EP0141932A2 - Procédé et installation pour l'élimination sans substance nuisible de matières nocives et résiduaires de pouvoir calorifique inférieur, en particulier des déchets, par combustion - Google Patents

Procédé et installation pour l'élimination sans substance nuisible de matières nocives et résiduaires de pouvoir calorifique inférieur, en particulier des déchets, par combustion Download PDFInfo

- Publication number

- EP0141932A2 EP0141932A2 EP84109711A EP84109711A EP0141932A2 EP 0141932 A2 EP0141932 A2 EP 0141932A2 EP 84109711 A EP84109711 A EP 84109711A EP 84109711 A EP84109711 A EP 84109711A EP 0141932 A2 EP0141932 A2 EP 0141932A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- combustion

- gas

- waste

- cement

- unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B7/00—Hydraulic cements

- C04B7/36—Manufacture of hydraulic cements in general

- C04B7/43—Heat treatment, e.g. precalcining, burning, melting; Cooling

- C04B7/44—Burning; Melting

- C04B7/4407—Treatment or selection of the fuel therefor, e.g. use of hazardous waste as secondary fuel ; Use of particular energy sources, e.g. waste hot gases from other processes

- C04B7/4446—Treatment or selection of the fuel therefor, e.g. use of hazardous waste as secondary fuel ; Use of particular energy sources, e.g. waste hot gases from other processes the fuel being treated in a separate gasifying or decomposing chamber, e.g. a separate combustion chamber

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L10/00—Use of additives to fuels or fires for particular purposes

- C10L10/06—Use of additives to fuels or fires for particular purposes for facilitating soot removal

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/006—General arrangement of incineration plant, e.g. flow sheets

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/02—Incineration of waste; Incinerator constructions; Details, accessories or control therefor with pretreatment

- F23G5/027—Incineration of waste; Incinerator constructions; Details, accessories or control therefor with pretreatment pyrolising or gasifying stage

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/08—Incineration of waste; Incinerator constructions; Details, accessories or control therefor having supplementary heating

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N5/00—Systems for controlling combustion

- F23N5/003—Systems for controlling combustion using detectors sensitive to combustion gas properties

- F23N5/006—Systems for controlling combustion using detectors sensitive to combustion gas properties the detector being sensitive to oxygen

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2201/00—Pretreatment

- F23G2201/30—Pyrolysing

- F23G2201/303—Burning pyrogases

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2201/00—Pretreatment

- F23G2201/30—Pyrolysing

- F23G2201/304—Burning pyrosolids

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2206/00—Waste heat recuperation

- F23G2206/20—Waste heat recuperation using the heat in association with another installation

- F23G2206/201—Waste heat recuperation using the heat in association with another installation with an industrial furnace

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E20/00—Combustion technologies with mitigation potential

- Y02E20/30—Technologies for a more efficient combustion or heat usage

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P40/00—Technologies relating to the processing of minerals

- Y02P40/10—Production of cement, e.g. improving or optimising the production methods; Cement grinding

- Y02P40/125—Fuels from renewable energy sources, e.g. waste or biomass

Definitions

- the invention relates to a method and a device for the pollution-free removal of pollutants and waste materials with a low calorific value, in particular waste, by incineration.

- the term “pollutants” and “waste materials” is intended to include, in particular, domestic, municipal, agricultural and industrial waste without excluding other substances, provided that they contain portions of combustible substances.

- leachable heavy metal compounds enter the biological cycle and accumulate during waste composting. Case by case there are also harmful organic compounds and / or coli bacteria, Salmonella and other pathogenic bacteria in the compost.

- landfills Similar dangers of soil and groundwater contamination also exist in landfills. Leaching or decomposition processes as well as enrichments allow pollutants, poisons and pathogens to enter the soil and groundwater from such landfills. In addition, landfill sites are hardly available in densely populated areas, are a nuisance to the populated area, and cannot be used as a building land and land of use for decades after a landfill has closed.

- Municipal household waste which is often disposed of in complex waste incineration plants in metropolitan areas, contains, for example, fuel components with an average calorific value of 2000 to 2200 kcal / kg.

- Garbage incineration plants which were promised decades ago a solution to the garbage disposal problem, have been in the flue gas recently and not because of their pollutant emissions

- Leach-resistant, in particular heavy metal residues in the fly ash or the wash water fall into the firing line of public criticism. Some of these plants therefore had to be shut down.

- the furnace does not reach the temperatures necessary for the safe decomposition of organically toxic compounds such as dioxins or polychlorinated biphenyls.

- the heavy metals that get into the fly ash or wash water are also not bound in a leach-resistant form and accumulate to dangerous concentrations when they are deposited.

- a disadvantage in addition to the cost increase is the difficulty of keeping the combustion temperature on the grate almost constant in the event of fluctuating material content of the waste.

- Waste incineration plants are therefore also subject to considerable difficulties and risks in the pyrolysis process.

- the invention has for its object to eliminate pollutants and waste materials by combustion in such a way that no polluting pollutants arise or are emitted, and that the heat content contained in the waste materials is used economically and technically sensible.

- a device suitable for this purpose should cause significantly lower investment and operating costs than those incurred, for example, in a conventional waste incineration plant.

- the device should be suitable for economically advantageous and technically problem-free coupling with an existing pyrotechnic system, for example a cement burning system.

