EP0143745A2 - Metal frame construction for windows or doors - Google Patents

Metal frame construction for windows or doors Download PDFInfo

- Publication number

- EP0143745A2 EP0143745A2 EP84810542A EP84810542A EP0143745A2 EP 0143745 A2 EP0143745 A2 EP 0143745A2 EP 84810542 A EP84810542 A EP 84810542A EP 84810542 A EP84810542 A EP 84810542A EP 0143745 A2 EP0143745 A2 EP 0143745A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- profile

- metal frame

- seal

- profiles

- glazing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000002184 metal Substances 0.000 title claims abstract description 24

- 238000010276 construction Methods 0.000 title claims abstract description 15

- 238000007789 sealing Methods 0.000 claims description 8

- 238000009413 insulation Methods 0.000 claims 1

- 239000011521 glass Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000004873 anchoring Methods 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B7/00—Special arrangements or measures in connection with doors or windows

- E06B7/16—Sealing arrangements on wings or parts co-operating with the wings

- E06B7/22—Sealing arrangements on wings or parts co-operating with the wings by means of elastic edgings, e.g. elastic rubber tubes; by means of resilient edgings, e.g. felt or plush strips, resilient metal strips

- E06B7/23—Plastic, sponge rubber, or like strips or tubes

- E06B7/2305—Plastic, sponge rubber, or like strips or tubes with an integrally formed part for fixing the edging

- E06B7/2307—Plastic, sponge rubber, or like strips or tubes with an integrally formed part for fixing the edging with a single sealing-line or -plane between the wing and the part co-operating with the wing

- E06B7/231—Plastic, sponge rubber, or like strips or tubes with an integrally formed part for fixing the edging with a single sealing-line or -plane between the wing and the part co-operating with the wing with a solid sealing part

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/26301—Frames with special provision for insulation with prefabricated insulating strips between two metal section members

- E06B3/26303—Frames with special provision for insulation with prefabricated insulating strips between two metal section members with thin strips, e.g. defining a hollow space between the metal section members

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/58—Fixing of glass panes or like plates by means of borders, cleats, or the like

- E06B3/62—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/26301—Frames with special provision for insulation with prefabricated insulating strips between two metal section members

- E06B3/26305—Connection details

- E06B2003/26309—Connection details using glue

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/26301—Frames with special provision for insulation with prefabricated insulating strips between two metal section members

- E06B3/26305—Connection details

- E06B2003/26312—Snap connections

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/2632—Frames with special provision for insulation with arrangements reducing the heat transmission, other than an interruption in a metal section

- E06B2003/26325—Frames with special provision for insulation with arrangements reducing the heat transmission, other than an interruption in a metal section the convection or radiation in a hollow space being reduced, e.g. by subdividing the hollow space

- E06B2003/2633—Frames with special provision for insulation with arrangements reducing the heat transmission, other than an interruption in a metal section the convection or radiation in a hollow space being reduced, e.g. by subdividing the hollow space the insulating strips between the metal sections having ribs extending into the hollow space

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/2632—Frames with special provision for insulation with arrangements reducing the heat transmission, other than an interruption in a metal section

- E06B2003/26332—Arrangements reducing the heat transfer in the glazing rabbet or the space between the wing and the casing frame

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26349—Details of insulating strips

- E06B2003/26387—Performing extra functions

- E06B2003/26389—Holding sealing strips or forming sealing abutments

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/58—Fixing of glass panes or like plates by means of borders, cleats, or the like

- E06B3/62—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats

- E06B2003/6217—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats with specific fixing means

- E06B2003/6223—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats with specific fixing means with protruding parts anchored in grooves

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/58—Fixing of glass panes or like plates by means of borders, cleats, or the like

- E06B3/62—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats

- E06B2003/6217—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats with specific fixing means

- E06B2003/6229—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats with specific fixing means with grooves anchoring the cleat on a rim

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/58—Fixing of glass panes or like plates by means of borders, cleats, or the like

- E06B3/62—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats

- E06B2003/6238—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats having extra functions

- E06B2003/6244—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats having extra functions with extra parts sealing against the bottom of the glazing rebate or against the edge of the pane

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/58—Fixing of glass panes or like plates by means of borders, cleats, or the like

- E06B3/62—Fixing of glass panes or like plates by means of borders, cleats, or the like of rubber-like elastic cleats

- E06B2003/625—Specific form characteristics

- E06B2003/6264—Specific form characteristics hollow

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S49/00—Movable or removable closures

- Y10S49/01—Thermal breaks for frames

Definitions

- the invention relates to a metal frame construction for windows or doors from at least two profiles, which are connected to one another via an insulating rod.

- Such metal frame structures are known for example from CH-PS 584 338.

- a composite profile for window frames is shown, in which the frame is composed of two profiles which are connected by means of an insulating rod.

- the cross-section of this insulating rod consists of a wedge-shaped block, on the wedge tip of which a sealing profile of the casement strikes in the closed position.

- These block-like insulating rods have the disadvantage that they or the like even before the window is installed or even before the window is delivered to a construction site. must be installed. In addition, they cannot be assigned a function other than the prevention of cold bridges alone.

- the inventor has set itself the goal of making the insulating rods much easier to handle. In addition, they should be designed so that they can also perform other functions within the frame construction.

- the insulating rod has a groove channel for receiving a seal.

- the seals necessary in metal frame constructions are in the metal frame profiles self-made grooves used. This can result in the elastic seals being damaged, for example in the event of poor deburring of metal edges, which is avoided by the plastic material of the insulating rods.

- the center seals of the frame profiles that need to be installed do not have to grow with them, but can be inserted or replaced in the insulating rod. This also enables a more effective configuration of center seals, in particular in the area of the glazing, as is described below according to the invention.

- the groove channel is preferably formed by two inclined clamp strips protruding from the insulating rod, which grip around a hammer head-like molding on the seal.

- the seal can consist of any material. Rubber-like seals are preferred.

- an insulating rod should be shaped so that the clip strips partially overlap a web which is delimited on both sides by heads.

- heads which are preferably wedge-shaped, the insulating rod engages in undercut grooves in the profiles to be connected. This ensures its firm hold, whereby the heads can additionally have a longitudinal groove, by means of which inaccuracies in the fit of the groove are compensated for.

- the web is divided on both sides into an upper lip and a lower lip, which together form a mouth opening.

- this jaw opening receives a tongue which is molded onto the profiles to be connected and which, if appropriate, also has a raster toothing which corresponds to an internal toothing. This improves the anchoring of the insulating rods to the frame profiles.

