EP0182012B1 - Dispositif pour réaliser une épissure de conducteur - Google Patents

Dispositif pour réaliser une épissure de conducteur Download PDFInfo

- Publication number

- EP0182012B1 EP0182012B1 EP85110494A EP85110494A EP0182012B1 EP 0182012 B1 EP0182012 B1 EP 0182012B1 EP 85110494 A EP85110494 A EP 85110494A EP 85110494 A EP85110494 A EP 85110494A EP 0182012 B1 EP0182012 B1 EP 0182012B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- cutting

- channels

- channel

- cores

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004020 conductor Substances 0.000 title claims description 3

- 238000005520 cutting process Methods 0.000 claims description 37

- 238000003780 insertion Methods 0.000 claims description 7

- 230000037431 insertion Effects 0.000 claims description 7

- 238000003825 pressing Methods 0.000 claims description 3

- 238000007789 sealing Methods 0.000 claims 2

- 238000013016 damping Methods 0.000 claims 1

- 230000035515 penetration Effects 0.000 claims 1

- 238000009434 installation Methods 0.000 description 4

- 238000000034 method Methods 0.000 description 2

- 238000004904 shortening Methods 0.000 description 2

- 239000011324 bead Substances 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 210000003462 vein Anatomy 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/24—Connections using contact members penetrating or cutting insulation or cable strands

- H01R4/2416—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type

- H01R4/242—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type the contact members being plates having a single slot

- H01R4/2425—Flat plates, e.g. multi-layered flat plates

- H01R4/2429—Flat plates, e.g. multi-layered flat plates mounted in an insulating base

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/24—Connections using contact members penetrating or cutting insulation or cable strands

- H01R4/2416—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type

- H01R4/2445—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type the contact members having additional means acting on the insulation or the wire, e.g. additional insulation penetrating means, strain relief means or wire cutting knives

- H01R4/245—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type the contact members having additional means acting on the insulation or the wire, e.g. additional insulation penetrating means, strain relief means or wire cutting knives the additional means having two or more slotted flat portions

Definitions

- the invention is directed to a device for producing a wire splice, in particular wires of telephone cables, with a cutting / clamping element electrically connecting the conductors of the individual others with a housing surrounding the connection point, the housing being provided with at least two channels allowing the passage of wires is, wherein the channels are arranged substantially at right angles to each other and are provided with the common electrically conductive cutting / clamping element for insulation-free electrically conductive connection of the cable cores inserted into the channels.

- Such a device is known, for example, from DE-B-1 212 180, which has a plurality of parallel, mutually adjacent channels for receiving insulated electrical lines to be connected, a connector designed as a cutting / clamping element transverse to the longitudinal direction of the channels can be used with a number of slots corresponding to the number of channels for insulation-free contacting of the lines.

- a similar solution is shown in DE-B-1 257 921, in which a receiving channel is also provided for each line.

- DE-A-2 405 418 in which at least one receiving channel is arranged at right angles to the other channels, which can be advantageous in certain applications for reasons of space.

- the object of the invention is to provide a solution which enables uninterrupted splicing in operation, in particular for pairs of wires, the splicing being easy to handle and ensuring reliable contacting of the wire to be spliced in.

- this object is achieved according to the invention in that, in addition to the two through channels, at least one channel parallel to one of the channels and ending in the device is provided for the blunt insertion of a free end of a wire, the cutting / Clamping element is also arranged in areas engaging in this channel.

- a continuous wire is first inserted into a channel of the device, while the wire to be spliced is inserted with its free end into the channel ending in the device. Because of the insulation-free, electrically conductive connection which then takes place via the cutting / clamping element, the wire to be spliced is connected without interruption to the continuous wire.

- the pre-arrested, spliced-in wire is inserted in a loop-like manner into the through channel not yet occupied and contacted by the cutting / clamping element in such a way that it can be shortened to the desired installation length loop-shaped part can be removed without an interruption taking place during operation.

- the invention provides that the contact point in the common cutting / clamping element, after contacting the cable wires inserted in the channels, is designed as an upwardly open cutting blade which enables the subsequent insertion of a cable wire. This configuration enables particularly simple handling.