- the object is achieved with the method according to the invention in that the combustion process is carried out in a combustion unit with the supply of hot combustion air as an energy source of such a high temperature that combustion and / or flue gas temperatures of at least 1250 ° C. are reached.

- the incineration of garbage with the supply of hot combustion air advantageously enables a temperature range of 1250 ° C to be reached even if the calorific value of the flue and waste materials to be incinerated is low and, as with garbage for example, they also burn with a certain moisture content .

- Compliance with the specified temperature range is advantageous because, on the one hand, there is complete decomposition of almost all pollutants, such as cyclic hydrocarbons or toxic compounds of sulfur, halogens or holgenides, alkalis, etc., and on the other hand compliance with this limit in the range up to 1250 ° C practically prevents the thermal formation of harmful amounts of toxic nitrogen oxides.

- pollutants such as cyclic hydrocarbons or toxic compounds of sulfur, halogens or holgenides, alkalis, etc.

- one embodiment of the method provides that the temperature of the combustion air is set in accordance with the calorific value of the substances to be burned or in accordance with the combustion and flue gas temperatures.

- one embodiment of the invention provides that the combustion air is fed to the combustion unit at a temperature in the range between 600 ° C. and 950 ° C., preferably at approx. 800 ° C. becomes.

- the desired high-temperature combustion is preferably achieved without the addition of other fuels and the hot combustion air is sufficient as an energy source to initiate and maintain a clean, environmentally friendly combustion process.

- an embodiment suggests that the combustion process be carried out with a proportion of hot combustion air that is at least balanced in relation to the fuel proportion becomes.

- combustion air for the combustion process of the pollutants from the clinker cooling process branched off hot cooler exhaust air flow and flue gas from the pollutant combustion process is introduced into the system of the cement clinker combustion plant.

- the return of the exhaust gases from the firing process into the system of the cement kiln also enables an economically and technically sensible use of their heat content, for example in the calcination of the raw meal, during its preheating, or in a grinding drying system upstream of the cement kiln.

- the introduction of the gases in the calciner, cyclone heat exchanger and mill drying has the advantage that pollutants contained in the exhaust gas are adsorptively or chemically bound to the goods . As a result, the emission of these pollutants is largely or almost completely prevented.

- the known method has the disadvantage that the quality of the combustible material can be considerably reduced as a result of the mixture with the waste.

- the CaO content of the fired product is between 30% and 70%, preferably between 40% and 55%, the amount added advantageously being set in accordance with the type and amount of the pollutants to be separated from the resulting gas.

- carbonate-containing material in the form of a dust cloud can be introduced into the exhaust gas in accordance with the pollutants to be separated from the gas, and the exhaust gas can be cleaned of pollutants such as S0 2 by the dust filter acting as a reactive retention filter.

- the flue gases generated in the firing unit are introduced at locations where sufficiently long reaction times and the presence of reactive cement raw materials, such as in the calcination zone, allow sufficiently long reaction times to favor the adsorptive or chemical bonding of pollutants to the cement raw materials.

- the invention makes use of the known measure of partial gas extraction (bypass).

- an embodiment of the method provides that mineralized residues of the pollutant combustion process are at least partially added to the firing material of the cement kiln and optionally burned, cooled and / or ground together with the clinker.

- the fuel product in the case of a pollutant content, can be processed to a consistency just before further use or rejection, in which pollutants are present in a bond that precludes any danger to the environment.

- This consistency of the firing product can preferably be produced by hydration with or without the addition of additives and / or other binders.

- combustion residues which mostly contain ash, slag and / or small amounts of metals, can in many cases be easily added to the cement clinker without reducing its quality.

- the waste disposal device By designing the waste disposal device with a separate, self-contained firing unit, there are not only the advantages mentioned above when coupled with a plant for firing minerals such as cement, but also with advantage also the possibility to optimize the combustion process of the waste materials and independently the combustion process of the minerals.

- the ignition temperature and especially the willingness to ignite of the waste materials is reliably achieved even with a low calorific value by connecting the combustion unit to a hot gas source, the supply of high-quality fuels, which has so far been frequently required in waste incineration, as an additional energy source is eliminated.

- the combustion unit can advantageously be designed to be relatively uncomplicated in comparison to conventional waste incineration plants, in particular if it is designed with a fluidized bed combustion unit. This results in significant savings in investment and operating costs.

- cement raw meal for the addition of lime-containing carbonate carriers is extremely inexpensive and constantly available without major transport problems.

- the preheating and calcining station 1 comprises a preheating and calcining station 1, a firing station 2 and one Cooling station 3.

- the preheating and calcining station 1 is charged with a calcareous carbonate carrier 4 in the form of a flour.

- This material is heated in direct heat exchange in counterflow to hot furnace gas 5 of the firing station 2 and at least partially calcined.

- fuel 6 is supplied to cover the heat requirement in the endothermic calcination process.

- the heated and partially deacidified raw meal 7 reaches the firing station 2 in the further course of the process. This is also given to waste 8. Waste 8 and deacidified raw meal 7 are intimately mixed with one another in the firing station 2 and, if necessary, fired with the addition of fuel 9 at temperatures above 1250.degree.