- two insulating rods are each arranged in mirror image to one another. Their respective groove channels point outwards and can be fitted with a seal as required.

- a particularly favorable embodiment according to the invention can be carried out, for example, in the case of a window or a door with glazing if a groove channel of an insulating rod seals a rubber seal with a hammer head-shaped formation on which the glazing rests and which, in the position of use, loops around the glazing and is pressed against the glazing with a lip seal from the inside of the window by a holding profile.

- the frame or sash consists of at least three profiles.

- the window frame consisting of the visible profile and the inner profile

- the glazing is inserted into the window reveal, then the glazing is inserted and the sealing lip is placed around the inner glass pane and this is clamped with the holding profile.

- the window frame consists of a sight profile and an inner profile

- the casement frame consists of an outer profile and a stop profile, the respective profiles being connected to one another via insulating rods and the holding profile after insertion the loop-shaped window seal and the glazing with the outer profile make a snap connection.

- This sealing of the glazing creates a very effective vapor barrier.

- additional sealing elements for both frame parts are to be provided in a window or door made from a window frame and a casement frame which will be provided.

- a sealing lip is fixed in the insulating rods connecting the casement profiles, which lies in the closed position of the window or door on a stop lug of a rubber profile, this rubber profile in turn resting in a groove channel of one of the insulating rods connecting the frame profiles.

- the invention is not limited to the g here e-signposted embodiments but is for other variations of windows and doors, for example, tilting windows or sliding doors, applicable. Overall, there is a very far-reaching design option for the designer, with the manufacture of windows being simplified.

- a metal frame construction R for windows or doors with putty-free glazing consists of a frame 1 and a casement 2, which - not shown - via hinges or the like. is movable during the Frame 1 or the like in a wall reveal. is fixed.

- the frame 1 is formed by a view profile 3 and an inner profile 4. Both profiles, 3 and 4 are connected via insulating rods 5 to avoid cold bridges.

- an insulating rod 5 has a web strip 6, which is bulged on both sides to form an upper lip 7 and a lower lip 8 with a mouth opening 9 formed therebetween.

- This jaw opening 9 engages in each case the visible profile 3 and the inner profile 4 tongue 10 which carries a raster toothing 11 towards the upper lip 7.

- the tongue 10 forms, together with a profile strip 12 protruding from the visible profile 3 or inner profile 4, an undercut groove 14 in which the upper lip 7 is fixed.

- the sash frame 2 consists of an outer profile 25, which in turn is connected to a stop profile 27 by insulating rods 26. Between the outer profile 25 and an attached to the stop profile 27 and by a snap connection 28 fixed holding profile 29 there is a glazing 30, which consists of two glass panes 31 with an evacuable air space 32 formed between them, the glazing 30 being supported by rubber seals 33 and 34.

- two insulating bars 26 connect the outer profile 25 and the stop profile 27, each touching with their heads 35 and being held apart approximately centrally by support webs 36.

- Two heads 35 on one side are clamped in by wedge-shaped profile strips 37.

- In the heads 35 there is a channel 38 for receiving sealing and adhesive material and for compensating for inaccuracies in fit.

- Each two heads 35 are in turn connected by a web 6, which - as shown in the insulating rods 5 - is partially overlapped by clip strips 15, which have a groove channel 16 for receiving a hammer-head-shaped molding 39 on the rubber seal 34 and a hammer-head-like molding 41 have cross-sectionally wedge-shaped sealing lip 40.

- the latter lies in the closed position of the metal frame profile R of the stop lug 23 of the rubber profile 17 (FIG. 1).

- the rubber seal 34 is placed in a loop 43 between the hammer head-like formation 39 and a lip seal 42 adjacent to the glazing 30 over the profile strips 37 or parts of the outer profile 25 and the stop profile 27 and thus prevents any passage of air or steam into the holding profile 29 or an interior.

- Such vapor-tight glazing can be carried out in a simple manner from the inside according to the invention the, because only after the installation of frame 1 and sash 2 with its outer profile 25 and its stop profile 27, the glazing 30 is placed on the rubber seal 34 and the lip seal 42 is then pressed with the installation of the holding profile 29 on the inner glass pane 31.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

- Securing Of Glass Panes Or The Like (AREA)

Abstract

Bei einer Metall-Rahmenkonstruktion für Fenster oder Türen aus zumindest zwei Profilen (3, 4 bzw. 25, 27), welche über einen Isolierstab miteinander verbunden sind, weist der Isolierstab (5 und/oder 26) einen Nutkanal (16) zur Aufnahme von einer Dichtung (17 und/oder 34 und/oder 40) auf.In the case of a metal frame construction for windows or doors made of at least two profiles (3, 4 or 25, 27) which are connected to one another via an insulating rod, the insulating rod (5 and / or 26) has a groove channel (16) for receiving a seal (17 and / or 34 and / or 40).

Description

Die Erfindung betrifft eine Metall-Rahmenkonstruktion für Fenster oder Türen aus zumindest zwei Profilen, welche über einen Isolierstab miteinander verbunden sind.The invention relates to a metal frame construction for windows or doors from at least two profiles, which are connected to one another via an insulating rod.

Derartige Metall-Rahmenkonstruktionen sind beispielsweise aus der CH-PS 584 338 bekannt. Dort ist ein Verbundprofil für Fensterrahmen dargestellt, bei welchem der Blendrahmen aus zwei Profilen zusammengesetzt ist, welche mittels eines Isolierstabes verbunden sind. Dieser Isolierstab besteht querschnittlich aus einem keilförmigen Block, an dessen Keilspitze in Schliesslage ein Dichtungsprofil des Flügelrahmens anschlägt. Diese blockartigen Isolierstäbe haben den Nachteil, dass sie bereits vor dem Einbau des Fensters bzw. sogar vor Anlieferung des Fensters zu einer Baustelle od.dgl. eingebaut sein müssen. Zudem kann ihnen keine andere Funktion als die alleinige Verhinderung von Kältebrücken zugeordnet werden.Such metal frame structures are known for example from CH-PS 584 338. There is a composite profile for window frames is shown, in which the frame is composed of two profiles which are connected by means of an insulating rod. The cross-section of this insulating rod consists of a wedge-shaped block, on the wedge tip of which a sealing profile of the casement strikes in the closed position. These block-like insulating rods have the disadvantage that they or the like even before the window is installed or even before the window is delivered to a construction site. must be installed. In addition, they cannot be assigned a function other than the prevention of cold bridges alone.