- the invention also provides that guides for engaging cutting knives are provided perpendicular to the channels in the passage areas of the cable wires.

- the continuous wire is inserted into a channel as described above.

- the free end of the wire to be spliced is inserted into the blunt channel and then inserted through the device into the other through-channel, forming a loop.

- the cutting / clamping element first contacts the continuous wire and twice the wire to be spliced through its loop formation.

- cutting knives are inserted in the guides arranged perpendicular to the channels, which then cut off both the old wire and form the loop Area of the wire to be spliced in without the electrical line being interrupted during the entire process.

- the invention also provides that the cutting knives are arranged in a separate rough part.

- This separate component can, for example, be arranged on a pressure plate of a pair of pliers.

- it can also be expedient to provide the cutting knives directly in the end cover of the device, so that the cutting process is carried out when the cover is applied.

- the housing and the end cover are each equipped with corresponding elements of a snap connection, e.g. Grooves can be provided on the edge side in the housing, which are overlapped by corresponding locking beads in the interior of the cover.

- the device In order to simplify assembly - the device is a comparatively very small component in many applications - the invention also provides that the housing with engagement grooves for engaging a pressing tool to carry out the engagement movement of the cutting / clamping element and / or the cutting knife and / or snap connection between cover and housing is equipped.

- a locking device is provided for temporarily holding the inserted cable core.

- This locking device can be formed, for example, by corresponding tabs in the insertion opening, or else by a molded-in clamping hook behind which the inserted wire can be clamped.

- the invention also provides that the housing is equipped on at least one side with a receiving bore and on the side opposite this receiving bore with a latch pin for engaging in the receiving bore of an adjacent housing, so that a plurality of devices can be plugged together into strips .

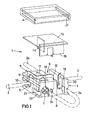

- the device for generating a vein splice i.e. for the electrically conductive connection of an initially continuous core 2 with a core 2a to be spliced, in the example shown consists of an essentially rectangular housing 3 with a housing cover 4.

- the housing 3 has two channels 5 at right angles to one another for the wire 2 and 6 for the wire 2a and an additional channel 7 which ends in the housing 3 and runs parallel to the channel 6 and into which the free end (designated 8 in FIG. 1) the wire 2a can be inserted.

- a cutting / clamping element 9 engages, which is equipped with contact cutting edges for penetrating the insulation of the wires 2 and 2a.

- the contact point for the initially continuous wire 2 is labeled 10.

- the contact point for the free end 8 of the wire 2a with 11 and the second contact point for the wire 2a after return and insertion into the channel 6 is finally designated 12.

- 3 guide slots are provided in the housing for cutting knives 14, 15 and 16 shown on a separate carrier plate 13 in FIG. 1, these guide slots being designated 17, 18 and 19. These guide slots 17-19 are arranged perpendicular to the channels 5, 6 and 7.

- the support member 13 for the cutting knife 14-16 can be, for example, the claw of a pair of pliers, not shown, or an integral part of the cover 4, so that the cutting movement is exerted when the cover 4 is pressed onto the housing 3.

- a snap connection between the housing 3 and cover 4 is provided, which in the example shown are composed of locking grooves 20 in the housing 3 and locking cams 21 in the cover 4.

- the housing 3 also has engaging grooves 22 for engaging a press tool, not shown.

- the pliers which can be equipped with the cutting knives, can also be designed in a fork-like manner in order to be able to engage in these grooves 22. If necessary, after inserting the cable wires 2 and 2a, both the contacting, i.e. the cutting / clamping element 9 is pressed in, as is the subsequent separation of the free end 8 or the part of the continuous cable core 2 which is no longer required by inserting the cutting knives 14-16 into the grooves 17-19 and then pressing the cover 4 on.

- a lock 23 is provided on the channel 7, which there consists of plastic lamellae which, after insertion of the free end 8 into this channel, holds this free end there without the invention being specific to this Design of locking would be limited.

- At least a receiving bore 24 is provided on the housing 3 for receiving a ratchet pin 25 of an adjacent housing 3 so that the devices can be fixed to one another line by line.