- the garbage 8 is reacted with calcareous and in particular carbonate-containing substances 4 at temperatures, for example around 1350 ° C. and higher, to give the fuel 10.

- This passes from the burning station 2 into the cooling station 3, where it is cooled with cooling air 11 and discharged as the end product 12.

- the cooling air 11 heats up and is introduced as hot combustion air 13 at temperatures between 800 and 1000 ° C. into the combustion station and, if necessary, generates a high-temperature waste incineration there with additional fuel 9.

- exhaust gas 14 is eliminated from the process.

- Fig. 2 shows a similar process family tree, also with the basic three stations, namely the preheating and calcining station 1, the Firing station 2 and aer cooling station 3.

- the preheating and calcining station 1 is preceded by a mill-drying station 15 for the carbonate carrier base material 4 '.

- This is fed into the mill drying station 15 in a pit-damp state and dried therein in the exhaust gas stream 14 and ground into flour in a purely schematically indicated comminution device 16.

- the mill drying device for the exhaust gas 14 additionally acts as a reactive or adsorptive filter through which the exhaust gas 14 is additionally cleaned. If pollutant residues are nevertheless present in the exhaust gas 14, this can be fed to a known gas cleaning system.

- the gas discharge 17, which branches off from the combustion station 2 achieves a considerable discharge of pollutants in the gas household of the method.

- elements which tend to evaporation or condensation cycles such as halogens or sulfur at a harmful concentration, are at least partially withdrawn from the combustion process by the gas vent 17.

- the gas withdrawn can be supplemented by hot combustion air 13 from the cooling station 3 by a bypass line 18.

- waste 8 is fed into a pyrolysis station 19.

- this waste 8 is subjected to a dry distillation with the supply of heat in a chamber in the absence of oxygen. External heating 20 is used for starting until carbonization gas 21 arises. This is fed to the fuel feed 9 of the burning station 2.

- a branched-off partial stream 22 of the carbonization gas covers the heat requirement of the pyrolysis station 19.

- Waste 8 is introduced into the chamber with the exclusion of air and pyrolysis residue 8 'is fed in after the gasification of the waste from the combustion station 2 and mixed therein with deacidified raw material 7 and to the combustion product, as already previously described, fired or sintered.

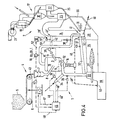

- FIG. 4 shows a device 1 for removing pollutants and waste materials in accordance with the invention in connection with a cement burning plant 2.

- the device for disposal 1 has a self-contained combustion unit 3 which is designed as a fluidized bed furnace.

- the firing unit can also be another type of furnace, for example a rotary kiln.

- a feeder device 4 for this has the storage container 5, which is equipped with a gravimetric metering discharge element 6. In the example shown, it is a dynamic weighing device in the form of a continuously operating dosing belt scale 6. This feeds the pollutants and waste materials to be burned according to arrow 43 via a material lock 7 and an inlet chute 8 into the combustion chamber 10 of the combustion unit 3. There the substances initially remain on the grate 9.

- the combustion unit is designed with a conical base part 12, into which the combustion air supply 13 opens.

- a pilot and auxiliary burner 11 projects into the combustion chamber 10 and its fuel supply is adjusted by the control element 39.

- a flue gas pipe 15 leads out of the gas chamber or combustion chamber 10 of the combustion unit 3, in a measuring device 16 is arranged, with which the gas composition, in particular fractions of free oxygen and / or C0, and optionally the temperature of the flue gas are preferably measured.

- the determined measured values of a control unit 45 are applied via a signal line 43 and converted there into control pulses which, by means of control lines 46, 46 ', 46'', adjust the throttling elements 35 (fresh air), 36 (hot combustion air) and 39 (fuel for the auxiliary burner) ) influence.

- the combustion process in the combustion unit 3 is controlled with a relatively small amount of control equipment according to the flue gas temperature or a predetermined flue gas composition.

- the specified feed quantity of the substances to be burned is controlled by means of the dosing belt scale 6 by means of a target / actual value comparison via the signal line 47 and the control line 48.

- the cement combustion plant 2 has a preheater line 17 with the cyclone heat exchangers 18, 18 ', 22 and 23.

- the exhaust gas line 20 opens into an exhaust port or an exhaust gas blower 21, the pressure line of which leads to a chimney (not shown).

- the cement kiln 2 further comprises the rotary kiln 26 with burner 27 and a downstream cooler 28.

- a line 30 for calcined flour opens into the kiln inlet housing 29, which is connected to the lowest heat exchanger cyclone 23.

- the calciner 24 is arranged between the furnace inlet housing 29 and the preheating line 17 designed as a reaction shaft with a cranked upper end.

- the down line 25 for preheated raw meal from the cyclone heat exchanger 22 opens at the same height opposite the tertiary air line 32, and a fuel feed 31 a preferably adjustable throttle body 36, 37.

- the throttling elements 36, 37 are required in order to be able to set a defined quantitative ratio between the tertiary air and the branched hot combustion air. Instead of such throttling elements, the design of which is arbitrary, resistors in the form of pipe constrictions can also be installed.

- the coupling of the device for the removal or disposal of pollutants and waste materials with the cement burning plant 2 is provided according to the invention such that on the one hand the combustion air supply 13 to the combustion unit 3 is connected to the hot air outlet 33 of the cooler 28, and on the other hand the flue gas line 15 from the combustion unit to the Position 41 opens into the calculator 24. This has as

- the throttle member 38 is additionally advantageously installed, which controls an adjustment of the flow speed in accordance with the quantity of material burned per unit of time.