Der Erfinder hat sich zum Ziel gesetzt, die Isolierstäbe wesentlich einfacher handhabbar zu machen. Zudem sollen sie so ausgelegt werden, dass sie auch andere Funktionen innerhalb der Rahmenkonstruktion erfüllen können.The inventor has set itself the goal of making the insulating rods much easier to handle. In addition, they should be designed so that they can also perform other functions within the frame construction.

Zur Lösung dieser Aufgabe führt, dass der Isolierstab einen Nutkanal zur Aufnahme von einer Dichtung aufweist.To achieve this object, the insulating rod has a groove channel for receiving a seal.

Ueblicherweise werden die in Metall-Rahmenkonstruktionen notwendigen Dichtungen in von den Metall-Rahmenprofilen selbst gebildete Nuten eingesetzt. Dies kann dazu führen, dass die elastischen Dichtungen, z.B. bei schlechter Entgratung von Metallkanten, verletzt werden, was durch das Kunststoffmaterial der Isolierstäbe vermieden wird. Zudem ist es erheblich aufwendiger, Metall-Rahmenkonstruktionen mit notwendigen Nuten zu versehen, als diese zusammen in den Kunststoff der Isolierstäbe einzuformen. Speziell bei immer grösser werdenden Abständen von Metallprofilen brauchen auch die einzubauenden Mitteldichtungen der Rahmenprofile nicht mitzuwachsen, sondern können in den Isolierstab eingesetzt bzw. ausgetauscht werden. Auch ist hierdurch noch eine wirkungsvollere Ausgestaltung von Mitteldichtungen, insbesondere im Bereich der Verglasung, möglich, wie dies erfindungsgemäss weiter unten beschrieben wird.Usually, the seals necessary in metal frame constructions are in the metal frame profiles self-made grooves used. This can result in the elastic seals being damaged, for example in the event of poor deburring of metal edges, which is avoided by the plastic material of the insulating rods. In addition, it is considerably more complex to provide metal frame structures with the necessary grooves than to form them together in the plastic of the insulating rods. Especially when the spacing between metal profiles increases, the center seals of the frame profiles that need to be installed do not have to grow with them, but can be inserted or replaced in the insulating rod. This also enables a more effective configuration of center seals, in particular in the area of the glazing, as is described below according to the invention.

Bevorzugt wird der Nutkanal von zwei vom Isolierstab abragenden geneigten Klammerstreifen gebildet, welche eine hammerkopfartige Anformung an der Dichtung umgreifen. Die Dichtung kann dabei aus beliebigem Material bestehen. Bevorzugt werden gummiartige Dichtungen.The groove channel is preferably formed by two inclined clamp strips protruding from the insulating rod, which grip around a hammer head-like molding on the seal. The seal can consist of any material. Rubber-like seals are preferred.

Insgesamt soll ein Isolierstab so geformt sein, dass die Klammerstreifen einen Steg teilweise übergreifen, welcher beidseits von Köpfen begrenzt ist. Mit diesen Köpfen, die bevorzugt keilförmig ausgestaltet sind, greift der Isolierstab in ebenfalls hinterschnittene Nuten in den zu verbindenden Profilen ein. Damit wird sein fester Halt gesichert, wobei die Köpfe noch zusätzlich eine Längsrinne aufweisen können, mittels welcher Ungenauigkeiten in der Passform der Nut ausgeglichen werden.Overall, an insulating rod should be shaped so that the clip strips partially overlap a web which is delimited on both sides by heads. With these heads, which are preferably wedge-shaped, the insulating rod engages in undercut grooves in the profiles to be connected. This ensures its firm hold, whereby the heads can additionally have a longitudinal groove, by means of which inaccuracies in the fit of the groove are compensated for.

Eine weitere Möglichkeit der Ausgestaltung der Isolierstäbe besteht darin, dass der Steg sich beidseits in eine Oberlippe und eine Unterlippe teilt, welche zusammen eine Maulöffnung bilden. Diese Maulöffnung nimmt in Gebrauchslage eine den zu verbindenden Profilen anformte Zunge auf, welche gegebenenfalls noch eine Rasterzahnung aufweist, die mit einer Maulinnenzahnung übereinstimmt. Damit wird die Verankerung der Isolierstäbe mit den Rahmenprofilen verbessert.Another possibility of designing the insulating rods is that the web is divided on both sides into an upper lip and a lower lip, which together form a mouth opening. In the position of use, this jaw opening receives a tongue which is molded onto the profiles to be connected and which, if appropriate, also has a raster toothing which corresponds to an internal toothing. This improves the anchoring of the insulating rods to the frame profiles.

Zu einer weiteren Verbesserung der Verbindung der Rahmenprofile ist vorgesehen, dass jeweils zwei Isolierstäbe spiegelbildlich zueinander angeordnet sind. Dabei weisen ihre jeweiligen Nutkanäle nach aussen und können je nach Belieben mit einer Dichtung beaufschlagt werden.To further improve the connection of the frame profiles, it is provided that two insulating rods are each arranged in mirror image to one another. Their respective groove channels point outwards and can be fitted with a seal as required.

Mit derart ausgestalteten Isolierstäben ist eine sehr flexible Handhabung für Rahmenkonstruktionen möglich, wobei der besondere Vorteil darin besteht, dass je nach Anforderungen unterschiedliche Rahmenprofile miteinander verbunden werden können. Deswegen bedarf es einer geringeren Anzahl unterschiedlicher Rahmenprofile, was die Fertigung von Metall-Rahmenkonstruktionen insgesamt verbilligt. So ist es auch möglich, mittels dieser Isolierstäbe Profile für Rahmen von feststehenden Fenstern oder Fenstern mit Flügelrahmen bzw. Rahmen für Türen zu verbinden.With insulating rods designed in this way, very flexible handling for frame constructions is possible, the particular advantage being that, depending on the requirements, different frame profiles can be connected to one another. Therefore, a smaller number of different frame profiles is required, which makes the manufacture of metal frame structures cheaper overall. It is also possible to connect profiles for frames of fixed windows or windows with casements or frames for doors using these insulating bars.