- This plug connection results in particular in connection with FIG. 2.

- a continuous cable core 2 is exposed from an existing cable 26, the right-hand side of which is to be spliced off at 26 ', and inserted into the continuous channel 5.

- the new cable is labeled 27, the new cable spliced with 2a. This is first inserted with its free end 8 into the housing 3, namely there in the channel 7.

- the substantially L-shaped cutting / clamping element 9 is now pushed on, so that the continuous wire 2 is connected to the free end 8 of the wire 2a in an electrically conductive manner.

- the wire 2a to be spliced is placed in a loop and is returned through the housing 3, as shown in FIG. 4, through the continuous channel 6 running parallel to channel 7. Clamping element 9 pressed from above that an electrically conductive connection is made. In this state, the wire 2 a is double electrically connected to the wire 2 that is still continuous.

- the described exemplary embodiment of the invention can be modified in many ways without departing from the basic idea.

- the invention is not limited to the special spatial arrangement of the channels in the device.

- Other angular parallelism or the like can also be provided here. This also applies to the design of the cutting / contact element as well as the separating knife 14-16 and / or the connection cover / housing.

Landscapes

- Connections By Means Of Piercing Elements, Nuts, Or Screws (AREA)

- Multi-Conductor Connections (AREA)

Claims (9)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8433159U | 1984-11-13 | ||

| DE8433159U DE8433159U1 (de) | 1984-11-13 | 1984-11-13 | Vorrichtung zur Erzeugung eines Aderspleißes |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0182012A2 EP0182012A2 (fr) | 1986-05-28 |

| EP0182012A3 EP0182012A3 (en) | 1989-03-15 |

| EP0182012B1 true EP0182012B1 (fr) | 1990-06-20 |

Family

ID=6772638

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85110494A Expired - Lifetime EP0182012B1 (fr) | 1984-11-13 | 1985-08-21 | Dispositif pour réaliser une épissure de conducteur |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4725247A (fr) |

| EP (1) | EP0182012B1 (fr) |

| DE (2) | DE8433159U1 (fr) |

| ES (1) | ES8702087A1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2009282C (fr) * | 1989-02-06 | 2001-01-23 | Paul Lindsay Rishworth | Connecteur de cable electrique multiconducteur |

| US5586905A (en) * | 1993-11-01 | 1996-12-24 | Molex Incorporated | Insulation displacement electrical connector with improved strain relief |

| DE69521249T2 (de) * | 1994-08-23 | 2002-04-18 | Sumitomo Wiring Systems, Ltd. | Verdrahtungskonstruktion einer elektrischen Anschlussdose |

| JPH08162177A (ja) * | 1994-12-05 | 1996-06-21 | Yazaki Corp | 圧接コネクタへの電線圧接方法及び圧接コネクタ |

| FR2819977B1 (fr) * | 2001-01-23 | 2003-04-11 | Sofanou Sa | Piece de support et de fixation d'un composant electrique |

| US7186132B2 (en) | 2005-05-31 | 2007-03-06 | Raul Quintanilla | Electrical and electronic connector with blade closed by lever |

| JP7265458B2 (ja) * | 2019-09-26 | 2023-04-26 | 日本航空電子工業株式会社 | コネクタおよび接続方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1290153A (en) * | 1918-03-30 | 1919-01-07 | Joseph Fitzpatrick | Wire-tapper. |

| US1488636A (en) * | 1920-05-24 | 1924-04-01 | Geiser John Albert | Wire connecter |

| US2469397A (en) * | 1945-11-14 | 1949-05-10 | Melvin E Mezek | Electrical connector |

| US2928066A (en) * | 1956-11-28 | 1960-03-08 | Gordon James | Electrical terminal block |

| US3258733A (en) * | 1959-03-19 | 1966-06-28 | Wire connector | |

| US3718888A (en) * | 1971-01-04 | 1973-02-27 | Bell Telephone Labor Inc | Universal connector for cable conductors |

| CA1001250A (en) * | 1973-02-02 | 1976-12-07 | Thomas J. Antolak | Solderless electrical contact element assembly, receptacle and applicator |