- This throttle member 38 is connected to the control unit 50 via the control line 51.

- the control unit 50 is in turn connected to the measuring device 16 by a control line 52.

- a control circuit is provided, for example, so that the flue gas line is throttled by the throttle element 38 in the event of an inadmissible temperature rise in the flue gas.

- the arrangement of a branch line 42 is provided (shown in broken lines), which allows flue gas to flow into the calciner at a higher point 41 'thereof.

- the device 1 for the removal of pollutants and waste materials also provides that combustion residues from the combustion unit 3 are either introduced into the rotary kiln 26 or into the cooler 28.

- a transport device 49 or 49 ' is connected downstream of the outlet 14 at the lower end of the conical base part 12, through which combustion residues either through a lock 52 into the furnace inlet 29 or can be introduced through an opening 53 into a central part of the cooler 28.

- Other uses of the combustion residue are also possible, for example addition to the finished cement product. Leach-resistant residues can also be deposited.

- the throttle elements 36 in the combustion air supply 13 and 38 in the flue gas line 15 are closed as long as the device 1 for disposal is not yet in operation.

- the cement kiln 2 works on its own without any interference from the device 1 disposed in parallel for the disposal of waste materials.

- the two throttling members 36 and 38 are gradually opened.

- hot cooler air flows through the still empty combustion unit 3 in the bypass to the tertiary air line 32 and heats the parts of the system which were previously cold.

- the pilot and auxiliary burner 39 is ignited at the same time.

- waste 42 is withdrawn from the storage bunker 5 with the aid of the feeder device 4 by starting the gravimetric extraction device 6 and fed through the lock 7 into the combustion chamber 10 of the firing unit 3.

- the estate ignites due to the high temperatures in the combustion chamber 3. Now the throttling elements 36 and 38 are opened further and the combustion starts fully.

- the throttle element 37 in the tertiary air line 32 must be throttled in order to regulate corresponding hot gas flow rates.

- control technology devices described above ensure after the device 1 has been started up via the control unit 45 and the throttle elements 35, 36 and 39 controlled by it, that the combustion process of the waste materials in the combustion chamber runs continuously.

- the conduit path of the exhaust gas or the point of introduction into the calciner is reversed between the positions 41 and 41'.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Combustion & Propulsion (AREA)

- Organic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Processing Of Solid Wastes (AREA)

- Curing Cements, Concrete, And Artificial Stone (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19833330667 DE3330667A1 (de) | 1983-08-25 | 1983-08-25 | Verfahren und einrichtung zur entsorgung von schad- und abfallstoffen, insbesondere mit geringem heizwert, durch verbrennung |

| DE3330667 | 1983-08-25 | ||

| DE19843415211 DE3415211A1 (de) | 1984-04-21 | 1984-04-21 | Verfahren zur schadstofffreien beseitigung von muell, insbesondere kommunalmuell |

| DE3415211 | 1984-04-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0141932A2 true EP0141932A2 (fr) | 1985-05-22 |

| EP0141932A3 EP0141932A3 (fr) | 1986-11-26 |

Family

ID=25813461

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84109711A Withdrawn EP0141932A3 (fr) | 1983-08-25 | 1984-08-16 | Procédé et installation pour l'élimination sans substance nuisible de matières nocives et résiduaires de pouvoir calorifique inférieur, en particulier des déchets, par combustion |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US4640681A (fr) |

| EP (1) | EP0141932A3 (fr) |

| ES (1) | ES8505076A1 (fr) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1987001692A2 (fr) * | 1985-09-21 | 1987-03-26 | Klöckner-Humboldt-Deutz Aktiengesellschaft | Utilisation de dechets a pouvoir calorifique pour la production de ciment |

| EP0162215B1 (fr) * | 1984-03-27 | 1989-08-09 | Alexander Grisar | Procédé pour la mise au rebut de déchets combustibles |

| WO1990007681A1 (fr) * | 1988-09-14 | 1990-07-12 | K + K Ofenbau Gmbh | Procede et dispositif de combustion et de postcombustion de residus |

| EP0417705A1 (fr) * | 1989-09-11 | 1991-03-20 | Onoda Cement Company, Ltd. | Procédé et système pour mise au rebut de boues d'égout aqueuses |

| US5217624A (en) * | 1989-09-11 | 1993-06-08 | Onoda Cement Co., Ltd. | Method for the disposal of aqueous sewage sludge |

| EP0764614A2 (fr) * | 1995-09-22 | 1997-03-26 | Krupp Polysius Ag | Installation et procédé de préparation de clinker de ciment |

| DE19633567A1 (de) * | 1996-08-21 | 1998-02-26 | Abb Patent Gmbh | Verfahren und Einrichtung zur umweltfreundlichen Müllverbrennung |