Eine besonders günstige erfindungsgemässe Ausgestaltung kann beispielsweise bei einem Fenster oder einer Tür mit Verglasung dann durchgeführt werden, wenn ein Nutkanal eines Isolierstabes eine Gummidichtung mit einer hammerkopfförmigen Anformung aufnimmt, auf der die Verglasung ruht und die sich in Gebrauchslage in einer Schleife um die Verglasung legt und mit einer Lippendichtung von der Innenseite des Fensters her durch ein Halteprofil an die Verglasung gepresst ist. Dies bedeutet, dass entweder bei feststehenden Fenstern mit nur einem Blendrahmen oder bei öffenbaren Fenstern oder Türen mit einem Blendrahmen und einem Flügelrahmen der Blendrahmen oder der Flügelrahmen aus zumindest drei Profilen besteht. Neben einem Sichtprofil und einem Innenprofil tritt bei feststehenden Fenstern noch ein Halteprofil hinzu, welches mit dem Innenprofil eine Rastverbindung eingeht. In diesem Fall wird der Blendrahmen, bestehend aus dem Sichtprofil und dem Innenprofil, in die Fensterlaibung eingesetzt, sodann die Verglasung eingefügt und die Dichtungslippe um die Innenglasscheibe gelegt sowie diese mit dem Halteprofil festgespannt. Dadurch können gewisse bauseitige Toleranzen ausgeglichen werden. Bei einem Fenster oder einer Tür mit einem Blendrahmen und einem Flügelrahmen ist dagegen vorgesehen, dass der Blendrahmen aus einem Sichtprofil und einem Innenprofil und der Flügelrahmen aus einem Aussenprofil und einem Anschlagprofil besteht, wobei die jeweiligen Profile über Isolierstäbe miteinander verbunden sind und das Halteprofil nach Einlegen der schleifenförmigen Fensterdichtung und der Verglasung mit dem Aussenprofil eine Rastverbindung eingeht. Diese so vorgenommene Abdichtung der Verglasung erzeugt eine sehr wirkungsvolle Dampfsperre.A particularly favorable embodiment according to the invention can be carried out, for example, in the case of a window or a door with glazing if a groove channel of an insulating rod seals a rubber seal with a hammer head-shaped formation on which the glazing rests and which, in the position of use, loops around the glazing and is pressed against the glazing with a lip seal from the inside of the window by a holding profile. This means that either with fixed windows with only one frame or with openable windows or doors with a frame and a sash, the frame or sash consists of at least three profiles. In addition to a visible profile and an inner profile, there is also a holding profile for fixed windows, which enters into a snap connection with the inner profile. In this case, the window frame, consisting of the visible profile and the inner profile, is inserted into the window reveal, then the glazing is inserted and the sealing lip is placed around the inner glass pane and this is clamped with the holding profile. This allows certain on-site tolerances to be compensated for. In the case of a window or a door with a window frame and a casement frame, on the other hand, it is provided that the window frame consists of a sight profile and an inner profile and the casement frame consists of an outer profile and a stop profile, the respective profiles being connected to one another via insulating rods and the holding profile after insertion the loop-shaped window seal and the glazing with the outer profile make a snap connection. This sealing of the glazing creates a very effective vapor barrier.

Weiterhin sollen erfindungsgemäss bei einem Fenster oder einer Tür aus einem Blendrahmen und einem Flügelrahmen zusätzliche Dichtungselemente für beide Rahmenteile zueinander vorgesehen sein. Hierzu wird in den die Flügelrahmenprofile verbindenden Isolierstäben eine Dichtungslippe festgelegt, welche in Schliesslage des Fensters oder der Tür an einer Anschlagnase eines Gummiprofils liegt, wobei dieses Gummiprofil wiederum in einem Nutkanal eines der die Blendrahmenprofile verbindenden Isolierstäbe ruht.Furthermore, according to the invention, additional sealing elements for both frame parts are to be provided in a window or door made from a window frame and a casement frame which will be provided. For this purpose, a sealing lip is fixed in the insulating rods connecting the casement profiles, which lies in the closed position of the window or door on a stop lug of a rubber profile, this rubber profile in turn resting in a groove channel of one of the insulating rods connecting the frame profiles.

Die Erfindung beschränkt sich jedoch nicht auf die hier ge-schilderten Ausführungsbeispiele, sondern ist für weitere Variationen von Fenstern und Türen, beispielsweise Kippfenstern oder Schiebetüren, anwendbar. Insgesamt ergibt sich eine sehr weitreichende Ausgestaltungsmöglichkeit für den Konstrukteur, wobei die Herstellung von Fenstern vereinfacht ist.The invention is not limited to the g here e-signposted embodiments but is for other variations of windows and doors, for example, tilting windows or sliding doors, applicable. Overall, there is a very far-reaching design option for the designer, with the manufacture of windows being simplified.

Weitere Vorteile, Merkmale und Einzelheiten der Erfindung ergeben sich aus der nachfolgenden Beschreibung eines bevorzugten Ausführungsbeispiels sowie anhand der Zeichnung; diese zeigt in

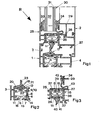

- Fig. 1 einen Querschnitt durch eine Metall-Rahmenkonstruktion mit teilweise dargestellter Verglasung;

- Fig. 2 einen Ausschnitt aus Fig. 1;

- Fig. 3 einen weiteren Ausschnitt aus Fig. 1.

- 1 shows a cross section through a metal frame construction with partially shown glazing.

- FIG. 2 shows a detail from FIG. 1;

- 3 shows a further detail from FIG. 1.

Eine Metall-Rahmenkonstruktion R für Fenster oder Türen mit kittloser Verglasung besteht nach Fig. 1 aus einem Blendrahmen 1 und einem Flügelrahmen 2, welcher -- nicht darqestellt -- über Scharniere od.dgl. bewegbar ist, während der Blendrahmen 1 in einer Mauerlaibung od.dgl. festliegt. Dabei wird der Blendrahmen 1 von einem Sichtprofil 3 und einem Innenprofil 4 gebildet. Beide Profile,3 und 4 sind über Isolierstäbe 5 zur Vermeidung von Kältebrücken verbunden.A metal frame construction R for windows or doors with putty-free glazing according to FIG. 1 consists of a

Ein Isolierstab 5 weist gemäss Fig. 2 einen Stegstreifen 6 auf, welcher beidseits zu einer Oberlippe 7 und einer Unterlippe 8 mit dazwischen gebildeter Maulöffnung 9 aufgebaucht ist. In diese Maulöffnung 9 greift eine jeweils dem Sichtprofil 3 und dem Innenprofil 4 angeformte Zunge 10 ein, welche zur Oberlippe 7 hin eine Rasterzahnung 11 trägt. Die Zunge 10 bildet zusammen mit einem vom Sichtprofil 3 bzw. Innenprofil 4 abragenden Profilstreifen 12 eine hinterschnittene Nut 14, in welcher die Oberlippe 7 festliegt. Von der Oberlippe 7 stehen, den Stegstreifen 6 teilweise übergreifend, zwei querschnittlich krallenartig zueinander geneigte Klammerstreifen 15 ab, welche zwischen sich einen hinterschnittenen Nutkanal 16 formen, in den ein Gummiprofil 17 eingesetzt ist. Dieses ist von zwei Ausgleichskammern 18 durchzogen und stützt sich beidseits durch Anschlagleisten 20 und 21 gegen die Profilstreifen 12 ab. Jenseits eines in den Nutkanal 16 eingreifenden Hammerkopfes 22 ist das Gummiprofil 17 zu einer Anschlagnase 23 hochgezogen.According to FIG. 2, an insulating rod 5 has a

