 (fr) |

| JP (1) | JP2606798B2 (fr) |

| DE (2) | DE3539673A1 (fr) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8715757U1 (de) * | 1987-11-25 | 1988-02-18 | Siemens AG, 1000 Berlin und 8000 München | Niederspannungs-Leistungsschalter |

| US4926018A (en) * | 1988-09-08 | 1990-05-15 | Siemens Energy & Automation, Inc. | Moving mains arc movement loop |

| JPH0684652U (ja) * | 1993-05-11 | 1994-12-02 | 株式会社東海理化電機製作所 | スライドスイッチ |

| DE19913236C2 (de) * | 1999-03-23 | 2001-02-22 | Siemens Ag | Verfahren zur Strombegrenzung in Niederspannungsnetzen und zugehörige Anordnung |

| DE19930813A1 (de) * | 1999-06-30 | 2001-01-04 | Siemens Ag | Leistungsschalter mit Anschlußschienen für verschiedene Nennströme |

| FR2795858B1 (fr) * | 1999-07-01 | 2001-09-14 | Schneider Electric Ind Sa | Appareillage electrique de coupure dont un organe de contact est muni d'un pare etincelle |

| DE19939710A1 (de) | 1999-08-18 | 2001-02-22 | Siemens Ag | Anschlußschienen für elektrische Geräte und Apparate für verschiedene Nennströme |

| DE10250950B4 (de) * | 2002-10-25 | 2004-10-28 | Siemens Ag | Niederspannungs-Leistungsschalter |

| JP6005085B2 (ja) * | 2014-03-10 | 2016-10-12 | 三菱電機株式会社 | 開閉装置 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1000486B (de) * | 1954-05-04 | 1957-01-10 | Calor Emag Elektrizitaets Ag | Hornfoermiger Schaltkontakt mit einer Einlage aus magnetischem Material |

| IT712788A (fr) * | 1963-08-21 | |||

| JPS4213041Y1 (fr) * | 1964-05-04 | 1967-07-25 | ||

| JPS4511130Y1 (fr) * | 1965-09-07 | 1970-05-19 | ||

| DE1690137B2 (de) * | 1968-01-31 | 1973-08-30 | Siemens AG, 1000 Berlin u 8000 München | Elektrischer leistungsschalter, insbesondere niederspannungs-leistungsschalter |

| US3749867A (en) * | 1971-04-01 | 1973-07-31 | Westinghouse Electric Corp | Spaced-metallic-plate-type of arc-chute for a switch |

| US3784775A (en) * | 1972-07-27 | 1974-01-08 | Ite Imperial Corp | Arc runner between stationary contacts |

-

1985

- 1985-11-06 DE DE19853539673 patent/DE3539673A1/de not_active Withdrawn

-

1986

- 1986-10-16 DE DE8686730160T patent/DE3668394D1/de not_active Expired - Fee Related

- 1986-10-16 EP EP86730160A patent/EP0222684B1/fr not_active Expired - Lifetime

- 1986-10-24 US US06/922,729 patent/US4720613A/en not_active Expired - Fee Related

- 1986-11-04 JP JP61262583A patent/JP2606798B2/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0222684A1 (fr) | 1987-05-20 |

| DE3539673A1 (de) | 1987-05-07 |

| DE3668394D1 (de) | 1990-02-22 |

| JPS62108418A (ja) | 1987-05-19 |

| US4720613A (en) | 1988-01-19 |

| JP2606798B2 (ja) | 1997-05-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0876671B1 (fr) | Appareil de commutation electrique | |

| EP1192628B1 (fr) | Ensemble contact de commutation de commande d'un disjoncteur basse tension dote de contacts principaux, de contacts intermediaires et de contacts de coupure | |

| DE3302884A1 (de) | Elektrischer leistungsschalter | |

| CH677045A5 (fr) | ||

| EP0222684B1 (fr) | Montage de contacts pour interrupteur à charge à basse tension avec des contacts principaux et des contacts d'amorçage d'arc | |

| EP0219449B1 (fr) | Disposition de contact pour un disjoncteur à basse tension à cordon de courant flexible | |

| DE9320696U1 (de) | Relais zum Schalten hoher Stromstärken | |

| DE3432086A1 (de) | Kontaktanordnung mit einer die kontaktkraft vergroessernden stromabhaengigen kraft | |

| EP1423862B1 (fr) | Systeme de contacts de commutation comportant un dispositif destine a amplifier une force de contact s'exer ant entre des contacts de commutation | |

| DE102019117804B4 (de) | Schalteinrichtung mit einem elektrischen Kontaktsystem | |

| EP1261981B1 (fr) | Pole de commutation pour appareils de commutation basse tension comportant un support de contacts a mouvement lineaire | |

| DE10048659A1 (de) | Schaltkontaktanordnung eines Niederspannungs-Leistungsschalter mit Kontaktkraftfedern | |

| EP0358287B1 (fr) | Elément-moteur pour un disjoncteur électrique multipolaire de puissance basse tension | |

| DE69030666T2 (de) | Ausschalter | |

| WO2002065494A1 (fr) | Dispositif a contact de commutation | |

| EP1374263B1 (fr) | Montage pour disjoncteur de puissance basse tension | |

| EP1218898A1 (fr) | Disjoncteur basse tension a chambre de commutation et porte-contact mobile | |

| DE2817668B1 (de) | Niederspannungs-Leistungsschalter mit einer Einrichtung zur Begrenzung von Kontaktabhebungen | |

| EP0091082B1 (fr) | Appareil de commutation actionné électromagnétiquement | |

| EP0910858B1 (fr) | Dispositif de contact de commutation pourvu d'une articulation destinee a un levier de contact | |

| EP0632928B1 (fr) | Interrupteur a vide avec un montage en boucle de courant | |

| DE2019885A1 (de) | Springkontaktsatz | |

| DE69305147T2 (de) | Kontaktvorrichtung | |

| EP0358288B1 (fr) | Agencement de contact pour un disjoncteur de puissance avec contacts auxiliaires et contacts principaux | |

| EP1298684B1 (fr) | Arrangement des contacts pour un interrupteur électrique à basse tension |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19870626 |

|

| 17Q | First examination report despatched |

Effective date: 19890116 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT SE |

|

| REF | Corresponds to: |

Ref document number: 3668394 Country of ref document: DE Date of ref document: 19900222 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 86730160.8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950918 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19951019 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19961016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19961017 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19961016 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 86730160.8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20031029 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20031217 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051016 |