Families Citing this family (54)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3522272A1 (de) * | 1985-03-22 | 1986-09-25 | Krupp Polysius Ag, 4720 Beckum | Verfahren und anlage zur waermebehandlung von feinkoernigem gut |

| DE3520058A1 (de) * | 1985-06-04 | 1986-12-04 | O & K Orenstein & Koppel Ag, 1000 Berlin | Verfahren zur waermebehandlung von feinkoernigem gut |

| DE3701967A1 (de) * | 1987-01-23 | 1988-08-04 | Krupp Polysius Ag | Vorrichtung zur waermebehandlung von feinkoernigem gut |

| DE3708220A1 (de) * | 1987-03-13 | 1988-09-22 | Krupp Polysius Ag | Verfahren und anlage zur ausnutzung der heizenergie von haus- und gewerbemuell |

| DE3718669A1 (de) * | 1987-06-04 | 1988-12-15 | Metallgesellschaft Ag | Verfahren zur aufarbeitung von kontaminierten mineralstoffen |

| US4863702A (en) * | 1987-09-01 | 1989-09-05 | Thermolytica Corporation | Autoclave for hazardous waste |

| KR900700824A (ko) * | 1988-03-18 | 1990-08-17 | 원본미기재 | 고체물질로 부터 휘발성 유기 화합물을 박리시키는 방법 및 장치 |

| US5220874A (en) * | 1988-03-22 | 1993-06-22 | Keating Environmental Service, Inc. | Method and apparatus for stripping volatile organic compounds from solid materials |

| US4956158A (en) * | 1988-03-29 | 1990-09-11 | Aluminum Company Of America | Stabilization of fluorides of spent potlining by chemical dispersion |

| US4950409A (en) * | 1988-06-10 | 1990-08-21 | Stanforth Robert R | Method for treating hazardous wastes |

| US4889640A (en) * | 1988-06-10 | 1989-12-26 | Rmt, Inc. | Method and mixture for treating hazardous wastes |

| US4921538A (en) * | 1988-06-16 | 1990-05-01 | Industrial Waste Management, Inc. | Method for recycle and use of contaminated soil and sludge |

| AU4305889A (en) * | 1988-08-08 | 1990-03-05 | Thermolytica Corporation | Thermolytic detoxification reactor system |

| US5083516A (en) * | 1988-11-23 | 1992-01-28 | Cadence Chemical Resources, Inc. | Processed wastes as supplemental fuel for modified cement films |

| US5224433A (en) * | 1988-11-23 | 1993-07-06 | Cadence Chemical Resources, Inc. | Waste fuel delivery to long kilns |

| US4984983A (en) * | 1989-02-07 | 1991-01-15 | F. L. Smidth & Co. A/S | Method of cofiring hazardous waste in industrial rotary kilns |

| US5156676A (en) * | 1990-04-13 | 1992-10-20 | Hoke M. Garrett | Manufacture of cement clinker in long rotary kilns by the addition of volatile fuel elements directly into the calcining zone of the rotary kiln |

| US5122189A (en) * | 1990-04-13 | 1992-06-16 | Hoke M. Garrett | Manufacture of cement clinker in long rotary kilns by the addition of volatile fuels components directly into the calcining zone of the rotary kiln |

| US5086716B1 (en) * | 1990-04-30 | 1995-08-29 | Perma Fix Corp | System, apparatus and method for disposing of solid waste |

| US5220111A (en) * | 1991-09-10 | 1993-06-15 | Air Products And Chemicals, Inc. | Fixation of heavy metals in scrubbed municipal solid waste incinerator ash |

| US5164174A (en) * | 1991-10-11 | 1992-11-17 | Reynolds Metals Company | Detoxification of aluminum spent potliner by thermal treatment, lime slurry quench and post-kiln treatment |

| US5170726A (en) * | 1991-11-18 | 1992-12-15 | Thermotech Systems Corporation | Apparatus and methods for remediating materials contaminated with hydrocarbons |

| US5372460A (en) * | 1992-03-18 | 1994-12-13 | Ruehl; Paul A. | Method of disposing of earth contaminated by petroleum products |

| US5851246A (en) * | 1992-05-07 | 1998-12-22 | Hylsa, S.A. De C.V. | Apparatus for gasifying organic materials |

| US5656044A (en) * | 1992-05-07 | 1997-08-12 | Hylsa S.A. De C.V. | Method and apparatus for gasification of organic materials |

| JPH0673384A (ja) * | 1992-05-07 | 1994-03-15 | Hylsa Sa | 有機物質をガス化するための方法および装置 |

| JPH07509688A (ja) * | 1992-07-14 | 1995-10-26 | アッシュ グローブ セメント カンパニー | 長尺キルン中でのセメント製造の改良法 |

| US5468327A (en) * | 1994-01-24 | 1995-11-21 | University Of Massachusetts Lowell | Method and device for continuous formation of braid reinforced thermoplastic structural and flexible members |

| US5536371A (en) * | 1994-02-10 | 1996-07-16 | The Onix Corporation | Papermaking sludge recovery process and apparatus |

| US6176187B1 (en) | 1994-03-16 | 2001-01-23 | Cement Industry Environmental Consortium | Sludge handling and feeding system |

| US5586510A (en) * | 1994-03-16 | 1996-12-24 | Cement Industry Environment Consortium | Method and system for controlling pollutant emissions in combustion operations |

| US5816795A (en) * | 1996-05-24 | 1998-10-06 | Cadence Environmental Energy, Inc. | Apparatus and method for providing supplemental fuel to a preheater/precalciner kiln |