Der Flügelrahmen 2 besteht in dem in Fig. 1 gezeigten Ausführungsbeispiel aus einem Aussenprofil 25, welches wiederum durch Isolierstäbe 26 mit einem Anschlagprofil 27 verbunden ist. Zwischen dem Aussenprofil 25 und einem dem Anschlagprofil 27 aufgesetzten und durch eine Rastverbindung 28 festgelegten Halteprofil 29 befindet sich eine Verglasung 30, welche aus zwei Glasscheiben 31 mit zwischen ihnen gebildetem evakuierbaren Luftraum 32 besteht, wobei die Verglasung 30 von Gummidichtungen 33 und 34 abgestützt ist.In the exemplary embodiment shown in FIG. 1, the

Wie in Fig. 3 näher gezeigt, verbinden zwei Isolierstäbe 26 das Aussenprofil 25 und das Anschlagprofil 27, wobei sie sich jeweils mit ihren Köpfen 35 berühren und etwa mittig durch Stützstege 36 auseinander gehalten werden. Zwei Köpfe 35 einer Seite werden von keilförmigen Profilstreifen 37 eingeklemmt. In den Köpfen 35 befindet sich eine Rinne 38 zur Aufnahme von Dicht- und Klebematerial und zum Ausgleich von Passungenauigkeiten. Jeweils zwei Köpfe 35 sind wiederum durch einen Steg 6 verbunden, welcher -- wie bei den Isolierstäben 5 dargestellt -- von Klammerstreifen 15 teilweise übergriffen ist, die einen Nutkanal 16 zur Aufnahme einer hammerkopfartigen Anformung 39 an der Gummidichtung 34 und einer hammerkopfartigen Anformung 41 einer querschnittlich keilförmigen Dichtungslippe 40 aufweisen. Letztere liegt in Schliesslage des Metall-Rahmenprofils R der Anschlagnase 23 des Gummiprofils 17 an (Fig. 1).As shown in FIG. 3 in more detail, two

Zwischen der hammerkopfartigen Anformung 39 und einer der Verglasung 30 anliegenden Lippendichtung 42 ist die Gummidichtung 34 in einer Schleife 43 über die Profilstreifen 37 bzw. Teile des Aussenprofils 25 und des Anschlagprofils 27 gelegt und verhindert so jeglichen Durchtritt von Luft oder Dampf in das Halteprofil 29 oder einen Innenraum.The

Eine derartige dampfdichte Verglasung kann erfindungsgemäss auf einfache Weise von der Innenseite her vorgenommen werden, da erst nach dem Einbau von Blendrahmen 1 und Flügelrahmen 2 mit seinem Aussenprofil 25 und seinem Anschlagprofil 27 die Verglasung 30 auf die Gummidichtung 34 gesetzt und deren Lippendichtung 42 anschliessend mit dem Einbau des Halteprofils 29 an die innere Glasscheibe 31 gepresst wird.Such vapor-tight glazing can be carried out in a simple manner from the inside according to the invention the, because only after the installation of

Claims (11)

dadurch gekennzeichnet,

dass der Isolierstab (5 und/oder 26) einen Nutkanal (16) zur Aufnahme von einer Dichtung (17 und/oder 34 und/oder 40) aufweist.1. metal frame construction for windows or doors from at least two profiles which are connected to one another by an insulating rod,

characterized,

that the insulating rod (5 and / or 26) has a groove channel (16) for receiving a seal (17 and / or 34 and / or 40).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH638783 | 1983-11-30 | ||

| CH6387/83 | 1983-11-30 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0143745A2 true EP0143745A2 (en) | 1985-06-05 |

| EP0143745A3 EP0143745A3 (en) | 1986-02-26 |

Family

ID=4308789

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84810542A Ceased EP0143745A3 (en) | 1983-11-30 | 1984-11-09 | Metal frame construction for windows or doors |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4614062A (en) |

| EP (1) | EP0143745A3 (en) |

| DE (1) | DE3343687A1 (en) |

| FI (1) | FI844690L (en) |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2628786A1 (en) * | 1988-03-15 | 1989-09-22 | Ornago Hydro Alluminio | Aluminium extrusion system for window frames - has hollow inner chambers shaped to receive corner connectors |

| WO1992001853A1 (en) * | 1990-07-20 | 1992-02-06 | Häring & Co. Ag | Statically stable frame with full thermal break for windows and cladding panels |

| WO1993006329A1 (en) * | 1991-09-13 | 1993-04-01 | Joint S.R.L. | Composite framing profile |

| EP0733765A1 (en) * | 1995-03-20 | 1996-09-25 | METRA METALLURGICA TRAFILATI ALLUMINIO S.p.A. | Section member and fitting assembly for making high thermal insulation wood coated window and door frames |

| EP0799964A1 (en) * | 1996-04-01 | 1997-10-08 | EVG Bauprofil-System Entwicklungs- und Vermarktungsgesellschaft mbH | Thermally insulating coupling bar |

| FR2753228A1 (en) * | 1996-09-06 | 1998-03-13 | Ouest Alu | Window frame PVC joining and thermal block profile |

| EP1580388A3 (en) * | 2004-03-23 | 2007-04-04 | Norsk Hydro Asa | Thermally insulating body for a thermal break section for window and door frames or the like |

| DE102010035347A1 (en) * | 2010-08-24 | 2012-03-01 | Schindler Gmbh & Co. Kg | Windows with improved insulation |

| EP2672053A1 (en) * | 2012-06-05 | 2013-12-11 | Alcoa Aluminium Deutschland, Inc. | Profile assembly |

| EP2767661A3 (en) * | 2012-11-28 | 2015-01-07 | J. Friedrich Ammon GmbH & Co. KG | Building door |

| US9111138B2 (en) | 2010-11-30 | 2015-08-18 | Cisco Technology, Inc. | System and method for gesture interface control |

| US9143725B2 (en) | 2010-11-15 | 2015-09-22 | Cisco Technology, Inc. | System and method for providing enhanced graphics in a video environment |

| EP2942468A1 (en) * | 2014-05-05 | 2015-11-11 | SCHÜCO International KG | Composite profile for doors, window or façade elements |

| WO2015169669A1 (en) * | 2014-05-05 | 2015-11-12 | SCHÜCO International KG | Door, window, or facade element with a sealing system |

| WO2015169670A1 (en) * | 2014-05-05 | 2015-11-12 | SCHÜCO International KG | Composite profiled section for doors, windows, or facade elements |

| EP2754831A3 (en) * | 2013-01-10 | 2017-01-11 | SCHÜCO International KG | Heat insulating strip and frame profile for a window, a door, a façade or a skylight with a flat element |

| WO2018065841A1 (en) * | 2016-10-06 | 2018-04-12 | Reynaers Aluminium, Naamloze Vennootschap | Compound profile for a window or door and a window or door assembled with such profiles |