| NL155989B (nl) * | 1973-12-19 | 1978-02-15 | Amp Inc | Elektrisch verbindingsorgaan met isolatiedoorsnijgleuven. |

| US4326767A (en) * | 1979-03-12 | 1982-04-27 | Minnesota Mining And Manufacturing Company | Wire cutting electrical connector |

| US4232927A (en) * | 1979-03-16 | 1980-11-11 | E. I. Du Pont De Nemours And Company | Electrical connector |

| US4364622A (en) * | 1980-05-09 | 1982-12-21 | Minnesota Mining And Manufacturing Company | Connector for flat cable |

| US4441779A (en) * | 1980-12-31 | 1984-04-10 | E. I. Du Pont De Nemours & Company | Contact device for a multiconductor cable |

-

1984

- 1984-11-13 DE DE8433159U patent/DE8433159U1/de not_active Expired

-

1985

- 1985-08-21 EP EP85110494A patent/EP0182012B1/fr not_active Expired - Lifetime

- 1985-08-21 DE DE8585110494T patent/DE3578365D1/de not_active Expired - Fee Related

- 1985-09-05 ES ES546732A patent/ES8702087A1/es not_active Expired

-

1987

- 1987-06-08 US US07/059,234 patent/US4725247A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US4725247A (en) | 1988-02-16 |

| DE3578365D1 (de) | 1990-07-26 |

| ES546732A0 (es) | 1986-12-01 |

| EP0182012A2 (fr) | 1986-05-28 |

| ES8702087A1 (es) | 1986-12-01 |

| DE8433159U1 (de) | 1985-02-07 |

| EP0182012A3 (en) | 1989-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3711675C2 (fr) | ||

| DE2314330C2 (de) | Elektrischer Verbinder | |

| EP0196495B1 (fr) | Pince | |

| EP0244347B1 (fr) | Réglette de connexion pour fils de câbles, particulièrement de câbles téléphoniques | |

| DE2443476C2 (de) | Elektrisches Verbindungsstück | |

| DE4437022C1 (de) | Anschlußelement | |

| DE3239708C2 (fr) | ||

| DE69417306T2 (de) | Trennbarer steckverbinder für kommunikationsnetz | |

| EP0595234A1 (fr) | Connecteur de câble pour câbles multibrins | |

| DE2338056B2 (de) | Elektrische Anschlußklemme | |

| DE69416079T2 (de) | Klemmverbinder | |

| DE3009675C2 (fr) | ||

| DE19735835A1 (de) | Elektr. Klemme | |

| DE2735838C2 (de) | Elektrische Anschlußklemme und elektrisches Kabelverbindungsglied | |

| WO2003021721A1 (fr) | Raccord de cables | |

| DE2948725A1 (de) | Kontaktelement fuer ein elektrisches verbindungsstueck | |

| DE2328505C2 (de) | Elektrischer Verbinder zur elektrischen Verbindung wenigstens zweier Leitungsdrähte | |

| DE19838423C2 (de) | Flachbandkabelverbinder | |

| EP0182012B1 (fr) | Dispositif pour réaliser une épissure de conducteur | |

| DE69019187T2 (de) | Elektrischer Mehrleiterkabelverbinder. | |

| DE602005004414T2 (de) | Vorrichtung zur elektrischen verbindung diskontinuierlicher leiter | |

| DE19903030C1 (de) | Vorrichtung zur abisolierfreien Kontaktierung eines Flachkabels | |

| DE2131769B2 (de) | Klemmelement zum lötfreien Anschluß isolierter elektrischer Leiter | |

| DE69326458T2 (de) | Verbindervorrichtung für elektrische Bauteile | |

| DE19949386C2 (de) | Geräte-Anschlusskasten mit Schneidtechnik |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19890206 |

|

| 17Q | First examination report despatched |

Effective date: 19890728 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT SE |

|

| REF | Corresponds to: |

Ref document number: 3578365 Country of ref document: DE Date of ref document: 19900726 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930802 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930803 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930813 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940821 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19940822 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 85110494.3 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940821 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19950428 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 85110494.3 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19980827 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000601 |