| WO1998003250A1 (fr) * | 1996-07-18 | 1998-01-29 | Hoelter Heinz | Procede de traitement des gaz brules se degageant dans une installation d'incineration de dechets organiques |

| CZ295708B6 (cs) * | 1998-12-28 | 2005-10-12 | Psp Engineering A. S. | Cyklonový výměník tepla |

| GB2359125A (en) | 2000-02-08 | 2001-08-15 | Green Island Environmental Tec | Integrated cement production and waste disposal facility |

| US7229281B2 (en) * | 2000-09-11 | 2007-06-12 | Cadence Environmental Energy, Inc. | Method of mixing high temperature gases in mineral processing kilns |

| US7107916B2 (en) * | 2000-11-17 | 2006-09-19 | Owens Corning Fiberglas Technology, Inc. | Method for recycling building materials |

| US20070144414A1 (en) * | 2000-11-17 | 2007-06-28 | Bland Brian W | Method for recycling building |

| US6439139B1 (en) * | 2000-11-17 | 2002-08-27 | Owens Corning Fiberglas Technology, Inc. | Method for recycling building materials |

| DE10146418A1 (de) * | 2001-09-20 | 2003-04-17 | Kloeckner Humboldt Wedag | Verfahren und Anlage zur thermischen Behandlung von mehlförmigen Rohmaterialien |

| DE102004002388A1 (de) * | 2004-01-15 | 2005-08-11 | Swb Erzeugung Gmbh & Co.Kg, | Verfahren zur energetischen Nutzung von Ersatzbrennstoffen, Pyrolyseanlage für Ersatzbrennstoffe sowie Kombination aus Pyrolyseanlage und Feuerungsanlage zur Verfeuerung von Pyrolysegasen |

| BRPI0510786A (pt) * | 2004-05-10 | 2007-11-20 | Smidth As F L | método e dispositivo para incineração de resìduo combustìvel |

| AT502256A1 (de) * | 2005-08-11 | 2007-02-15 | Holcim Ltd | Verfahren und vorrichtung zum verwerten von alternativen brennstoffen bei der klinker- bzw. zementherstellung |

| DE102005052753A1 (de) * | 2005-11-04 | 2007-05-10 | Polysius Ag | Anlage und Verfahren zur Herstellung von Zementklinker |

| DE102005057346A1 (de) * | 2005-12-01 | 2007-06-06 | Khd Humboldt Wedag Gmbh | Anlage zur Herstellung von Zementklinker, und Verfahren zum Betrieb einer solchen Anlage |

| JPWO2009157325A1 (ja) * | 2008-06-24 | 2011-12-08 | 三菱電機株式会社 | 冷凍サイクル装置及び空気調和装置 |

| DE102009041089C5 (de) * | 2009-09-10 | 2013-06-27 | Khd Humboldt Wedag Gmbh | Verfahren und Anlage zur Herstellung von Zement mit verringerter CO2-Emission |

| CN103153905B (zh) * | 2010-08-06 | 2015-04-22 | 英派尔科技开发有限公司 | 用于采用废弃物材料制备水泥熟料的系统和方法 |

| JP5753585B2 (ja) * | 2010-10-21 | 2015-07-22 | 川崎重工業株式会社 | 廃棄物処理設備 |

| JP5541406B2 (ja) * | 2012-08-28 | 2014-07-09 | 三菱マテリアル株式会社 | セメント製造装置 |

| JP5583198B2 (ja) * | 2012-12-14 | 2014-09-03 | 三菱重工業株式会社 | 石炭乾留装置 |

| DE102017212322A1 (de) * | 2017-07-19 | 2019-01-24 | Thyssenkrupp Ag | Verfahren und System zum Reinigen eines Gasstroms |

| CN112424530B (zh) * | 2018-09-14 | 2024-03-05 | 敏普拉斯有限责任公司 | 操作包括捕获烟道气体夹带的灰分的设备的焚烧装置的方法 |

| CN115323164B (zh) * | 2022-09-16 | 2024-02-20 | 赣州华卓再生资源回收利用有限公司 | 一种钕铁硼废料多段煅烧方法 |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1168005B (de) * | 1960-01-16 | 1964-04-16 | Roman Rummel | Verfahren und Vorrichtung zum Verbrennen von festen Abfallstoffen |

| US3235239A (en) * | 1963-12-23 | 1966-02-15 | Smidth & Co As F L | Method and apparatus for making cement |

| DE2112797A1 (de) * | 1970-03-18 | 1971-09-30 | Tampella Oy Ab | Verfahren und Vorrichtung zur Behandlung von Abfall,Muell u. dgl. |

| DE1776258A1 (de) * | 1967-02-24 | 1975-05-07 | Gerhard Steen | Verfahren zur schmelzverbrennung von abfallstoffen und/oder geringerwertigen brennstoffen |

| FR2359800A1 (fr) * | 1976-07-28 | 1978-02-24 | Creusot Loire | Procede et dispositif de precalcination de matieres pulverulentes |

| DE2745459A1 (de) * | 1976-12-14 | 1978-06-15 | Measurex Corp | Einrichtung zur steuerung des verbrennungswirkungsgrades |

| US4179263A (en) * | 1976-10-29 | 1979-12-18 | Perlmooser Zementwerke Aktiengesellschaft | Process for the utilization of waste substances and device for carrying out the process |