Families Citing this family (55)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3406018A1 (en) * | 1984-02-20 | 1985-08-29 | Ritter Aluminium Gmbh, 7300 Esslingen | Sealing profile, in particular for window, door and facade structures |

| DE3526714A1 (en) * | 1985-07-26 | 1987-02-05 | Wieland Werke Ag | Window frame, door frame or the like with vapour seal |

| US4704839A (en) * | 1985-12-06 | 1987-11-10 | Products Research & Chemical Corporation | Thermal barrier extrusion |

| US5042212A (en) * | 1988-09-12 | 1991-08-27 | Selig Golen | Security closure assembly |

| CA2009435C (en) * | 1990-02-06 | 1993-01-19 | John Harbom | Window structure |

| DE4321702A1 (en) * | 1993-06-30 | 1995-01-19 | Hueck Eduard Gmbh Co Kg | Frame for a window, door or facade |

| DE4424934A1 (en) * | 1994-07-14 | 1996-01-25 | Sommer Metallbau Stahlbau Gmbh | Glazing seal for composite profiles |

| DE4437634C2 (en) * | 1994-10-21 | 1998-05-14 | Broekelmann Aluminium F W | Thermally insulated composite profile for window, door frames or the like |

| DE19504924A1 (en) * | 1995-01-11 | 1996-07-25 | Joseph Fischl | Exterior French window or door for building |

| DE29516734U1 (en) * | 1995-10-24 | 1995-12-14 | Syntax Rackwitz Systemtechnik GmbH, 04519 Rackwitz | Clamping frame |

| CH688938A5 (en) * | 1995-11-21 | 1998-06-15 | 4B Holding Ag | Window or tuerkonstruktion |

| DE19613043A1 (en) * | 1996-04-01 | 1997-10-02 | Evg Bauprofil System Entwicklungs & Vermarktungsgesellschaft Mbh | Post-rung construction |

| DE29608742U1 (en) * | 1996-05-14 | 1996-08-01 | Sommer Metallbau-Stahlbau GmbH & Co KG, 95182 Döhlau | Composite profile |

| EP0957226A1 (en) * | 1998-05-14 | 1999-11-17 | Technoform Caprano + Brunnhofer oHG | Compound section member for doors, windows, facades or the like, IR-reflective film especially adapted for this section member and the use of this film in the compound section member |

| DE29818767U1 (en) * | 1998-10-22 | 1999-12-02 | Fa. Otto Fuchs, 58540 Meinerzhagen | Connecting bridge for creating a composite profile and composite profile |

| DE20003060U1 (en) | 2000-02-19 | 2000-04-20 | Seuffert, Günther Hermann, 97297 Waldbüttelbrunn | Wing profile |

| DE10015986C2 (en) * | 2000-03-31 | 2002-08-01 | Schueco Int Kg | Composite profile and method for producing a composite profile |

| IT250161Y1 (en) | 2000-07-25 | 2003-07-24 | Mazzer Materie Plastiche Di Gi | INSULATING STRIP FOR THE CONNECTION OF COMPOSITE METAL PROFILES |

| WO2004106689A2 (en) * | 2003-05-23 | 2004-12-09 | Masonite Corporation | Door, method of making the door and panel component made therefrom |

| EP1555376A1 (en) * | 2004-01-19 | 2005-07-20 | Technoform Caprano + Brunnhofer GmbH & Co. KG | Composite profile |

| CZ14844U1 (en) * | 2004-07-02 | 2004-10-25 | Čechoplast, Spol. S R. O. | Insulation cage |

| DE102006061035C5 (en) * | 2006-12-22 | 2014-09-04 | Technoform Bautec Holding Gmbh | Plastic profile for window, door and facade elements |

| GB0702958D0 (en) * | 2007-02-15 | 2007-03-28 | Franklin David R | Thermal composite window |

| DE202007016649U1 (en) * | 2007-04-02 | 2008-04-30 | Technoform Caprano Und Brunnhofer Gmbh & Co. Kg | Ladder-shaped insulating bar for a composite profile for window, door and facade elements and composite profile for window, door and facade elements |

| US8112941B2 (en) * | 2007-05-16 | 2012-02-14 | Alcoa Commercial Windows Llc | Construction product having a moveable element with multi-functional thermal break |

| US7987633B2 (en) * | 2007-05-16 | 2011-08-02 | Alcoa Commercial Windows Llc | Construction product having a frame with multi-functional thermal break |

| US20100083582A1 (en) * | 2008-10-07 | 2010-04-08 | Tran Tuan A | structure to be attached to a window frame |

| US8322090B2 (en) * | 2009-01-13 | 2012-12-04 | Ykk Corporation Of America | Thermally efficient window assembly |

| JP5815677B2 (en) * | 2010-04-26 | 2015-11-17 | ブランキング システムズ インクBlanking Systems, Inc. | Frame member for structure |

| FR2967445B1 (en) * | 2010-11-12 | 2013-09-06 | Kawneer France | SLIDING FRAME DEVICE |

| FR2972753B1 (en) * | 2011-03-14 | 2015-12-11 | Kawneer France | SLIDING FRAME DEVICE. |

| US8955270B2 (en) * | 2012-05-16 | 2015-02-17 | Olmos Scofield, Llc | Window assemblies including bronze elements |

| DE102012010028A1 (en) * | 2012-05-21 | 2013-11-21 | Hörmann KG Brockhagen | FRAME ARRANGEMENT FOR A SECTIONAL PANEL |

| WO2013180805A1 (en) * | 2012-05-30 | 2013-12-05 | Oldcastle BuildingEnvelope Inc. | Method and system for insulating structural building components |

| US8484902B1 (en) * | 2012-10-17 | 2013-07-16 | Hope's Window, Inc. | Window assembly having a thermal break liner |

| DE102013100278A1 (en) * | 2013-01-11 | 2014-07-17 | SCHÜCO International KG | Method and device for inserting a disk into a frame |