| DE3021945A1 (de) * | 1980-06-12 | 1982-01-07 | Heinz Ing.(grad.) 4390 Gladbeck Hölter | Verfahren zur herstellung von produkten aus rueckstaenden der chemisorption hinter muellverbrennungsanlagen, die deponiefaehig sind |

| WO1982002585A1 (fr) * | 1981-01-22 | 1982-08-05 | Riemann Hanns Helmut | Procede d'exploitation thermique des ordures et installation pour la mise en oeuvre du procede |

| EP0059509A1 (fr) * | 1981-02-28 | 1982-09-08 | Metallgesellschaft Ag | Procédé de préparation de clinker de ciment |

| DE3126200A1 (de) * | 1981-07-03 | 1983-01-20 | Hölter, Heinz, Dipl.-Ing., 4390 Gladbeck | "verfahren zur beseitigung von rueckstandsprodukten aus muellverbrennungsanlagen" |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2745425C3 (de) * | 1977-10-08 | 1986-02-13 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Verfahren und Vorrichtung zur Aufbereitung von Kohle in einer Luftstrom-Mahltrocknungs-Anlage |

| DE2850895C2 (de) * | 1978-11-24 | 1986-06-12 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Verfahren und Vorrichtung zur Erzeugung von Kohlenstaub |

| JPS55136154A (en) * | 1979-04-03 | 1980-10-23 | Sumitomo Cement Co | Method and device for utilizing combustible matter |

| DE2931214C2 (de) * | 1979-08-01 | 1986-06-12 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Verfahren und Vorrichtung zur Trocknung und Feinmahlung von Kohle |

| DE2933289C2 (de) * | 1979-08-17 | 1985-10-03 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Verfahren zum Brennen von Klinker aus Zementrohstoffen |

| US4285283A (en) * | 1979-12-07 | 1981-08-25 | Exxon Research & Engineering Co. | Coal combustion process |

| JPS56113988A (en) * | 1980-02-15 | 1981-09-08 | Sumitomo Cement Co | Method and device for recovering exhaust gas from combustion furnace in generating set using combustible as fuel |

| DE3130038A1 (de) * | 1980-09-04 | 1982-04-08 | ARBED S.A., 2930 Luxembourg | Verfahren zum kontinuierlichen einblasen von ueberwiegend aus steinkohle bestehenden, feinkoernigen reduktionsmitteln in einen schachtofen |

| DE3164457D1 (en) * | 1980-11-17 | 1984-08-02 | Smidth & Co As F L | Method and apparatus for thermally treating pulverulent material |

| US4397248A (en) * | 1981-05-26 | 1983-08-09 | Combustion Engineering, Inc. | Coal beneficiation/combustion system |

| US4462794A (en) * | 1982-11-12 | 1984-07-31 | Intermountain Research & Development | Method of operating a rotary calciner retrofitted to coal-firing |

-

1984

- 1984-08-16 EP EP84109711A patent/EP0141932A3/fr not_active Withdrawn

- 1984-08-22 ES ES535335A patent/ES8505076A1/es not_active Expired

-

1985

- 1985-08-30 US US06/771,156 patent/US4640681A/en not_active Expired - Fee Related

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1168005B (de) * | 1960-01-16 | 1964-04-16 | Roman Rummel | Verfahren und Vorrichtung zum Verbrennen von festen Abfallstoffen |

| US3235239A (en) * | 1963-12-23 | 1966-02-15 | Smidth & Co As F L | Method and apparatus for making cement |

| DE1776258A1 (de) * | 1967-02-24 | 1975-05-07 | Gerhard Steen | Verfahren zur schmelzverbrennung von abfallstoffen und/oder geringerwertigen brennstoffen |

| DE2112797A1 (de) * | 1970-03-18 | 1971-09-30 | Tampella Oy Ab | Verfahren und Vorrichtung zur Behandlung von Abfall,Muell u. dgl. |

| FR2359800A1 (fr) * | 1976-07-28 | 1978-02-24 | Creusot Loire | Procede et dispositif de precalcination de matieres pulverulentes |

| US4179263A (en) * | 1976-10-29 | 1979-12-18 | Perlmooser Zementwerke Aktiengesellschaft | Process for the utilization of waste substances and device for carrying out the process |

| DE2745459A1 (de) * | 1976-12-14 | 1978-06-15 | Measurex Corp | Einrichtung zur steuerung des verbrennungswirkungsgrades |

| DE3021945A1 (de) * | 1980-06-12 | 1982-01-07 | Heinz Ing.(grad.) 4390 Gladbeck Hölter | Verfahren zur herstellung von produkten aus rueckstaenden der chemisorption hinter muellverbrennungsanlagen, die deponiefaehig sind |

| WO1982002585A1 (fr) * | 1981-01-22 | 1982-08-05 | Riemann Hanns Helmut | Procede d'exploitation thermique des ordures et installation pour la mise en oeuvre du procede |

| EP0059509A1 (fr) * | 1981-02-28 | 1982-09-08 | Metallgesellschaft Ag | Procédé de préparation de clinker de ciment |

| DE3126200A1 (de) * | 1981-07-03 | 1983-01-20 | Hölter, Heinz, Dipl.-Ing., 4390 Gladbeck | "verfahren zur beseitigung von rueckstandsprodukten aus muellverbrennungsanlagen" |