| BE1021797B1 (en) * | 2013-12-20 | 2016-01-19 | BLYWEERT ALUMINIUM, naamloze vennootschap | PLASTIC INSULATION RAIL, COMPOSED PROFILE AND WINDOW INCLUDING SUCH INSULATION RAIL AND METHOD OF MANUFACTURING A FRAMEWORK FOR A WINDOW |

| US9441412B1 (en) * | 2015-04-29 | 2016-09-13 | Alcoa Inc. | High thermal performance window frame |

| DE102016109037A1 (en) * | 2016-05-17 | 2017-11-23 | SCHÜCO International KG | Composite profile for doors, windows or façade elements |

| DE102016219255A1 (en) * | 2016-10-05 | 2018-04-05 | Festool Gmbh | Table saw and splinter protection element |

| DE102016119580A1 (en) * | 2016-10-13 | 2018-04-19 | Ensinger Gmbh | Plastic profile for a metal-plastic composite profile |

| US20180135346A1 (en) * | 2016-11-15 | 2018-05-17 | Prestige Storefront Systems LLC | Modular storefront system |

| US10337239B2 (en) * | 2016-12-12 | 2019-07-02 | Gregory A. Header | High performance fenestration system |

| US10370893B2 (en) | 2017-09-15 | 2019-08-06 | Arconic Inc. | Apparatus and method for assembly of structural profiles and resultant structures |

| US10107027B1 (en) | 2017-10-24 | 2018-10-23 | Quaker Window Products Co. | Thermally enhanced multi-component window |

| US10947772B2 (en) * | 2017-10-24 | 2021-03-16 | Quaker Window Products Co. | Thermally enhanced multi-component glass doors and windows |

| US10415302B2 (en) * | 2018-01-08 | 2019-09-17 | Pgt Innovations, Inc. | Window setting block |

| US10711514B2 (en) * | 2018-07-26 | 2020-07-14 | Matrex Window System Inc. | Male and female gasket coupling for a window frame |

| US11199045B2 (en) * | 2018-07-26 | 2021-12-14 | Matrex Window System Inc. | Jacking screw for adjusting a window frame |

| US10844651B2 (en) | 2018-07-26 | 2020-11-24 | Matrex Window System Inc. | Compression gasket for sealing a window in a window frame |

| US10731402B2 (en) * | 2018-07-26 | 2020-08-04 | Matrex Window System Inc. | Jacking screw for adjusting a window frame |

| US10689899B2 (en) | 2018-10-17 | 2020-06-23 | Matrex Window System Inc. | Gasket railing system for a window frame |

| US10590696B2 (en) * | 2018-07-26 | 2020-03-17 | Matrex Window System Inc. | Sill track seal for a window frame |

| WO2023060373A1 (en) * | 2021-10-11 | 2023-04-20 | 北京门赢进出口贸易有限公司 | Assembling pipe for mounting door/window |

| US20240076930A1 (en) * | 2022-09-07 | 2024-03-07 | Jeld-Wen, Inc. | Mulling system for plural fenestration assemblies with joining plates and deflectable seal member therebetween |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH584338A5 (en) * | 1974-06-19 | 1977-01-31 | Alusuisse | |

| DE2650944A1 (en) * | 1976-11-08 | 1978-05-11 | Erich Schlenker | Window and facade structure composite profile bar - has lengthways wedges between profile pieces and cross-arm permitting differing heat expansion |

| DE2755891A1 (en) * | 1976-12-28 | 1978-07-06 | Metallurg De Saint Louis S A S | Door or window wing frame connection - uses tongue and groove elements to retain bar in turned locking position |

| DE8003277U1 (en) * | 1980-02-08 | 1980-05-08 | Schwartz, Werner, 6676 Mandelbachtal | ALLOY WINDOW WING WITH BUILT-IN TEMPERATURE LOCK |

| US4344254A (en) * | 1979-05-02 | 1982-08-17 | Feal S.P.A. | Thermally insulated aluminum door or window frame |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2877515A (en) * | 1957-11-01 | 1959-03-17 | Window Products Inc | Insulated metal-framed window sash |

| FR1478602A (en) * | 1966-03-16 | 1967-04-28 | Danois & Fils Ets J | Metal furniture, in particular window |

| US3420026A (en) * | 1966-10-06 | 1969-01-07 | Reynolds Metals Co | Thermal insulating apparatus and method of making same |

| DE2515536A1 (en) * | 1975-04-09 | 1976-10-21 | Weru Gmbh & Co Kg | FRAME FOR WINDOWS, DOORS AND THE LIKE |

| DE7613917U1 (en) * | 1976-05-03 | 1976-09-02 | Schlenker, Erich, 3500 Kassel | COMPOSITE PROFILE BAR FOR WINDOW AND FAÇADE CONSTRUCTIONS |

| US4115972A (en) * | 1976-05-24 | 1978-09-26 | Giovanni Varlonga | Fixed and movable frame fixtures for doors and windows |

| DE8221342U1 (en) * | 1982-07-27 | 1983-02-10 | Hasselbacher, Geb. Schoetz, Annemarie, 8530 Neustadt | HEAT-INSULATING CONNECTING DEVICE |

-

1983

- 1983-12-02 DE DE19833343687 patent/DE3343687A1/en not_active Withdrawn

-

1984

- 1984-11-09 EP EP84810542A patent/EP0143745A3/en not_active Ceased

- 1984-11-19 US US06/672,704 patent/US4614062A/en not_active Expired - Fee Related

- 1984-11-29 FI FI844690A patent/FI844690L/en not_active Application Discontinuation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH584338A5 (en) * | 1974-06-19 | 1977-01-31 | Alusuisse | |

| DE2650944A1 (en) * | 1976-11-08 | 1978-05-11 | Erich Schlenker | Window and facade structure composite profile bar - has lengthways wedges between profile pieces and cross-arm permitting differing heat expansion |

| DE2755891A1 (en) * | 1976-12-28 | 1978-07-06 | Metallurg De Saint Louis S A S | Door or window wing frame connection - uses tongue and groove elements to retain bar in turned locking position |

| US4344254A (en) * | 1979-05-02 | 1982-08-17 | Feal S.P.A. | Thermally insulated aluminum door or window frame |

| DE8003277U1 (en) * | 1980-02-08 | 1980-05-08 | Schwartz, Werner, 6676 Mandelbachtal | ALLOY WINDOW WING WITH BUILT-IN TEMPERATURE LOCK |

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2628786A1 (en) * | 1988-03-15 | 1989-09-22 | Ornago Hydro Alluminio | Aluminium extrusion system for window frames - has hollow inner chambers shaped to receive corner connectors |

| GR880100807A (en) * | 1988-03-15 | 1990-01-19 | Ornago Hydro Alluminio | Built up aluminium profile members for the formation of window frames |

| WO1992001853A1 (en) * | 1990-07-20 | 1992-02-06 | Häring & Co. Ag | Statically stable frame with full thermal break for windows and cladding panels |

| WO1993006329A1 (en) * | 1991-09-13 | 1993-04-01 | Joint S.R.L. | Composite framing profile |

| EP0733765A1 (en) * | 1995-03-20 | 1996-09-25 | METRA METALLURGICA TRAFILATI ALLUMINIO S.p.A. | Section member and fitting assembly for making high thermal insulation wood coated window and door frames |

| EP0799964A1 (en) * | 1996-04-01 | 1997-10-08 | EVG Bauprofil-System Entwicklungs- und Vermarktungsgesellschaft mbH | Thermally insulating coupling bar |

| FR2753228A1 (en) * | 1996-09-06 | 1998-03-13 | Ouest Alu | Window frame PVC joining and thermal block profile |

| EP1580388A3 (en) * | 2004-03-23 | 2007-04-04 | Norsk Hydro Asa | Thermally insulating body for a thermal break section for window and door frames or the like |

| DE102010035347A1 (en) * | 2010-08-24 | 2012-03-01 | Schindler Gmbh & Co. Kg | Windows with improved insulation |

| DE102010035347B4 (en) * | 2010-08-24 | 2015-11-12 | Schindler Fenster + Fassaden Gmbh | Windows with improved insulation |

| US9143725B2 (en) | 2010-11-15 | 2015-09-22 | Cisco Technology, Inc. | System and method for providing enhanced graphics in a video environment |

| US9111138B2 (en) | 2010-11-30 | 2015-08-18 | Cisco Technology, Inc. | System and method for gesture interface control |

| EP2672053A1 (en) * | 2012-06-05 | 2013-12-11 | Alcoa Aluminium Deutschland, Inc. | Profile assembly |

| EP2767661A3 (en) * | 2012-11-28 | 2015-01-07 | J. Friedrich Ammon GmbH & Co. KG | Building door |

| EP2754831A3 (en) * | 2013-01-10 | 2017-01-11 | SCHÜCO International KG | Heat insulating strip and frame profile for a window, a door, a façade or a skylight with a flat element |

| WO2015169669A1 (en) * | 2014-05-05 | 2015-11-12 | SCHÜCO International KG | Door, window, or facade element with a sealing system |

| WO2015169670A1 (en) * | 2014-05-05 | 2015-11-12 | SCHÜCO International KG | Composite profiled section for doors, windows, or facade elements |

| EP2942468A1 (en) * | 2014-05-05 | 2015-11-11 | SCHÜCO International KG | Composite profile for doors, window or façade elements |

| CN106460445A (en) * | 2014-05-05 | 2017-02-22 | 许克国际两合公司 | Door, window, or facade element with a sealing system |

| RU2698188C2 (en) * | 2014-05-05 | 2019-08-22 | Шюко Интернациональ Кг | Sealing system for door, window or front element |

| CN111255339A (en) * | 2014-05-05 | 2020-06-09 | 许克国际两合公司 | Door, window or building facade element with sealing system |

| CN106460445B (en) * | 2014-05-05 | 2021-02-02 | 许克国际两合公司 | Door, window or building facade element with sealing system |

| WO2018065841A1 (en) * | 2016-10-06 | 2018-04-12 | Reynaers Aluminium, Naamloze Vennootschap | Compound profile for a window or door and a window or door assembled with such profiles |

| BE1024626B1 (en) * | 2016-10-06 | 2018-05-07 | Reynaers Aluminium Naamloze Vennootschap | Composite profile for a window or door and window or door assembled with such profiles. |

Also Published As

| Publication number | Publication date |

|---|---|

| US4614062A (en) | 1986-09-30 |

| FI844690A0 (en) | 1984-11-29 |

| DE3343687A1 (en) | 1985-06-05 |

| FI844690L (en) | 1985-05-31 |

| EP0143745A3 (en) | 1986-02-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0143745A2 (en) | Metal frame construction for windows or doors | |

| DE3011946C2 (en) | Sliding window or door | |

| EP3259428B1 (en) | Sealing device for window and door elements | |

| DE69429052T2 (en) | Door with associated frame and trim frame | |

| DE7517020U (en) | COMPOSITE WINDOWS WITH TWO LEAF FRAMES AND TRIPLE GLAZING | |

| DE2915255A1 (en) | COMPOSITE PROFILE | |

| DE69333450T2 (en) | glazing bar | |

| DE2932812C2 (en) | Sash and frame for windows or glazed doors | |

| DE69601801T2 (en) | THERMAL INSULATION ELEMENT IN PARTICULAR FOR WINDOW AND DOOR FRAMES AND THE LIKE | |

| EP0182227A2 (en) | Pane retaining strip | |

| DE2130023C2 (en) | Plastics door or window frame - has groove between external chamber containing metal reinforcement and two inner chambers | |

| DE2313662A1 (en) | WINDOW AND METHOD OF ITS MANUFACTURING | |

| DE2437296C2 (en) | Hollow profile strip | |

| EP1091081A2 (en) | Guide device for a roller shutter, a blind or similar | |

| DE2219268A1 (en) | KIT OF MATCHED PROFILES FOR THE MANUFACTURING OF FRAME AND LEAF FRAMES FOR WINDOWS, DOORS OR DGL | |

| DE3134742C2 (en) | Window or door sash | |

| DE2013319C3 (en) | Sealing device for pivoting or turning sashes of windows, doors or the like | |

| EP0564821A1 (en) | Light metal security profile system | |

| DE2244590A1 (en) | PROFILE FOR THE MANUFACTURE OF WINDOWS, DOORS OR. DGL | |

| DE2720920A1 (en) | LEAF AND FRAME PROFILE FOR WINDOW | |

| AT519973A4 (en) | WINDOW FRAME SYSTEM | |

| DE2601795C2 (en) | Seal on the center joint of windows or doors with horizontally sliding sashes | |

| DE4212902C1 (en) | Window and frame with transom - has transom window suspended by linkage from frame members and forming stop for hinging leaves | |

| AT316829B (en) | Metal frame | |

| DE2026947A1 (en) | Metal construction, in particular for the production of inserts, fastenings and the like in buildings |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB LI NL |

|

| 17P | Request for examination filed |

Effective date: 19860816 |

|

| 17Q | First examination report despatched |

Effective date: 19871202 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALUSUISSE-LONZA SERVICES AG |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19910328 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SPERR, KARL |