Non-Patent Citations (1)

| Title |

|---|

| ZEMENT-KALK-GIPS, Band 35, Nr. 5, Mai 1982, Seiten 259-263, Wiesbaden-Biebrich, DE; W.G. QUITTKAT et al.: "Brennstoffersparnis bei der Zementproduktion durch Pyrolyse" * |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0162215B1 (fr) * | 1984-03-27 | 1989-08-09 | Alexander Grisar | Procédé pour la mise au rebut de déchets combustibles |

| WO1987001692A2 (fr) * | 1985-09-21 | 1987-03-26 | Klöckner-Humboldt-Deutz Aktiengesellschaft | Utilisation de dechets a pouvoir calorifique pour la production de ciment |

| WO1987001692A3 (fr) * | 1985-09-21 | 1988-04-21 | Kloeckner Humboldt Deutz Ag | Utilisation de dechets a pouvoir calorifique pour la production de ciment |

| WO1990007681A1 (fr) * | 1988-09-14 | 1990-07-12 | K + K Ofenbau Gmbh | Procede et dispositif de combustion et de postcombustion de residus |

| US5046435A (en) * | 1988-09-14 | 1991-09-10 | K+K Ofenbau Gmbh | Process and apparatus for combustion of waste, such as household and other waste, and afterburning of residues from the combustion |

| EP0417705A1 (fr) * | 1989-09-11 | 1991-03-20 | Onoda Cement Company, Ltd. | Procédé et système pour mise au rebut de boues d'égout aqueuses |

| US5217624A (en) * | 1989-09-11 | 1993-06-08 | Onoda Cement Co., Ltd. | Method for the disposal of aqueous sewage sludge |

| EP0764614A2 (fr) * | 1995-09-22 | 1997-03-26 | Krupp Polysius Ag | Installation et procédé de préparation de clinker de ciment |

| EP0764614A3 (fr) * | 1995-09-22 | 1998-02-11 | Krupp Polysius Ag | Installation et procédé de préparation de clinker de ciment |

| DE19633567A1 (de) * | 1996-08-21 | 1998-02-26 | Abb Patent Gmbh | Verfahren und Einrichtung zur umweltfreundlichen Müllverbrennung |

Also Published As

| Publication number | Publication date |

|---|---|

| ES535335A0 (es) | 1985-05-16 |

| ES8505076A1 (es) | 1985-05-16 |

| EP0141932A3 (fr) | 1986-11-26 |

| US4640681A (en) | 1987-02-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0141932A2 (fr) | Procédé et installation pour l'élimination sans substance nuisible de matières nocives et résiduaires de pouvoir calorifique inférieur, en particulier des déchets, par combustion | |

| EP0162215B1 (fr) | Procédé pour la mise au rebut de déchets combustibles | |

| DE68921013T2 (de) | Verfahren zur Herstellung von Schlacke und Beseitigung von gefährlichen festen Abfällen. | |

| DE3012167C2 (fr) | ||

| DE2702048C2 (de) | Verfahren zur Herstellung von Portlandzement | |

| DE3788871T2 (de) | Verfahren zur abfallverarbeitung sowie drehofen für diesen zweck. | |

| EP0841968B1 (fr) | Procede d'elimination de mercure | |

| DE10202776A1 (de) | Anlage zur Herstellung von Zementklinker | |

| DE69304842T2 (de) | Abfallverbrennungsverfahren in einem Zementofen | |

| DE4107200A1 (de) | Verfahren und anlage zur thermischen abfallbehandlung | |

| DE2748510A1 (de) | Verfahren zur verwertung von abfallstoffen mit brennbaren bestandteilen | |

| DE69027675T2 (de) | Vorrichtung und verfahren zur behandlung von abfällen | |

| CH629731A5 (de) | Verfahren zur herstellung von zementklinkern. | |

| AT394358B (de) | Verfahren zur zementherstellung | |

| EP0581918B1 (fr) | Procede de fusion de residus de combustion dans des scories | |

| DE3444073A1 (de) | Verfahren und anlage zum verbrennen von abfaellen wie haus-, industrie- und sondermuell | |

| DE2624971A1 (de) | Verfahren zur verwertung industrieller abfaelle | |

| DE3533775C2 (fr) | ||

| DE3718669A1 (de) | Verfahren zur aufarbeitung von kontaminierten mineralstoffen | |

| DE3411144A1 (de) | Verfahren zur entsorgung von brennbaren abfaellen | |

| EP0728713B1 (fr) | Procédé d'utilisation de matériaux de déchets pour la fabrication de ciment | |

| DE3912450C2 (fr) | ||

| EP0347808B1 (fr) | Procédé pour le traitement de boue d'épuration | |

| DE69101064T2 (de) | Verfahren und vorrichtung zum verbrennen von feststoffabfällen und möglicherweise flüssigen abfällen verschiedener art. | |

| DE3537595C3 (de) | Verfahren und Anlage zur Verwertung von feuchten Abfällen, insbesondere Klärschlamm |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL |

|

| 17P | Request for examination filed |

Effective date: 19861219 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19880229 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: STEINBISS, EBERHARD Inventor name: WOLTER, ALBRECHT, DR. Inventor name: HERCHENBACH, HORST |